Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 Creedmoor

- Thread starter Sportin Wood

- Start date

H4350 works well with 153s also. I use 40.6 grns and get 2680fps with the 153 ATips. Also works with the 147 ELDs.

I tried the 144s with h4350 not too long ago and got up to 2800 without having any pressure signs so it works there too. But I probably won't be running them that fast. I'll back down to 2760ish or 2780ish to preserve brass life.

Has anybody tried 153.5s in a 18-20” barrel? If so, what was your MV and powder? I’m trying to build an NRL open light rig with hopes to cut weight by going to a 18-20” barrel, Then compensate loss of speed with weight.

Has anybody tried 153.5s in a 18-20” barrel? If so, what was your MV and powder? I’m trying to build an NRL open light rig with hopes to cut weight by going to a 18-20” barrel, Then compensate loss of speed with weight.

You'll want to look for unicorn dust. Either rl16 or rl26

First 6.5, stock tikka ctr 24" stainless.

Went with 41.2gr H4350 under 140gr Hornady bthps just to get the gun shot in. Very happy, those are both 5 round groups. These were the first two groups after 6 rounds getting newly mounted scope on paper. A little slow but should be fine inside of 1200, brass looks like it will last.

Tried some 120 ELDs with superformance and got up to nearly 3000 fps with no real pressure signs, will probably settle around 2930ish and see how they group. Just shot single round charge weights checking speed and brass for pressure. Did Varget too.

Went with 41.2gr H4350 under 140gr Hornady bthps just to get the gun shot in. Very happy, those are both 5 round groups. These were the first two groups after 6 rounds getting newly mounted scope on paper. A little slow but should be fine inside of 1200, brass looks like it will last.

Tried some 120 ELDs with superformance and got up to nearly 3000 fps with no real pressure signs, will probably settle around 2930ish and see how they group. Just shot single round charge weights checking speed and brass for pressure. Did Varget too.

Attachments

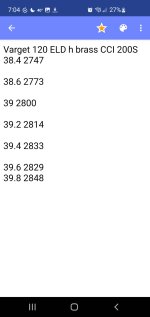

Here are my results with Varget and Superformance, Hornady brass, CCI 200s, 24" factory tikka. 5,000ft, 50f.Anyone have good load data for 120ELD-M’s

I plan on using Lapua SR brass with H4350.

Attachments

Also this barrel is brand new and had about 40 rounds on it at this pointHere are my results with Varget and Superformance, Hornady brass, CCI 200s, 24" factory tikka. 5,000ft, 50f.

Thank you!Here are my results with Varget and Superformance, Hornady brass, CCI 200s, 24" factory tikka. 5,000ft, 50f.

Here is the factory load for the 156’sWhat charges y’all running with Berger 153’s and H4350?

Last edited:

What charges y’all running with Berger 153’s and H4350?

I run 153 ATips with 40.6grns of H4350 loaded at 2.860” in Hornady brass.

I was thinking of trying 40.0g and 40.3g. Just get close to book max for BergerI run 153 ATips with 40.6grns of H4350 loaded at 2.860” in Hornady brass.

I was thinking of trying 40.0g and 40.3g. Just get close to book max for Berger

Hodgdon lists 41 as their max load with Hornady brass and at saami oal so you should be good in that range.

Those superformance loads are hot, even on the lower end so be very careful and work up.Thank you!

Hey guys, quick question. What is considered a far bullet jump when loading from magazines. I’m using an XLR chassis with Hawkins Mags and currently jumping .145 with 140 TMK or 140 Berger Hybrids. I can probably load .020 closer to the lands but I’m just trying to get a feel for how far off I am compaired to others who mag feed there bolt guns…

What’s your load if you don’t mind? I’m using H4350 but I’m only getting around 2750 out of a 22” barrel.When I load my 140gr ELD-Ms to max magazine length, I am about .05 jump, which is where I want to be with this bullet.

They shoot fine, 2840fps, sub moa, and hit at 1240yds consistently.

If I want to push them a bit closer to the lands, I just have to single load them.

42.4gr H4350, but out of a 26" barrel.What’s your load if you don’t mind? I’m using H4350 but I’m only getting around 2750 out of a 22” barrel.

Can’t really go wrong with any of them. Lapua has never let me down.Alpha, Lapua or Peterson for my first batch of small primer brass?

Yes. 2750 to 2800 is common. If I recall correctly the 6.5 creed was designed to run a 140 at 2750, may have been 2700 to 2750, but those speeds are normal.Is 2800 fps + with 140s common place? That seems fast but I am new to 6.5

To get 140 hybrids to fit in several brands of mags it’s not uncommon for them to fit to be jumping .120 if your using 140 hybrids and there not accurate at any amount of jump then there’s something wrong with your rifle. Don’t be afraid of massive jump they just don’t care. You can buy mags with no binder plate and jump less if you want but if using the 140 hybrid don’t waste your money and just load them to mag lenght, likely they’ll shoot great.Hey guys, quick question. What is considered a far bullet jump when loading from magazines. I’m using an XLR chassis with Hawkins Mags and currently jumping .145 with 140 TMK or 140 Berger Hybrids. I can probably load .020 closer to the lands but I’m just trying to get a feel for how far off I am compaired to others who mag feed there bolt guns…

140gr bullets are what the 6.5 cm seems to like the best.

It's difficult to make a 140gr bullet, no matter who the mfg is, not perform well.

Obviously a bit of tweeking might be needed to get the "perfect" load, but they tend to not really care what oal and what jump you choose to load to.

It's difficult to make a 140gr bullet, no matter who the mfg is, not perform well.

Obviously a bit of tweeking might be needed to get the "perfect" load, but they tend to not really care what oal and what jump you choose to load to.

That's the 140 Amax?

Had my first head separation over the weekend, goes about 300 degrees around the brass and is above the sizing die mark. Looking for some input/advice to look out for.

2x fired hornady brass, this was the 3rd firing. Picked up 300 once-fired brass from gunwerks (not doing once fired anymore, I know) and 200 factory hornady brass from my gun that I am loading. Second loading on all brass was done with a lee full length sizer with ~.002” shoulder bump. Annealed after the 2nd firing and all sizing for the current (3rd firing) loads was done on a SAC die with bushing and mandrel for .002” bump and neck tension. Not running a hot load, cci 200 with 42.5gr staball 6.5 with 140gr eld-m @2650 fps in a 24” bergara HMR.

Is it possible I just got one piece of bad brass? I shot ~80 rounds and this is the only one I saw this on. I visually checked all the brass before loading and looked fine though (I am pretty conservative and turned any I had any hesitation on into dummy rounds that were probably still fine) did not do the paperclip test though as it was only the 3rd time it would be fired. I checked half of the ones fired the same day and some of the ones I have not loaded yet with the paperclip test (dental curved pick) and none seem to have any groove forming inside. I have reloaded a lot of hunting ammo but only up to 3x so far, but with starting PRS shooting, is there anything I am missing that I should be doing besides running the paper clip test? This one scared me a little.

Have a barreled action being spun and will be using lapua brass in that but will still load and shoot this.

2x fired hornady brass, this was the 3rd firing. Picked up 300 once-fired brass from gunwerks (not doing once fired anymore, I know) and 200 factory hornady brass from my gun that I am loading. Second loading on all brass was done with a lee full length sizer with ~.002” shoulder bump. Annealed after the 2nd firing and all sizing for the current (3rd firing) loads was done on a SAC die with bushing and mandrel for .002” bump and neck tension. Not running a hot load, cci 200 with 42.5gr staball 6.5 with 140gr eld-m @2650 fps in a 24” bergara HMR.

Is it possible I just got one piece of bad brass? I shot ~80 rounds and this is the only one I saw this on. I visually checked all the brass before loading and looked fine though (I am pretty conservative and turned any I had any hesitation on into dummy rounds that were probably still fine) did not do the paperclip test though as it was only the 3rd time it would be fired. I checked half of the ones fired the same day and some of the ones I have not loaded yet with the paperclip test (dental curved pick) and none seem to have any groove forming inside. I have reloaded a lot of hunting ammo but only up to 3x so far, but with starting PRS shooting, is there anything I am missing that I should be doing besides running the paper clip test? This one scared me a little.

Have a barreled action being spun and will be using lapua brass in that but will still load and shoot this.

No, it was through gunwerks. There’s a 60% chance it was one of the once fired since I mixed the 300 once fired with the 200 factory brass I fired. Just kind of a sanity check here, I dont think I did anything wrong that would have caused this. Load process isThat’s odd. I have brass with almost three times as many firings with higher velocities and no issues.

You bought it once fired? Any idea what it was shot through?

1. Deprime

2. Wet tumble

3. Anneal (only plan to do every 3 or so)

4. imperial dry lube on neck and imperial wax on body.

5. Size to .002 bump

6. Trim and chamfer

7. Wipe brass with rag with alcohol on it to remove wax

8. Charge with autotrickler

9. Seat

Hope this is just a bad piece of brass or I figure out something I am missing that caused it.

It could be bad brass, but 90% of the time it is caused by excess head space, either in your rifle or the one your "once" fired brass came from.. If your loading for more than one 6.5 Creed your technique is great, since they have to fit multiple chambers. However, if your reloading for just one 6.5 Creedmoor, your bolt action Bergara, then the best case gauge is your rifle's own chamber.No, it was through gunwerks. There’s a 60% chance it was one of the once fired since I mixed the 300 once fired with the 200 factory brass I fired. Just kind of a sanity check here, I dont think I did anything wrong that would have caused this. Load process is

1. Deprime

2. Wet tumble

3. Anneal (only plan to do every 3 or so)

4. imperial dry lube on neck and imperial wax on body.

5. Size to .002 bump

6. Trim and chamfer

7. Wipe brass with rag with alcohol on it to remove wax

8. Charge with autotrickler

9. Seat

Hope this is just a bad piece of brass or I figure out something I am missing that caused it.

To do that you must neck size only. Then test a dummy round to see if it fits. If it does, it does not need a shoulder bump yet. If it does not fit, then do a partial FL resize, in small increments, until that case just fits.

You may have a chamber that's on the large end of SAAMI tolerances and a resizing die that's on the small end of SAMMI tolerances. At least this is a easy and inexpensive way to check how your brass fits before you bump it back .002 or whatever. It's trouble shooting 101.

Last edited:

I primarily load SRP Lapua, on my 4th firing, but have a loaded Hordany, S&B and Federal.

In my experience Hordany is very soft compared to others that I have put through the press.

It’s possible you got a bunk piece of brass that slipped through Hordany QC.

In my experience Hordany is very soft compared to others that I have put through the press.

It’s possible you got a bunk piece of brass that slipped through Hordany QC.

So, the second loading was actually .003” bump. I had been full length sizing with a .002 to make sure I have reliable feeding. I figured if It were still growing it would grow on the second firing more than half what it did after the initial firing. The fired brass will fit in the chamber and the bolt will close. After sizing, it does not fully fit in the lyman case gauge I have. Should I be looking to neck size only or setting no bump on the first loading?It could be bad brass, but 90% of the time it is caused by excess head space, either in your rifle or the one your "once" fired brass came from.. If your loading for more than one 6.5 Creed your technique is great, since they have to fit multiple chambers. However, if your reloading for just one 6.5 Creedmoor, your bolt action Bergara, then the best case gauge is your rifle's own chamber.

To do that you must neck size only. Then test a dummy round to see if it fits. If it does, it does not need a should bump yet. If it does not fit, then do a partial FL resize, in small increments, until that case just fits.

You may have a chamber that's on the large end of SAAMI tolerances and a resizing die that's on the small end of SAMMI tolerances. At least this is a easy and inexpensive way to check how your brass fits before you bump it back .002 or whatever. It's trouble shooting 101.

I took these measurements on headspace:

Factory ammo new - 1.557-1.559

Factory ammo fired - 1.5635 (grew .0055)

Once fired sized - 1.5615

Once fired shot - 1.5645 (grew .003)

Twice fired sized - 1.5615

Twice fired shot - 1.5645 (grew .003)

Twice fired that separated 1.5660

And yes, I only have the one 6.5 creedmoor right now. All shooting I have done is with this gun, then whatever the “once fired” brass was from. I mixed the brass like an idiot so no way to tell if this was that or my original factory also the last time I’m messing with once fired.It could be bad brass, but 90% of the time it is caused by excess head space, either in your rifle or the one your "once" fired brass came from.. If your loading for more than one 6.5 Creed your technique is great, since they have to fit multiple chambers. However, if your reloading for just one 6.5 Creedmoor, your bolt action Bergara, then the best case gauge is your rifle's own chamber.

To do that you must neck size only. Then test a dummy round to see if it fits. If it does, it does not need a should bump yet. If it does not fit, then do a partial FL resize, in small increments, until that case just fits.

You may have a chamber that's on the large end of SAAMI tolerances and a resizing die that's on the small end of SAMMI tolerances. At least this is a easy and inexpensive way to check how your brass fits before you bump it back .002 or whatever. It's trouble shooting 101.

I added a piece of scotch tape to the end of a piece of fired brass today which is .002” and tried to feed it, bolt was very snug. two pieces at .004 the bolt would not close. So this fired brass should be right at chamber size. I was shooting for .002” bump, I’m at more .002-.003” from that fired brass length headspaceIt could be bad brass, but 90% of the time it is caused by excess head space, either in your rifle or the one your "once" fired brass came from.. If your loading for more than one 6.5 Creed your technique is great, since they have to fit multiple chambers. However, if your reloading for just one 6.5 Creedmoor, your bolt action Bergara, then the best case gauge is your rifle's own chamber.

To do that you must neck size only. Then test a dummy round to see if it fits. If it does, it does not need a shoulder bump yet. If it does not fit, then do a partial FL resize, in small increments, until that case just fits.

You may have a chamber that's on the large end of SAAMI tolerances and a resizing die that's on the small end of SAMMI tolerances. At least this is a easy and inexpensive way to check how your brass fits before you bump it back .002 or whatever. It's trouble shooting 101.

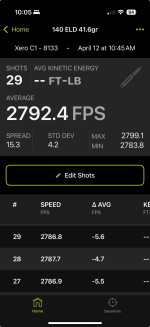

Made 2 impacts in a row at 1807yd last Saturday at Rifle Ranch in AL. First 10 shots danced around the target as we were dealing with a nasty tail wind. Winds calmed down and took 5 more shots and impacted with the final 2. Forgot to mil the target but it was probably 18" wide and 36" tall.

Alpha brass, CCI 450s, 41.6gr H4350 and 140gr ELD-M. I forgot my loaded Berger 140gr HT ammo at the house, damn it!

Factory MPA PMR Pro 2 with the Curtis action.

Alpha brass, CCI 450s, 41.6gr H4350 and 140gr ELD-M. I forgot my loaded Berger 140gr HT ammo at the house, damn it!

Factory MPA PMR Pro 2 with the Curtis action.

Attachments

so I looked at a diagram that shows the speeds of powder and like you mentioned, found that 4320 is right in between Win 748 and Varget. According to thee Hodgdon load website and found that Win 748 has a load range of 36 to 40.4 gr for the 120gr bullet. Varget shows the load range of 36 to 40gr for the same bullet. BLC-2 shows pretty much the same thing. makes me think that it would be safe to use that same range as the other three powder for 4320I havnt used it but it should be fine for 120s similar to varget and rl15. I used rl15 behind a 130 for a long time and it was a very accurate speedy load in 6.5 I would think you could start a low rl15 load and then work your way up from there. Maybe others will chime in.

Similar threads

- Replies

- 28

- Views

- 866

- Replies

- 11

- Views

- 561

- Replies

- 3

- Views

- 410

- Replies

- 2

- Views

- 871