I'm working on testing methods and products and gathering data on bullet seating. I'll be posting some comprehensive data once I get to an appropriate point of collection, but I just got some interesting information that I though was worth sharing.

I bought an AMP Press a number of months ago and have been testing different neck lubes, different processes, annealing vs. not, etc. Tomorrow I'm heading out to BLM land to do some ~2k yard ELR with my 300, and some closer in stuff with my 6 BRA, which means tonight I'm doing a bunch of loading. For my 300, I tried two slightly different processes:

Process 1:

- Anneal

- Size

- Lube necks with moly (topic for another post, but I've found moly to be the best neck lube on annealed brass)

- Mandrel

- Trim

- Primer, charge, seat

Process 2:

- Anneal

- Size

- Lube necks with moly

- Mandrel

- Trim

- Lube a second time

- Primer, charge, seat

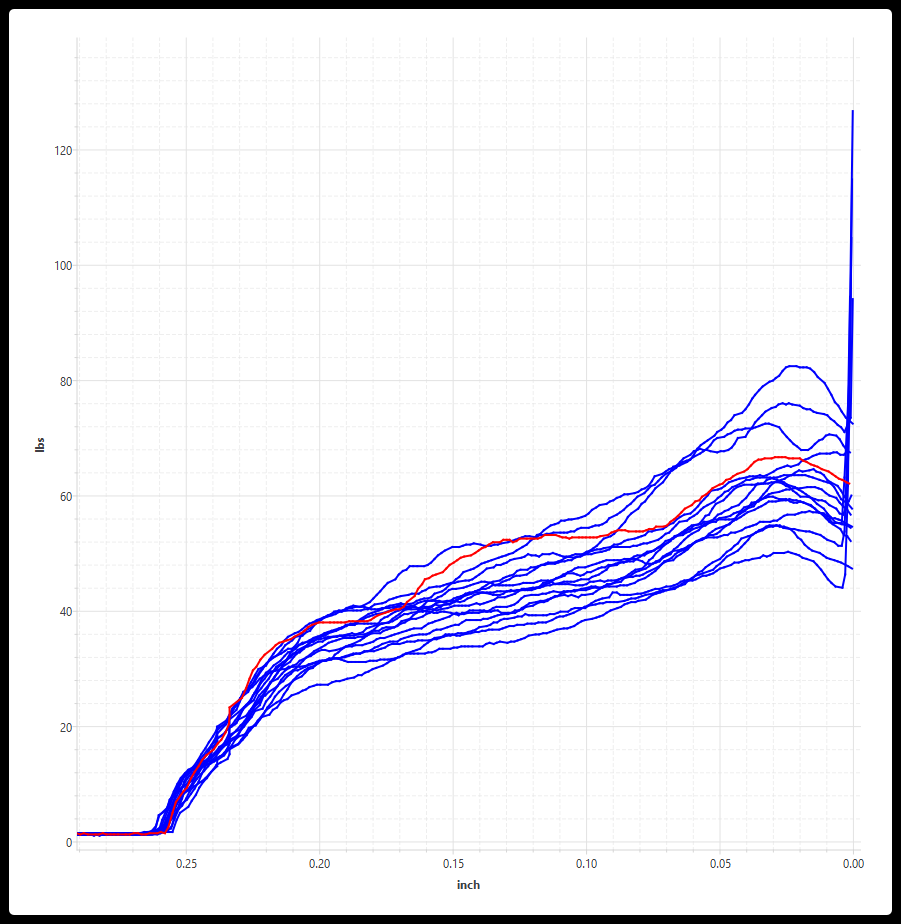

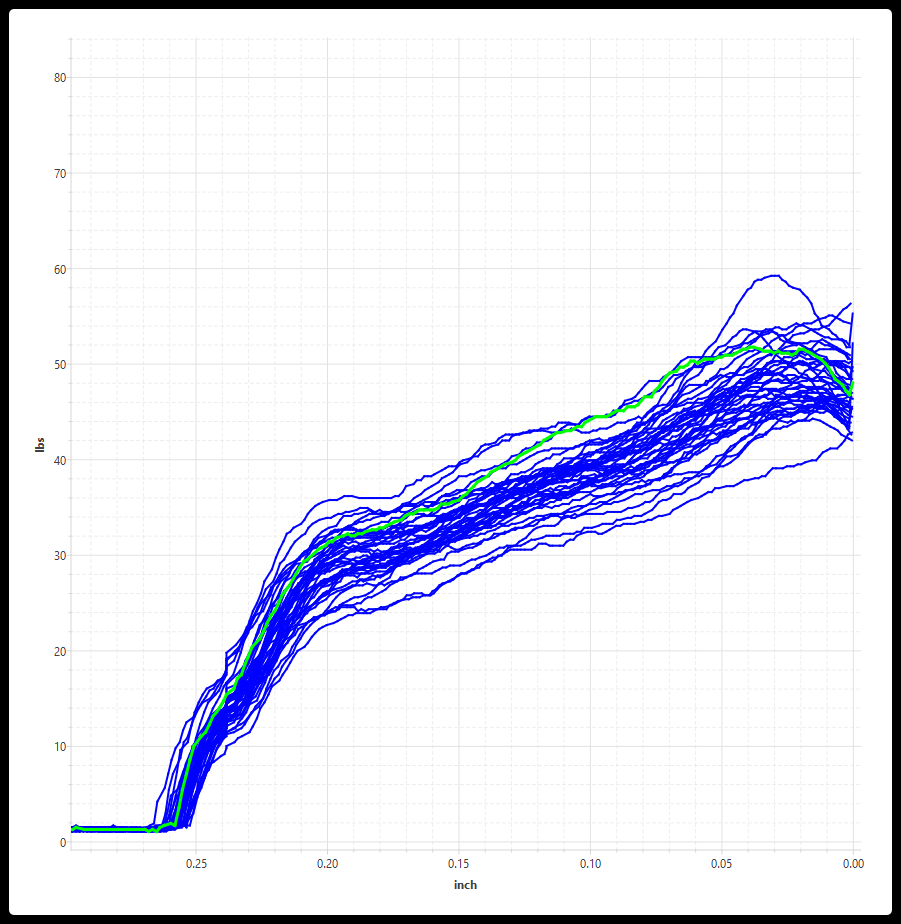

Below are the graphs from the AMP Press showing the difference. I did 16 on process 1 and 46 on process 2.

Process 1: Single neck lube before trim, primer, charge, etc.

Process 2: Neck lube before trim, then second neck lube before primer, charge, etc.

Notes:

- On process 1, some of the plots spike at the end because I needed to re-zero the press height

- You can see that the extra lube step on process 2 pretty dramatically brought in spread. It's about a 30lb spread on process 1 vs. a 16lb spread on process 2.

- I'll post the muzzle velocity results after I get back tomorrow.

- I'm expecting somewhat of an SD improvement from the set of process 1 vs process 2, as I've already documented a correlation between seating force SDs and muzzle velocity SDs in my Mandrel Musings thread.

- For my 6 BRA, the two different plots I've got show a stark difference - includes annealing vs. not for one firing. But there is also one other factor that plays a significant role that was unexpected. More on that later.

I bought an AMP Press a number of months ago and have been testing different neck lubes, different processes, annealing vs. not, etc. Tomorrow I'm heading out to BLM land to do some ~2k yard ELR with my 300, and some closer in stuff with my 6 BRA, which means tonight I'm doing a bunch of loading. For my 300, I tried two slightly different processes:

Process 1:

- Anneal

- Size

- Lube necks with moly (topic for another post, but I've found moly to be the best neck lube on annealed brass)

- Mandrel

- Trim

- Primer, charge, seat

Process 2:

- Anneal

- Size

- Lube necks with moly

- Mandrel

- Trim

- Lube a second time

- Primer, charge, seat

Below are the graphs from the AMP Press showing the difference. I did 16 on process 1 and 46 on process 2.

Process 1: Single neck lube before trim, primer, charge, etc.

Process 2: Neck lube before trim, then second neck lube before primer, charge, etc.

Notes:

- On process 1, some of the plots spike at the end because I needed to re-zero the press height

- You can see that the extra lube step on process 2 pretty dramatically brought in spread. It's about a 30lb spread on process 1 vs. a 16lb spread on process 2.

- I'll post the muzzle velocity results after I get back tomorrow.

- I'm expecting somewhat of an SD improvement from the set of process 1 vs process 2, as I've already documented a correlation between seating force SDs and muzzle velocity SDs in my Mandrel Musings thread.

- For my 6 BRA, the two different plots I've got show a stark difference - includes annealing vs. not for one firing. But there is also one other factor that plays a significant role that was unexpected. More on that later.