Rifle is a Ruger SFAR. I’ve had this happen a few times now but only twice where I’ve had to use a brass punch and hammer on the bolt to move the bolt back. This is a suppressed rifle but happens randomly and certainly within 20-30 rounds when it does, so although the chamber has that dry dirty look to it, I don’t think it’s a dirt build up issue.

I’m working up some home loads so I need your wisdom as to where I’m screwing up (I’m not new to hand loading though)

The bolt picks up a new round, slams it into the chamber but won’t go into battery. You have to pull the charging handle REALLY hard with butt against your chest to get it to extract the round. Twice I’ve made the mistake of nudging the forward assist to try to get it to chamber and both times it has jammed up so bad that I need a punch and hammer to drive the bolt back. Once the bolt moves a quarter inch, maybe less, it’s free again.

I’m .120 off the lands so that’s not it.

The round , just dropped into the chamber sits .017 off of fully seated yet a factory round drops straight in.

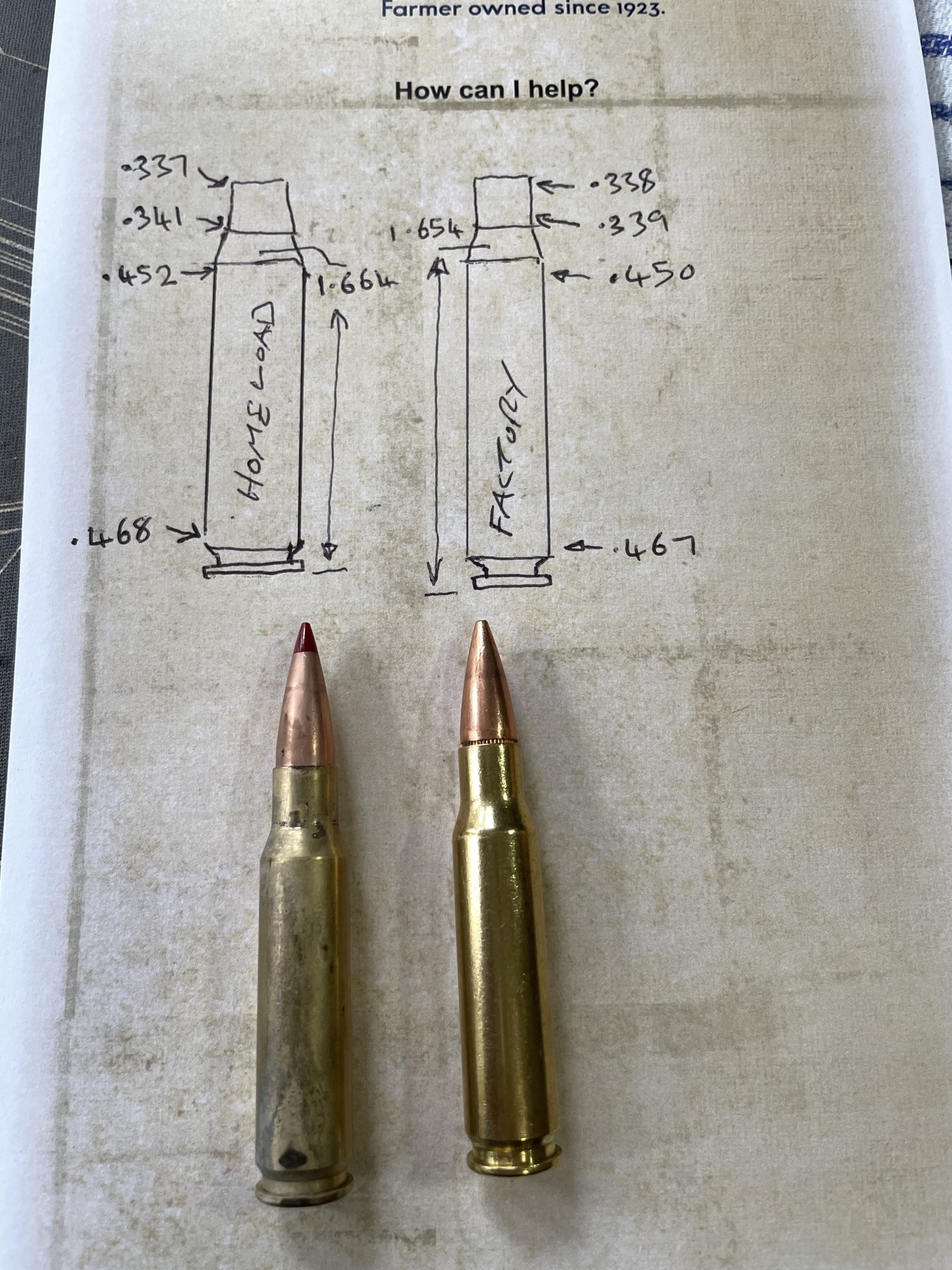

See photo for measurements. I only had a 6.5cm neck comparator but it gives you a comparison.

Are these difference in measurements enough to be the problem? Which one?

I’m using Hornady custom grade dies. Bad sizing die?

I’d shot around 35 hand loads 110,150, 165 before these 200 elf-x but I think it’s just coincidence as this has happened with 168 smk before.

Any thoughts?

I’m working up some home loads so I need your wisdom as to where I’m screwing up (I’m not new to hand loading though)

The bolt picks up a new round, slams it into the chamber but won’t go into battery. You have to pull the charging handle REALLY hard with butt against your chest to get it to extract the round. Twice I’ve made the mistake of nudging the forward assist to try to get it to chamber and both times it has jammed up so bad that I need a punch and hammer to drive the bolt back. Once the bolt moves a quarter inch, maybe less, it’s free again.

I’m .120 off the lands so that’s not it.

The round , just dropped into the chamber sits .017 off of fully seated yet a factory round drops straight in.

See photo for measurements. I only had a 6.5cm neck comparator but it gives you a comparison.

Are these difference in measurements enough to be the problem? Which one?

I’m using Hornady custom grade dies. Bad sizing die?

I’d shot around 35 hand loads 110,150, 165 before these 200 elf-x but I think it’s just coincidence as this has happened with 168 smk before.

Any thoughts?