Right, but are you mixing it with alcohol or applying it dry? I've done moly coating but it's traditionally tumbled on bullets.When I use moly powder, I use a bore mop of the appropriate size for the case mouth.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post Your AMP Press Plots

- Thread starter Rocketmandb

- Start date

Right, but are you mixing it with alcohol or applying it dry? I've done moly coating but it's traditionally tumbled on bullets.

Ah. For dry moly I use the bore mop. I use q-tips for liquid like neolube. I've also used small paint brushes. But q-tip seems faster.

I'm going to try pouring neolube into a dish with a waterline at the neck/shoulder junction. Dip the case neck down, wipe the outside off with rag and put case into loading tray.

I use q-tips with Neo and just swab the necks. That's why I'm asking about Moly. I hate dealing with moly coating bullets and why I went to HBN 15+ years ago. Eventually I just stopped coating bullets. Swabbing necks is much easier in small scale.Ah. For dry moly I use the bore mop. I use q-tips for liquid like neolube. I've also used small paint brushes. But q-tip seems faster.

I'm going to try pouring neolube into a dish with a waterline at the neck/shoulder junction. Dip the case neck down, wipe the outside off with rag and put case into loading tray.

How are you guys applying the Moly?

I use essentially the same 1mm plastic spheres that the graphite lube from Imperial uses. Dip it in multiple times then wipe off the outside with a rag/old t-shirt.

I bought a bag of the spheres on Amazon and put them into little plastic jars (also bought on Amazon) - just add moly.

EDIT: Dry moly

to stir the pot in this topic too?

No, genuinely curious. I've done quite a bit of testing with brass prep and never found very much of it to really make changes or make changes that were worth the effort for me, but this appears to show a new layer of resolution in at least one portion of the process that we didn't have or couldn't record easily before.

If you can clearly trend something, that's worth knowing and quantifying.

I'm going to try pouring neolube into a dish with a waterline at the neck/shoulder junction. Dip the case neck down, wipe the outside off with rag and put case into loading tray.

I'm going out to the hills on Saturday to lob a bunch of lead out to 2k (and shorter). I'm going to load a bunch of 300, 6mm and virgin 308. I might try this on some of my 6mm cases.

Recommendation on dry time for this?

I'm going out to the hills on Saturday to lob a bunch of lead out to 2k (and shorter). I'm going to load a bunch of 300, 6mm and virgin 308. I might try this on some of my 6mm cases.

Recommendation on dry time for this?

5-10 at min should be plenty I'd think. The alcohol should almost flash dry.

Wipe the necks as soon as you dip them, easier to clean.

I'm going out to the hills on Saturday to lob a bunch of lead out to 2k (and shorter). I'm going to load a bunch of 300, 6mm and virgin 308. I might try this on some of my 6mm cases.

Recommendation on dry time for this?

Also, FWIW, I've found that putting the cases in container or tray neck up works the best. I tried it neck down so any excess would run out. But too much ended up runny out. For some reason it doesn't migrate down into the body as much as it runs out the neck when upside down.

And do it before priming. Since dipping, might be getting a good amount of excess.....don't want it running down and into the primer. Into the body doesn't seem to matter, since its essentially carbon.

I was trying to resist, but...

@Rio Precision Gunworks, I said your data is suspect (actually, more like useless) because you're not testing for anything useful so far in how it pertains to making better ammo. You're just testing which lube works best when seating bullets in less-than-ideal cases.

You're going back and forth with ways to apply lube to the inside of the necks of cases... missing the fact that the inside of dirty/fired brass is already coated with a thin layer of graphite (aka carbon, which is what graphite is made from).

Fired cases, unlike a chamber that's seen hundreds of rounds developing a carbon ring, only develop a thin, relatively uniform coating of carbon, the thickness of which has to be measured in microns (with the excess cooking off during combustion, and forming that carbon ring in your chamber I mentioned). Even after multiple firings, it doesn't accumulate enough to even measure it with calipers or common tools one has in the average reloading room.

I don't care what one old Benchrest guy said one time, they also tell tall tales about mythical "nodes" and such too. Cleaning the inside of case necks is a mistake and bad practice.

The AMP press measures friction if you distill it down... and unless/until you find a way to apply lube to the inside of case necks as evenly and uniformly as combustion does, you're just wasting your time looking for what is second best (more like fourth best, since lube on top of graphite-coated brass is slicker than lube on bare brass).

@Cascade Hemi I'm not trying to come at you, I'd just figure out what lube works for you and roll, I'd just say don't clean your necks lol.

@Rio Precision Gunworks, I said your data is suspect (actually, more like useless) because you're not testing for anything useful so far in how it pertains to making better ammo. You're just testing which lube works best when seating bullets in less-than-ideal cases.

You're going back and forth with ways to apply lube to the inside of the necks of cases... missing the fact that the inside of dirty/fired brass is already coated with a thin layer of graphite (aka carbon, which is what graphite is made from).

Fired cases, unlike a chamber that's seen hundreds of rounds developing a carbon ring, only develop a thin, relatively uniform coating of carbon, the thickness of which has to be measured in microns (with the excess cooking off during combustion, and forming that carbon ring in your chamber I mentioned). Even after multiple firings, it doesn't accumulate enough to even measure it with calipers or common tools one has in the average reloading room.

I don't care what one old Benchrest guy said one time, they also tell tall tales about mythical "nodes" and such too. Cleaning the inside of case necks is a mistake and bad practice.

The AMP press measures friction if you distill it down... and unless/until you find a way to apply lube to the inside of case necks as evenly and uniformly as combustion does, you're just wasting your time looking for what is second best (more like fourth best, since lube on top of graphite-coated brass is slicker than lube on bare brass).

@Cascade Hemi I'm not trying to come at you, I'd just figure out what lube works for you and roll, I'd just say don't clean your necks lol.

Last edited:

I was trying to resist, but...

I said your data is suspect (actually, more like useless) because you're not testing for anything useful so far in how it pertains to making better ammo. You're just testing which lube works best on less-than-ideal cases.

You're going back and forth with ways to apply lube to the inside of the necks of cases... missing the fact that the inside of dirty/fired brass is already coated with a thin layer of graphite (aka carbon, which is what graphite is made from).

Fired cases, unlike a chamber that's seen hundreds of rounds developing a carbon ring, only develop a thin, relatively uniform coating of carbon, the thickness of which has to be measured in microns (with the excess cooking off during combustion, and forming that carbon ring in your chamber I mentioned). Even after multiple firings, it doesn't accumulate enough to even measure it with calipers or common tools one has the average reloading room.

The AMP press measures friction if you distill it down... and unless/until you find a way to apply lube to the inside of case necks as evenly and uniformly as combustion does, you're just wasting your time looking for what is second best.

LOL. There's several in this thread that have already tested this. As well as many others not in this thread. Fired brass with carbon left in the neck on average performs second best to fired brass that is cleaned completely and then lubed with a well performing lube like NeoLube.

But, last week you were telling everyone your experience and data is better than Applied Ballistics. So it lines up pretty well that you're gonna double down on this. Essentially, you're now saying that your ammo is better than the likes of Tony Boyer.

People like you are why people/places such as Cortina, Applied Ballistics and several others all stay behind paywalls and off public forums.

Maybe you guys don't realise that the latest research studies are reporting primer pressures of 3KPsi + well before powder ignition & one study reports the primer pressure wave front compressing the powder & pushing the projectile out of the neck up to 20 to 30 mm into the rifling.

With this latest revelation, it's very unlikely that either neck preparation, neck tension or neck ID coating could make much if any difference.

With this latest revelation, it's very unlikely that either neck preparation, neck tension or neck ID coating could make much if any difference.

You have to remember that he also doesn’t believe load development has any effectLOL. There's several in this thread that have already tested this. As well as many others not in this thread. Fired brass with carbon left in the neck on average performs second best to fired brass that is cleaned completely and then lubed with a well performing lube like NeoLube.

But, last week you were telling everyone your experience and data is better than Applied Ballistics. So it lines up pretty well that you're gonna double down on this. Essentially, you're now saying that your ammo is better than the likes of Tony Boyer.

People like you are why people/places such as Cortina, Applied Ballistics and several others all stay behind paywalls and off public forums.

You have to remember that he also doesn’t believe load development has any effect

What's this "load development" you speak of?

With this latest revelation, it's very unlikely that either neck preparation, neck tension or neck ID coating could make much if any difference.

Then why are many of us seeing and measuring differences in performance by varying the above parameters?

Thinking about this, though, if what you postulate is true (I have no information to say one way or the other), then I'd argue that minor differences in effective neck tension (combination of all of the above) would actually have MORE impact on the bullet, because the forces applied against the bullet by the neck are a higher ratio against the forces pushing the bullet.

If X is the effective neck tension, then X/3000psi is far greater than X/60000psi and therefore impacts the bullet dynamics more.

Just to be clear, I am not postulating that the primer pushes the projectile into the barrel & clear out of the case. It's been measured with specifically designed equipment.Then why are many of us seeing and measuring differences in performance by varying the above parameters?

Thinking about this, though, if what you postulate is true (I have no information to say one way or the other), then I'd argue that minor differences in effective neck tension (combination of all of the above) would actually have MORE impact on the bullet, because the forces applied against the bullet by the neck are a higher ratio against the forces pushing the bullet.

If X is the effective neck tension, then X/3000psi is far greater than X/60000psi and therefore impacts the bullet dynamics more.

With regard to the primer generated pressures when compared to neck tension, it's basically irrelevant as far as I can see. 20 Lb, 30 Lb, 50 LB 120 lb of neck tension is virtually non existent. In the latest study that I have, specialised equipment measuring the primer at the base of the case showed pressures of 15KPi & as high as 25KPi although most were around 5KPi. The most important information gleaned from the tests was how early in the interior ballistics cycle these pressures were generated & were well before powder ignition.

The very basic math for a very simplistic estimation would be more in line with ( 3KPi-33Psi ). The 33 Psi in the equation represents a figure of roughly 50Lb of projectile seating force of a .308" calibre cartridge, provided my conversions are correct.

Although none of the testing covered neck tension, I find it difficult to believe that such minor forces could have much if any effect on the outcome.

Although none of the testing covered neck tension, I find it difficult to believe that such minor forces could have much if any effect on the outcome.

I agree, it's difficult to believe, but they do have an effect. Many people have proven it. I've measured how consistency in bullet seating force, which has a correlation to effective neck tension, manifests in SDs.

Regardless, believe it, or not, that's your prerogative. I've proven it to my satisfaction, whether or not it is within your realm of belief is for you to decide.

Where you state that "many people have proven it" is really the crux of the issue here. This presupposes that the testing undertaken was "statistically significant" & so we get back to the old argument of what people think statistical significance is & how to achieve it.I agree, it's difficult to believe, but they do have an effect. Many people have proven it. I've measured how consistency in bullet seating force, which has a correlation to effective neck tension, manifests in SDs.

Regardless, believe it, or not, that's your prerogative. I've proven it to my satisfaction, whether or not it is within your realm of belief is for you to decide.

For example, there have been many commissioned studies on the velocity stability of military ammunition &, although it appears to be represented by a wider, shallower gaussian curve than high quality handloads, the general precepts of statistical analysis still apply whereby, given any particular probability weighting &, utilizing the calculated minimum number of samples to establish a reliable SD, it can be seen that the tails of the curve extend out between 3 SD & 6 SD. Due to the general belief that high level competition loads have a much narrower probability density, there is some controversy that 6SD is a true representation which, does appear to have some Merritt however, even if we ignore a 6SD probability density, we are still left with at least a 3SD two tailed probability density which I have never seen refuted. So, in relevant terms, anyone who claims to have a velocity SD of 5 (for arguments sake) upon continued testing see a two tailed distribution (<>) of 3SD = an SD of at least +/-15ft/sec either side of the established mean velocity. As I've stated before in earlier threads, the whole concept of results of a robust statistical analysis are completely misunderstood by the majority of people in that there is no absolute SD number which represents the reality of any situation, whether that be velocity, group size & etc... A Gaussian curve represents a probability density once a true SD has been established & that probability density is represented by the area under the curve & the left & right tails of the curve. An absolute SD number can only be used to calculate the probable variation or range which can be expected.

Below is the what the statistics tell us the variability will be based on a true SD.

- Around 68% of values are within 1 standard deviation from the mean.

- Around 95% of values are within 2 standard deviations from the mean.

- Around 99.7% of values are within 3 standard deviations from the mean.

I have read graduate level mathematical probability and statistics textbooks and understood them better than whatever you're trying to say.Where you state that "many people have proven it" is really the crux of the issue here. This presupposes that the testing undertaken was "statistically significant" & so we get back to the old argument of what people think statistical significance is & how to achieve it.

For example, there have been many commissioned studies on the velocity stability of military ammunition &, although it appears to be represented by a wider, shallower gaussian curve than high quality handloads, the general precepts of statistical analysis still apply whereby, given any particular probability weighting &, utilizing the calculated minimum number of samples to establish a reliable SD, it can be seen that the tails of the curve extend out between 3 SD & 6 SD. Due to the general belief that high level competition loads have a much narrower probability density, there is some controversy that 6SD is a true representation which, does appear to have some Merritt however, even if we ignore a 6SD probability density, we are still left with at least a 3SD two tailed probability density which I have never seen refuted. So, in relevant terms, anyone who claims to have a velocity SD of 5 (for arguments sake) upon continued testing see a two tailed distribution (<>) of 3SD = an SD of at least +/-15ft/sec either side of the established mean velocity. As I've stated before in earlier threads, the whole concept of results of a robust statistical analysis are completely misunderstood by the majority of people in that there is no absolute SD number which represents the reality of any situation, whether that be velocity, group size & etc... A Gaussian curve represents a probability density once a true SD has been established & that probability density is represented by the area under the curve & the left & right tails of the curve. An absolute SD number can only be used to calculate the probable variation or range which can be expected.

Below is the what the statistics tell us the variability will be based on a true SD.

- Around 68% of values are within 1 standard deviation from the mean.

- Around 95% of values are within 2 standard deviations from the mean.

- Around 99.7% of values are within 3 standard deviations from the mean.

The only data in that thread that is of any significance in terms of dispersion is on page two where "No graphite lube, no mandrel" and "Graphite lube, mandrel." Everything else is null.It helps immensely

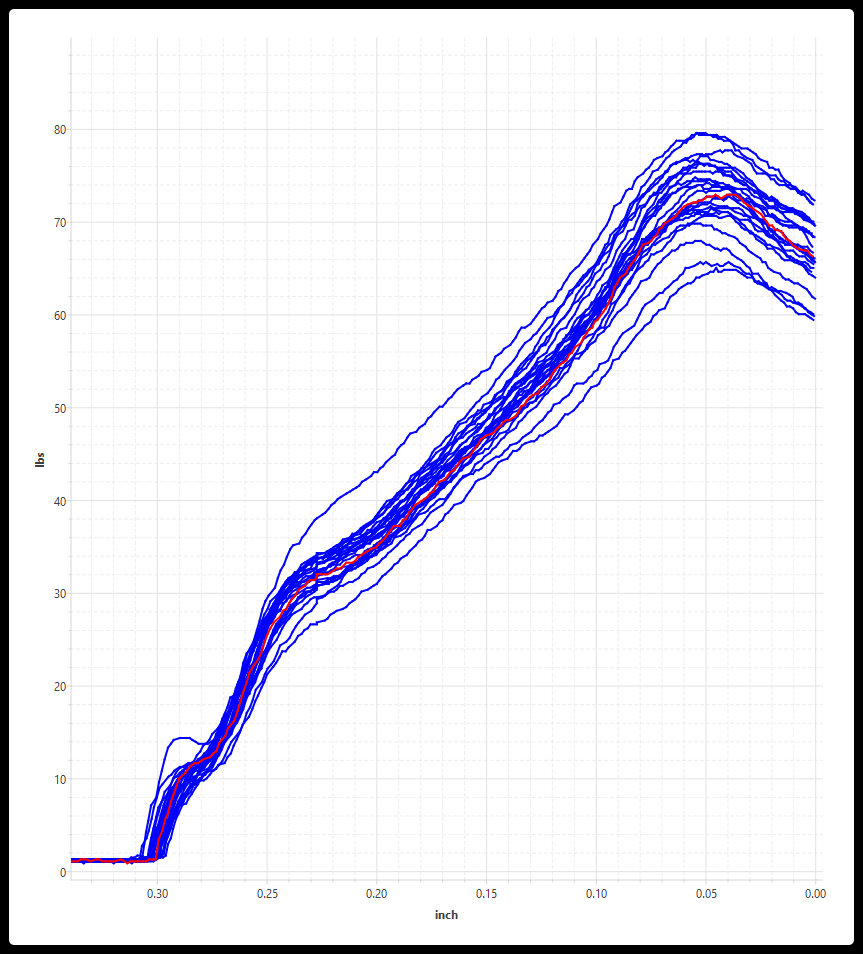

Examples from earlier 6 BRA plots:

Test with no mandrel, no lube:

View attachment 8371141

Test with mandrel, no lube:

View attachment 8371142

In my Mandrel Musings thread I documented that there is a correlation between seating force SDs and muzzle velocity SDs.

Mandrel Musings

When I first got my K&M arbor press for seating, I was somewhat surprised at the spread of the values of force required to seat bullets. Knowing that neck tension plays a significant role in ES/SD, I started doing various things to try to bring seating force in line. I had been doing most my...www.snipershide.com

Last edited:

Maybe you guys don't realise that the latest research studies are reporting primer pressures of 3KPsi + well before powder ignition & one study reports the primer pressure wave front compressing the powder & pushing the projectile out of the neck up to 20 to 30 mm into the rifling.

With this latest revelation, it's very unlikely that either neck preparation, neck tension or neck ID coating could make much if any difference.

If by "latest" you mean well over a decade ago.........sure. This isn't anything new. Hence why you can still get a squib when you forget to put powder in a case.

I'd have to read over any specific testing on this. Anecdotally, you can observe some rounds missing powder produce a squib and some rounds missing powder do not.

Which would indicate that the 3-5k pressure isn't enough to universally start a bullet into the rifling. Which would in turn indicate that that it's very possible your neck prep dictates if the premier ignition pressure is enough to dislodge the bullet. Obviously a powdered case and not powdered are different animals though.

What is the ass is this new witchcraft? (Amp has a press? dear god my pocketbook...)

Can't tell if serious...........

(The press has been on market for several years now)

What kind of brass prep for these?

It's not the statistics I'm trying to explain. It's the application of the results which most don't seem to understand.I have read graduate level mathematical probability and statistics textbooks and understood them better than whatever you're trying to say.

The truth of the matter is that the vast majority of what is called "testing" is not statistically significant. Not withstanding that, it is my belief that for most purposes, a reasonable approximation of SD would suffice but, even in the event that a good approximation is used, the application is then bastardized.

Anyhow, here is a study which reveals a great deal about primer pressure generated & the relevant time frames measured. There are 1 or 2 more that I have to track down which are very interesting due to how & where the pressure measurements were derived.

Last edited:

Out of interest, what was the CBTO to the lands or, how far off the lands from the max listed CBTO?

0.02” jam to 0.08” jumpOut of interest, what was the CBTO to the lands or, how far off the lands from the max listed CBTO?

Yeah right. (meaning yes, that's interesting or seems ok)0.02” jam to 0.08” jump

Well that is definitely in the range where GRT makes fairly critical changes to it pressure curve algorithms.

If I may, how many samples per CBTO per neck mandrel dia were measured?

Last edited:

View attachment 8373373

Only loaded 10 so pretty small sample size. 6br

Pretty tight, and interesting full-up linear plot after the initial bit. What are you doing for brass prep?

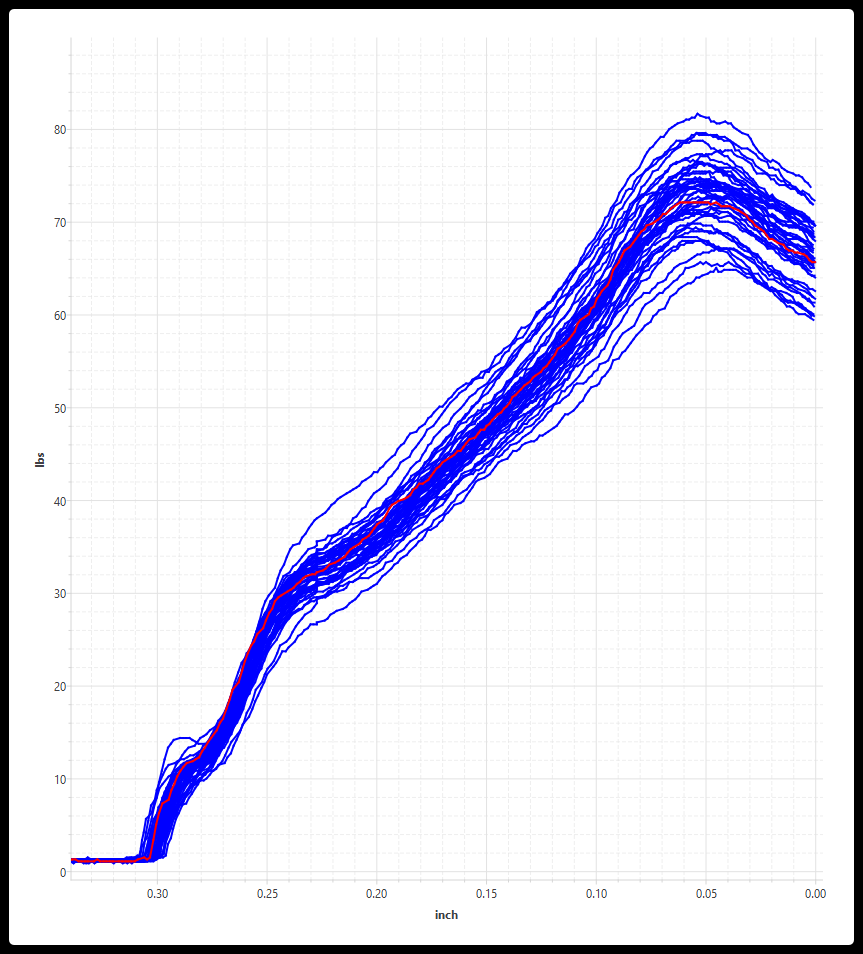

Two new plots - this time 300 PRC. First one is my standard process:

FL Size

Dry moly

Mandrel

Trim

Dry moly

Prime-Charge-Seat

25 cases done:

45 cases done:

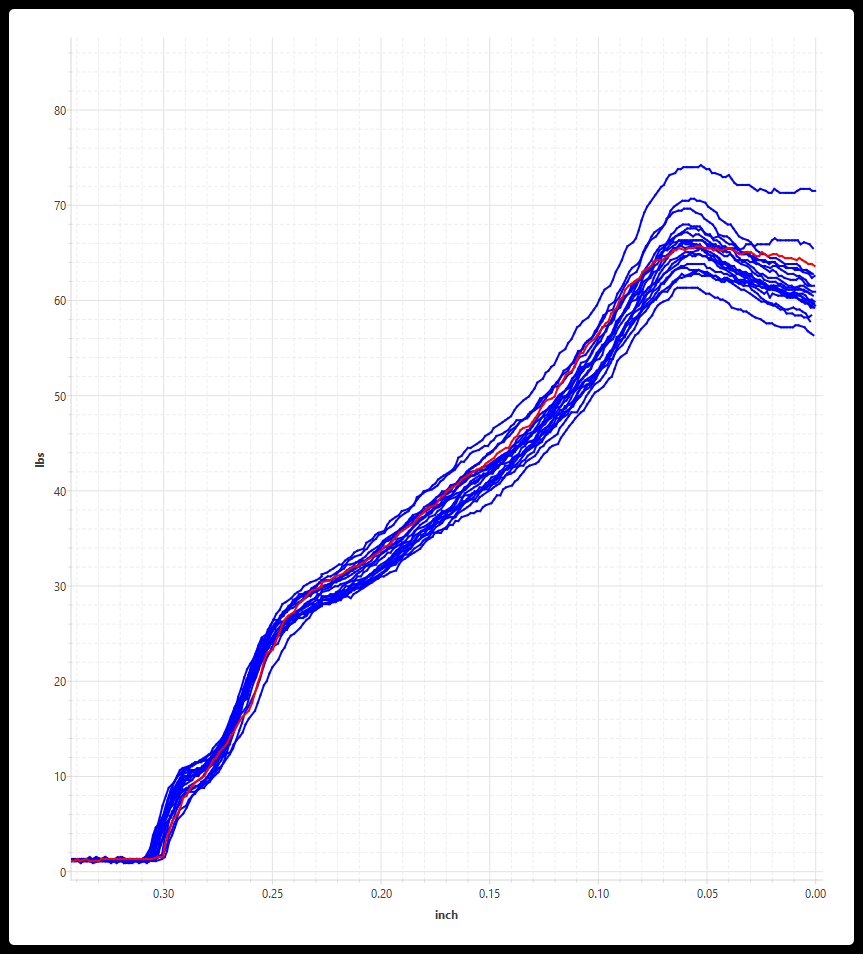

Second is same process, but instead of the second dry moly, I used Neo Lube and dipped the case necks instead of painting them with a Q-Tip like I did before (with only mediocre results).

20 cases

Synopsis:

The neck-dipped Neo Lube cases look to be more consistent on this case. If not for the one high flyer on the Neo Lube plot, this would have been about a 10 lb spread, with most falling within about 7 lb, which is pretty good for the 300 PRC.

FL Size

Dry moly

Mandrel

Trim

Dry moly

Prime-Charge-Seat

25 cases done:

45 cases done:

Second is same process, but instead of the second dry moly, I used Neo Lube and dipped the case necks instead of painting them with a Q-Tip like I did before (with only mediocre results).

20 cases

Synopsis:

The neck-dipped Neo Lube cases look to be more consistent on this case. If not for the one high flyer on the Neo Lube plot, this would have been about a 10 lb spread, with most falling within about 7 lb, which is pretty good for the 300 PRC.

aneal

Dry tumble in corn cob

Resize using area 419 die with .242 mandrel

Dry tumble again in corn cob

Run through my Henderson trimmer

Then run a brush right before seating.

I wish my seating pressure was lower but for whatever reason my 6br brass has always had a high seating pressure compared to my dasher. But it’s very consistent so I can’t complain much

Dry tumble in corn cob

Resize using area 419 die with .242 mandrel

Dry tumble again in corn cob

Run through my Henderson trimmer

Then run a brush right before seating.

I wish my seating pressure was lower but for whatever reason my 6br brass has always had a high seating pressure compared to my dasher. But it’s very consistent so I can’t complain much

Pretty tight, and interesting full-up linear plot after the initial bit. What are you doing for brass prep?

That's something I've been meaning to attempt to figure out. I'll probably put work into it this week or next.

Figure out what/why there are at times an initial spike, then moving up, some have a couple spikes, and other even just have a peak that rounds off and doesn't spike. I've even seen some graphs where it starts looking like the test die plot.

I doubt knowing the reasons why (obviously we can probably guess why, but I want to know if you can predict it and/or eliminate the spike) will actually make better ammo, as all the types of plots have ammo that shoots well in them. But, it's never bad to understand more.

I want to say that neck turned brass is more apt to have either a rounded spike or no real spike at all. Which would make sense.....thinner wall + consistent wall.

I want to say that neck turned brass is more apt to have either a rounded spike or no real spike at all. Which would make sense.....thinner wall + consistent wall.

I think that's my next thing to play with. Worked wonders with ADG brass - not sure how much effect it'll have on Lapua.

Here's another paper which measures bullet engraving pressure.

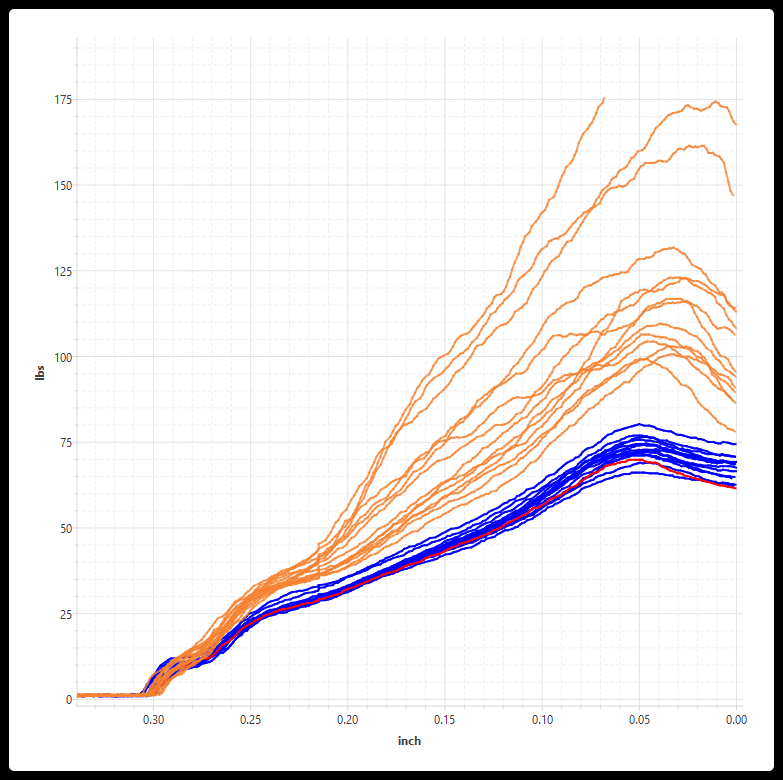

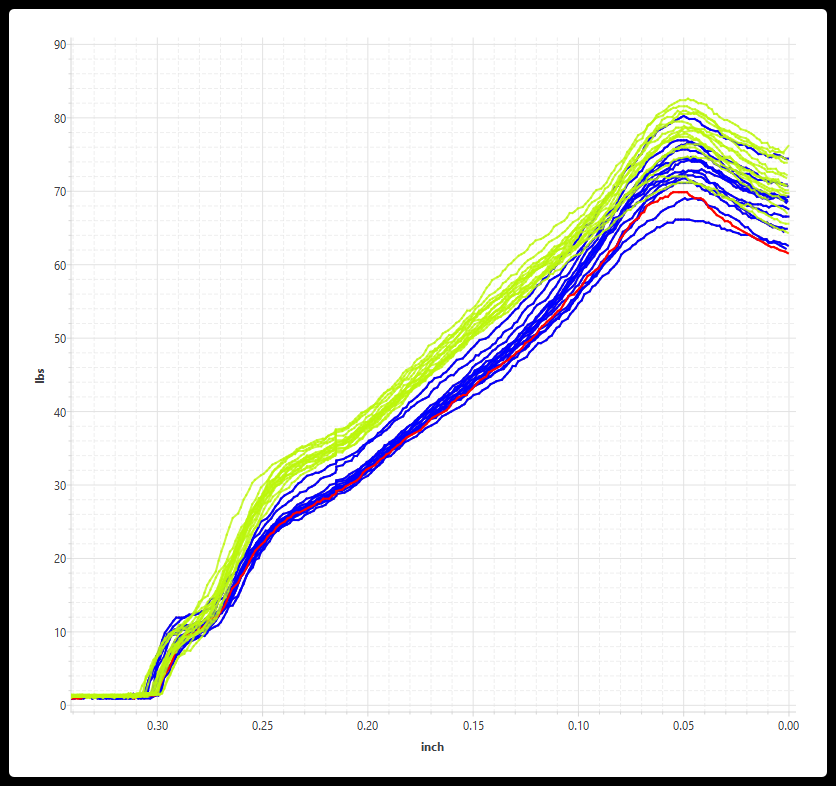

Three new plots to share overlaid on two graphs.

The baseline for both of these is using Neo Lube (dip method) after using a mandrel. The first comparison is the baseline (blue) vs using no lube at all.

EDIT: I should have mentioned that this was for the 300 PRC.

This is a pretty pronounced difference. It will be interesting to see how these chrono against each other.

The next one is baseline (orange) vs. applying NeoLube before the mandrel step (green). The purpose of this experiment was to see if there was any meaningful difference, thereby saving me a pre- or post-mandrel lubrication step.

Clearly, the seating force of the pre-mandrel lubed bullets is higher - not a ton higher, but higher nonetheless. This is an expected result, as you'd presume that some of the lube would come off on the mandrel. The thing is, while the average seating force is slightly higher, the spread is very similar (essentially the same at 13lb baseline vs. 12lb for the challenger).

I'll be going out to the hills on Saturday to take these out to a little more than a mile. I'll report back on the chrono data.

The baseline for both of these is using Neo Lube (dip method) after using a mandrel. The first comparison is the baseline (blue) vs using no lube at all.

EDIT: I should have mentioned that this was for the 300 PRC.

This is a pretty pronounced difference. It will be interesting to see how these chrono against each other.

The next one is baseline (orange) vs. applying NeoLube before the mandrel step (green). The purpose of this experiment was to see if there was any meaningful difference, thereby saving me a pre- or post-mandrel lubrication step.

Clearly, the seating force of the pre-mandrel lubed bullets is higher - not a ton higher, but higher nonetheless. This is an expected result, as you'd presume that some of the lube would come off on the mandrel. The thing is, while the average seating force is slightly higher, the spread is very similar (essentially the same at 13lb baseline vs. 12lb for the challenger).

I'll be going out to the hills on Saturday to take these out to a little more than a mile. I'll report back on the chrono data.

Last edited:

Three new plots to share overlaid on two graphs.

The baseline for both of these is using Neo Lube (dip method) after using a mandrel. The first comparison is the baseline (blue) vs using no lube at all.

View attachment 8389081

This is a pretty pronounced difference. It will be interesting to see how these chrono against each other.

The next one is baseline (orange) vs. applying NeoLube before the mandrel step (green). The purpose of this experiment was to see if there was any meaningful difference, thereby saving me a pre- or post-mandrel lubrication step.

View attachment 8389083

Clearly, the seating force of the pre-mandrel lubed bullets is higher - not a ton higher, but higher nonetheless. This is an expected result, as you'd presume that some of the lube would come off on the mandrel. The thing is, while the average seating force is slightly higher, the spread is very similar (essentially the same at 13lb baseline vs. 12lb for the challenger).

I'll be going out to the hills on Saturday to take these out to a little more than a mile. I'll report back on the chrono data.

Curious to see what, if any, downrange performance can be measured between the different procedures.

Curious to see what, if any, downrange performance can be measured between the different procedures.

The only true measurement is at the muzzle. You could shoot groups, but it introduces the randomness of the shooter. Since most my shooting is ELR, I do care quite a bit about velocity. We'll see how the three groups measure out on Saturday.

The only true measurement is at the muzzle. You could shoot groups, but it introduces the randomness of the shooter. Since most my shooting is ELR, I do care quite a bit about velocity. We'll see how the three groups measure out on Saturday.

I agree about the groups.

Will be interesting to see if there's any measurable difference in SD's.

I get lower SD's with NeoLube.

How much did your SD's drop with neolube? And did this occur across all cartridges you reload for?

I get lower SD's with NeoLube.

I haven't measured SDs yet using NeoLube vs my previous go-to of dry Moly, but the seating plots came out very similar, which means the SDs would be similar too. However, dipping with Neolube is significantly quicker to apply and actually less messy.

How much did your SD's drop with neolube? And did this occur across all cartridges you reload for?

I've only measured it for 6GT. I don't have the information in front of me but two or three from memory. That is NeoLube to uncleaned brass though.

I use foam q-tips from Amazon. The seating pressure difference is noticeable between dry and NeoLube. I don't measure seating force but I can feel the difference in pull. I'm seating with .004" interference.I haven't measured SDs yet using NeoLube vs my previous go-to of dry Moly, but the seating plots came out very similar, which means the SDs would be similar too. However, dipping with Neolube is significantly quicker to apply and actually less messy.

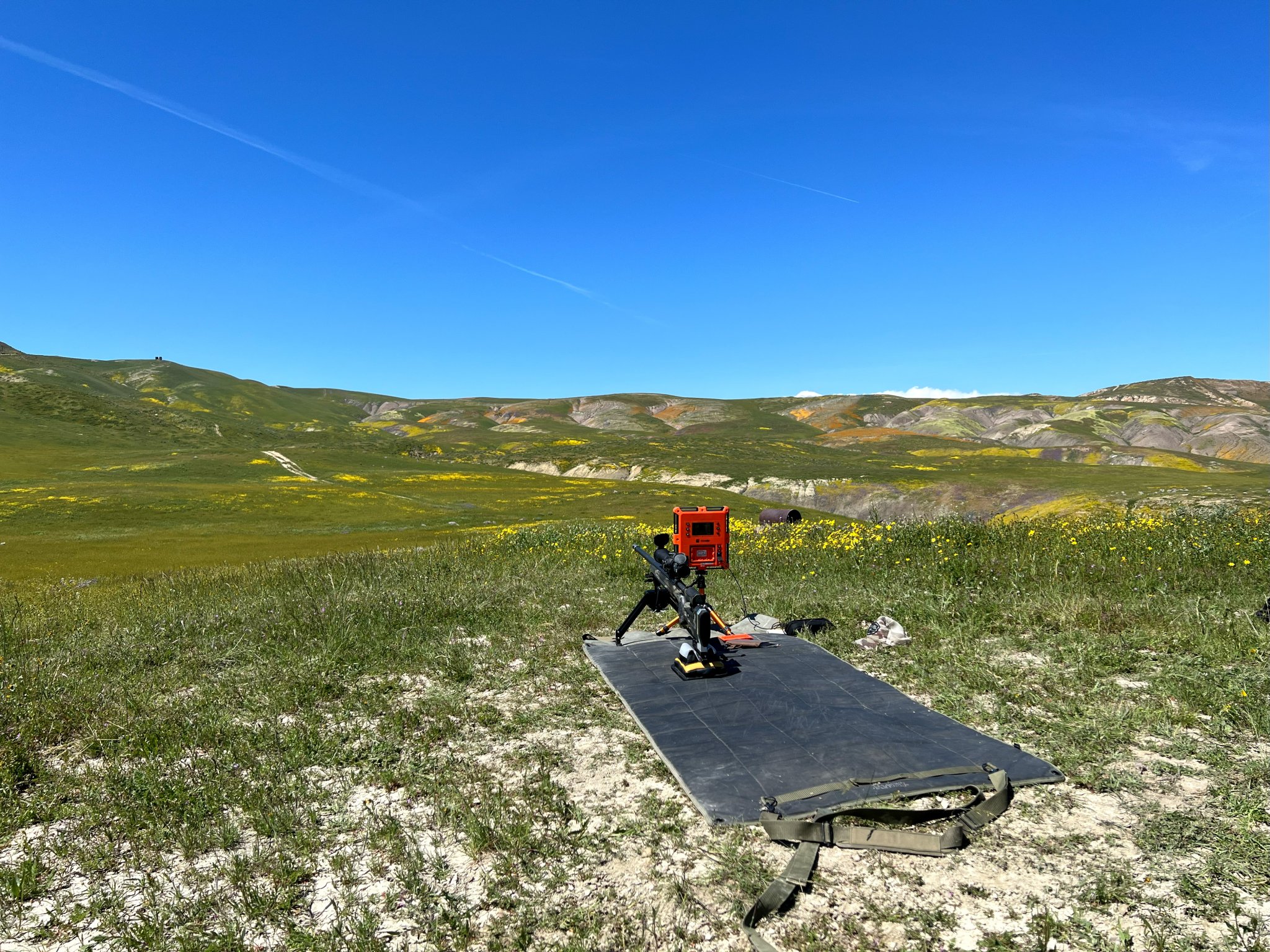

So, I was hoping to shoot yesterday in this:

Trying to get there, I got this:

When you're going up hill on a shelf road in 4WD low, and you're doing so sideways because you have no traction due to mud filling your treads, it's time to turn around. I have to say that coming down carried much more pucker factor than going up. I don't care to do that again.

The end result is actually positive for the purposes of this thread. We ended up finding a spot just out of the hills and set a target at just under 500 yards to shoot groups.

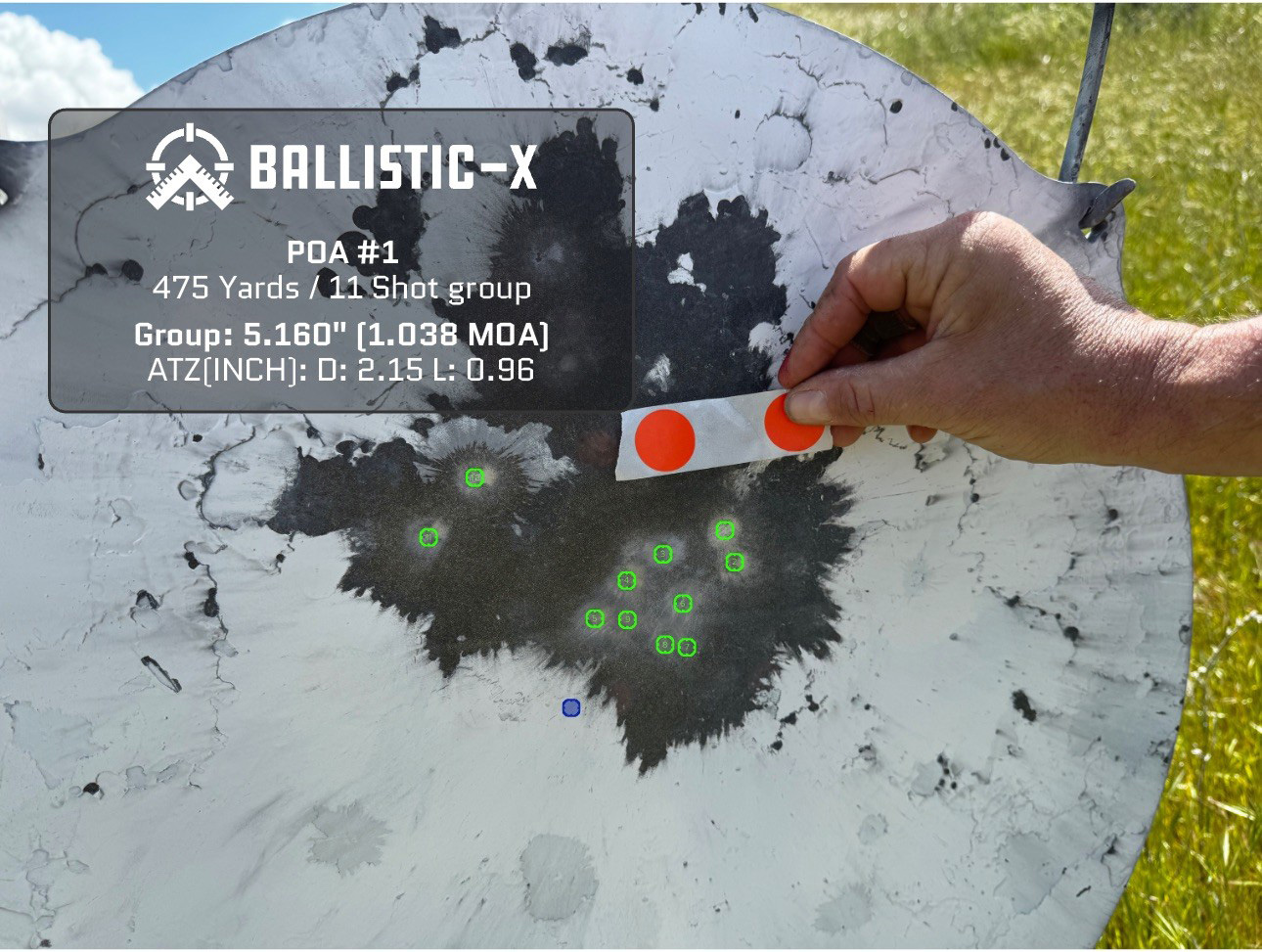

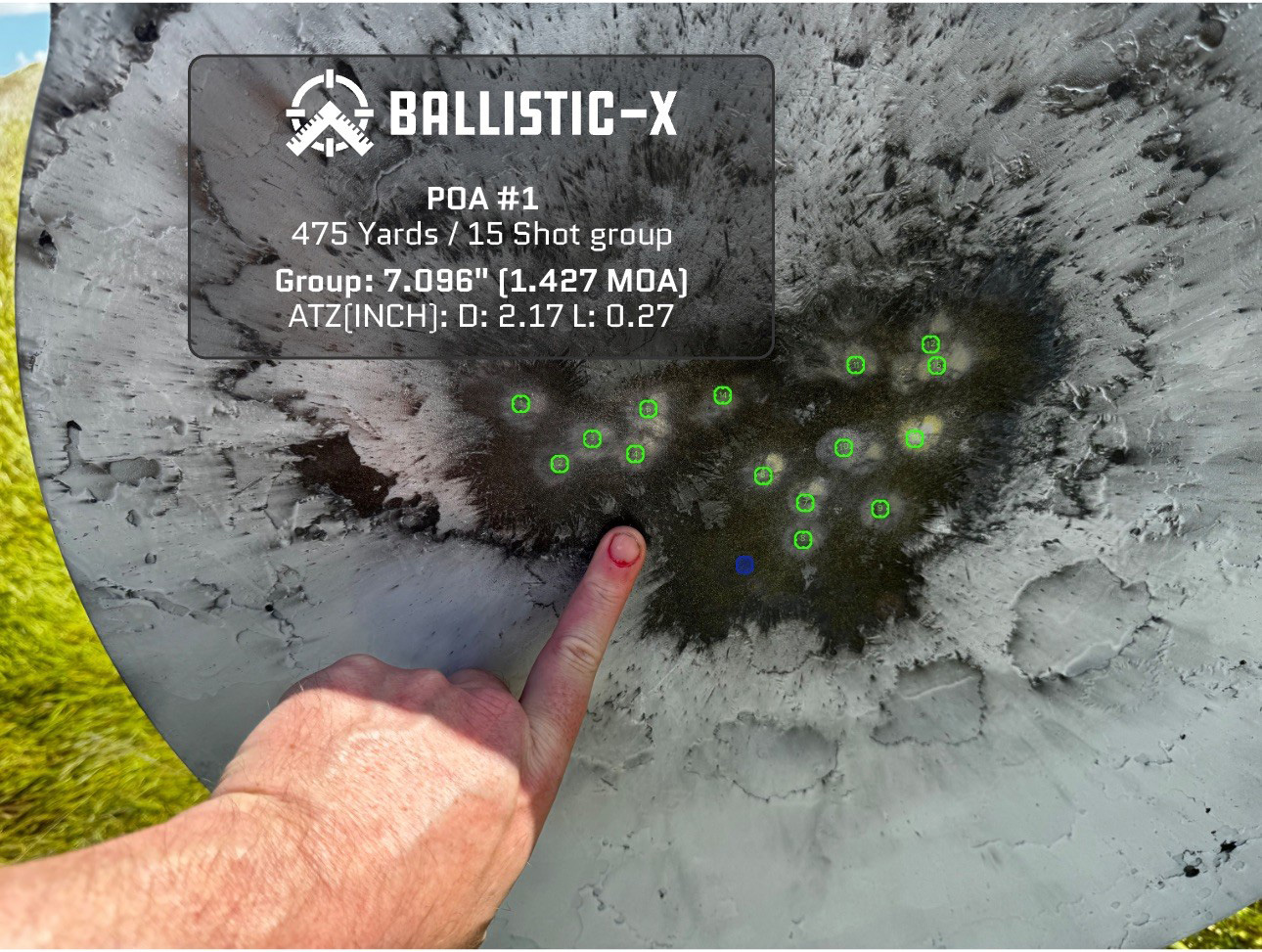

I shot 14 shots of the "champion" lube process (lube after mandrel - one bad primer in this group), 13 of the one where I lubed before mandrel, and 15 of no lube. The SD results were not surprising.

The first two came in essentially the same at the same of 6.6 and 6.3 fps respectively. The no lube group came in at 8.4 fps.

The big surprise to me was grouping. I hadn't anticipated doing anything group related, but due to my near-death experience on the attempt to get to our normal shooting spot we had the "opportunity" to do so. Below are pics of the 13-shot group and the 15-shot no lube group.

On the 13-shot group these were the first we shot of the day. My scope had gotten away from zero and the first shot was high, I adjusted for the second (still too high), then shot the remaining 11. The results are below:

The dispersion on the no-lube group is measurably higher than the lube group. I frankly didn't expect this. I expected some SD difference (which we got, but not this much dispersion difference.

Could this have been wind? It was maybe 3 - 8 mph all day, so I don't believe wind alone could be responsible. Could it have been me? Yes, I'll never rule that out. I'm not ready to make any conclusions based on this, but I may go run another test at a similar range - where I can actually drive to the target to paint - got to say that hoofing it 500 yards up and down stream beds and along steep terrain just to paint the target was not the most enjoyable.

@kthomas here is first evidence of downrange performance. As I mentioned, I'll likely do another bigger test a couple months down the road.

Trying to get there, I got this:

When you're going up hill on a shelf road in 4WD low, and you're doing so sideways because you have no traction due to mud filling your treads, it's time to turn around. I have to say that coming down carried much more pucker factor than going up. I don't care to do that again.

The end result is actually positive for the purposes of this thread. We ended up finding a spot just out of the hills and set a target at just under 500 yards to shoot groups.

I shot 14 shots of the "champion" lube process (lube after mandrel - one bad primer in this group), 13 of the one where I lubed before mandrel, and 15 of no lube. The SD results were not surprising.

The first two came in essentially the same at the same of 6.6 and 6.3 fps respectively. The no lube group came in at 8.4 fps.

The big surprise to me was grouping. I hadn't anticipated doing anything group related, but due to my near-death experience on the attempt to get to our normal shooting spot we had the "opportunity" to do so. Below are pics of the 13-shot group and the 15-shot no lube group.

On the 13-shot group these were the first we shot of the day. My scope had gotten away from zero and the first shot was high, I adjusted for the second (still too high), then shot the remaining 11. The results are below:

The dispersion on the no-lube group is measurably higher than the lube group. I frankly didn't expect this. I expected some SD difference (which we got, but not this much dispersion difference.

Could this have been wind? It was maybe 3 - 8 mph all day, so I don't believe wind alone could be responsible. Could it have been me? Yes, I'll never rule that out. I'm not ready to make any conclusions based on this, but I may go run another test at a similar range - where I can actually drive to the target to paint - got to say that hoofing it 500 yards up and down stream beds and along steep terrain just to paint the target was not the most enjoyable.

@kthomas here is first evidence of downrange performance. As I mentioned, I'll likely do another bigger test a couple months down the road.

Which picture goes to which treatment? Sounds like you had three batches, and I only see two pics?

Similar threads

- Replies

- 24

- Views

- 3K

- Replies

- 0

- Views

- 59