I am at the wits end with using a Forster FL die for my 6.5x47 Lapua. It seems that no matter what I do I can't seem to make it work. I have a similar product for my 6 mm BR and it works with no problems. But this....well...I have no idea what to do. Called the company but yet I have no solid direction as to what it might be wrong. If after reading this you have the desire, the knowledge, and a little time I would appreciate a short phone consultation when I get home from work today. The rifle is a Savage target action RBLP with a Criterion 28" barrel. When cycling a spent case things work well, namely I can close the bolt with not pressure. Then I put the case in the press and after I deccaped and resized the case I can only cycle that case with significant pressure (anything involving pressure on my part is no good). I use a Hornady Lock and Load headspace measuring tool (C = .375") and I see that even though the shoulder has been bumped by .001 or even stayed the same the cycling becomes as described above. I have tried to load a cartridge with powder and seat the bullet but discovered that it took significantly more pressure to sit the bullet and shaves of steel came at the mouth. One more thing, when I cycle the resized case with pressure I see a ring on the shoulder of the case. Can't explain what is happening. I tried all the methods suggested on this site and elsewhere regarding setting the die including the instructions which came with the die (raising the ram and have the shell holder touch the die then go 1/8-1/4 further clockwise).

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unusual request for a phone consultation

- Thread starter Cat64

- Start date

Let me see if I've got this right:

You can extract/rechamber a spent case just fine?

You decap that spent case, and zero your caliper/headspace comparator tool to that case?

You size the case and it measures .001" shorter than it did prior to sizing?

You attempt to chamber that case, and the bolt closes tight?

Even "camming over" your press during resizing, your bolt STILL closes tight?

My first thought is that you're setting your caliper with HS comparator to a spent case WITHOUT having decapped it first. That will give you a faulty zero.... That doesn't explain, however, why cases are still hard to chamber even if you cam-over your press.

...Meaning my theory only holds water if you're both not decapping prior to setting zero, AND your shellholder is too thick.

You can extract/rechamber a spent case just fine?

You decap that spent case, and zero your caliper/headspace comparator tool to that case?

You size the case and it measures .001" shorter than it did prior to sizing?

You attempt to chamber that case, and the bolt closes tight?

Even "camming over" your press during resizing, your bolt STILL closes tight?

My first thought is that you're setting your caliper with HS comparator to a spent case WITHOUT having decapped it first. That will give you a faulty zero.... That doesn't explain, however, why cases are still hard to chamber even if you cam-over your press.

...Meaning my theory only holds water if you're both not decapping prior to setting zero, AND your shellholder is too thick.

Let me see if I've got this right:

You can extract/rechamber a spent case just fine?

You decap that spent case, and zero your caliper/headspace comparator tool to that case?

You size the case and it measures .001" shorter than it did prior to sizing?

You attempt to chamber that case, and the bolt closes tight?

Even "camming over" your press during resizing, your bolt STILL closes tight?

My first thought is that you're setting your caliper with HS comparator to a spent case WITHOUT having decapped it first. That will give you a faulty zero.... That doesn't explain, however, why cases are still hard to chamber even if you cam-over your press.

...Meaning my theory only holds water if you're both not decapping prior to setting zero, AND your shellholder is too thick.

The underlined statements above are correct. The .001 refers to the shoulder not the overall case length. I was aware comparing the spent case with the spent primer still in vs the resized case with no primer would give erroneous readings…however I still have the dilemma as to why after resizing the cases are chambering with so much effort while the spent cases are not.

How hard is it to chamber a round when the shoulder is bumped .002" and .003"? That is If you are able to do so.

Last edited:

I use the D HS comp insert (same as for 308) in my 6.5x47. New Lapua measured 1.442, and after firing 1.444. I have a tight chamber and FL size back to 1.442. If you check a couple of good vs bad rounds with both inserts maybe something will show up different.

How hard is it to chamber a round when the shoulder is bumped .002" and .003"? That is If you are able to do so.

I was not able to get it to bump that far

I use the D HS comp insert (same as for 308) in my 6.5x47. New Lapua measured 1.442, and after firing 1.444. I have a tight chamber and FL size back to 1.442. If you check a couple of good vs bad rounds with both inserts maybe something will show up different.

I am not familiar with the inserts. You need a special die for that right? I would not be able to use mine. I was contemplating buying a new die but don't have money to blow. At least wanted to see if another die would work.

Just got home and checked again.

Outside neck diameter of fired brass = .293

outside diameter of FL sized brass =.289

Is this within normal parameters?

Looking in my book I see that the outside neck diameter listed is .291

Outside neck diameter of fired brass = .293

outside diameter of FL sized brass =.289

Is this within normal parameters?

Looking in my book I see that the outside neck diameter listed is .291

Last edited:

Cat64,

Your necks my be too tight after FL sizing, even though @ .293 it appears the chambering reamer was set up for a No turn neck. Neck Wall thickness can be measured best with a tubing micrometer, but a far simpler and cheaper test for excess brass in the neck area is to slide a bullet into a fired, unsized case neck. If you feel any interference, the neck should be reamed or outside neck turned.

If your neck is too tight, then the mere act of seating a bullet will take a lot of effort, and you may be creating a small bulge at the shoulder junction, that really can't be seen, but it does lead to hard chambering.

Your necks my be too tight after FL sizing, even though @ .293 it appears the chambering reamer was set up for a No turn neck. Neck Wall thickness can be measured best with a tubing micrometer, but a far simpler and cheaper test for excess brass in the neck area is to slide a bullet into a fired, unsized case neck. If you feel any interference, the neck should be reamed or outside neck turned.

If your neck is too tight, then the mere act of seating a bullet will take a lot of effort, and you may be creating a small bulge at the shoulder junction, that really can't be seen, but it does lead to hard chambering.

Cycling is hard either I have the bullet seated or not. The bullets slide in the fired case touching the mouth walls rather little. It does nor require force to push it in the case.

Last edited:

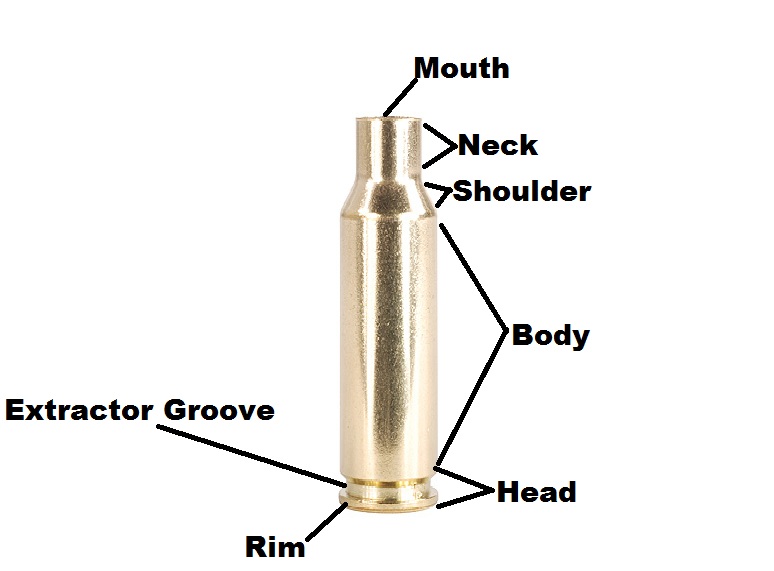

It is crazy but it appears the angle of the shoulder increases. I painted with a permanent marker the mouth and shoulder of a case which cycle with force and I see marks of pressure slightly above the datum line. The shoulder cannot bump up after resizing.

If possible try another brand of shellholder.

When I was 14 years old, my first attempt at reloading, that was the problem I had-shell holder out of spec, hard to close the bolt on a fired case because I couldn't size down far enough.

You trimmed the brass, right? and chamfered inside and outside of neck.

Bob could be correct. Maybe a tight neck reamer was used?!

When I was 14 years old, my first attempt at reloading, that was the problem I had-shell holder out of spec, hard to close the bolt on a fired case because I couldn't size down far enough.

You trimmed the brass, right? and chamfered inside and outside of neck.

Bob could be correct. Maybe a tight neck reamer was used?!

go 1/8 - 1/4 "counter clockwise" and see what happens...

I tried that. Nothing...

I had the same thing happen to me with some 308 brass. Purchase a wilson case gage and you will see with in 2 seconds that your head space is off. With the case gage you just drop the case in and you will see if the head space is out of spec. It's kind of hard for me to explain, like lawman29 said above, turn that die clockwise down a little at a time until the case closes in chamber and head space is correct. Once head space is correct, you will be able to insert a empty piece of brass in your chamber and the bolt will close with really no force.

https://www.youtube.com/watch?v=wkWQde_b2G8

https://www.youtube.com/watch?v=85JIIAIil98

https://www.youtube.com/watch?v=wkWQde_b2G8

https://www.youtube.com/watch?v=85JIIAIil98

Last edited:

Cat64, I think you are running into a common problem. You are not bumping the shoulder enough and the die is already in contact with the shellholder....so you can't bump any further. The easiest solution is to put a file on the table and run the bottom of your sizing die (or the top of your shell holder) over it to shave a few thousandths off. This will give you the ability to turn the die down further and get the shoulder bump you need. If you have a friend with a lathe, he can shave a few thousandths off the bottom for you as well.....but the file will work fine. I've had this same problem with a few factory dies.

Also, your bump gage can give you faulty feedback. The best way to see if you are bumping the shoulder enough is to use the chamber of your rifle. Remove both the firing pin and ejector from your bolt..this greatly increases your feel. Bump the shoulder just enough so that the bolt handle falls freely when released. You will have to force the bolt handle closed if the shoulder is not bumped enough. Hope that makes sense. If not, PM me and we can talk over the phone.

Scott

Also, your bump gage can give you faulty feedback. The best way to see if you are bumping the shoulder enough is to use the chamber of your rifle. Remove both the firing pin and ejector from your bolt..this greatly increases your feel. Bump the shoulder just enough so that the bolt handle falls freely when released. You will have to force the bolt handle closed if the shoulder is not bumped enough. Hope that makes sense. If not, PM me and we can talk over the phone.

Scott

Cat64, silly question but after you FL your cases did you also check your case OAL. Probably need to trim them before trying to chamber, mine all grow after FL sizing. They might be too long

Cat64, silly question but after you FL your cases did you also check your case OAL. Probably need to trim them before trying to chamber, mine all grow after FL sizing. They might be too long

Nothing is silly at this point. Yes I did measure. Cases are only increasing in overall length by very little which keeps them all well below specs.

Just for grins try sizing the case with the de-priming rod/expander ball removed then see if it chambers OK. If it does. Then re-install them and adjust the rod down so when the ram is fully up the de-priming rod can be turned freely showing that the ball is below the neck area. Forster mounts their expander ball higher than others so it is withdrawn through the neck while part of the neck is still in the neck portion of the die. This can yield some super straight cases but can also cause interference which can cause the neck/shoulder to be pulled out when the case is extracted.

I set mine by running the case fully into the die with the rod screwed in a few extra turns. I then back it off, with the case still in the die, until I feel the ball come in contact with the case. I screw the rod in one full turn and all my cases come out "dead on".

My experience with Forster F/L sizing dies is that they are pretty close to the design headspace for the given caliber. They don't oversize like many others do. This can be an issue if you have a short chamber so filing off a few thousandths of he die base may still be necessary.

Want a really good setup, take some extra meat off the die and then get a set of Redding Competition Shell Holders. You will then have a setup where the sizing die is tight against the shell holder and adjustments in headspace are made in .002" increments using the shell holders. By forcing the die firmly against the shell holder it cancels out any "flex" in the press and makes every case exactly the same as the last.

I set mine by running the case fully into the die with the rod screwed in a few extra turns. I then back it off, with the case still in the die, until I feel the ball come in contact with the case. I screw the rod in one full turn and all my cases come out "dead on".

My experience with Forster F/L sizing dies is that they are pretty close to the design headspace for the given caliber. They don't oversize like many others do. This can be an issue if you have a short chamber so filing off a few thousandths of he die base may still be necessary.

Want a really good setup, take some extra meat off the die and then get a set of Redding Competition Shell Holders. You will then have a setup where the sizing die is tight against the shell holder and adjustments in headspace are made in .002" increments using the shell holders. By forcing the die firmly against the shell holder it cancels out any "flex" in the press and makes every case exactly the same as the last.

Just for grins try sizing the case with the de-priming rod/expander ball removed then see if it chambers OK. If it does. Then re-install them and adjust the rod down so when the ram is fully up the de-priming rod can be turned freely showing that the ball is below the neck area. Forster mounts their expander ball higher than others so it is withdrawn through the neck while part of the neck is still in the neck portion of the die. This can yield some super straight cases but can also cause interference which can cause the neck/shoulder to be pulled out when the case is extracted.

I set mine by running the case fully into the die with the rod screwed in a few extra turns. I then back it off, with the case still in the die, until I feel the ball come in contact with the case. I screw the rod in one full turn and all my cases come out "dead on".

My experience with Forster F/L sizing dies is that they are pretty close to the design headspace for the given caliber. They don't oversize like many others do. This can be an issue if you have a short chamber so filing off a few thousandths of he die base may still be necessary.

Want a really good setup, take some extra meat off the die and then get a set of Redding Competition Shell Holders. You will then have a setup where the sizing die is tight against the shell holder and adjustments in headspace are made in .002" increments using the shell holders. By forcing the die firmly against the shell holder it cancels out any "flex" in the press and makes every case exactly the same as the last.

Will I achieve the same result by shaving the shell holder rather than the die? Can I irreparably damage anything by shaving the die? Also I am puzzled by the neck tension as stated in my other thread. Thank you for the answer.

Just for grins try sizing the case with the de-priming rod/expander ball removed then see if it chambers OK. If it does. Then re-install them and adjust the rod down so when the ram is fully up the de-priming rod can be turned freely showing that the ball is below the neck area. Forster mounts their expander ball higher than others so it is withdrawn through the neck while part of the neck is still in the neck portion of the die. This can yield some super straight cases but can also cause interference which can cause the neck/shoulder to be pulled out when the case is extracted.

I set mine by running the case fully into the die with the rod screwed in a few extra turns. I then back it off, with the case still in the die, until I feel the ball come in contact with the case. I screw the rod in one full turn and all my cases come out "dead on".

My experience with Forster F/L sizing dies is that they are pretty close to the design headspace for the given caliber. They don't oversize like many others do. This can be an issue if you have a short chamber so filing off a few thousandths of he die base may still be necessary.

Want a really good setup, take some extra meat off the die and then get a set of Redding Competition Shell Holders. You will then have a setup where the sizing die is tight against the shell holder and adjustments in headspace are made in .002" increments using the shell holders. By forcing the die firmly against the shell holder it cancels out any "flex" in the press and makes every case exactly the same as the last.

Just watched a youtube video on Redding competition dies. If I use that will I still need to shave the die?

Could your chamber have a tight neck and you aren't neck turning your cases? I would think the marks on the brass that is tough to chamber would tell you what's not fitting dimensionally. It's either got to to be:

-your chamber

-your die

-your die is set incorrectly

Are you sure when sizing the shellholder contacts the sizing die at the top of the stroke?

-your chamber

-your die

-your die is set incorrectly

Are you sure when sizing the shellholder contacts the sizing die at the top of the stroke?

Will I achieve the same result by shaving the shell holder rather than the die? Can I irreparably damage anything by shaving the die? Also I am puzzled by the neck tension as stated in my other thread. Thank you for the answer.

If you don't get crazy you won't hurt the die. The part you're removing is not what actually sizes the case but is more of a "guide". Just try and keep it "square". I don't like "shaving" shell holders as you can find yourself with a case stuck when the top of the shell holder is weakened and breaks. Just remember, you probably won't need to take more than .010" off to solve the problem. If that's too much just back off on the die.

Just watched a youtube video on Redding competition dies. If I use that will I still need to shave the die?

If your die isn't sizing the case enough then definitely yes. The redding set merely holds the case head farther out of the die and that doesn't sound like your problem.

If your die isn't sizing the case enough then definitely yes. The redding set merely holds the case head farther out of the die and that doesn't sound like your problem.

I had an extra shellholder which I shaved a little. Still not able to bump past a certain point. Two things happen: 1. I can tell that the shellholder is not "hitting" against the ram any longer if I go past 1/4 turn clockwise (I feel it and and don't hear the familiar sound) and 2. At this point I see a " pronounced" if you wish ring exactly where the shoulder ends and the mouth begins.

Send the die back to the manufacturer with 5 fired cases and a letter stating the problem.

I had this problem once and it turned out to be an out of spec die.

I had this problem once and it turned out to be an out of spec die.

I am at the wits end with using a Forster FL die for my 6.5x47 Lapua. It seems that no matter what I do I can't seem to make it work. I have a similar product for my 6 mm BR and it works with no problems. But this....well...I have no idea what to do. Called the company but yet I have no solid direction as what it might be wrong. If after reading this you have the desire, the knowledge, and a little time I would appreciate a short phone consultation when I get home from work today. The rifle is a Savage target action RBLP with a Criterion 28" barrel. When cycling a spent case things work well, namely I can close the bolt with not pressure. Then I put the case in the press and after I deccaped and resized the case I can only cycle that case with significant pressure (anything involving pressure on my part is no good). I use a Hornady Lock and Load headspace measuring tool (C = .375") and I see that even though the shoulder has been bumped by .001 or even stayed the same the cycling becomes as described above. I have tried to load a cartridge with powder and seat the bullet but discovered that it took significantly more pressure to sit the bullet and shaves of steel came at the mouth. One more thing, when I cycle the resized case with pressure I see a ring on the shoulder of the case. Can't explain what is happening. I tried all the methods suggested on this site and elsewhere regarding setting the die including the instructions which came with the die (raising the ram and have the shell holder touch the die then go 1/8-1/4 further clockwise).

OK. I have the exact same die set and it would not bump the shoulder enough either. I could get it to "kiss" the shoulder but no set back. I don't disagree with sending the die back to shave some off, but with a little bit of time (plus a hard level surface and a steady hand), you can do this yourself. Or consider shaving your shell holder. I know the shell holder is hard, but you are not taking .010" off. I tend to use one shell holder for each set of dies as they are not expensive and there is some variation between them, I consider it the easiest way. Call it OCD if you wish.

Either way, you gonna have to remove some material from one or the other.

When I bought my dies, the Forster FL Ultra die set was all that was available. I still use the BR seater and the FL sizer works well, but I prefer being able to adjust neck tension.

Oh, and chamfer those cases!

I had an extra shellholder which I shaved a little. Still not able to bump past a certain point. Two things happen: 1. I can tell that the shellholder is not "hitting" against the ram any longer if I go past 1/4 turn clockwise (I feel it and and don't hear the familiar sound) and 2. At this point I see a " pronounced" if you wish ring exactly where the shoulder ends and the mouth begins.

There's something here that doesn't ring true. You should be able to hit the ram no matter how much you cut of either shell holder or die, that is until you run out of threads on he die. Have you turned the die into the press far enough so the handle "cam's over" when the ram is at the top of it's stroke? You should be able to bump the shoulder back with no problem at all, expecially if you've shaved die or shell holder. You do have to turn the die in far enough to overcome any flex in the press and that may be a lot more than the 1/8-1/4 turn on your press.

I'd screw the die in so far, using an unmodified shell holder, that without a case it takes a fairly heavy press on the lever to get it to cam over. Then size a case and measure it. Make sure that with the case fully into the die there is NO gap whatever between die and shell holder.

While using my Redding shell holder set I have the die adjusted so the cam over is very pronounced and when sizing a case there is NO gap between shell holder and die. Not even enough to see the slightest sliver of light or measure with a .001" feeler gauge. I then adjust headspace by selecting the right shell holder.

It's very possible you have some "press issues".

As for the "ring" at the junction of shoulder and "mouth", are you referring to where the case neck begins?

Would be nice to see a picture so we could see what your describing.

Last edited:

I had the same issue with my Lee cast, I switched over to Hornady shell holder, there is a set put out by Redding that will push the shell up in the die higher too, I also started annealing which helped consistence. This issue caused me to jump in with both feet, concentricity check on everything, neck turning, annealing, weighing each component, I just got my Coax from a group buy but have not used it yet, its a sickness.

BTW the hornady shell holder fixed the original issue.

BTW the hornady shell holder fixed the original issue.

probably not your problem but i had something similar. remington 260, lapua brass, when reloaded, very very hard to close bolt, all dimensions 'appeared' to be correct, saami chamber. what it trued out to be was the lip of the casing was thicker than the rest of the case, once a bullet was seated this portion of the loaded round was slightly bigger than the rest of the neck. it absolutely drove me crazy. i kept measuring the neck, measure the shoulder, measure the length, on and on. then i put a caliper on the very lip of the round with the bullet seated and it was too large.

thats when i got into turning my necks and all my problems went away. But it was the very tip of the casing that was the problem. i had one or two boxes of lapua 260 that this seemed to be the issue with.

thats when i got into turning my necks and all my problems went away. But it was the very tip of the casing that was the problem. i had one or two boxes of lapua 260 that this seemed to be the issue with.

Take a small piece of aluminum foil and fold it a few times and insert it under the case when it is in the shell holder. You can achieve the same affect with a feeler gage. It will raise the case in the holder enough to bump the shoulder back and allow it to chamber in your gun. This has the same result as shaving the bottom of the die or the top of the shell holder without doing either.

I had a similar quandary with a custom 308. The bump gauge shows I was bumping the shoulder back. But the brass has to go somewhere, it was actually making the body slightly wider (fatter). A full length sizing die worked well but worked the neck way too much. In the end I bought a redding small base body die and it gave me the right dimensions. Headspace has tolerances and so do dies. If you can easily cycle a spent case then that dimension is "loose" enough to float in your chamber. Measure the base of the brass and compare after bumping the shoulder.

I had an extra shellholder which I shaved a little. Still not able to bump past a certain point. Two things happen: 1. I can tell that the shellholder is not "hitting" against the ram any longer if I go past 1/4 turn clockwise (I feel it and and don't hear the familiar sound) and 2. At this point I see a " pronounced" if you wish ring exactly where the shoulder ends and the mouth begins.

Similar threads

- Replies

- 24

- Views

- 487