I got the idea from 375 ultra mag thread.

I decided to do a 375 Rum with a 40* shoulder, moved ahead .053" and taper reduced to .006"

A guy over on that forum had done a similar cartridge several years ago and called it the 375 Box Monkey Express.

Initially I tried to seat the bullet hard into the lands to jam the case head against the bolt face but that wasn't working. I believe the firing pin strike was pushing the case onto the bullet causing excessive head space and I was almost getting case head separations. I ended up having to neck them up to .416 and then size back down to .375 and make a false shoulder (wish I'd have taken pictures of those cases). I ended up with some fairly crooked necks so I had to trim off a bit more than I would have liked.

I have the intention to run this rifle at Ko2M Canada which has a 10k Joules limit, I was hoping to get the 390gr A-tips to 2900 fps. which I can get it there but the node seems to be around 2870 unless the barrel speeds up which I'm not expecting now. I have about 140 rounds through it (including 100 FF)

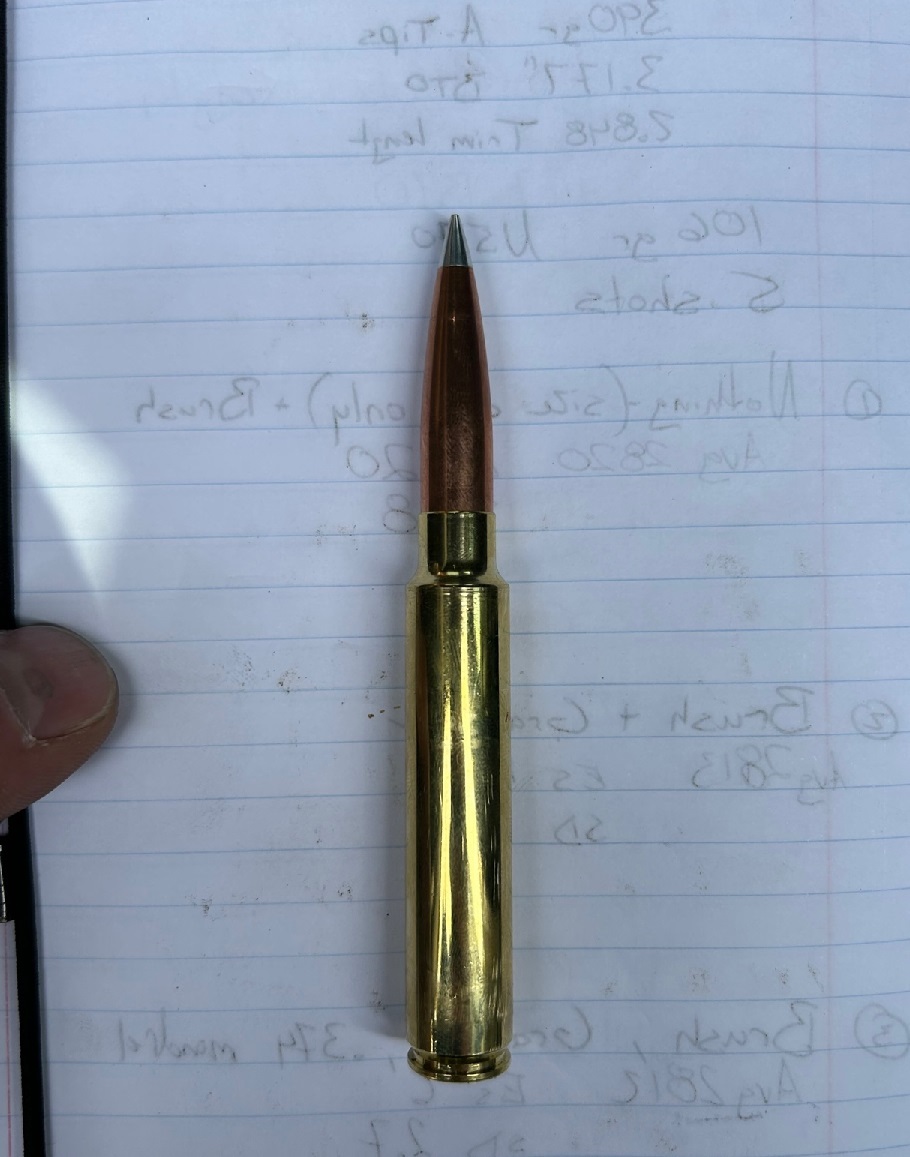

-Formed case on the left, Factory brass right.

I did initial powder test 104-110 gr and never saw pressure to stop (I don't have this data handy)

Second powder ladder was 107-112gr N570, with 390 A-tips. BTO 3.177" (barrel 32" long, 1:9 twist)

107- 2830 fps

108- 2840 fps

109- 2875 fps

110- 2893 fps (very faint ejector mark)

111- 2898 fps (light ejector mark)

112- 2940 fps (light ejector mark, Bolt click at top)

Next I went to testing load stability. I did 5 Shot groups and on paper they all shot the same about 1.25" which I am not happy about so I hope I can bring that in with seating depth.

108 - 2858 fps, ES 9, SD 3

109 - 2881 fps, ES 8, SD 2

110- 2887 fps, ES 39, SD 16

111- 2906 fps, ES 43, SD 20

At 111 I started to notice a very slight click at the top of the bolt throw, that and the massive ES makes me want to stay away from here. I wish I would have loaded 107gr to see if the window goes that low. I am planning to run powder charge at 108.5 gr and do a seating depth test. I also have a couple new tricks to hopefully lower ES/SD a bit that I didn't do to these cases.

I also need to add some weight to the rig. It weighs about 20lbs. I have a steel arca rail coming that is about 3lbs and then I will likely add a bipod extension and a belly weight and see where it ends up.

I will try and post some groups when I get to seating depth testing.

I also have some solids to try at some point but I wanted to shoot these a-tips for the splash.

In the end I don't know if the effort of custom reamer and dies was worth it for the few FPS over what the standard chambering is doing but it's fun to learn. There is a few guys can say "I told you so" but I've got my fingers crossed it still picks up 30-40 fps

I decided to do a 375 Rum with a 40* shoulder, moved ahead .053" and taper reduced to .006"

A guy over on that forum had done a similar cartridge several years ago and called it the 375 Box Monkey Express.

Initially I tried to seat the bullet hard into the lands to jam the case head against the bolt face but that wasn't working. I believe the firing pin strike was pushing the case onto the bullet causing excessive head space and I was almost getting case head separations. I ended up having to neck them up to .416 and then size back down to .375 and make a false shoulder (wish I'd have taken pictures of those cases). I ended up with some fairly crooked necks so I had to trim off a bit more than I would have liked.

I have the intention to run this rifle at Ko2M Canada which has a 10k Joules limit, I was hoping to get the 390gr A-tips to 2900 fps. which I can get it there but the node seems to be around 2870 unless the barrel speeds up which I'm not expecting now. I have about 140 rounds through it (including 100 FF)

-Formed case on the left, Factory brass right.

I did initial powder test 104-110 gr and never saw pressure to stop (I don't have this data handy)

Second powder ladder was 107-112gr N570, with 390 A-tips. BTO 3.177" (barrel 32" long, 1:9 twist)

107- 2830 fps

108- 2840 fps

109- 2875 fps

110- 2893 fps (very faint ejector mark)

111- 2898 fps (light ejector mark)

112- 2940 fps (light ejector mark, Bolt click at top)

Next I went to testing load stability. I did 5 Shot groups and on paper they all shot the same about 1.25" which I am not happy about so I hope I can bring that in with seating depth.

108 - 2858 fps, ES 9, SD 3

109 - 2881 fps, ES 8, SD 2

110- 2887 fps, ES 39, SD 16

111- 2906 fps, ES 43, SD 20

At 111 I started to notice a very slight click at the top of the bolt throw, that and the massive ES makes me want to stay away from here. I wish I would have loaded 107gr to see if the window goes that low. I am planning to run powder charge at 108.5 gr and do a seating depth test. I also have a couple new tricks to hopefully lower ES/SD a bit that I didn't do to these cases.

I also need to add some weight to the rig. It weighs about 20lbs. I have a steel arca rail coming that is about 3lbs and then I will likely add a bipod extension and a belly weight and see where it ends up.

I will try and post some groups when I get to seating depth testing.

I also have some solids to try at some point but I wanted to shoot these a-tips for the splash.

In the end I don't know if the effort of custom reamer and dies was worth it for the few FPS over what the standard chambering is doing but it's fun to learn. There is a few guys can say "I told you so" but I've got my fingers crossed it still picks up 30-40 fps

Last edited: