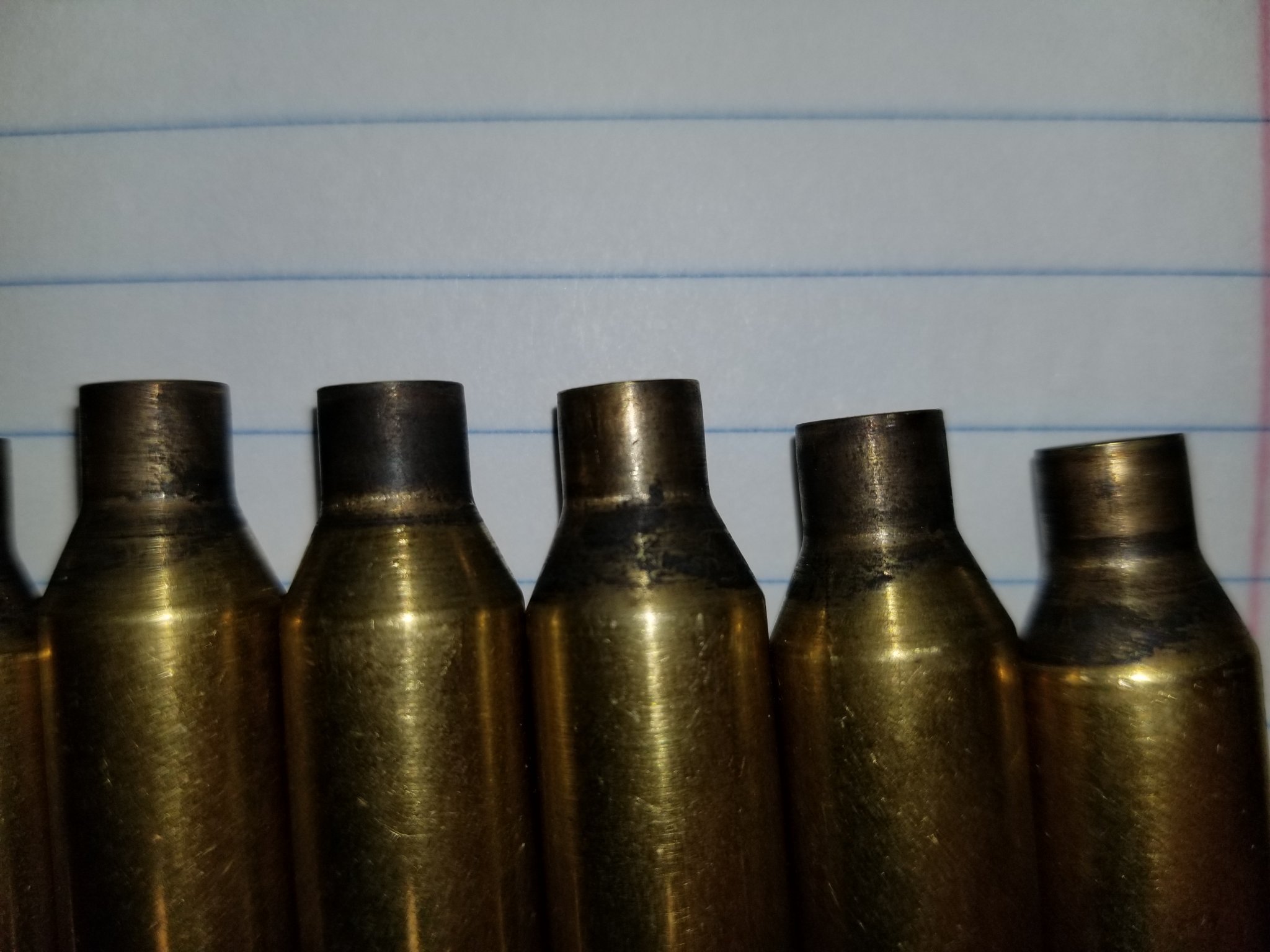

This is the 3 re-load for these 264 Win Mag cases. However, I've been seeing a lot of fouling on almost all of the cases from this rifle no matter if they're virgin brass or not. It seems to have gotten worse lately though. Sometimes the entire neck and shoulder are fouled 360 degrees. Can anyone give me a reason or reasons this may be happening? I full-length re-size btw.

I tried to take the best photos I could for illustration.

TIA for your suggestions.

I tried to take the best photos I could for illustration.

TIA for your suggestions.