The answer is Yes! I too watched Frank and Erik's podcast. Quite informative. Frank is very knowledgeable.

I know abrasive polishes - have used them for decades on my cars' clear coats. Like Frank said, don't use them if you don't know how to and how they actually work. I wrote another post here where I tested J-B Blue label and IOSSO against my car polishes. I'll leave a link to that post below.

Three things affect the amount of material abrasive polishes remove. Four counting ignorance

- the size of the abrasive particles, the quantity of particles in suspension and the composition.

Of those three the most important ones are composition, followed by particle size.

Composition: Most newer, advanced polishes use particles that DISSOLVE when the polish is applied - this is critical.

Particle size: The bigger they are the more time they take to dissolve. That's how they work. Think of sandpaper grits.

The beauty of polishers is that you can pick a specific a specific need and if you don't now which one to use - DON'T use them!

If you do use them do so only when absolutely needed. If you polished your vehicle's clear coat every time you washed it, pretty soon you'd have no clear coat left!

Frank mentioned Remington 40-X as a possible choice. I beg to differ on that one because the label states the abrasives are earth? That sounds to me like Diatomaceous Earth. That's a natural abrasive but as far as I know it does not dissolve. Definitely NOT for inexperienced users.

So far the best I've tested is B-J Blue label. In the description at Brownells site it says the past liquefies when used, sounds like a dissolving type but in reality it still leaves particles in the barrel. Read the instructions and follow them! I use a lot of oil on patches after using J-B to make sure all the abrasive particles left behind are removed.

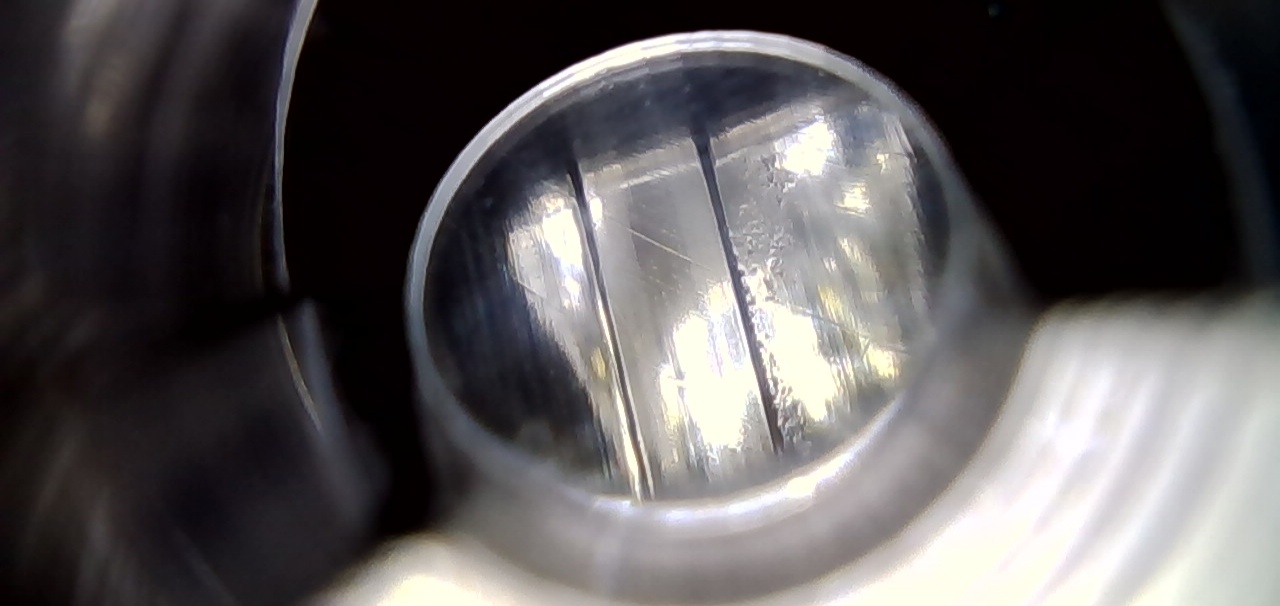

I recently did use J-B - first time in years and have pictures of the before and after. It's not as strong as some people think. It's a long story but after watching the podcast I got curious and so, I went in the closet and got my bore scope.

I had never used it on my 6mm ARC bolt gun since new, now approaching 500 rounds. I did not like what I saw. I clean my rifle after each use. My clean rifle was covered in carbon from the carbon ring to 6-inces past that point. The rest of the barrel was clean with some minor brass streaking. I did 5 strokes (10 passes) with J-B on the affected area and got most but not all of the stuff out.

I now realize I got carried into this whole "new wave" of expensive nylon brushes and bore tech carbon remover trend. They obviously don't work!

So, from now on I'm back to what always worked for me. Bench Rest type copper brushes, Hoppes, and every few cleanings a thorough one including Remington Brite Bore and a copper brush. That stuff works like magic for me! With no abrasives....

Link to my post on abrasives:

https://www.snipershide.com/shooting/threads/how-clean-is-clean-enough.7102738/post-9989219