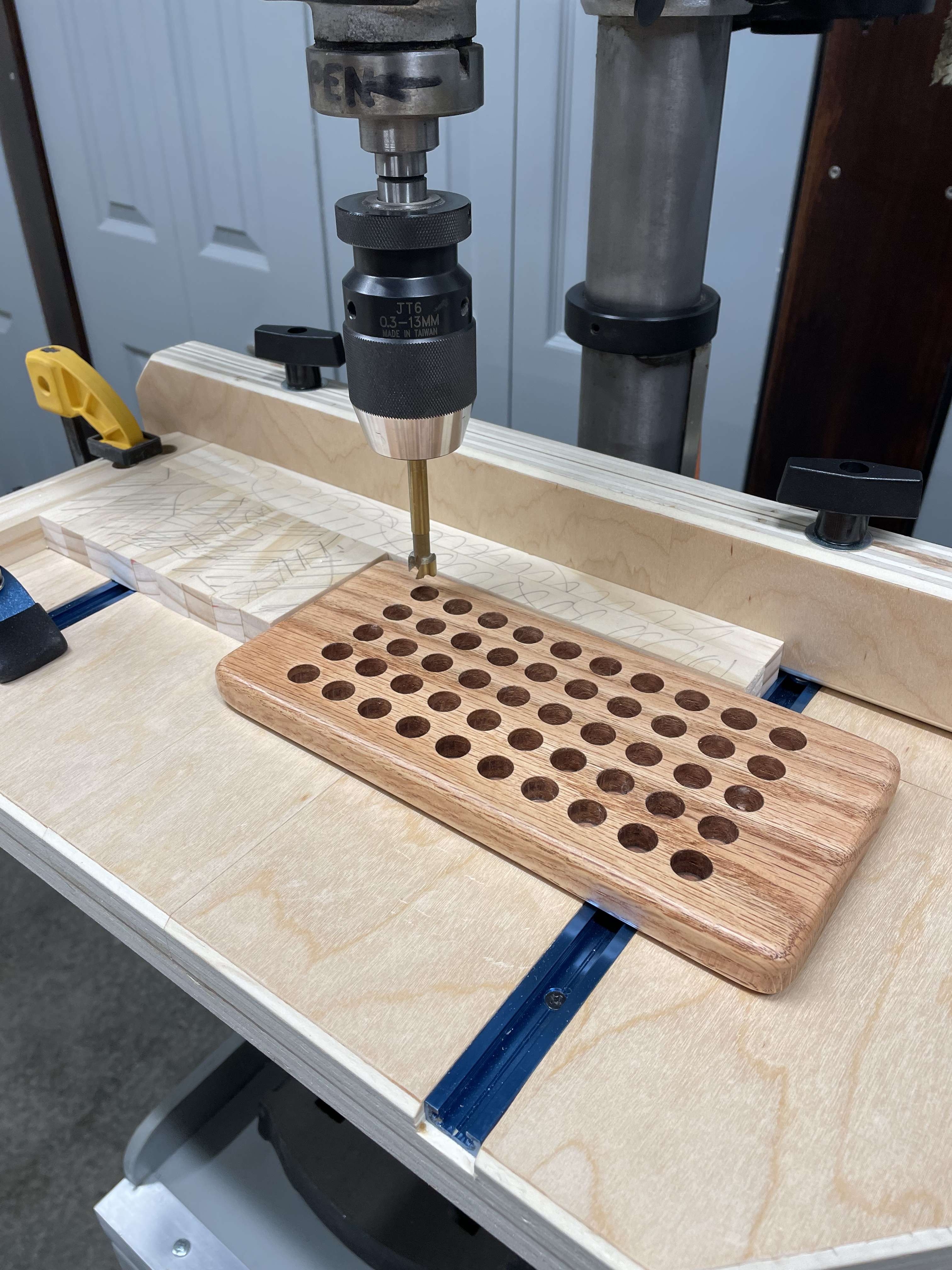

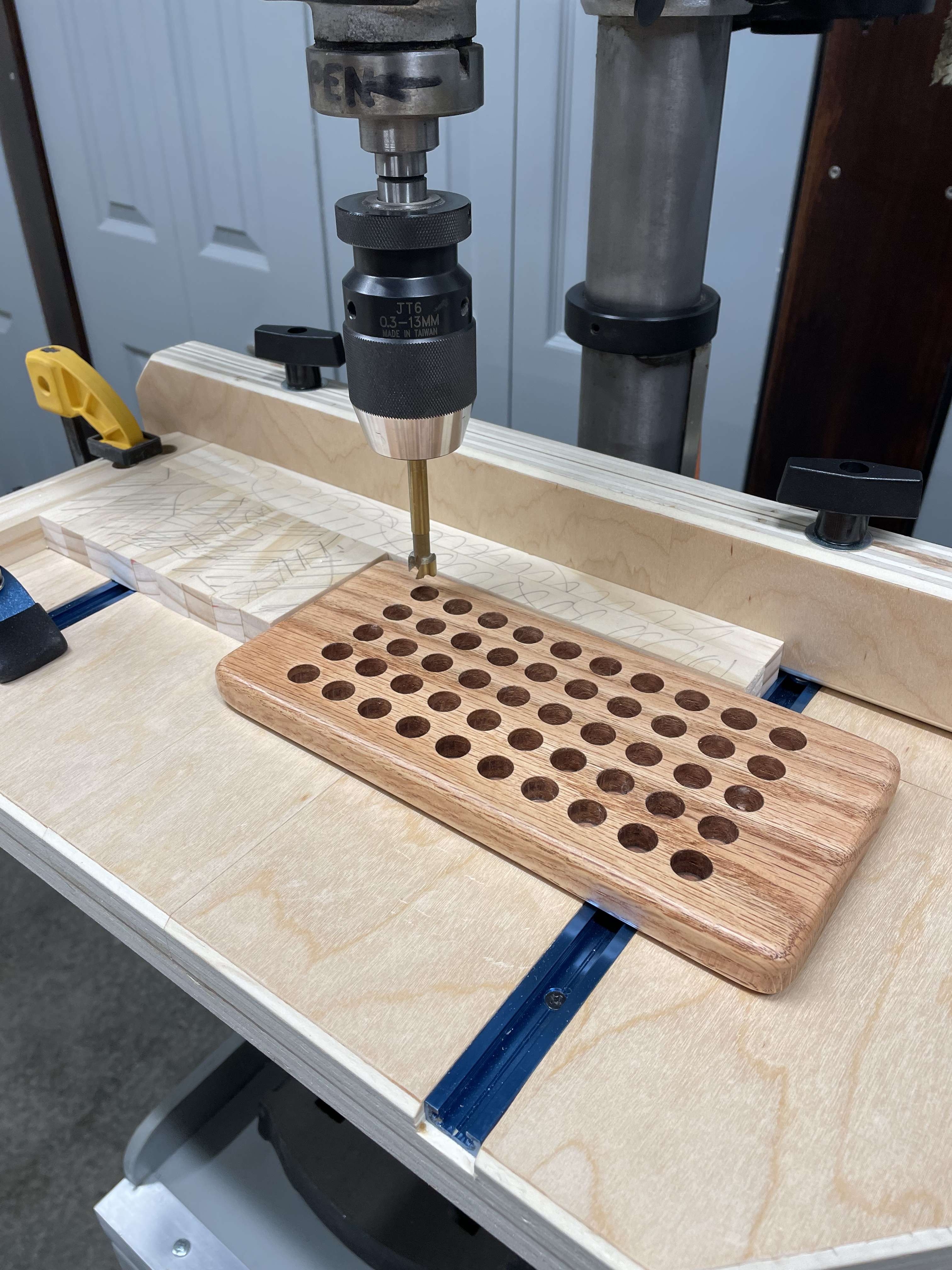

The easiest way I found to get consistent results were to make some spacers the size of the center to center spacing I wanted. For these I was after 3/4”. I cut two long pieces and a dozen small ones, nine short ones were used for this project. The pencil lines were to assure the correct side was up.

Set your fence and stop block to the center hole on both x and y axis on the right or left end, wherever you wish to start. Drill your first hole, insert a spacer next to the stop block, repeat till you reach your desired hole count.

To start a new line of holes insert one of the long spacers against the fence and repeat the drill a hole, insert spacer thing until you reach the end. If you have made the loading block to be the same distance edge to center of the holes on the end you can simply rotate the block and drill two rows of holes at each of the spacer settings.

Last pic shows both back spacers and all short ones.

If you wanted a different hole spacing it would be a simple matter of cutting your spacers to whatever size suits you.

I made these for the pattern to be 1-1/2“ in from the ends and 3/4” in from the sides.

Set your fence and stop block to the center hole on both x and y axis on the right or left end, wherever you wish to start. Drill your first hole, insert a spacer next to the stop block, repeat till you reach your desired hole count.

To start a new line of holes insert one of the long spacers against the fence and repeat the drill a hole, insert spacer thing until you reach the end. If you have made the loading block to be the same distance edge to center of the holes on the end you can simply rotate the block and drill two rows of holes at each of the spacer settings.

Last pic shows both back spacers and all short ones.

If you wanted a different hole spacing it would be a simple matter of cutting your spacers to whatever size suits you.

I made these for the pattern to be 1-1/2“ in from the ends and 3/4” in from the sides.

Last edited: