Your answer to the pole above should not be based on what is available now. It's would you if there were a better solution that was reasonable on cost with a pretty quick turn around. Think about LRI's blueprinted 700 barreled action group buy. How many people dug that old 700 out and shipped it once that option presented itself.

I know there are a lot more people on the hide with a mini 14 burred somewhere deep in there safe. After experiencing the accuracy of a good AR it kind of ruins the mini.

My stainless ranch rifle hasn't been fired in 10 years. I just haven't shot the damn thing, but can't bring my self to get rid of it. Maybe just nostalgia, I love the look, size & weight.

Dug it out of the back of safe in December and tore it down completely to try to assess what could be done. Did a nice trigger job that turned out great, but that scrawny ass non floated spaghetti barrel is the pits. The way Ruger chose to manufacture it does not lend itself well to barrel upgrades.

I got to thinking that 350 Legend would be about perfect for a mini 14 ranch rifle. I would shoot the hell out of that & it would be a great pig gun.

I called Paul Craddock about the possibility of having him make a 17" or 18" 350 Legend barrel for it with a heavy couture .850 through gas block, stepped down to .750 out to muzzle with 5/8"x 24 thread. Paul actually said he also had an old ranch rifle he just hangs onto & was receptive to the idea. Then, all this Covid shit started & I got side tracked with bolt gun and AR projects. It would be a labor of love, but the heart wants what it wants.

Accuracy Systems does heavy barrel mini's, but there is a lot of hand fitting & wait is pretty damn long. If you ever need to replace barrel the whole process has to repeat.

Another thread on here got me thinking about it again and I just had a bit of a brainstorm. The problem with re barreling as I understand it, is that the receiver threads aren't clocked consistently. So even if you wanted to screw in a bone stock factory take off barrel, the gas port, extractor groove location, and head space would be wrong 9 out 10 times.

There are a lot of good parts for the mini, the barrel is the problem. Never mind that I'd personally like to do it in 350L, think whatever AR caliber floats your boat.

My brilliant idea is this:

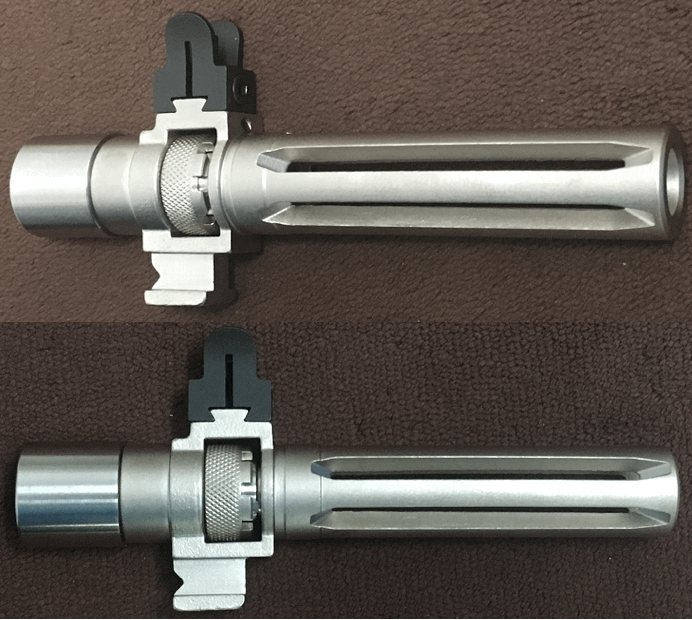

Accuracy Systems 5/8" x 24 adapter to index-able M1A style sight/flash hider. This sets front sight at proper height for mini 14

I know there are a lot more people on the hide with a mini 14 burred somewhere deep in there safe. After experiencing the accuracy of a good AR it kind of ruins the mini.

My stainless ranch rifle hasn't been fired in 10 years. I just haven't shot the damn thing, but can't bring my self to get rid of it. Maybe just nostalgia, I love the look, size & weight.

Dug it out of the back of safe in December and tore it down completely to try to assess what could be done. Did a nice trigger job that turned out great, but that scrawny ass non floated spaghetti barrel is the pits. The way Ruger chose to manufacture it does not lend itself well to barrel upgrades.

I got to thinking that 350 Legend would be about perfect for a mini 14 ranch rifle. I would shoot the hell out of that & it would be a great pig gun.

I called Paul Craddock about the possibility of having him make a 17" or 18" 350 Legend barrel for it with a heavy couture .850 through gas block, stepped down to .750 out to muzzle with 5/8"x 24 thread. Paul actually said he also had an old ranch rifle he just hangs onto & was receptive to the idea. Then, all this Covid shit started & I got side tracked with bolt gun and AR projects. It would be a labor of love, but the heart wants what it wants.

Accuracy Systems does heavy barrel mini's, but there is a lot of hand fitting & wait is pretty damn long. If you ever need to replace barrel the whole process has to repeat.

Another thread on here got me thinking about it again and I just had a bit of a brainstorm. The problem with re barreling as I understand it, is that the receiver threads aren't clocked consistently. So even if you wanted to screw in a bone stock factory take off barrel, the gas port, extractor groove location, and head space would be wrong 9 out 10 times.

There are a lot of good parts for the mini, the barrel is the problem. Never mind that I'd personally like to do it in 350L, think whatever AR caliber floats your boat.

My brilliant idea is this:

- Gage interest for a possible group buy. Snipers Hide poll.

- There has got to be a way to automate this via CNC

- Coerce @LongRifles Inc. into writing a receiver blue print program to single point cut receiver thread oversize, but start clocking at exactly the same spot for every one. I'm not sure it's even possible. Is there enough meat in the receiver? Unlike the AR, mini barrel is supported at front and receiver is steel or investment cast Stainless so it may be possible.

- If the above is possible then a prefit/single barrel program could be written that would fit any blueprinted receiver.

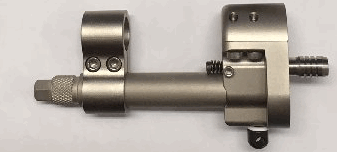

- Purchase a heavy gas block/adjustable gas block from accuracy systems. There's a good variety available .750 - 1", with/without strut rod etc. I would use the .850 one pictured below since I like the Mini M1A look.

- Add flash hider brake combo of your choosing. Again there is a good selection available that include front sight if desired. I'll be using the M1A style index-able 5/8" x 24 flash hider sight combo shown below (in my case have it bored to .357+clearance).

- Sign me up to be guinea pig!

- Hell yeah a 350 Legend mini M1A, kind of a modern replacement for the M1 Carbine.

- Mini 14's would be relevant again! To me anyway.

Accuracy Systems 5/8" x 24 adapter to index-able M1A style sight/flash hider. This sets front sight at proper height for mini 14

Last edited: