I did not see a .408 reloading thread so figured I’d make one.

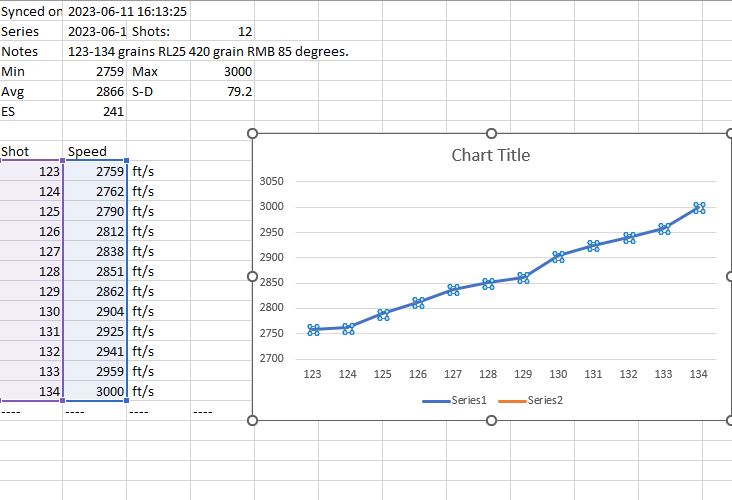

I did a pressure test with RL25 with 420 grain Parker Productions (Formerly known as RMB) this weekend. I loaded them .025 off the lands

At 134 grains I saw pressure signs start to show on the brass. No heavy bolt lift.

From what I have observed with Retumbo and these bullets they seem to like the 2850 range. So I will test the 128-129 grain charge next time I get to the range.

I used Peterson Brass & FED215 primers.

Rifle was a factory Desert Tech HTI 29” 1:13 barrel.

I did a pressure test with RL25 with 420 grain Parker Productions (Formerly known as RMB) this weekend. I loaded them .025 off the lands

At 134 grains I saw pressure signs start to show on the brass. No heavy bolt lift.

From what I have observed with Retumbo and these bullets they seem to like the 2850 range. So I will test the 128-129 grain charge next time I get to the range.

I used Peterson Brass & FED215 primers.

Rifle was a factory Desert Tech HTI 29” 1:13 barrel.

Last edited: