Hi all,

I'm new to this forum, not new to guns. I am a hobbyist builder, and I do own some basic tooling for my projects (lathe, mill, reamers etc). A while ago I decided to build most accurate AR 10 that I can do, and thought I'll share details so maybe some people will find it helpful.

I could have just bought a barrel from a reputable maker but I thoughtI wouldn't learn much.

So I decided to make one from scratch.. well, from a blank.

First attempt was not a success. I bought a cheap 16" blank made by Bergara, turned it into ar-10 barrel, .750 gas block at mid-length, chambered, put on a receiver. It shot ~1.5 moa on average, occasionally getting sub-moa groups. Not good enough. and I did not know how to troubleshoot it - too many variables, and some (like chamber, profile, etc) are already there and I cannot change them.

So on the second attempt, I decided to make step by step approach, testing accuracy between the steps - that way if accuracy is good in the beginning and then drops, I at least know which step is to blame.

The steps will be:

1) Barrel blank threaded and chambered, muzzle crowned, full 28" lenth, maximum thickness profile (1.200")

2) Blank cut to final length (20"), muzzle threaded 5/8x24, profiled (I'm thinking of rifle length gas system, .875 gas block, 1.000" between chamber end and tenon, .850 from gas block to the muzzle). I see no point testing accuracy after cutting to the length but before profiling - as shorter barrel of the same profile should not have any drop in accuracy

3) Drill gas port and install gas system, finally turning it from bolt action to semi-auto

My accuracy testing protocol will be 6 groups of 5 shots each from 100 yards, 175gr smk bullets, increasing Varget load from 42 to 44.5 grains, 0.5 gains step

The parts I have for this project are:

1) Shilen match blank 308, 1 in 10", 28" unturned

2) BAT machine 308 extension

3) 308 Winchester AR reamer from Pacific tool and gauge

Ultimately I'd like to achieve 0.5 moa with reloads

So far only the first step is completed - if there is interest, I will keep this thread updated as it progresses.

I do appreciate comments, feedback, suggestions (especially from folks with experience in similar projects)

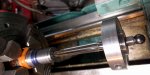

Now it looks like a monster, it won't stay that way though

Assembled and ready for first accuracy testing

I'm new to this forum, not new to guns. I am a hobbyist builder, and I do own some basic tooling for my projects (lathe, mill, reamers etc). A while ago I decided to build most accurate AR 10 that I can do, and thought I'll share details so maybe some people will find it helpful.

I could have just bought a barrel from a reputable maker but I thoughtI wouldn't learn much.

So I decided to make one from scratch.. well, from a blank.

First attempt was not a success. I bought a cheap 16" blank made by Bergara, turned it into ar-10 barrel, .750 gas block at mid-length, chambered, put on a receiver. It shot ~1.5 moa on average, occasionally getting sub-moa groups. Not good enough. and I did not know how to troubleshoot it - too many variables, and some (like chamber, profile, etc) are already there and I cannot change them.

So on the second attempt, I decided to make step by step approach, testing accuracy between the steps - that way if accuracy is good in the beginning and then drops, I at least know which step is to blame.

The steps will be:

1) Barrel blank threaded and chambered, muzzle crowned, full 28" lenth, maximum thickness profile (1.200")

2) Blank cut to final length (20"), muzzle threaded 5/8x24, profiled (I'm thinking of rifle length gas system, .875 gas block, 1.000" between chamber end and tenon, .850 from gas block to the muzzle). I see no point testing accuracy after cutting to the length but before profiling - as shorter barrel of the same profile should not have any drop in accuracy

3) Drill gas port and install gas system, finally turning it from bolt action to semi-auto

My accuracy testing protocol will be 6 groups of 5 shots each from 100 yards, 175gr smk bullets, increasing Varget load from 42 to 44.5 grains, 0.5 gains step

The parts I have for this project are:

1) Shilen match blank 308, 1 in 10", 28" unturned

2) BAT machine 308 extension

3) 308 Winchester AR reamer from Pacific tool and gauge

Ultimately I'd like to achieve 0.5 moa with reloads

So far only the first step is completed - if there is interest, I will keep this thread updated as it progresses.

I do appreciate comments, feedback, suggestions (especially from folks with experience in similar projects)

Now it looks like a monster, it won't stay that way though

Assembled and ready for first accuracy testing

Attachments

Last edited: