Well I've been wanting to build some of my own stuff for some time now but being a Cop and a Carpenter leaves me with little machinging skills...well lets face it ZERO so what the hell lets buy a Lathe and have at it!!

I decided to build two rifles in .308 for my son Cole and Godson Zach as gifts before this coming hunting season. They had no idea they were getting these...with the help from Ozzie Suarez & Jon Beanland and a few others here this was possible.

These were complete builds from start to finish so I had to make some jigs along the way and lots of other things.

The builds consisted of Remington actions, Bartlien Barrels cut to 22", PTG Recoil Lugs, HS Precision DBM, HS Stock for Zachs and a Manners for Cole, both have factory triggers adjusted to 2lbs.

As stated this was my first time for everything from Chambering, crowning, bedding, Cerakoting, you name it but I think they turned out pretty good.

Some steps along the way

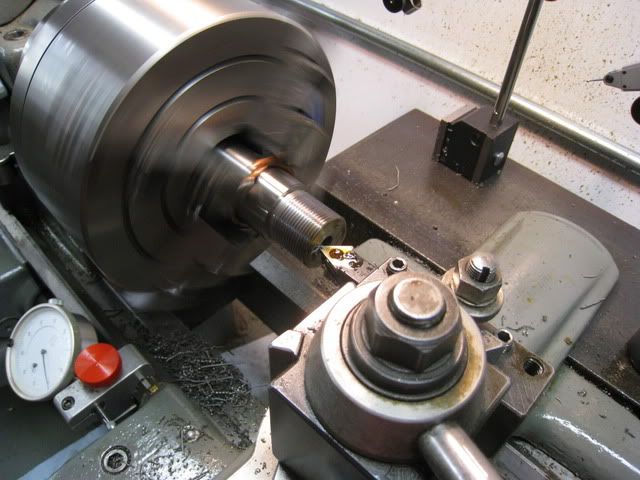

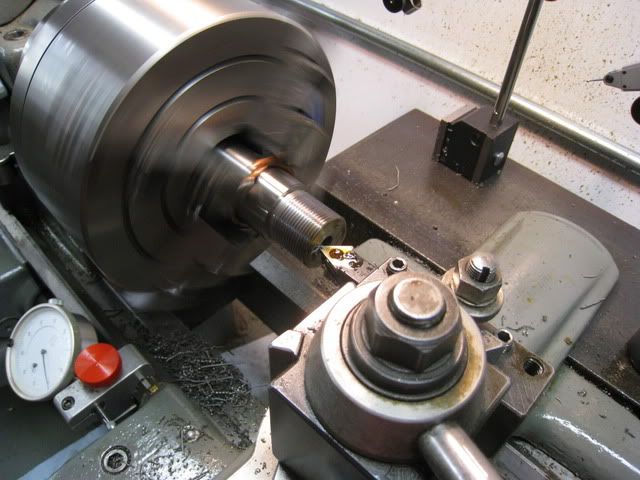

Truing the action, threads were opened up to 1.075

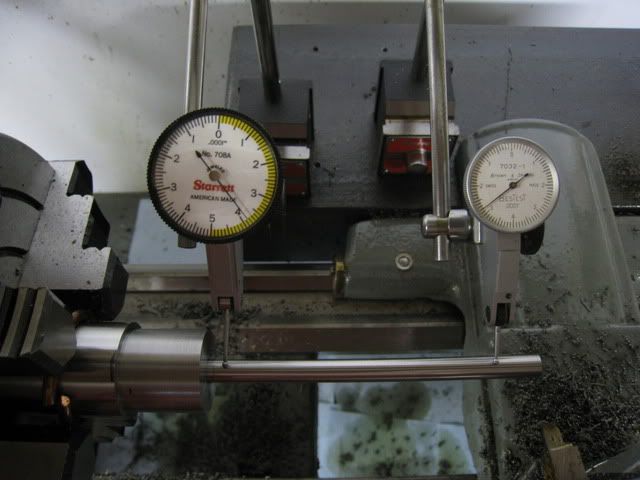

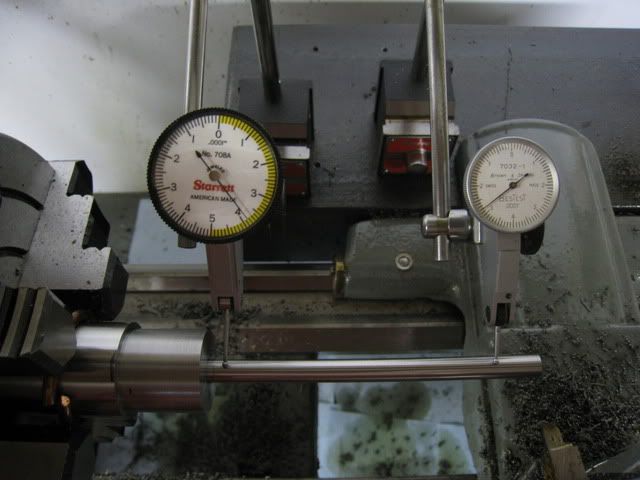

Dialing in the Barrel

Bedded both rifles with Pillars, no Mill yet so working on my Press with Rotary table had to do...just lots of finger turning!!

Wanted to Cerakote everything and have only done some small parts in the past so building an oven was in order. I bought a stack on safe, insulated it with Fiberglass Foil Ducting board, then covered it with 5/8 Fireboard. Ordered some controlling parts and an oven element rigged 220V and walla worked like a charm...Takes about 15 minutes to reach 250 and stays right there. Thanks Sean for the heads up on the controller and some tips!

I decided to build two rifles in .308 for my son Cole and Godson Zach as gifts before this coming hunting season. They had no idea they were getting these...with the help from Ozzie Suarez & Jon Beanland and a few others here this was possible.

These were complete builds from start to finish so I had to make some jigs along the way and lots of other things.

The builds consisted of Remington actions, Bartlien Barrels cut to 22", PTG Recoil Lugs, HS Precision DBM, HS Stock for Zachs and a Manners for Cole, both have factory triggers adjusted to 2lbs.

As stated this was my first time for everything from Chambering, crowning, bedding, Cerakoting, you name it but I think they turned out pretty good.

Some steps along the way

Truing the action, threads were opened up to 1.075

Dialing in the Barrel

Bedded both rifles with Pillars, no Mill yet so working on my Press with Rotary table had to do...just lots of finger turning!!

Wanted to Cerakote everything and have only done some small parts in the past so building an oven was in order. I bought a stack on safe, insulated it with Fiberglass Foil Ducting board, then covered it with 5/8 Fireboard. Ordered some controlling parts and an oven element rigged 220V and walla worked like a charm...Takes about 15 minutes to reach 250 and stays right there. Thanks Sean for the heads up on the controller and some tips!