An incredibly versatile tool... and great addition to the workbench. Although certainly not heavy duty, its nice to have around when small amounts of material need to removed, shaped or polish.

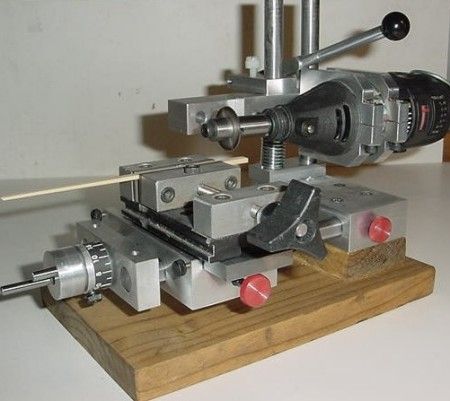

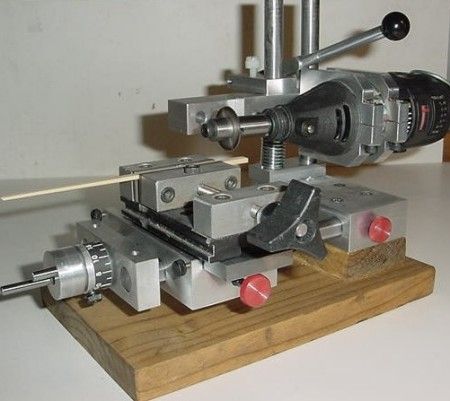

Part of my interest in writing this was to make a place where recommended additions (perhaps a 3rd party workstation like shown at bottom) or unique purposes for a Dremel/other rotary tool could be shared.

Have you made a compartment or smoothed a junction in a pistol grip or stock?

Have you squared off or shortened a sight post you ordered that was too high?

Have you used chromium oxide or jewelers rouge with a buffing attachment to polish a trigger, sear or bolt?

Have you found better quality bits?

Have you learned the hard way where or how it can mess something up or is the wrong tool for the job?

I think it could be also constructive if anyone has discovered things to avoid as well, such as an inferior model or use. Might save someone the wasted material or headache.

My new Dremel 4000 (6 attachment 50 piece kit with workstation)

What I like about the 4000

Variable output is 5,000-35,000 RPM at 1.6 amp

Operation is smooth with very little vibration throughout its range.

Compatible with all previous and current attachments

5 year warrantee (longest from product line)

I'm a fan of the three foot flex cable available by Dremel and would certainly recommend it. The small, pen sized body makes detail work much easier than trying to steady the whole 18-20oz.

I'll add that it's not suited to sharpen blades, the high RPM at even the lowest setting could build up enough heat to ruin the temper of your steel. Additionally, removing material so quickly would make it near impossible to create an even bevel.

I stumbled across this in a search. Any of you using something similar?

Whats your experience?

Part of my interest in writing this was to make a place where recommended additions (perhaps a 3rd party workstation like shown at bottom) or unique purposes for a Dremel/other rotary tool could be shared.

Have you made a compartment or smoothed a junction in a pistol grip or stock?

Have you squared off or shortened a sight post you ordered that was too high?

Have you used chromium oxide or jewelers rouge with a buffing attachment to polish a trigger, sear or bolt?

Have you found better quality bits?

Have you learned the hard way where or how it can mess something up or is the wrong tool for the job?

I think it could be also constructive if anyone has discovered things to avoid as well, such as an inferior model or use. Might save someone the wasted material or headache.

My new Dremel 4000 (6 attachment 50 piece kit with workstation)

What I like about the 4000

Variable output is 5,000-35,000 RPM at 1.6 amp

Operation is smooth with very little vibration throughout its range.

Compatible with all previous and current attachments

5 year warrantee (longest from product line)

I'm a fan of the three foot flex cable available by Dremel and would certainly recommend it. The small, pen sized body makes detail work much easier than trying to steady the whole 18-20oz.

I'll add that it's not suited to sharpen blades, the high RPM at even the lowest setting could build up enough heat to ruin the temper of your steel. Additionally, removing material so quickly would make it near impossible to create an even bevel.

I stumbled across this in a search. Any of you using something similar?

Whats your experience?