Justin, the next time you shoot the rifle take a photo of the leade (like in post 113) before you clean it please.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The First Thousand Shots

- Thread starter justin amateur

- Start date

A problem with evaluating by visual means any bore changes resulting shooting is that a borescope can only reveal limited information. If things look different between a before and after image, then that can be noted. But a borescope doesn't tell the user anything about anything really specific. It doesn't measure anything, whether it's changes, if any, in aspects such as in bore smoothness or rifling wear. Many changes are of a nature that borescope images can't show.

Another note of caution concerns assessing changes in accuracy over time. In order to compare accuracy results at certain intervals, whether they are every 1000 rounds or more, it's necessary to compare apples to apples as much as possible. That means comparing results with the same lot of ammo under conditions as similar as possible. It's pointless to compare accuracy between different lots of ammo. In addition, enough data must be compared to provide a more reliable assessment.

Another note of caution concerns assessing changes in accuracy over time. In order to compare accuracy results at certain intervals, whether they are every 1000 rounds or more, it's necessary to compare apples to apples as much as possible. That means comparing results with the same lot of ammo under conditions as similar as possible. It's pointless to compare accuracy between different lots of ammo. In addition, enough data must be compared to provide a more reliable assessment.

The equipment cost alone for a surface finish assessment and bore measuring devices would make it prohibited at this time. This is just a curiosity item where a person started to try a initial thought about the possibility of determining a small amount of accuracy variances on breaking in a barrel. This was never intended to be a full out scientific evaluation of anything. You want that get your own asses in gear instead of hiding behind a keyboard.

1BD, excellent suggestion.

Visual check for residue on the surfaces of the leade.

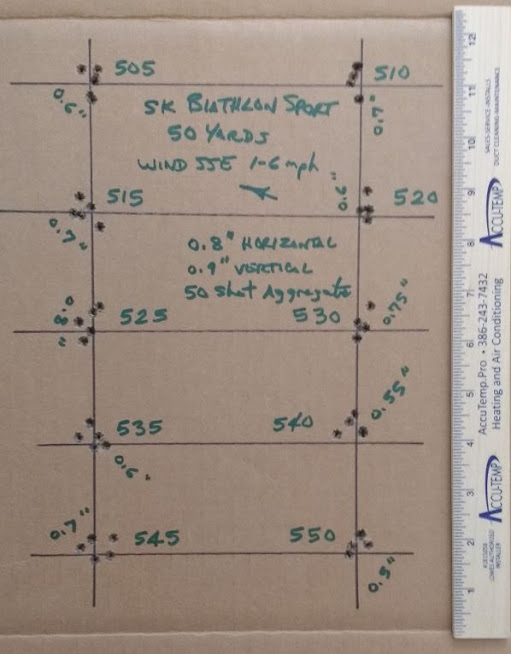

I am using the same brick of SK Biathlon Sport as proved most consistent at 200 yards.

Those are the targets to view for results at 50, 250, 500, 750 and 1000 shots.

Those groups and aggregate sizes are my reference for improvement.

Not the bulk ammo being shot to act as grit carriers.

I'm working with what I have.

Certainly not preventing any of you skilled machinists from improving on my procedures.

Air guage before, during and after.

Test from a fixture in a tunnel with computer scoring and analysis for every shot.

I am not a professional. Just someone who decided to see what actually occurs.

Talking about what might be happening, wasn't going to answer the question.

I'll post all my targets and bore images.

After that, each of you can decide what has happened.

Your decision, not mine.

Did the barrel improve?

Is it due to the abrasive wear caused by primer/ powder residue?

I'm just the technician, taking the time and spending my cash

in order to provide enough data to draw a conclusion.

If you can improve on what I've started, don't talk about it, do it.

Visual check for residue on the surfaces of the leade.

I am using the same brick of SK Biathlon Sport as proved most consistent at 200 yards.

Those are the targets to view for results at 50, 250, 500, 750 and 1000 shots.

Those groups and aggregate sizes are my reference for improvement.

Not the bulk ammo being shot to act as grit carriers.

I'm working with what I have.

Certainly not preventing any of you skilled machinists from improving on my procedures.

Air guage before, during and after.

Test from a fixture in a tunnel with computer scoring and analysis for every shot.

I am not a professional. Just someone who decided to see what actually occurs.

Talking about what might be happening, wasn't going to answer the question.

I'll post all my targets and bore images.

After that, each of you can decide what has happened.

Your decision, not mine.

Did the barrel improve?

Is it due to the abrasive wear caused by primer/ powder residue?

I'm just the technician, taking the time and spending my cash

in order to provide enough data to draw a conclusion.

If you can improve on what I've started, don't talk about it, do it.

Last edited:

I can attest to the fact of accuracy improvments with barrel wear. Its doesnt take a very scientific approach to record a difference. When I first had my IBI I was disappointed with the accuracy. It wasnt picky but at 50 yd it shot everything good and bulk in the 0.7" average with 10 shot groups. Now I'm in the 0.5s with good ammo the bulk is still 0.7" why the bulk didnt change i dont know. This is all recorded at below freezing temp this winter.

Up until this thread I assumed that this was more to do with fouling then wear.

The following is with my Ruger precision rimfire.

Because I shoot PRS consistency is more important then raw accuracy. I found with previous rifles (all factory) that POI moved as the bore fouled. Not like the first 10 are all over but the first group and the 20th would be in a different place. I went from cleaning every 1000 to 5000 and then quit all together. Everytime I cleaned the rifle shot worse and wasn't consistent. Now last years rig has 15k since last cleaned. It shoots better then ever. This is why I ASSUMED fouling was the key...

This puts a new dimension to it.

I have no before and after pictures of the bore never thought of it. Like seriously there is no way lead can wear steel... that guy who has 60k through his savage mark 2 and said it quit shooting because the rifling was wore out.. maybe he wasnt crazy....

Up until this thread I assumed that this was more to do with fouling then wear.

The following is with my Ruger precision rimfire.

Because I shoot PRS consistency is more important then raw accuracy. I found with previous rifles (all factory) that POI moved as the bore fouled. Not like the first 10 are all over but the first group and the 20th would be in a different place. I went from cleaning every 1000 to 5000 and then quit all together. Everytime I cleaned the rifle shot worse and wasn't consistent. Now last years rig has 15k since last cleaned. It shoots better then ever. This is why I ASSUMED fouling was the key...

This puts a new dimension to it.

I have no before and after pictures of the bore never thought of it. Like seriously there is no way lead can wear steel... that guy who has 60k through his savage mark 2 and said it quit shooting because the rifling was wore out.. maybe he wasnt crazy....

Last edited:

That rifle cant. Never could never will. 0.825 is its average.If you haven’t cleaned in 15k rounds, I’d love to see a 6 X 10 with everything inside .5 inch.

There is a difference between internal finish on a match type barrel and a factory barrel and while one might see improvement the other will reach optimum accuracy as soon as the microscopic burs are smoothed from crown, throat and chamber. This is achieved during initial lot testing.

Wish I could.I know it’s changed substantially by talking with ELEY people but have zero idea if/where that would be published. Gotta have an information networking system Justin, mine took 20 years.Tim, the technology changes so rapidly it's difficult to keep up.

I read everything I can find, rarely is it regarding state of the art.

As you said earlier, proprietary information, unlikely to be found.

Research is attempting to eliminate the toxic compounds currently in use.

More specifically the lead byproducts created by primer and powder combustion.

Point me towards the information, I'll keep working my way through it.

Sorry Its two different rifles the Ruger is the 15k since last cleaned. Im at 31450 total with that rifle.Sorry, I’ll have to reread your post about 0.5s with good ammo.

Last outing with it.

All 5 shot groups top row is prone mid is standing off a barricade, bottom is kneeling its off of a barricade. So not a 6x5 but its what I have.

Here is a 6x5 with the Rim X the rifle I said will do 0.5s this is 5 shot typically I do 10 but I did 5 here to see how much 10 makes a difference.

Here is a number of 10 shot groups with different ammo when I just got the RimX together.

I dont have a 6x5 thats current as I'm focused on 200 yd testing but heres what my spreadsheet has in for 50. This is all 10 shot groups. -0⁰c to -10⁰c

Attachments

Thanks for all the info and stimulation JA.

I have to say that these forums would be empty if everything posted had to be based on documented, repeatable, rigorous scientific method, unbiased assessment and statistical significance. At best, most of the time, we get a guy doing his best and reporting honestly, maybe offering an opinion based on FACT, not some hairy story he dreamed or misread/misremembered third hand from who knows where.

Personally, what I really value is that it gets me thinking and seeing thing from a different angle ... as CRPS just said above.

When I am doing my testing I choose to 'run with something' when it seems to be working, which is way before statistically proven. When Eley revisited and reinvented their processes and number of years back their sample size to pass/fail a lot of Tennex was 200 rounds. If I change something and shoot with it for a week or two that might be 600 to 1000 rounds. Not trivial says I.

It is impractical for me to source lot tested ammo. I buy several cases at a time and if I start a case I shoot at least half, usually all. After a few days I have an idea of my scores and group statistics(off the same targets) and I pretty well know what it can do. So when I make a change I have a baseline. In order to adopt the change I don't have have to know how many thousandths the average group has shrunk, just that I think it is an improvement that I have CONFIDENCE in. Confidence is a big deal in this game.

I have to say that these forums would be empty if everything posted had to be based on documented, repeatable, rigorous scientific method, unbiased assessment and statistical significance. At best, most of the time, we get a guy doing his best and reporting honestly, maybe offering an opinion based on FACT, not some hairy story he dreamed or misread/misremembered third hand from who knows where.

Personally, what I really value is that it gets me thinking and seeing thing from a different angle ... as CRPS just said above.

When I am doing my testing I choose to 'run with something' when it seems to be working, which is way before statistically proven. When Eley revisited and reinvented their processes and number of years back their sample size to pass/fail a lot of Tennex was 200 rounds. If I change something and shoot with it for a week or two that might be 600 to 1000 rounds. Not trivial says I.

It is impractical for me to source lot tested ammo. I buy several cases at a time and if I start a case I shoot at least half, usually all. After a few days I have an idea of my scores and group statistics(off the same targets) and I pretty well know what it can do. So when I make a change I have a baseline. In order to adopt the change I don't have have to know how many thousandths the average group has shrunk, just that I think it is an improvement that I have CONFIDENCE in. Confidence is a big deal in this game.

Aw cr*p.

Tim, Tim, Tim....what did you do?

I thought you didn't let anyone on the internet annoy you.

I'm guessing you really got pissed off-fa-fa.

When the ban hammer comes down on ya' at the 'hide,

ya' really have to work for it. Ya' must have let somebody get under y'er skin.

Oh well.... I was hoping for a lengthy critique pointing out all my mistakes

and faulty procedures and incorrect conclusions...such is life.

I guess I'll just have to make due with the rest of the y'all

to pick up the slack when I finally make it to the end.

Tim, Tim, Tim....what did you do?

I thought you didn't let anyone on the internet annoy you.

I'm guessing you really got pissed off-fa-fa.

When the ban hammer comes down on ya' at the 'hide,

ya' really have to work for it. Ya' must have let somebody get under y'er skin.

Oh well.... I was hoping for a lengthy critique pointing out all my mistakes

and faulty procedures and incorrect conclusions...such is life.

I guess I'll just have to make due with the rest of the y'all

to pick up the slack when I finally make it to the end.

Last edited:

If he truly knew as much as he let on he could of been a valuable resource here in the 22 section but instead he used his time to belittle and make fun of.

oh well . Justin I guess you’ll have to deal with the rest of us.

oh well . Justin I guess you’ll have to deal with the rest of us.

He claimed he read all 8000+ of my post and each and all were worthless. (I knew right then he was both dedicated and truthful)

He looked up my photo and found it wanting. (Very likely)

I inducted him into my fan club. (Only member but you gotta start somewhere.)

Damn!

He looked up my photo and found it wanting. (Very likely)

I inducted him into my fan club. (Only member but you gotta start somewhere.)

Damn!

Justin,

Yes, I’ve had a good bit of interest since I added the message that I know you. (sort of)

No actual members yet other than Tim. I think my initiation fee is a barrier. (.05) I’m considering waiving it. Might get a few who are on the cusp of committing to make the leap.

Yes, I’ve had a good bit of interest since I added the message that I know you. (sort of)

No actual members yet other than Tim. I think my initiation fee is a barrier. (.05) I’m considering waiving it. Might get a few who are on the cusp of committing to make the leap.

It's good to have connections in low places, eh?

Alright, back to mere details and fun with the borescope.

pics from the bore of my 54 AirKing

Link to folder https://photos.app.goo.gl/3tbzPXL15c6QHs41A

There's a lead deposit...almost 2500 pellets sent, might need to wire brush with solvent, eh?

Borescopes are kinda handy, with the prices dropping it was worth it.

Leading makes the surface rougher, not smoother, from what I can see.

Lead deposits decrease accuracy.

Areas without leading don't show smoothing, just the steel as shipped from the factory.

Alright, back to mere details and fun with the borescope.

pics from the bore of my 54 AirKing

Link to folder https://photos.app.goo.gl/3tbzPXL15c6QHs41A

There's a lead deposit...almost 2500 pellets sent, might need to wire brush with solvent, eh?

Borescopes are kinda handy, with the prices dropping it was worth it.

Leading makes the surface rougher, not smoother, from what I can see.

Lead deposits decrease accuracy.

Areas without leading don't show smoothing, just the steel as shipped from the factory.

Aw cr*p.

Tim, Tim, Tim....what did you do?

He started treating the technical forums like the bear pit and was trading insults. It appears to be only for a few days. Perhaps it will give him some time to write some detailed notes for you.

Personally, I'm too far behind in skill or technical aptitude to be allowed in anyone's fan club much less contribute anything but encouragement for your efforts. For what its worth, your journey has helped me out and so you have my gratitude for sharing.

Something I forgot to note, one bit of evidence that is totally based on my perception.

The amount of effort it requires to pull a patch through the barrel.

The first cleaning those rough areas and burrs grabbed and pulled back

at the patches, needing some extra oomph to pull them through.

This last cleaning after 500 shots, the rifling has been smoothed out,

the burrs knocked off, the patches pull through with a minimum of effort.

I should have used a pull gauge to measure the difference.

It would have provided a useful data point for comparison.

The amount of effort it requires to pull a patch through the barrel.

The first cleaning those rough areas and burrs grabbed and pulled back

at the patches, needing some extra oomph to pull them through.

This last cleaning after 500 shots, the rifling has been smoothed out,

the burrs knocked off, the patches pull through with a minimum of effort.

I should have used a pull gauge to measure the difference.

It would have provided a useful data point for comparison.

@1badDart ...per y'er request...grit, grit and more grit in the leade

Look at the outer perimeter of the mirror, the borescope catches the profile of the leade.

Those white specs are likely the bits of silica left after being blown out of the brass.

It's all through the bore, on the lands and in the grooves.

Link to folder of the leade pics before cleaning https://photos.app.goo.gl/G79cRJw2ScaV9b8f9

Look at the outer perimeter of the mirror, the borescope catches the profile of the leade.

Those white specs are likely the bits of silica left after being blown out of the brass.

It's all through the bore, on the lands and in the grooves.

Link to folder of the leade pics before cleaning https://photos.app.goo.gl/G79cRJw2ScaV9b8f9

Last edited:

Next box of SK Biathlon Sport at 50 yards

50 yards off the heavy bags to see if the results are improving

5 shot group size looks to be remaining about the same

but the 50 shot aggregate has decreased, again.

Shots 501 to 550

50 yards off the heavy bags to see if the results are improving

5 shot group size looks to be remaining about the same

but the 50 shot aggregate has decreased, again.

Shots 501 to 550

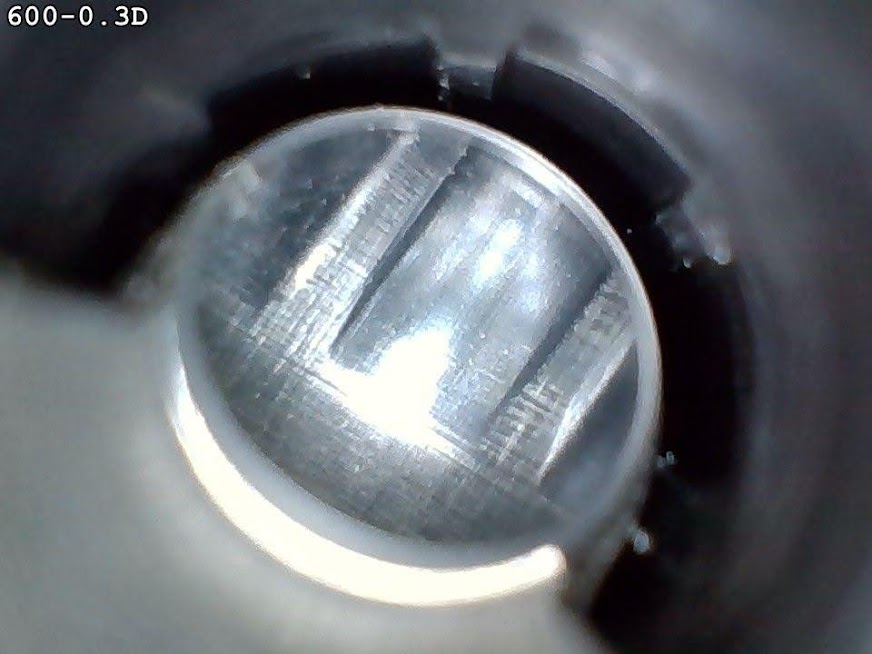

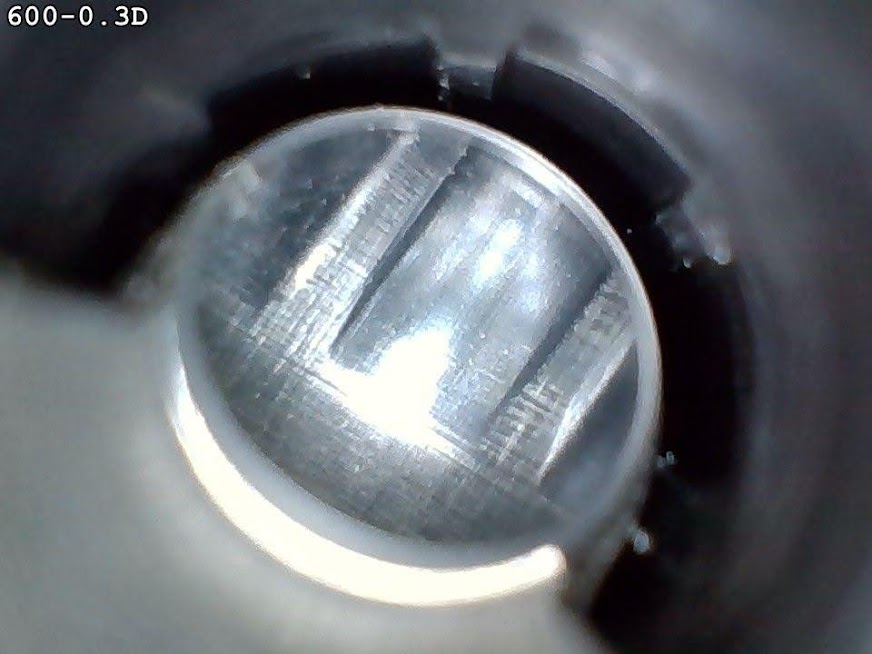

600 shots sent, wear is showing up.

Looks like those particles of grit are acting to cut away the rough surfaces.

Link to the borescope images after 600 shots https://photos.app.goo.gl/LXBGdSQmmCiB84nBA

Looks like those particles of grit are acting to cut away the rough surfaces.

Link to the borescope images after 600 shots https://photos.app.goo.gl/LXBGdSQmmCiB84nBA

Last edited:

Justin, is this the same patent you found or is it more recent ?

Primer composition - ELEY LTD (freepatentsonline.com)

CA2156974C - Primer composition - Google Patents

Primer composition - ELEY LTD (freepatentsonline.com)

CA2156974C - Primer composition - Google Patents

Quite a change over the course of 600 rounds. I look forward to comparing your photos of the leade from start to finish.600 shots sent, wear is showing up.

Looks like those particles of grit are acting to cut away the rough surfaces.

Link to the borescope images after 600 shots https://photos.app.goo.gl/LXBGdSQmmCiB84nBA

Are you at the point where the group sizes have settled in or is it still improving? My CZ457 seemed to settle in after about 700 rounds.

Lastly, have you encountered any of the dreaded ”carbon ring” or are you cleaning before the pictures?

Thank you for putting this together, happy shooting

Average group size looks to have settled, but 50 shot aggregate has decreased on size again.

No carbon ring seen, 100 shot cleaning interval seems to prevent it from forming.

I believe the number of shots needed to smooth the rifling

depends on just how poorly the hammer forging, crown/chamber is accomplished.

I've had barrels that were acceptable after only a few hundred rounds

and one barrel that needed almost 8 bricks before it stopped spitting strays.

It all depends on y'er luck with the rimfire lottery.

No carbon ring seen, 100 shot cleaning interval seems to prevent it from forming.

I believe the number of shots needed to smooth the rifling

depends on just how poorly the hammer forging, crown/chamber is accomplished.

I've had barrels that were acceptable after only a few hundred rounds

and one barrel that needed almost 8 bricks before it stopped spitting strays.

It all depends on y'er luck with the rimfire lottery.

Now I'm curious.. you say strays. You think you got less fliers or general dispersion got less?

My IBI i looked at before i shot. In my books it was a perfect looking bore. Very clean. The leade had the typical tooling marks but nothing out of ordinary. Some very fine scuffs from the pilot almost not noticeable.

I seen improvement until 1000 rounds maybe a little more. That was with a cute bore to start.

My IBI i looked at before i shot. In my books it was a perfect looking bore. Very clean. The leade had the typical tooling marks but nothing out of ordinary. Some very fine scuffs from the pilot almost not noticeable.

I seen improvement until 1000 rounds maybe a little more. That was with a cute bore to start.

Y'er description is more accurate, dispersion halved.

Discussion with a much more knowledgeable shooter

pointed to the likelihood of a large burr(s) in the leade due to a worn reamer.

It took that long for the burr to finally wear and break loose.

Since then I've seen pics of those type of burrs and it makes sense.

Discussion with a much more knowledgeable shooter

pointed to the likelihood of a large burr(s) in the leade due to a worn reamer.

It took that long for the burr to finally wear and break loose.

Since then I've seen pics of those type of burrs and it makes sense.

As it was explained to me, an irregularly formed leade can deform the bullet

causing an uneven heel and changing the balance of the bullet.

As it exits the barrel there is an uneven pressure release tipping the bullet off line and wobbling.

That would produce unpredictable trajectories, increased spread,

depending on the severity of the deformation.

causing an uneven heel and changing the balance of the bullet.

As it exits the barrel there is an uneven pressure release tipping the bullet off line and wobbling.

That would produce unpredictable trajectories, increased spread,

depending on the severity of the deformation.

Never thought of heel damage. But yes a little burr could easy make a notch in the heel. Interesting....

Think of what a bit of smeared land would do to the bottom edge of the bullet

if it looked like this one...

How many shots would it require to wear that steel away?

A brick? 5? I don't know. But until it was gone I'd expect problems.

if it looked like this one...

How many shots would it require to wear that steel away?

A brick? 5? I don't know. But until it was gone I'd expect problems.

Last edited:

The off balance thing makes me thing. If one side of the leade has more drag then the other with soft lead it could very well make the bullet go crooked.

The damaged heel it would have to be a large burr. I have a rifle that marks the bullet as it come out of the mag but collecting fired bullets I can't find the marks. You would have to groove it to make a difference I think.

The damaged heel it would have to be a large burr. I have a rifle that marks the bullet as it come out of the mag but collecting fired bullets I can't find the marks. You would have to groove it to make a difference I think.

I've deliberately damaged 22lr cartridges to determine which problem

causes the most dispersion when fired, 50 shots with damage at different locations.

The worst spread occurred when the drive band is deformed at the crimp line.

Even the slightest unevenness of the trailing edge of the bullet caused some hefty spread.

Damage to the nose or leading edge of the drive bands produced minimal variations in trajectories.

I think that explains why those leade burrs have so much effect.

They are the last thing that expanding bullet heel contacts as it enters the bore.

causes the most dispersion when fired, 50 shots with damage at different locations.

The worst spread occurred when the drive band is deformed at the crimp line.

Even the slightest unevenness of the trailing edge of the bullet caused some hefty spread.

Damage to the nose or leading edge of the drive bands produced minimal variations in trajectories.

I think that explains why those leade burrs have so much effect.

They are the last thing that expanding bullet heel contacts as it enters the bore.

Last edited:

I understand the rear damage vs front from pellets in years gone by.

The bullet heel being forced out against the leade or burr would make good sense because in my case the marking along the driving bands in not actually causing any damage to the very rear. So little effect on the bullet flight.

This is off topic but thinking of the leade I have wonder a bit the last while about chambers and clambering for a specific ammo. Is there something to that? Leade angle, chamber length etc.

I'm newer to rimfire and my primary focus is field matches. ELR is interesting too...

The bullet heel being forced out against the leade or burr would make good sense because in my case the marking along the driving bands in not actually causing any damage to the very rear. So little effect on the bullet flight.

This is off topic but thinking of the leade I have wonder a bit the last while about chambers and clambering for a specific ammo. Is there something to that? Leade angle, chamber length etc.

I'm newer to rimfire and my primary focus is field matches. ELR is interesting too...

justin,I've deliberately damaged 22lr cartridges to determine which problem

causes the most dispersion when fired, 50 shots with damage at different locations.

The worst spread occurred when the drive band is deformed at the crimp line.

Even the slightest unevenness of the trailing edge of the bullet caused some hefty spread.

Damage to the nose or leading edge of the drive bands produced minimal variations in trajectories.

I think that explains why those leade burrs have so much effect.

They are the last thing that expanding bullet heel contacts as it enters the bore.

In your opinion, would drive band scraping like this have an effect on dispersion/flyers?

The first one is from the first round out of the magazine, the second cycled slowly, #3-5 cycled at regular speed.

TIA and happy shooting

If it's just scraping lubricant, effect would be minimal.

If it's removing lead the length of the drive bands

or damaging the brass at the crimp, I'd expect strays.

If it's removing lead the length of the drive bands

or damaging the brass at the crimp, I'd expect strays.

What frankly amazes me is that we can hit anything at all with .22 rimfire ammunition. First of all it is a heeled bullet. That technology dates from the Civil War for crying out loud. Then we manufacture them at a rate comparable to a stream of water. The swaged soft lead bullets are shoved into the case mouth and crimped. Priming and charging with powder performed at a dizzying, mechanized rate. Anyone that hand loads ammo for any type of precision would be aghast at the treatment of this ammo.

Then contemplate the angst of the bullet caster/hand loader. The pains we take to attain perfection during every aspect from blending alloy, to casting, sizing, lubricating, seating, typically not crimping at all for target grade ammo. Powder selection to match burning rates and pressure curves relative to the hardness of our alloys. Each charge scale weighed and lovingly deposited into each casing. We have gas checks to protect the bases of our bullets for velocities over 1,400 fps. My best cast bullet ammo shoots about like my best .22 ammo. 10 and 20 shot groups at 100 yards run about an inch and a quarter, from my bench, with my technique, from my pretty good rifles.

I can positively state that imperfections in the base of the bullet will result in wider dispersion. I have personally tested cast bullets with flawed bases against visually perfect bullets. If we were able to pull, damage in a controlled manner, and reload and re-crimp .22 ammo, we could easily demonstrate how critical base perfection is. What allows us to hit anything at all is the fact that the soft lead swaged .22 bullet has a slightly cupped base that obturates, or expands when swatted in the ass with 28,000 psi of the typical .22 l.r. The bullet then fully seals the space available to it, including those areas that are less than perfect. Imperfections in the barrel will damage those fragile bullets whether they are manufacturing defects or defects caused by some level of leading or carbon build up. Imperfections or damage to the bullet whether it is prior to being loaded or afterward during handling, shipping, and being cycled into the rifle cannot be made up for by a perfect rifle as Justin has often noted.

Then contemplate the angst of the bullet caster/hand loader. The pains we take to attain perfection during every aspect from blending alloy, to casting, sizing, lubricating, seating, typically not crimping at all for target grade ammo. Powder selection to match burning rates and pressure curves relative to the hardness of our alloys. Each charge scale weighed and lovingly deposited into each casing. We have gas checks to protect the bases of our bullets for velocities over 1,400 fps. My best cast bullet ammo shoots about like my best .22 ammo. 10 and 20 shot groups at 100 yards run about an inch and a quarter, from my bench, with my technique, from my pretty good rifles.

I can positively state that imperfections in the base of the bullet will result in wider dispersion. I have personally tested cast bullets with flawed bases against visually perfect bullets. If we were able to pull, damage in a controlled manner, and reload and re-crimp .22 ammo, we could easily demonstrate how critical base perfection is. What allows us to hit anything at all is the fact that the soft lead swaged .22 bullet has a slightly cupped base that obturates, or expands when swatted in the ass with 28,000 psi of the typical .22 l.r. The bullet then fully seals the space available to it, including those areas that are less than perfect. Imperfections in the barrel will damage those fragile bullets whether they are manufacturing defects or defects caused by some level of leading or carbon build up. Imperfections or damage to the bullet whether it is prior to being loaded or afterward during handling, shipping, and being cycled into the rifle cannot be made up for by a perfect rifle as Justin has often noted.

One of the things to remember here is that the groove to top of the land is only about .003 so the lead area is very small. Any small particulates would have an effect.Think of what a bit of smeared land would do to the bottom edge of the bullet

if it looked like this one...

How many shots would it require to wear that steel away?

A brick? 5? I don't know. But until it was gone I'd expect problems.

I had an attention getter this morning.

I was mumbling to myself about how burn residue is all over the bore.

I was overheard and was reminded condensation occurs in the bore after every shot.

High pressure and temperature to ambient air pressure and temperature after every shot.

The combustion byproducts include water which condenses on the particles and sticks to the rifling.

That explains why I see bits of residue all over the bore, not just on the bottom.

The water evaporates leaving the residue stuck in place.

As requested pics of the bore in the upright position

immediately after shooting, bottom of image is bottom of bore.

There's grit from the case mouth to the muzzle.

Red penlight diffuser at the muzzle to illuminate the rifling.

Link to grit deposit image folder https://photos.app.goo.gl/MZntRmUrz5F8shHv5

Burn residue and silica end up deposited on all the surfaces of the bore

from the mouth of the brass to the crown. As a result, abrasion occurs

from case mouth to muzzle, every time a cartridge is fired.

That's why those linear abrasion marks appear from leade to muzzle.

The residue adheres to the entire surface of the bore.

Explains why the wear pattern is so even in appearance.

After 700 shots here are the borescope pics https://photos.app.goo.gl/4BTqQUpwzH9TNJgC6

I was mumbling to myself about how burn residue is all over the bore.

I was overheard and was reminded condensation occurs in the bore after every shot.

High pressure and temperature to ambient air pressure and temperature after every shot.

The combustion byproducts include water which condenses on the particles and sticks to the rifling.

That explains why I see bits of residue all over the bore, not just on the bottom.

The water evaporates leaving the residue stuck in place.

As requested pics of the bore in the upright position

immediately after shooting, bottom of image is bottom of bore.

There's grit from the case mouth to the muzzle.

Red penlight diffuser at the muzzle to illuminate the rifling.

Link to grit deposit image folder https://photos.app.goo.gl/MZntRmUrz5F8shHv5

Burn residue and silica end up deposited on all the surfaces of the bore

from the mouth of the brass to the crown. As a result, abrasion occurs

from case mouth to muzzle, every time a cartridge is fired.

That's why those linear abrasion marks appear from leade to muzzle.

The residue adheres to the entire surface of the bore.

Explains why the wear pattern is so even in appearance.

After 700 shots here are the borescope pics https://photos.app.goo.gl/4BTqQUpwzH9TNJgC6

Last edited:

Hunh? What? oh yeah, update....can do.

Discussion with the other old coots at the local range, is how the silica is being moved.

Is it being embedded in the lead or snowplowed through the bore?

A couple dozen bullets were captured in my poly-fil bullet trap.

A decent sized sample from copper plated and lubricated lead 22lr.

After an hour at the workbench, I've decided the silica is not being embedded in the bullets.

After repeated attempts to create scratches with the fired bullets on a polished stainless steel plate, it doesn't happen.

Not even with extreme force being applied. So it appears the bullets are shoving the burn residue

through the barrel on the leading edge of the drive bands. Any scratching or cutting that takes place

can only occur at that location. On impact with the poly-fil trap and all the individual fibers,

the bullets are wiped clean including removing any lubricant. No visible particles of any sort.

The snowplow effect appears to be what is happening.

If the plow shoves a rock along the pavement ahead of it,

the rock will scratch the pavement. If it hits a ridge in the pavement

that rock will punch a hole through the softer asphalt ridge.

I'm thinking that is what is occurring with the silica in the barrel.

Discussion with the other old coots at the local range, is how the silica is being moved.

Is it being embedded in the lead or snowplowed through the bore?

A couple dozen bullets were captured in my poly-fil bullet trap.

A decent sized sample from copper plated and lubricated lead 22lr.

After an hour at the workbench, I've decided the silica is not being embedded in the bullets.

After repeated attempts to create scratches with the fired bullets on a polished stainless steel plate, it doesn't happen.

Not even with extreme force being applied. So it appears the bullets are shoving the burn residue

through the barrel on the leading edge of the drive bands. Any scratching or cutting that takes place

can only occur at that location. On impact with the poly-fil trap and all the individual fibers,

the bullets are wiped clean including removing any lubricant. No visible particles of any sort.

The snowplow effect appears to be what is happening.

If the plow shoves a rock along the pavement ahead of it,

the rock will scratch the pavement. If it hits a ridge in the pavement

that rock will punch a hole through the softer asphalt ridge.

I'm thinking that is what is occurring with the silica in the barrel.

Last edited:

I'm told by reliable industry sources that rimfire bbls really don't "wear" ... at least anything comparable to CF bbls.

I dunno.

Most CF bbls seem to be kaput under 6,000 rounds. Rimfires seem to go well over 10,000. Typically much, much more.

I do know I've gotten repeated match winning results long b4 1000 rounds from both of my Vudoos. And the rifles I've bought that shot average or crappy at 250 rounds (CZ 455 / 457) continued to do so after 1,000 rounds.

Is my 4 rifle sample indicative of the entire industry? I dunno. My experiences maybe entirely unique to me. But somehow, I doubt I got magic unicorn rifles.

I dunno.

Most CF bbls seem to be kaput under 6,000 rounds. Rimfires seem to go well over 10,000. Typically much, much more.

I do know I've gotten repeated match winning results long b4 1000 rounds from both of my Vudoos. And the rifles I've bought that shot average or crappy at 250 rounds (CZ 455 / 457) continued to do so after 1,000 rounds.

Is my 4 rifle sample indicative of the entire industry? I dunno. My experiences maybe entirely unique to me. But somehow, I doubt I got magic unicorn rifles.

Last edited: