Hello snipers

Introduction/background:

I'm pretty new to all this. Always had a interest in long range precision shooting I've just never made the leap and put the money into it. I'm really into bow hunting and know all to well constancy is accuracy, that small errors become bigger and bigger the further away you shoot. I have and have owned many guns but mainly average hunting rifles.($200-$600 range moa rifles with 3lbs+ triggers and sportster barrels)

I've made the leap and purchased a savage 10 6.5 creedmoor the previous owner had the barrel cut from 24" to 18" threaded and was kind enough to send me a flash hider to protect the threads. Problem is I have to take the FH off everytime I shoot because it decreases accuracy. My guess is it's not indexed( I don't have shims or a crush washer). I've only fired 20 rounds of ELD-m 140grain total so I don't have much info to share but here is my first 4 round group after firing only 6 shots before hand at 100yard. 3 rounds to check point of impact 3 rounds to confirm zero then this group.

That's without the FH shooting off a crappy walmart sand bag and my jacket lol but I'm fairly certain the gun will shoot even tighter of it wasn't for me. I'm not used to this 1.5lbs trigger at all but I love it haha.

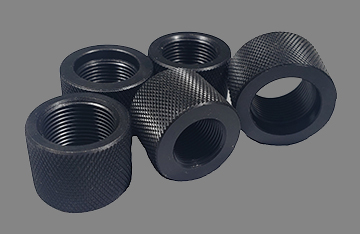

Anyways if I snug the FH on the point of impact changes and I get a looser group/"gathering ". Instead of buying a new FH or shims/crush washer to improve it I'd just rather have a simple thread protector.

". Instead of buying a new FH or shims/crush washer to improve it I'd just rather have a simple thread protector.

I'm just worried a thread protector will also affect accuracy if I don't buy a proper one for my rifle. "Proper" as in a certain type of metal, thickness to match barrel, length and shape also since I have no plans to screw on a can, MB or FH I thought maybe I should use a crush washer to torque it down to have even contact or even glue/seal it to minimize it coming loose and slightly altering vibrations) keeping the same contact. I've looked at alot of thread protectors and I have no clue how know if it's the same thickness as my barrel or if the threads are long enough,what metal it should be made of etc.

Forgot to mention how ugly it looks with open threads and I know ugly decreases accuracy too

so It be a plus if the thread protector wasn't a hideous eye sore too.

so It be a plus if the thread protector wasn't a hideous eye sore too.

Only info I have is:

6.5 creedmoor

Savage model 10( possibly model 10T)

1/8 twist 24" cut to 18" bull barrel

Threaded 5/8-24

Don't know what type of crown was put on it.

Here are some pics..

Warning

Warning  the following bpictures could cause spontaneous gagging and eye pain.

the following bpictures could cause spontaneous gagging and eye pain.

Introduction/background:

I'm pretty new to all this. Always had a interest in long range precision shooting I've just never made the leap and put the money into it. I'm really into bow hunting and know all to well constancy is accuracy, that small errors become bigger and bigger the further away you shoot. I have and have owned many guns but mainly average hunting rifles.($200-$600 range moa rifles with 3lbs+ triggers and sportster barrels)

I've made the leap and purchased a savage 10 6.5 creedmoor the previous owner had the barrel cut from 24" to 18" threaded and was kind enough to send me a flash hider to protect the threads. Problem is I have to take the FH off everytime I shoot because it decreases accuracy. My guess is it's not indexed( I don't have shims or a crush washer). I've only fired 20 rounds of ELD-m 140grain total so I don't have much info to share but here is my first 4 round group after firing only 6 shots before hand at 100yard. 3 rounds to check point of impact 3 rounds to confirm zero then this group.

That's without the FH shooting off a crappy walmart sand bag and my jacket lol but I'm fairly certain the gun will shoot even tighter of it wasn't for me. I'm not used to this 1.5lbs trigger at all but I love it haha.

Anyways if I snug the FH on the point of impact changes and I get a looser group/"gathering

I'm just worried a thread protector will also affect accuracy if I don't buy a proper one for my rifle. "Proper" as in a certain type of metal, thickness to match barrel, length and shape also since I have no plans to screw on a can, MB or FH I thought maybe I should use a crush washer to torque it down to have even contact or even glue/seal it to minimize it coming loose and slightly altering vibrations) keeping the same contact. I've looked at alot of thread protectors and I have no clue how know if it's the same thickness as my barrel or if the threads are long enough,what metal it should be made of etc.

Forgot to mention how ugly it looks with open threads and I know ugly decreases accuracy too

Only info I have is:

6.5 creedmoor

Savage model 10( possibly model 10T)

1/8 twist 24" cut to 18" bull barrel

Threaded 5/8-24

Don't know what type of crown was put on it.

Here are some pics..