Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thoughts on the Aero Precision SOLUS ?

- Thread starter zenpre

- Start date

He didnt compare it to any one particular action, he compared it to known mechanical principles. Many principles of which other manufactures have discovered and corrected already for themselves for the very reasons Terry described.. Love that movie. But I mean, Come on. Says you can't compare two actions, and then literally goes on to compare the SOLUS and an action he won't name? Seems mongoloid-ish to me. just mind boggling that someone would come on here to call someone else a retard, while literally doing the exact same thing that the person who they called a retard did.

View attachment 8070151

Shit, subes has already gone to filing on his ejectors on is action to fix issues that Terry described.

I still don't get it. The spring loaded ejectors are the fulcrum. I guess I don't understand the physics of it.Moving the ejectors to the side farther from the extractor will provide more mechanical leverage for the ejector (making it easier for the ejector to push the case) think of a pry bar with the case head being the bar and the extractor being the pry location and ejector your hand pushing.

The dual ejectors close to the extractor is interesting, I don’t think I have seen that before. Could help with the short cases like the BR’s.

and you know...knowing how something is supposed to work often trumps knowing why it works! Although the why it works comes in handy when the how it works stops working!I still don't get it. The spring loaded ejectors are the fulcrum. I guess I don't understand the physics of it.

"He didn't compare it to any particular action." No, no, He didn't compare it to ANY action. He said "Force to lift bolt during cocking is very favorable compared to similar 3 lug actions." What's similar, and what action? Again, I'm sorry, but if your going to call someone a retard, I feel you better have your house in order, and be clear and concise on what you are comparing and describing. To me his statement is just as ambiguous as the other statement.He didnt compare it to any one particular action, he compared it to known mechanical principles. Many principles of which other manufactures have discovered and corrected already for themselves for the very reasons Terry described.

I just get my panties all bunched up when people talk shit online, cause 99 percent of them wouldn't say what they are typing to someone's face.

This retard is gonna go shoot his SOLUS and get back with you all, because If I'm gonna be called a retard, I want to be the retard giving a review with some rounds through the fucking thing!"He didn't compare it to any particular action." No, no, He didn't compare it to ANY action. He said "Force to lift bolt during cocking is very favorable compared to similar 3 lug actions." What's similar, and what action? Again, I'm sorry, but if your going to call someone a retard, I feel you better have your house in order, and be clear and concise on what you are comparing and describing. To me his statement is just as ambiguous as the other statement.

I just get my panties all bunched up when people talk shit online, cause 99 percent of them wouldn't say what they are typing to someone's face.

Im not going to put words in his mouth but I am going to go out on a limb here and say that if any one individual on this forum has his house in order its Terry Cross."He didn't compare it to any particular action." No, no, He didn't compare it to ANY action. He said "Force to lift bolt during cocking is very favorable compared to similar 3 lug actions." What's similar, and what action? Again, I'm sorry, but if your going to call someone a retard, I feel you better have your house in order, and be clear and concise on what you are comparing and describing. To me his statement is just as ambiguous as the other statement.

I just get my panties all bunched up when people talk shit online, cause 99 percent of them wouldn't say what they are typing to someone's face.

I hear you. I'm not saying he doesn't. But I just felt like it could have been worded differently, without insulting someone else trying to give information. Now I sound like a big pussy.Im not going to put words in his mouth but I am going to go out on a limb here and say that if any one individual on this forum has his house in order its Terry Cross.

The most important sentence in my entire post above:I hear you. I'm not saying he doesn't. But I just felt like it could have been worded differently, without insulting someone else trying to give information. Now I sound like a big pussy.

"*It is noted that my opinion is worth exactly the price you are paying to read this right now….."

I will admit I could have used a different adjective than retarded.

My first real job was working around special kids and adults to fund my first 2 years of college. I respect them more than most other supposedly "normal" humans. Rather than delete or edit that word from my post I will just own up that I suck at etiquette and apologize if anyone was offended by its use.

I stand by my opinions of 2 lug vs 3 lug action bolt lift as well as comparing new actions to used actions for "smoothness" and I believe I would have the same opinion regardless of what actions are considered.

Carry on with your day and never mind me.

Would the extractor not be the fulcrum (point of pivot or rotation)?I still don't get it. The spring loaded ejectors are the fulcrum. I guess I don't understand the physics of it.

If so, the further the point of force (the ejectors) is away from that pivot point, the more leverage would be exerted on the object being moved. Yes?

.

Yes, I guess the leverage would be more but the travel of the lever arm (cartridge base) would be less. In my mind I was equating the further travel of the lever arm with more leverage.Would the extractor not be the fulcrum (point of pivot or rotation)?

If so, the further the point of force (the ejectors) is away from that pivot point, the more leverage would be exerted on the object being moved. Yes?

.

So the question would be why. Two springs would overcome the loss of leverage from moving them. I can only think it was done to maintain sideways leverage for the benefit of short cases so they dont pop out of the extractor while pulling the bolt back? I'm thinking as an example the difference of a rem 700 223 and 221 fireball where the ejector plunger is closer to the extractor on the 221.

Last edited:

Given the same amount of ejector travel beyond the breech face, you are correct in that the closer ejectors would stay in contact and push through more degrees of arc.Yes, I guess the leverage would be more but the travel of the lever arm (cartridge base) would be less. In my mind I was equating the further travel of the lever arm with more leverage.

The question becomes, if we move the ejector position further across the breech face from the extractor is it still enough to efficiently and consistently get the case clear of the ejection port ?

Remington, Impact, Surgeon, Defiance, BAT, Stiller, every standard AR15 pattern bolt and every standard pattern AR10 bolt shows that it is a solid approach with good results.

.

Objectively, there has been a lot of retardation in the various Aero threads.

No doubt super short cases in the BR/Dasher and sub/223 families would benefit from the closer positioning.Yes, I guess the leverage would be more but the travel of the lever arm (cartridge base) would be less. In my mind I was equating the further travel of the lever arm with more leverage.

So the question would be why. Two springs would overcome the loss of leverage from moving them. I can only think it was done to maintain sideways leverage for the benefit of short cases so they dont pop out of the extractor while pulling the bolt back? I'm thinking as an example the difference of a rem 700 223 and 221 fireball where the ejector plunger is closer to the extractor on the 221.

I would have a WAG that the vast majority of their user market is not going to be running the more specialty PRS/BR short cases.

I think they could certainly keep the current positioning but would be afraid their super short length/small diameter ejector plungers combined with short/high load springs are going to be an issue.

.

No argument here. I was just trying to come up with a reason why that choice was made. Was it an egnineering solution looking for a problem or just some engineer got tired of having to pull 300 blackout cases out of the raceway? I laugh to myself thinking about it.No doubt super short cases in the BR/Dasher and sub/223 families would benefit from the closer positioning.

I would have a WAG that the vast majority of their user market is not going to be running the more specialty PRS/BR short cases.

I think they could certainly keep the current positioning but would be afraid their super short length/small diameter ejector plungers combined with short/high load springs are going to be an issue.

.

Hey Terry, you know how stubby cases (The BR, 221 fb etc) tend to eject poorly out of a standard R700 because the ejector is basically out of stroke by the time the case neck hits the 3 oclock raceway. Then when the case neck clears the front end of the e-port, there’s almost nothing left.I received one of these and finally made time to look it over.

I figured I would send some of the bolt parts off for IonBond with a large batch of other parts already going and then barrel it up for a class loaner rifle to see how it holds up.

I have not fired any rounds through this action yet but already have some opinions*.

*It is noted that my opinion is worth exactly the price you are paying to read this right now…..

Regarding some posts comparing the “feel” of a SOLUS cycling to another brand of action that has already had thousands of cycles.

That is retarded.

Cycling an action many times is a big deal in smoothing out the feel as the bolt unlocks, cycles back and forth and then goes back into battery.

Zero points given to anyone’s feedback on such a comparison.

Regarding some posts comparing the “feel” and force needed to cock a SOLUS to another brand of action that has a 2-lug/90 degree design.

That is retarded.

3 lug actions must attempt to get the same amount of primary extraction camming done with 33% less lug and handle boss rotation. More rotational force needed to accomplish the same rearward movement via the cam surface.

Zero points given to anyone’s feedback on such a comparison.

My perception of the action.

Pros:

Very good receiver and bolt body design.

Great surface finish with few machine marks.

Good bolt stop design.

Good trigger hangar design.

Generous ejection port.

Force to lift bolt during cocking is very favorable compared to similar 3 lug actions.

Double cocking piece design provides 2 separate cam surfaces 180 degrees apart at the rear of the bolt. This allows the camming operation work to be shared across 2 equal camming surfaces. Pretty smart.

Bottom mag feed cut and ramp in the bottom of the receiver is well done.

Cons:

The bolt head has 2 ejectors. Both are too close to the extractor.

Both are too short to operate smoothly in their host holes under repeated load. Both have springs that are too short to allow smooth movement across the ejector’s travel.

Simply moving their location to the other side of the breech face would double the amount of leverage they could provide in relation to the pivot point of the extractor.

View attachment 8070092

Both ejectors have no chamfer at the rear face which when combined with their short length and no center spring guide feature allows the ejectors to try to twist and bite in their respective holes.

View attachment 8070093

The existing bolt head has ample room and material available to change the ejector position, go to a larger diameter/ deeper depth hole that would allow a Rem700’ish ejector with spring guide feature and longer spring. Even a single ejector with such a proven design and location would far outperform their current double ejector design.

The Extractor is small and is not smooth in its movement. I believe the spring needs to be longer and the host hole deeper for a smoother function within the load range it will live at.

View attachment 8070094

My current feeling is that they did a LOT of things right with this design.

Seemingly all the hard shit was designed and machined quite well and then they dropped the ball with the ejector and extractor details.

Both are going to be hard to service.

Both are going to cause issues and make their phone ring.

Both could be addressed and improved upon at the same or less production $.

When these bolt parts get back from IonBond, we will run the crap out of it and see if any of my worries are warranted.

./

Could they have been addressing that for the shooters who are going BR?

Thanks for the review, I agree completely.

@Supersubes , WTF do you have me on ignore? lol

I dont think so, but somehow i missed a bunch of replies including yours and Terry’s. I’ll see myself out.

When I read "retard" I was like, "Oh yeah, this is SH and we can talk like grown men do. LOL. I too reserve the adjective for non mentally challenged folks who act like they are or shouldn't!The most important sentence in my entire post above:

"*It is noted that my opinion is worth exactly the price you are paying to read this right now….."

I will admit I could have used a different adjective than retarded.

My first real job was working around special kids and adults to fund my first 2 years of college. I respect them more than most other supposedly "normal" humans. Rather than delete or edit that word from my post I will just own up that I suck at etiquette and apologize if anyone was offended by its use.

I stand by my opinions of 2 lug vs 3 lug action bolt lift as well as comparing new actions to used actions for "smoothness" and I believe I would have the same opinion regardless of what actions are considered.

Carry on with your day and never mind me.

I wish people could read threads and not automatically get thin skinned. I know we can't see body language, tone, and such, and god forbid we forget to put a smiley in for sarcasm/satire! Well, I am gonna '"rainman out" on the data I collected from today's range trip with the SOLUS. Please do keep up the good posts you make!

Where the data?When I read "retard" I was like, "Oh yeah, this is SH and we can talk like grown men do. LOL. I too reserve the adjective for non mentally challenged folks who act like they are or shouldn't!I ran with it a bit for some levity and humor.

I wish people could read threads and not automatically get thin skinned. I know we can't see body language, tone, and such, and god forbid we forget to put a smiley in for sarcasm/satire! Well, I am gonna '"rainman out" on the data I collected from today's range trip with the SOLUS. Please do keep up the good posts you make!

Working on it. I'll post soon.Where the data?

You're good. My apologies for being a douche about it. HahaThe most important sentence in my entire post above:

"*It is noted that my opinion is worth exactly the price you are paying to read this right now….."

I will admit I could have used a different adjective than retarded.

My first real job was working around special kids and adults to fund my first 2 years of college. I respect them more than most other supposedly "normal" humans. Rather than delete or edit that word from my post I will just own up that I suck at etiquette and apologize if anyone was offended by its use.

I stand by my opinions of 2 lug vs 3 lug action bolt lift as well as comparing new actions to used actions for "smoothness" and I believe I would have the same opinion regardless of what actions are considered.

Carry on with your day and never mind me.

While I am not sure if I am the retard or not I was not comparing 2 lugs to 3 lug actions. I was comparing two entry level actions at budget price points. One that has a track record of awesomeness and the other that seems to be not so much. But who am I to say what you should spend you're money on. My opinion is only that.

Most certainly they could have.Hey Terry, you know how stubby cases (The BR, 221 fb etc) tend to eject poorly out of a standard R700 because the ejector is basically out of stroke by the time the case neck hits the 3 oclock raceway. Then when the case neck clears the front end of the e-port, there’s almost nothing left.

Could they have been addressing that for the shooters who are going BR?

Their reasons are sort of like Hootsie Owl and how many licks to get to the Tootsie Roll center of a Tootsie Pop.....

The world may never know...

If that is the case, I would encourage them to rethink the design of the ejector plungers and their springs and keep them located as currently produced.

What’s to stop one from having a Krieger, Lilja, Brux, etc spun up for one. Not trying to be smarta$$. I just want to know because that was my plan.The action seems decent enough; a great buy when they do one of their sales. But I don't really care about BA's AR barrels so why would I want a bolt barrel from them?

You can find savage factory take offs for around 200$ which will probably shoot better since they have been making bolt guns for a long time. They will have to price the barreled actions at 1100$ since that's what I can put one together for.

I “gambled” and picked up a Solus. Put a 24” Proof CF, Savage pre-fit in 6.5 CM on it. It is in a KRG Bravo stock with TT trigger. I really like the hanger system.

I shot a variety of ammo through it suppressed and unsuppressed. The Proof is super accurate. My older Prime 130s shot .3 moa at 100 yds at (2860 fps). I was a little surprised by the Proofs POI shift suppressed and unsuppressed. I had to come down 1.5 mils suppressed at 100 yds.

As someone who has shot primarily with factory Rem 700 actions, I like the Solus' 60 degree bolt throw. I attempted to cycle the bolt aggressively and with speed, and I felt like it took little effort to match my R700 speed and confidence.

Also, the SOLUS fed, extracted and ejected without any issues. I was using Magpul AICS mags.

As to barrels Origin, Savage small shank...too easy

I shot a variety of ammo through it suppressed and unsuppressed. The Proof is super accurate. My older Prime 130s shot .3 moa at 100 yds at (2860 fps). I was a little surprised by the Proofs POI shift suppressed and unsuppressed. I had to come down 1.5 mils suppressed at 100 yds.

As someone who has shot primarily with factory Rem 700 actions, I like the Solus' 60 degree bolt throw. I attempted to cycle the bolt aggressively and with speed, and I felt like it took little effort to match my R700 speed and confidence.

Also, the SOLUS fed, extracted and ejected without any issues. I was using Magpul AICS mags.

As to barrels Origin, Savage small shank...too easy

Attachments

Probably the 4-500 dollar cost difference I'd imagine. LolWhat’s to stop one from having a Krieger, Lilja, Brux, etc spun up for one. Not trying to be smarta$$. I just want to know because that was my plan.

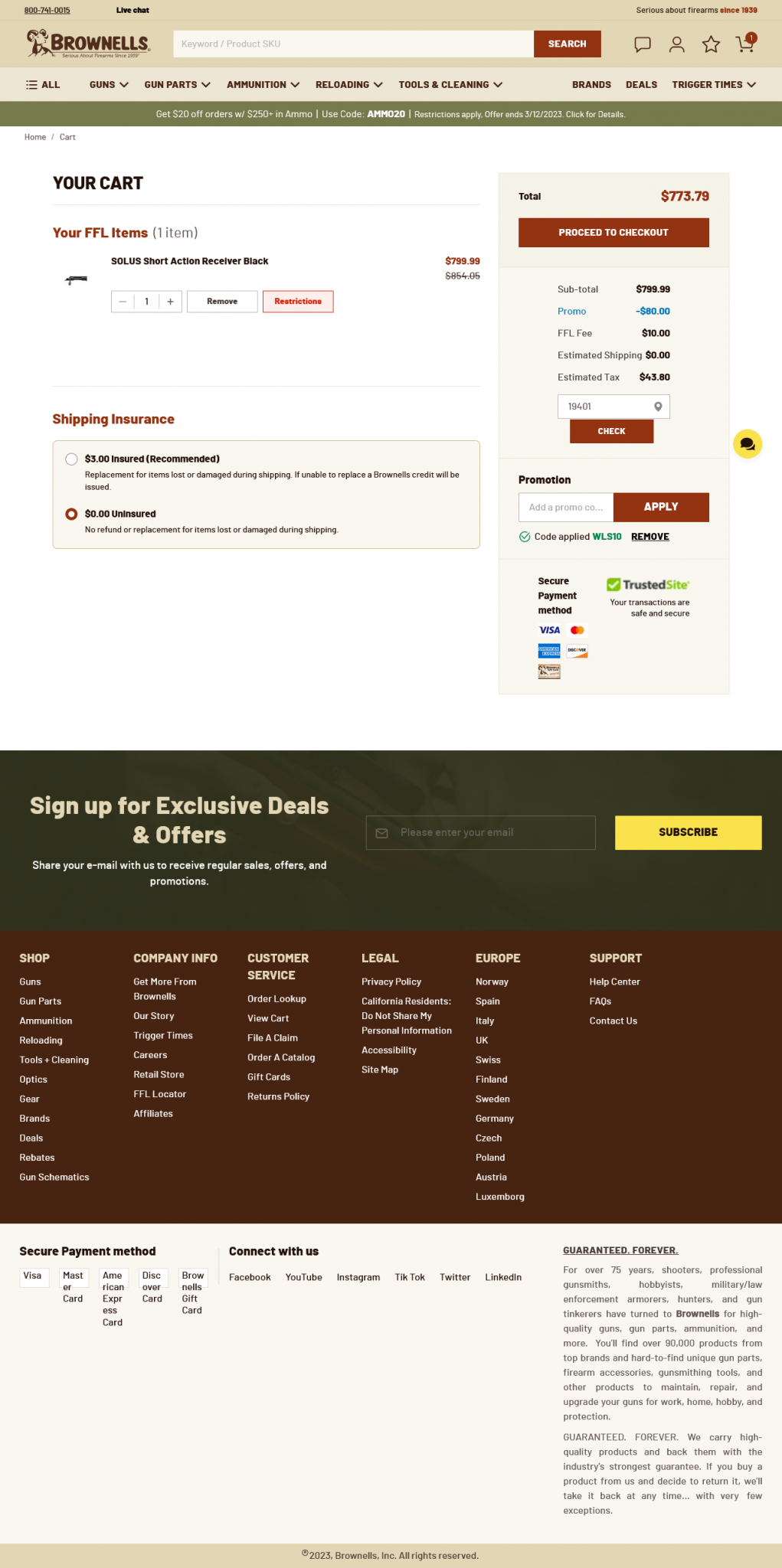

For $773 shipped, not a bad deal, although the CDG would be my choice. Code "WLS10" knocks $80 off and 10off at stocky stocks can get you an Origin prefit for $468.

TM6

TM6

thats a bit of an exaggeration, don’t you think? I can get a fluted Brux for $430 and have it chambered for $250. A prefit criterion is $410 + $150 for fluting. That’s only a $120 deltaProbably the 4-500 dollar cost difference I'd imagine. Lol

Huh? You literally compared two barrels, one with fluting and one without. Also, who mentioned fluting? Secondly. A criterion prefit from NSS in 20-26in is $325. not $410. A blank brux from bugholes is $400 alone. Plus chambering and threading costs...so yeah about a $3-400 difference is correct. Not $120. If $120 was all that separated a chambered brux,bart,proof,Krieger etc...criterion would be out of business.thats a bit of an exaggeration, don’t you think? I can get a fluted Brux for $430 and have it chambered for $250. A prefit criterion is $410 + $150 for fluting. That’s only a $120 delta

"He didn't compare it to any particular action." No, no, He didn't compare it to ANY action. He said "Force to lift bolt during cocking is very favorable compared to similar 3 lug actions." What's similar, and what action? Again, I'm sorry, but if your going to call someone a retard, I feel you better have your house in order, and be clear and concise on what you are comparing and describing. To me his statement is just as ambiguous as the other statement.

I just get my panties all bunched up when people talk shit online, cause 99 percent of them wouldn't say what they are typing to someone's face.

I imagine that if he mentioned the specific actions he compared it to, the thread would become even more of a shit show. The minute you throw brands in the mix, people jump in to defend them (and demonize others), as if the brand carries their own last name.

Yup. Aero and ARC got my business. I have a Magpul Pro, Aero 17" chassis stock coming to try out too.

This is more or less the comparison Im looking for. If Im building me a cheapo bolt action on a rem 700 platform (I dont have a 308 yet, maybe this will be it), should I dump the quarters I found under the couch cushions into a Solus or the Magpul pro..or is there objectively no added benefit at all, and just pickup another MDT Oryx.

To the other points mentioned in here about Aero..I dont know anyone who owns a complete Aero rifle. To me (and my peers) they've always been a parts shop. Cheap LPKs and decent receivers. I know a lot of guys run their handguards but to me, aside from the simple ratcheting design of the wedge, Im not a fan of the overall design.

The feedback on ballistic advantage barrels is that they've went down the crapper..and at north of $230...makes no sense to buy anymore when criterion offerings can be had on sale for $250. Previously when you could pick up a BA Hanson for less than $150, it was worth the gamble when nothing else in the price point was better than dog shit.

At this point, Im more interested in letting others be the first to take the leap on a complete aero rifle.

Last edited:

A fluted blank from Brux is $430. Called them yesterday. Prefit Criterion from NSS is $410. Called them yesterday too. My guy chambers for $250. I stand by what I said. You want to keep pissing, then have at it.Huh? You literally compared two barrels, one with fluting and one without. Also, who mentioned fluting? Secondly. A criterion prefit from NSS in 20-26in is $325. not $410. A blank brux from bugholes is $400 alone. Plus chambering and threading costs...so yeah about a $3-400 difference is correct. Not $120. If $120 was all that separated a chambered brux,bart,proof,Krieger etc...criterion would be out of business.

Dude you're burnt. A chambered and threaded barrel from NSS is $400 before tax depending on length. That's CHAMBERED and THREADED. Not a blank you dipshit. So with your theory and math....once again about a $3-400 difference. Congratulations you're stupid in multiple posts. That's why this forum is full of nonsensical bullshit, because of people like you. It's like, why? Why even make a statement when you don't know what you are talking about? What's the point?A fluted blank from Brux is $430. Called them yesterday. Prefit Criterion from NSS is $410. Called them yesterday too. My guy chambers for $250. I stand by what I said. You want to keep pissing, then have at it.

I just bought a Solus action and have a savage style 6creed barrel on order. This is the first bolt action I’ve headspaced and was wondering about the ejector and extractor interfering with properly head spacing the barrel. I can’t find any specific info to this platform but the info I’ve found on other actions recommend removing them. As I said I have no experience in this area yet so wanted to get the opinion of people with more experience.

The ejector(s) have a fairly long roll pin but was actually easy to take out and put back in even though there are two ejectors.

I cut down a .308 case and use a plastic wood clamp & the cut down case to collapse the ejectors taking spring tension off the ejectors. Then small punch to remove the roll pin.

I cut down a .308 case and use a plastic wood clamp & the cut down case to collapse the ejectors taking spring tension off the ejectors. Then small punch to remove the roll pin.

I appreciate the input. I was thinking of using a clamp too, to collapse the ejectors. I was going to see if I can find a c lamp with a small enough end to fit inside the bolt face but I like the old case method. I have some old 8x57 Mauser brass that has the correct size head so I’ll cut one of those down and give it a try.

just purchased one anyone got any thoughts on barrel trigger chassis? combo or anyone have any experience with one yet

aint heard yet mines standard 478Has Aero said that they plan to release other (.378,.540) bolt heads to swap?

I've cut some shouldered barrels on 3 of them, 2-6.5CM, 1-6CM.just purchased one anyone got any thoughts on barrel trigger chassis? combo or anyone have any experience with one yet

1 went into a KRG Whiskey-3, 1 in a KRG X-Ray, 1 in a MPA. All running Timney Triggers. Proof, Criterion, and X-Caliber barrels on them.

Really just pick the flavor you like and run with it, so far liking the actions.

Yes. "Two Weeks"Has Aero said that they plan to release other (.378,.540) bolt heads to swap?

My Solus action just came in Monday afternoon. I'm building a .25CM with a 20" 1:7 carbon fiber barrel. Only parts left to order is the barrel. I ordered one of their chassis, and all that's left is a scope and barrel. Still haven't decided which barrel company I'm going to go with.

I wish Proof Research offered Solus shouldered prefits chambered with the .25 Creedmoor Blackjack spec reamer. Or the Alpha spec reamer for the Alpha Munitions brass. With the 1:7 twist, and you can pick your finished length and muzzle threads and all that.

I wish Proof Research offered Solus shouldered prefits chambered with the .25 Creedmoor Blackjack spec reamer. Or the Alpha spec reamer for the Alpha Munitions brass. With the 1:7 twist, and you can pick your finished length and muzzle threads and all that.

Topped off with a Leupold, right?My Solus action just came in Monday afternoon. I'm building a .25CM with a 20" 1:7 carbon fiber barrel. Only parts left to order is the barrel. I ordered one of their chassis, and all that's left is a scope and barrel. Still haven't decided which barrel company I'm going to go with.

I wish Proof Research offered Solus shouldered prefits chambered with the .25 Creedmoor Blackjack spec reamer. Or the Alpha spec reamer for the Alpha Munitions brass. With the 1:7 twist, and you can pick your finished length and muzzle threads and all that.

You know it! I might even put an old VX3 3.5-10x50 on there... "Finest damn scope ever made!"Topped off with a Leupold, right?

We have them on sale for $699!!!

www.snipershide.com

www.snipershide.com

Firearms - Aero Precision SOLUS Short Action receiver on sale $699.97!

Aero Precision SOLUS Short Action RH receiver in stock $699.97 with free shipping! https://cstactical.com/aero-precision-solus-short-action-478-bolt-face/ SOLUS Short Action - .478 Bolt Face - 6mm/6.5 Creedmoor, 243 Win, 308 Win, 8.6 Blackout The heart of the Solus product line is the Solus...

Shoot me an email [email protected] Ill get a sample sent out to you. We have a special pricing program for type 7 holders.With what's going on in the industry with prices of custom actions I like it, I'd want to get one in and run it before I start building them for customers.

Also coming from a gunsmith who does threading and chambering, I don't necessarily like "pre-fit" actions but its what the industry is moving to....

You are 100% correct BA Ar barrels can be hit or miss, their whole business model is volume. We went down to BA and spent a week with them standing up a line of barrels that are 100% checked before they ship to us. Then we 100% QC them. Every complete rifle is test-fired before being sent. If a barrel is out of spec it gets scrapped, no exceptions.Lol, I just have bad reading comprehension. I agree. BA seems to be hit or miss, and when they miss, its bad. First sr barrel I ever had was a 5.56 barrel from BA. Tried every factory load, and hand load I could think of, and it wouldn't group under 1moa at 100 yards. Thought it was me the whole time. Got a WOA barrel, and the problem went away real quick.

Similar threads

- Replies

- 7

- Views

- 311