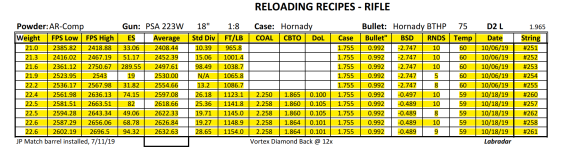

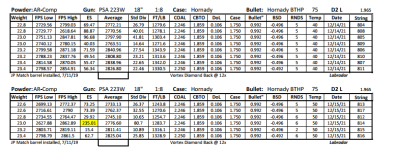

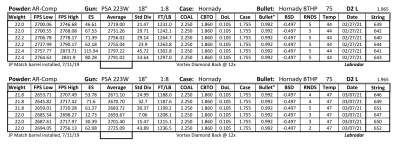

I have several precision bolt guns that I've manage to work up very accurate loads. Combination of QuickLoad, lots of Labradar strings and spreadsheet data analyses and worked up loads that pretty consistently yield 1/2" groups at 100Y. I also have a custom AR build as a semi-precision gun that I can't get to group. Really nice upper/lower/stock/trigger build with a JP Super Match 18" barrel and thermal dissipator. Had the barrel installation work done by the JP gunsmith, about $750 total. Get groups typically in the 1-1/2" +/- range. The gun SHOULD be good, can't get a consistent load. My other rifles are Lapua brass, Sierra bullets and Redding competition dies and getting SD's in the 4 to 9 range. Pretty happy with those. The 223 is the only setup using Honady Match dies, Hornady brass and Hornady 75g BTHP bullets. Brass prep includes bevel and chamfer necks, pocket prep. Using AR-Comp powder I'm getting SDs typically in the mid 20's up to the 40's. AR-Comp is NOT temperature stable if if they say it is. I finding velocity drop at higher temps, increase at lower temps. IE: 22.6g at 60 degrees = 2630fps, 22.6g at 40 degrees = 2755fps. 108% fill so 8% compress load with 100% burn.

I think the Hornady Match dies are giving very inconsistent neck tension and the AR-Comp is not giving consistent results. The only other powder I have that might work in 223 with 75g bullets is Varget. To achieve similar velocity QuickLoads shows 111% capacity with 93% powder burn. To slow of a burn.

I'm attaching one of the typical analysis/target sheets I typically do and the last page of the seven page spreadsheet of chrono data.

Frustrated.

I think the Hornady Match dies are giving very inconsistent neck tension and the AR-Comp is not giving consistent results. The only other powder I have that might work in 223 with 75g bullets is Varget. To achieve similar velocity QuickLoads shows 111% capacity with 93% powder burn. To slow of a burn.

I'm attaching one of the typical analysis/target sheets I typically do and the last page of the seven page spreadsheet of chrono data.

Frustrated.

Attachments

-

Reloading Recipes-Rifle (PSA 223) pg7.pdf85.1 KB · Views: 219

-

SeriesData_PSA-223 #806_12-14-21 ([email protected] Target.pdf211.6 KB · Views: 142