Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

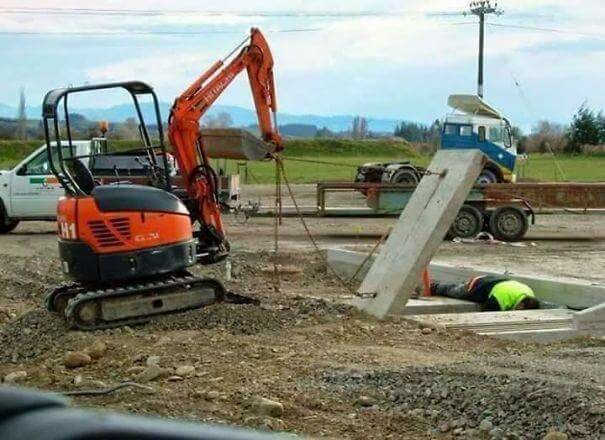

Maggie’s Funny & awesome pics, vids and memes thread (work safe, no nudity)

- Thread starter Lawless

- Start date

You know... art like this... someone should do a coffee table book.

Really. Best Cold War ads for planes and other defense products.

There is lots of money to be made off coffee table books.

Cheers,

Sirhr

Yes, 1980 Chevy P/U with 40k original miles......they had a issue with cheap iron they used in the cam back then, notoriously went flat usually #5 or #7 lobes.

Manufacturers never really solved the flat lobe issue based on this Motortrend article:

"Unfortunately, the only fix for a flattened cam is to replace it and the lifters with a new one, and it's at this point that most people switch to a roller cam.

To be honest, we're kind of jaded on flat-tapped hydraulic cams, generally. Today's retail consumer "starburst" motor oils lack the critical ZDDP zinc compound necessary for keeping flat-tappet lifters alive with today's modern cam profiles. Comp Cams' Valvetrain Engineering Group Leader Billy Godbold affirms this, saying, "You can do everything right to reduce the number of flat-tappet cam failures, but you cannot bring that number to zero."

Not A New Problem

Not that flat-tappet cam failures were unknown 40 years ago. Even back in the '80s, when lifters and oil were still "good," Godbold maintains, "U.S. automakers were seeing too many unexplained cam failures that cost them more to fix than the upgrade to a roller tappet would cost." And that's with mild OE smog-era cams.Some sources attribute this to lower cruise rpm (and hence lower sustained oil pressure) from mild rear axle ratios and overdrive transmissions used to meet tightening mileage and emissions standards. Regardless of the cause, Godbold claims, "Over hundreds of thousands of cars, flat-tappet cam and lifter failures were costing GM, Ford, and Chrysler on the order of over $100 per car on warranty and repair claims."

In sum, durability, not performance, was the initial impetus for the OEs' switch to roller tappets. Later, as carmakers got a handle on emissions and mileage, they developed a new generation of detonation-resistant fast-burn heads that worked with higher compression ratios and new high-lift roller cam profiles that can't be duplicated using flat-tappet technology. Bottom line: Go with a hydraulic roller cam if you can afford it, both for performance as well as reliability.

Any time you have a cam failure, a bottom-end inspection is also in order because all the debris from the failed lifter and cam lobe must go somewhere. The gunk in Hicks' oil pan didn't look good, so Sanchez prepared for the worst

Showing only minor normal wear, the main and rod bearings were fortunately reusable. The oil pump was another story, with scored internal gears. Sanchez replaced it with a Melling high-volume pump, transferring over the old screen after a thorough cleanup"

It would probably be worth cutting the oil filter open to see what's in there.

Never gets old….but I’d kill that sumbeech

Ghetto Quarrel Snake

That is some Tumble weave shit right there…

That is gayer than jizz on a moustache!

This is funnier for me because there’s a fucking regard I work with named Paul that does this same thing. Not only is he fucking stupid, he eats the worst shit…err, food in the world and has a bunch of gut problems.

Similar threads

- Replies

- 5

- Views

- 724

- Replies

- 5

- Views

- 409

- Replies

- 56

- Views

- 2K