Hey everyone I need some help with this.. basically I'm getting carbon back on the case body and around the case head.. the headspace is about .0025 shorter then a normal fired piece. Gun is a .22bra with a .160 freebore, I've seen some other posts of people with a similar issue saying it's because the bullet isn't seated enough in the case which I can say where I was shooting these 85.5s at the base of the bullet isn't even at the neck shoulder junction so idk please help if you can thanks

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What is causing this?

- Thread starter NFshooter150

- Start date

So, you're seating to a little more than touch. With a COAL at 2.355, you've only got ~.110 of shank seated depth (more or less depending on case length). It doesn't appear the necks and shoulders are getting coated with soot. That makes me wonder if your primers a leaking when I see soot in that end of a case???Hey everyone I need some help with this.. basically I'm getting carbon back on the case body and around the case head.. the headspace is about .0025 shorter then a normal fired piece. Gun is a .22bra with a .160 freebore, I've seen some other posts of people with a similar issue saying it's because the bullet isn't seated enough in the case which I can say where I was shooting these 85.5s at the base of the bullet isn't even at the neck shoulder junction so idk please help if you can thanksView attachment 8425338View attachment 8425339View attachment 8425341

What problem/issue do you think you will fix if you stop getting carbon on the case? I.E. why do you feel you need to stop whatever is happening.....from happening?

If you didn't look at your brass, just shot it, cleaned, loaded.......for the entire life of the barrel.......what problem do you think would happen if you didn't recognize this prior to firing 2500 rounds or so?

Would you have degradation in precision? Would you have damage to the rifle in some way?

If you didn't look at your brass, just shot it, cleaned, loaded.......for the entire life of the barrel.......what problem do you think would happen if you didn't recognize this prior to firing 2500 rounds or so?

Would you have degradation in precision? Would you have damage to the rifle in some way?

Well the SD's are way off in the mid teens for 5 shots accuracy on target though was actually pretty good. I did just load up 10 rounds of different lengths each I did 2.390(original length), 2.355, and 2.320. which 2.320 is about .100 off the lands. All with the same charge weight. It's definitely not the primers because it's not on the bottom of the case it's just down the side to the rim of the case head is where the soot is.What problem/issue do you think you will fix if you stop getting carbon on the case? I.E. why do you feel you need to stop whatever is happening.....from happening?

If you didn't look at your brass, just shot it, cleaned, loaded.......for the entire life of the barrel.......what problem do you think would happen if you didn't recognize this prior to firing 2500 rounds or so?

Would you have degradation in precision? Would you have damage to the rifle in some way?

For the soot to come way down the side it means that the case did not expand under pressure. This happens when not seating the bullet deep enough and the neck never expands. But then you should see soot down the side of the case. Did you wipe the cases before the photos?

Im not familiar with a .22bra. Is this a bolt action rifle?

Im not familiar with a .22bra. Is this a bolt action rifle?

No I think some of those in the photos with all in the box got soot on them from soot being in the chamber.. the ones that are short on headspace have it down the side of the case and to the rim particularly just one half of the rim really.. I hope I can confirm this is my issue when I test the other lengths. I'll take another photo of the really bad ones that you can see down the side as well.. the bolt lift when extracting also felt like there is nothing in the chamber and the headspace was shorter. If this is the case I wonder why anyone would want a .160 freebore in these I mean I guess maybe to strictly shoot the heavy for caliber projectilesFor the soot to come way down the side it means that the case did not expand under pressure. This happens when not seating the bullet deep enough and the neck never expands. But then you should see soot down the side of the case. Did you wipe the cases before the photos?

Im not familiar with a .22bra. Is this a bolt action rifle?

No I think some of those in the photos with all in the box got soot on them from soot being in the chamber.. the ones that are short on headspace have it down the side of the case and to the rim particularly just one half of the rim really.. I hope I can confirm this is my issue when I test the other lengths. I'll take another photo of the really bad ones that you can see down the side as well.. the bolt lift when extracting also felt like there is nothing in the chamber and the headspace was shorter. If this is the case I wonder why anyone would want a .160 freebore in these I mean I guess maybe to strictly shoot the heavy for caliber projectiles

Well the SD's are way off in the mid teens for 5 shots accuracy on target though was actually pretty good. I did just load up 10 rounds of different lengths each I did 2.390(original length), 2.355, and 2.320. which 2.320 is about .100 off the lands. All with the same charge weight. It's definitely not the primers because it's not on the bottom of the case it's just down the side to the rim of the case head is where the soot is.

Just test things like powder charge and seating depth for now. I wouldn't stress over the carbon on brass at the moment.

The last time I had something like this happen I annealed the case necks and that fixed it. I don't normally anneal but when I do it's with a propane torch and a drill.

Either increase your charge and/or seat the bullets deeper into the case.

From what I can see on the internet, 2850fps is a light load 80gr bullets out of a .22BR. I suspect that your load does not produce enough pressure to expand the case and seal the chamber. Specially not with how shallow you seat the bullets.

The .160" freebore is for shooting the heavy-for-calibre bullets like the 88gr ELD-M's. Should work well with the 85.5gr Bergers, just seat them deeper. Regardless of jump, I'm usually not comfortable shooting any bullet with less than at least 80% of the bearing surface inside the case neck.

From what I can see on the internet, 2850fps is a light load 80gr bullets out of a .22BR. I suspect that your load does not produce enough pressure to expand the case and seal the chamber. Specially not with how shallow you seat the bullets.

The .160" freebore is for shooting the heavy-for-calibre bullets like the 88gr ELD-M's. Should work well with the 85.5gr Bergers, just seat them deeper. Regardless of jump, I'm usually not comfortable shooting any bullet with less than at least 80% of the bearing surface inside the case neck.

I'm pretty sure jerkyfreak nailed it on the head, from everything I've read and found that's what makes sense, of the only thing was just a dirty case I wouldn't worry much but the case is not sealing in the chamber guys and that will destroy your SD's and performance downrange. I'll update after I test the seating depth loads.

The last time I had something like this happen I annealed the case necks and that fixed it. I don't normally anneal but when I do it's with a propane torch and a drill.

Ya I know but unfortunately in my case I'm not..Could also happen if you're shooting suppressed.

Yep I think that's my issue the bullet barely seated in the case so not enough time for chamber pressure to build and this causing the sootIf your brass is already fire formed, sooting is generally caused by low chamber pressure.

Alpha specs their br based reamers with a lil smaller dimension on the body VS most that are developed for Lapua brass. It's going to take a few firings for that brass to grow and start gripping the chamber. I fought alpha 6bra for a while and pretty much just threw in the towel and punched it out to 6gt.

Alpha brass doesn't like being sized a lot by the die, as the brass is tough as hell and doesn't come back like lapua. So I'd start with a Forster bushing bump die that just sizes neck and can bump the shoulder a lil if you want. Once brass has grown enough that it won't chamber and needs FL sized, you'll want to use a die that sizes the base just a lil bit. I'd probably start with a Harrels D1 die. I had a D3 for my rifle and it'd size a fired case from 0.4695 to 0.4675 which is around where a brand new case is. Too much in my findings. I tried 3 different dies, and had all my barrels recut from a jgs spec to a new alpha 6bra reamer, was still fighting bolt lift, swipe and low velocity in the 6bra. I think it was the sized brass to chamber relationship.

Up your powder charge to increase chamber pressure to help sealing. Also, if a fired case fits inside the chamber, just

try neck sizing only for a bit and see if it goes away. I am also perplexed like previous responses how there is soot in the extractor cut, but none on the case walls. The extractor cut isn't even technically inside the chamber when ignition happens.

Alpha brass doesn't like being sized a lot by the die, as the brass is tough as hell and doesn't come back like lapua. So I'd start with a Forster bushing bump die that just sizes neck and can bump the shoulder a lil if you want. Once brass has grown enough that it won't chamber and needs FL sized, you'll want to use a die that sizes the base just a lil bit. I'd probably start with a Harrels D1 die. I had a D3 for my rifle and it'd size a fired case from 0.4695 to 0.4675 which is around where a brand new case is. Too much in my findings. I tried 3 different dies, and had all my barrels recut from a jgs spec to a new alpha 6bra reamer, was still fighting bolt lift, swipe and low velocity in the 6bra. I think it was the sized brass to chamber relationship.

Up your powder charge to increase chamber pressure to help sealing. Also, if a fired case fits inside the chamber, just

try neck sizing only for a bit and see if it goes away. I am also perplexed like previous responses how there is soot in the extractor cut, but none on the case walls. The extractor cut isn't even technically inside the chamber when ignition happens.

Take a close look at post #7 there is soot all over the outside of the case.Alpha specs their br based reamers with a lil smaller dimension on the body VS most that are developed for Lapua brass. It's going to take a few firings for that brass to grow and start gripping the chamber. I fought alpha 6bra for a while and pretty much just threw in the towel and punched it out to 6gt.

Alpha brass doesn't like being sized a lot by the die, as the brass is tough as hell and doesn't come back like lapua. So I'd start with a Forster bushing bump die that just sizes neck and can bump the shoulder a lil if you want. Once brass has grown enough that it won't chamber and needs FL sized, you'll want to use a die that sizes the base just a lil bit. I'd probably start with a Harrels D1 die. I had a D3 for my rifle and it'd size a fired case from 0.4695 to 0.4675 which is around where a brand new case is. Too much in my findings. I tried 3 different dies, and had all my barrels recut from a jgs spec to a new alpha 6bra reamer, was still fighting bolt lift, swipe and low velocity in the 6bra. I think it was the sized brass to chamber relationship.

Up your powder charge to increase chamber pressure to help sealing. Also, if a fired case fits inside the chamber, just

try neck sizing only for a bit and see if it goes away. I am also perplexed like previous responses how there is soot in the extractor cut, but none on the case walls. The extractor cut isn't even technically inside the chamber when ignition happens.

@NFshooter150 Try a faster powder...VV 140, Varget and I'll bet that cures your issue.

I haven't had any of the issues with my .308 Alpha cases that you've described. After the first firing, for fire forming using my good go to load, I took measurements before sizing and recorded them to compare to their virgin state and how they compared to my Lapua and Peterson brass (see pic below). On second firing, everything looks good and normal. Though on my first test rounds of 10 using CCI400's, I had some pierced primers. From there I used CCI450's and no further problems.Alpha specs their br based reamers with a lil smaller dimension on the body VS most that are developed for Lapua brass. It's going to take a few firings for that brass to grow and start gripping the chamber. I fought alpha 6bra for a while and pretty much just threw in the towel and punched it out to 6gt.

Alpha brass doesn't like being sized a lot by the die, as the brass is tough as hell and doesn't come back like lapua. So I'd start with a Forster bushing bump die that just sizes neck and can bump the shoulder a lil if you want. Once brass has grown enough that it won't chamber and needs FL sized, you'll want to use a die that sizes the base just a lil bit. I'd probably start with a Harrels D1 die. I had a D3 for my rifle and it'd size a fired case from 0.4695 to 0.4675 which is around where a brand new case is. Too much in my findings. I tried 3 different dies, and had all my barrels recut from a jgs spec to a new alpha 6bra reamer, was still fighting bolt lift, swipe and low velocity in the 6bra. I think it was the sized brass to chamber relationship.

Up your powder charge to increase chamber pressure to help sealing. Also, if a fired case fits inside the chamber, just

try neck sizing only for a bit and see if it goes away. I am also perplexed like previous responses how there is soot in the extractor cut, but none on the case walls. The extractor cut isn't even technically inside the chamber when ignition happens.

@straightshooter1 I have not had any problems using the alpha ocd creed, gt, or 7saw brass. It's something to do with the extremely short br case wall. There are some guys who have no issues, others do. There's a very long and elaborate thread over on accurate shooter pertaining to alpha 6bra and a lot of guys frustrations associated.

Ya I'm gonna try this seating depth test and see how that goes.. the thing that worries me with pressures is I would get some that had the soot problem and others that had heavy bolt lift and ejector marks on the same load..

If the case walls aren't expanding and gripping the chamber, the brass grows more length wise inside the chamber. This will likely cause bolt lift, and signs on the case head. It's puzzling as your chamber pressure is likely not the problem at all, but it's the sized brass/chamber dimension relationship causing the frustrations.Ya I'm gonna try this seating depth test and see how that goes.. the thing that worries me with pressures is I would get some that had the soot problem and others that had heavy bolt lift and ejector marks on the same load..

Hmm I am using the sac modular BRA die but checking the measurements of fired and sized it's only sizing back 1.5 thou all down the case body. I talked to SAC and they said I can send in my die with fired and sized brass and they would check it outIf the case walls aren't expanding and gripping the chamber, the brass grows more length wise inside the chamber. This will likely cause bolt lift, and signs on the case head. It's puzzling as your chamber pressure is likely not the problem at all, but it's the sized brass/chamber dimension relationship causing the frustrations.

Are you using a micrometer? That's the most accurate tool for this task. The alpha brass is designed around CIP chamber specs, not saami. Most current lapua br variant chambers are 0.4714 at 0.200 line. I'm unsure of what alpha has, but I know it's a lil smaller at the base. What is your fired brass measuring down towards the base? What's it measure after sizing? What you should be shooting for is 0.469 sized and around .470-4705 fired.Hmm I am using the sac modular BRA die but checking the measurements of fired and sized it's only sizing back 1.5 thou all down the case body. I talked to SAC and they said I can send in my die with fired and sized brass and they would check it out

Yep I think that's my issue the bullet barely seated in the case so not enough time for chamber pressure to build and this causing the soot

Generally speaking sooty case necks or case bodies indicate non case expansion aka No sealing ,so gases are by passing throat down case .

Anneal a 1/2 dozen seat bullet further ,see if that fixes the issue . IF not Slug your chamber and check dimensions against your brass .

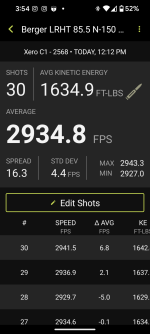

So I have had 2 range sessions now where I shot 80 rounds each session and with the seating depth test and increasing powder charge all the problems are now gone! And feel like I have a solid load for the 85.5 berger. I shot 30 shots avg of 2935 with 4.4sd and it was 10 different seating depths in increment of .005

Attachments

Good to hear.So I have had 2 range sessions now where I shot 80 rounds each session and with the seating depth test and increasing powder charge all the problems are now gone! And feel like I have a solid load for the 85.5 berger. I shot 30 shots avg of 2935 with 4.4sd and it was 10 different seating depths in increment of .005

What COAL did you wind up at?

2.355 which is about .080 jumpGood to hear.

What COAL did you wind up at?

My current chamber is a .160 freebore and the reamer I have coming is .100 but also I shortened the chamber length on my reamer to 1.555 instead of 1.570

One thing your photos make clear is that the Bergers do not have to be jammed for good results. That is generally true for most tangent ogive bullets

Hmmmm??? So, that's that same as before, only now with a different powder load?2.355 which is about .080 jump

Agreed here is both full targetsOne thing your photos make clear is that the Bergers do not have to be jammed for good results. That is generally true for most tangent ogive bullets

What do you mean same as before what?Hmmmm??? So, that's that same as before, only now with a different powder load?

Attachments

Your OP you showed your COAL was 2.355 and in the post#29 you say it's 2.355.What do you mean same as before what?

O gotcha ya that sticker was a different load and bullet. These ones are the 85.5 the seating depth I was having trouble at was 2.390 to 2.415Your OP you showed your COAL was 2.355 and in the post#29 you say it's 2.355.

Similar threads

- Replies

- 21

- Views

- 707