I have a load worked up for my Tikka CTR in 6.5 CR with RL26 over 147 Hornady ELDM . Best 5 shot group is just under 1/2 MOA with an SD of 2 and ES of 5, only hit that once though. It will usually run around an SD of 8 and ES of 15. Im getting MV's in the 2867 range. To date Ive only taken the 147's out to 650yrds but I was able to make hits constantly, on a 6in. plate in 25mph winds. I prefer this load over the RL16 over 140's load for both accuracy and MV. Hope that helpsAnyone run any of these recipes in a Tikka? What you getting for MV, ES and SD? Also how far off the lands are you? Thanks

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 Creedmoor 147 Gr ELD-M. RL16, RL26, H4831SC, H4350 Test and Data

- Thread starter EDMJustin

- Start date

Excellent info I just got A tikka 6.5 CM I have some RL 26 on the way but have some h4350 so I loaded some up last night I started at 40 which I should have done less but to late now, Hodgdon max is 41.8 and I ran into sticky bolt at 41.3, looking at the cases in better light seem to show pressure on pretty much all of them from 40+, 41 grains was a great group for me too. I’m .015 off the lands.

Maybe give them a bigger jump. You may find your pressures won’t be as high either.

I’ll give that a try thanks

Start at .030 off.

Hodgdon data uses Hornady brass. Your Lapua brass has lower case volume.

Hodgdon data uses Hornady brass. Your Lapua brass has lower case volume.

Start at .030 off.

Hodgdon data uses Hornady brass. Your Lapua brass has lower case volume.

Ok great thanks, 41 was a good group just had slight swipes, if I find a charge with a good group will changing seating depth make it go to shit or does it typically follow the charge through different seating depths? I’ll back off .03 and go from 39.5-41 and see if it still shows pressure

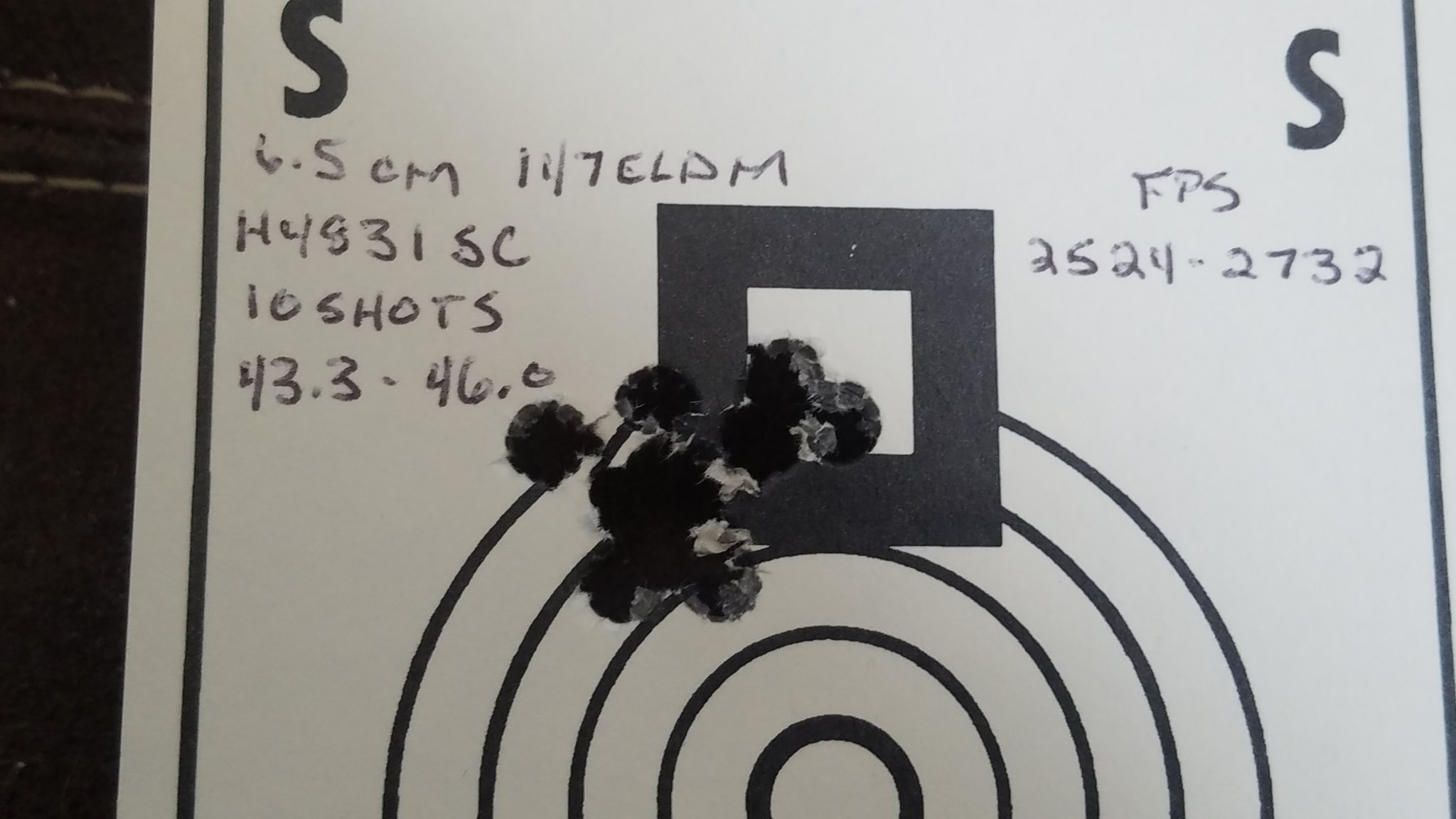

On the advice of others on here I ran a ladder to check velocity and pressure with H4831sc and the 147eldm. The group for the ten shot string was very similar to what I observed with H1000 with more speed but very little vertical dispersion over a 2.7 grain spread.

I wasn't totally focused on the group but wasn't being sloppy either.

6.5 Creedmoor Lapua brass

CCI450

43.3 2524fps

43.6 2555

43.9 2594

44.2 2615

44.5 2655

44.8 2656

45.1 2689

45.4 2689

45.7 2724

46.0 2732

I wasn't totally focused on the group but wasn't being sloppy either.

6.5 Creedmoor Lapua brass

CCI450

43.3 2524fps

43.6 2555

43.9 2594

44.2 2615

44.5 2655

44.8 2656

45.1 2689

45.4 2689

45.7 2724

46.0 2732

Ok fellas something is not right with the Tikka, all of the cases showed pressure even at mild charges, I looked at the cases from the first box I put through it factory hornAdy 140’s all of them show pressure as well. I chambered a brand new empty lapua case and when I ejected it there were marks from the extractor, I chambered it 3 times and this is what it looks like.

Thanks!! That's great work! I'm currently running 41.8 gn H4350 behind the 147's. Have you tried the new Berger 156gn'ers? Those are blistering loads with the RL26! I'll be looking forward to Phase 2!! That 41-42 gn H4350 looks an interesting prospect. Thanks again!So I have been lurking for a while now, I have made a few posts here and there, but nothing with much contribution yet. Now it is time to put up some meaningful data for all of you. I have noticed it can be hard to find load data on the Hornady 147 Gr ELD-M for the 6.5 Creedmoor. So I did some research and bought a few powders that interested me for this. I chose 4 different powders, loaded up 50 rounds of each, took it to the range and here are the results for anyone who is interested.

The powders I tested were RL16, RL26, H4831 SC, H4350. After testing all four I had great results with all of the in different ways. I will let you all be the judge of what might work for you. This data will hopefully help anyone trying to choose a good powder for the 147 ELD-M.

Use Caution when using any of these loads, be sure start low and work your way up. All these loads below, start high and get over recommended charges. Don't be a fool and blow up your tool.

The Rifle

View attachment 6905571

View attachment 6905576

Action - Defiance Deviant

Barrel - 26" Krieger 1:8 MTU

Break - Area 419 Hellfire

Trigger- Timney Calvin Elite 2 Stage

Chassis - MDT ESS

Rings - ARC M10 Medium

Scope - Minox ZP5 5-25x56

The Ammo

Bullet - Hornady 147 Gr ELD-M

Brass- Virgin Lapua Small Rifle 6.5 CM

Primer - CCI 450

OAL - 2.263

.020 Off the lands

Testing was done at my local range at 100m. Temperature was 22c with 30km wind gusting to 60km. Altitude was 805m above sea level. Sorry but all you guys from the USA will have to convert that from Canadian on your own eh.

Test #1 - RL16

Charge Muzzle Vel. SD ES Group Size "

40.3 2658 9.8 26 1.637

40.6 2687 8.1 18 .998

40.9 2707 6.0 13 .495

41.2 2721 5.6 15 .926

41.5 2749 8.1 22 .754

41.8 2771 6.6 15 .852

42.1 2788 4.5 12 .802

42.4 2808 9.8 26 .735

42.7 2835 6.7 14 1.040

43.0 2851 6.3 14 .926

View attachment 6905572

Test #2 - RL26

Charge Muzzle Vel. SD ES Group Size "

45.3 2715 4.7 12 .757

45.6 2759 8.7 22 .563

45.9 2776 9.5 25 .855

46.2 2794 6.4 16 .834

46.5 2817 5.1 13 .896

46.8 2844 9.2 21 .529

47.1 2855 6.9 19 1.093

47.4 2881 9.6 25 .905

47.7 2904 11 30 .739

48.0 2917 9.4 23 .826

View attachment 6905573

Test #3 - H4831 SC

Charge Muzzle Vel. SD ES Group Size "

42.5 2614 9.0 25 .516

42.8 2631 6.7 16 .555

43.1 2642 11 28 .826

43.4 2665 7.0 18 .668

43.7 2682 6.2 15 .915

44.0 2696 7.6 15 .507

44.3 2714 5.9 14 .437

44.6 2733 5.0 12 .878

44.9 2746 10.8 27 .607

45.2 2760 4.5 10 1.010

View attachment 6905574

Test #4 - H4350

Charge Muzzle Vel. SD ES Group Size "

40.0 2657 7.9 21 .971

40.3 2690 11 30 .888

40.6 2688 8.7 21 .799

40.9 2706 4.0 10 .799

41.2 2719 2.4 6 1.159

41.5 2737 4.7 12 .467

41.8 2750 4.4 11 .742

42.1 2769 9.9 25 .494

42.4 2792 2.6 7 .556

42.7 2806 7.4 19 .806

View attachment 6905575

After doing these tests I thought I would have a clear winner but now I just want to test these all more thoroughly. So this test has turned into phase 1 now. I will see what kind of fine tuning I can do to these in the future. I will keep you all posted when phase 2 is completed and I will post the results for you all.

Nothing is wrong. What you have is a minimum headspace dimension chamber with brass that essentially is "perfect fit" from the bolt face to the datum on the shoulder.Ok fellas something is not right with the Tikka, all of the cases showed pressure even at mild charges, I looked at the cases from the first box I put through it factory hornAdy 140’s all of them show pressure as well. I chambered a brand new empty lapua case and when I ejected it there were marks from the extractor, I chambered it 3 times and this is what it looks like.View attachment 7310743View attachment 7310744View attachment 7310745View attachment 7310746

Load, fire, reload the brass. Rinse, repeat. Have fun.

Nothing is wrong. What you have is a minimum headspace dimension chamber with brass that essentially is "perfect fit" from the bolt face to the datum on the shoulder.

Load, fire, reload the brass. Rinse, repeat. Have fun.

Thank you, there’s a little resistance closing the bolt with a case and nothing when empty, is that of any concern or just run it as it?

Slight resistance is OK. As long as you can feed, chamber, fire, extract, and eject without issue, then all is well.Thank you, there’s a little resistance closing the bolt with a case and nothing when empty, is that of any concern or just run it as it?

Yup just a little snug, I take it I’ll just go off velocity because I can’t read pressure signSlight resistance is OK. As long as you can feed, chamber, fire, extract, and eject without issue, then all is well.

Yup just a little snug, I take it I’ll just go off velocity because I can’t read pressure sign

I think @clcustom1911 is on the money with that but one other thing you can check just to eliminate one other possibility is verify that your ejector plunger on the bolt face isn't gummed up and causing additional restistence.

Just pull the bolt and use pin punch and depress the plunger and see if it is easily compressing to flush with the bolt face.

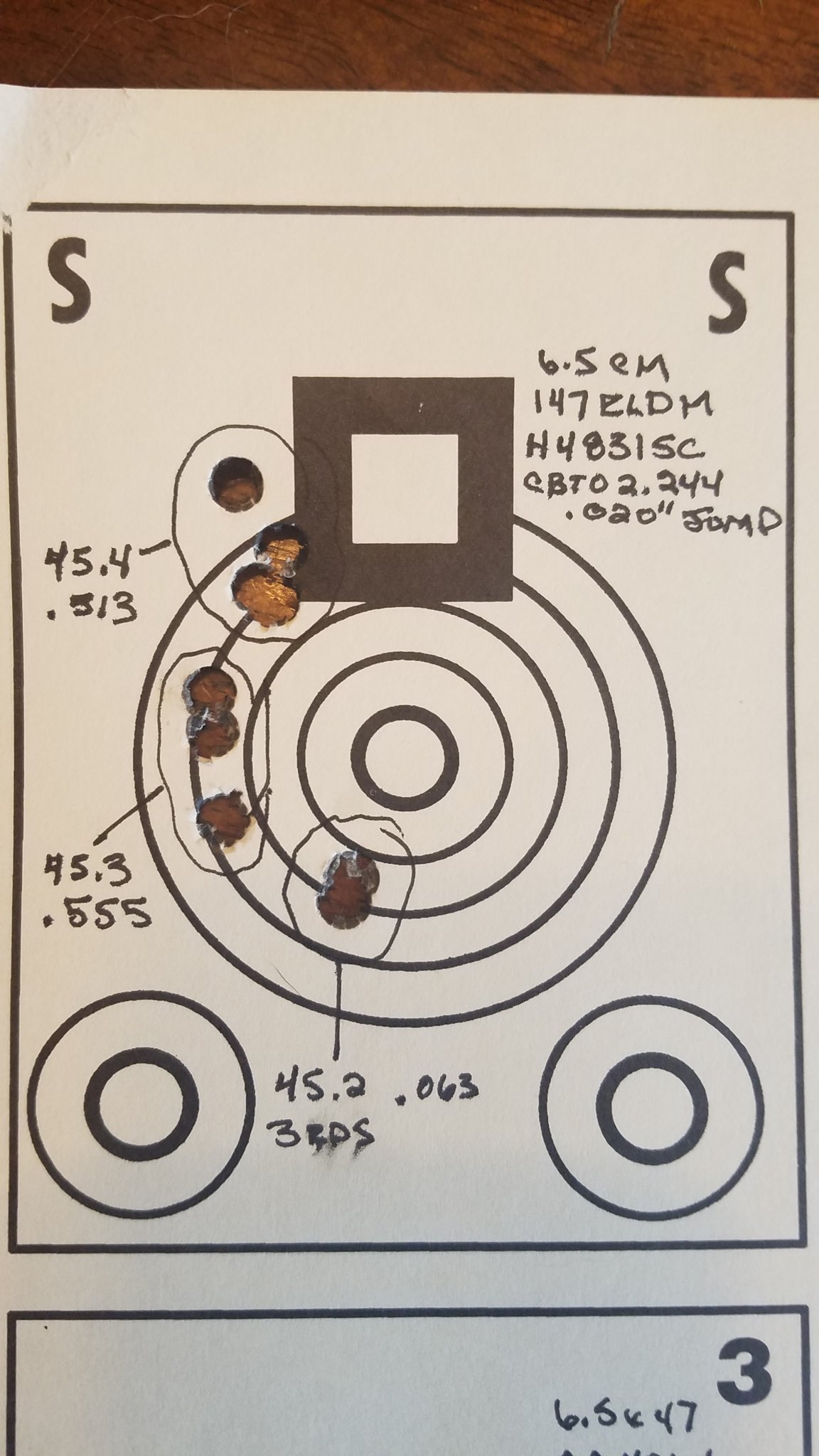

I ran a quick and dirty OCW test yesterday with H4831SC and the 147eldm in once fired Lapua brass.

The 45.4 charge was the only one that was 4 rounds and I believe would have been better but I really think I pulled the last shot when one of the guys a couple of benches down touched off a 50BMG as I was breaking the shot.

Either way the first 3 rd group was cold bore included and was .063" so can't really see improving on that.

Not bad at just shy of 2700fps from a 23" barrel with the 147eldm.

Barrel is a Bartlien 5r M24 profile 1-7.5 twist with SAAMI. 199" FB chambered by Kelblys

I need to load up 30-40 rounds at 45.2 and see how they hold up at 600 and 1200 yards when the winds aren't being to bitchy.

The 45.4 charge was the only one that was 4 rounds and I believe would have been better but I really think I pulled the last shot when one of the guys a couple of benches down touched off a 50BMG as I was breaking the shot.

Either way the first 3 rd group was cold bore included and was .063" so can't really see improving on that.

Not bad at just shy of 2700fps from a 23" barrel with the 147eldm.

Barrel is a Bartlien 5r M24 profile 1-7.5 twist with SAAMI. 199" FB chambered by Kelblys

I need to load up 30-40 rounds at 45.2 and see how they hold up at 600 and 1200 yards when the winds aren't being to bitchy.

Last edited:

Work seating depth at 41.8 is what I would do.I’m going to work up from here and pull the bolt apart tonight

View attachment 7311435View attachment 7311436

I think @clcustom1911 is on the money with that but one other thing you can check just to eliminate one other possibility is verify that your ejector plunger on the bolt face isn't gummed up and causing additional restistence.

Just pull the bolt and use pin punch and depress the plunger and see if it is easily compressing to flush with the bolt face.

It’s really stiff it takes a lot of pressure to depress it, I image that’s what it ejects brass 5 feet if I don’t catch it

It’s really stiff it takes a lot of pressure to depress it, I image that’s what it ejects brass 5 feet if I don’t catch it

So long as it will fully depress until it is flush with the bolt face and doesn't have any sharp edges on it I'm sure it's fine.

Just give it a good look over, if you see that it is shaving brass off remove and smooth any sharp edges if you have the tools to do it.

My T3 in 270win shows a bulge just forward of the case head on pretty much everything I shoot in it, not a pressure issue just a generous chamber dimension.

So long as it will fully depress until it is flush with the bolt face and doesn't have any sharp edges on it I'm sure it's fine.

Just give it a good look over, if you see that it is shaving brass off remove and smooth any sharp edges if you have the tools to do it.

My T3 in 270win shows a bulge just forward of the case head on pretty much everything I shoot in it, not a pressure issue just a generous chamber dimension.

Yea there was brass flakes all over the bolt face, I put a new piece of empty brass in and chambered it ran the bolt a few times and I can see where it’s making contact on the shoulder. Then I sized a new piece of brass and same thing

Yea there was brass flakes all over the bolt face, I put a new piece of empty brass in and chambered it ran the bolt a few times and I can see where it’s making contact on the shoulder. Then I sized a new piece of brass and same thing

Sounds like your chamber is at minimum spec for headspace or just slightly under.

If your die will bump it back enough to give .0015-.001" headspace that's probably about as good as your going to get.

Better tight than sloppy.

I set up my 243win with minimum headspace and it's perfect with everything I've tried but Nosler ammo and brass is a bit tight similar to the issue your having.

what kind of velocity, barrel length?5-shot group using 41.8 grn of H-4350 with 147 ELDM’s.

5-shot group using 41.8 grn of H-4350 with 147 ELDM’s.

that was my old load in my Savage as well. shot quite well and good SD's. was able to pull 1/2 MOA groups at 875 yards before my barrel started opening groups.

not sure it works on all rifle but some people seem to have some really good luck with this combo @ that charge.

Yea there was brass flakes all over the bolt face, I put a new piece of empty brass in and chambered it ran the bolt a few times and I can see where it’s making contact on the shoulder. Then I sized a new piece of brass and same thing

hopefully you got this issue sorted out. I'm not 100% convinced what your seeing is pressure especially with what appears to be zero flattening of the primers ( I don't mean flattened but those are very round!) I would imagine something to do with the bolt/chambering as your already investigating, did you ever find out what's causing this?

Pretty typical 5 rounds at 207 yards. However, I did all my load development in 60 and 70 degree weather. Went out the other day in 85+ degrees and about 8 out of 10 blew up. Went 5 out of 5 on steel at 1395 yards with 140 Hybrid Bergers that don't group near as well on paper. The load for both was 41.2 grains of H4350 and a cci small magnum primer in Lapua brass. About 2707fps average according to my magnetospeed.

hopefully you got this issue sorted out. I'm not 100% convinced what your seeing is pressure especially with what appears to be zero flattening of the primers ( I don't mean flattened but those are very round!) I would imagine something to do with the bolt/chambering as your already investigating, did you ever find out what's causing this?

I think so, seems like a tight chamber and when I pull the spring for the plunger it doesn’t mark the brass anymore. Also when spring is out of bolt and I chamber a once fired round it still binds up a tiny bit closing the bolt but when I take the same case and bump it back .003 it chambers fine. It shoots fine so I’ll leave it till I put a new barrel on

How are guys getting so much R26 in Lapua brass? I was crunching it in the 46g range and had to tap the cases to settle it. No pressure signs up to 47.2 but was only 15 degrees Celsius out. 147s are 0.03 off. Got me up to 2800 out of a 24 inch CTR. Brass was on its 3rd firing.

I use a old electric razor to vibrate the case. It condenses enough to seat the bullet without being compressed.How are guys getting so much R26 in Lapua brass? I was crunching it in the 46g range and had to tap the cases to settle it. No pressure signs up to 47.2 but was only 15 degrees Celsius out. 147s are 0.03 off. Got me up to 2800 out of a 24 inch CTR. Brass was on its 3rd firing.

Last edited:

Never too late. Thanks put a lot of effort into it at the time. My weekend getaway, Canadian Historical Arms Society Range. If that is yours we should go shooting one weekend. Always looking for more reason to go.I'm a bit late but good thread, good info! That range looks very familiar.

An electric toothbrush works good as well.I use a old electric razor to vibrate the case. It condenses enough to seat the bullet without being compressed.

That’s my load too but It has to go in a wsm magI replaced my barrel and it likes 147 ELD-M with 41.5 grn of H4350.

That’s my load too but It has to go in a wsm mag

Why a WSM mag? What mags and rifle?

They are pretty long it’s a trued remmy with a m24 1-8 I also had the action notched chasing the lands on my last barrel. The old barrel hammered as does this one. I had a whole bunch of left over loaded ammo so I gave it a whirl. No need to change the loadWhy a WSM mag? What mags and rifle?

Thank you, there’s a little resistance closing the bolt with a case and nothing when empty, is that of any concern or just run it as it?

In the T3 X that’s a little unusual…

It is very common to have the bolts start to stick as the action warms up and you go to extract a somewhat hot load.

I ran into this problem with a stock ticker T3X TAC A1. LRI makes a replacement bolt for these rifles that is boron nitrate coated, which helps a little bit with the sticky bolt syndrome.

Most factory ammo performs flawlessly in my rifle, but spark ammunition tends to start the stick after about 10 to 15 shots. Part of this is due to the design of the rifle and small angle bolt lift design.

After replacing the barrel with a proof carbon fiber drop in, I found this thing shot really well out to 1000 yards in lowlights class. (at least until I change to some thing that had a dramatic impact on where my rifle was doped to…)

Even with the rounds traveling at 2650 to 2670 I was having no problems hitting targets at distance… so I’m not really convinced that the 147 grain ELDM bullets from hornady need to be moving faster than 2700. I guess in an ideal world they be traveling at 2850, but the stories abound of these bullets not doing well at high pressures… Especially when they do perfectly fine in highwind and out to 1000 yards.

If the bolt is sticking when you chamber into the factory barrel then that’s because the brass is thicker than other factory brass…

Last edited:

How far off lands?5-shot group using 41.8 grn of H-4350 with 147 ELDM’s.

What was the velocity? I'm tuning Berger 140's right now and have a reference load for my Tikka T3x TAC A1 that groups like that, but I use 43.4gr of StaBall. My average velocity is 2660 with SD's of 5.5-ish. I'm shooting for distance so the velocity matters.I replaced my barrel and it likes 147 ELD-M with 41.5 grn of H4350.

My average velocity is 2789 with SD of 4.5 and ES of 12. I’m running a 26” barre.What was the velocity? I'm tuning Berger 140's right now and have a reference load for my Tikka T3x TAC A1 that groups like that, but I use 43.4gr of StaBall. My average velocity is 2660 with SD's of 5.5-ish. I'm shooting for distance so the velocity matters.

Old thread but my .223 T3x is a little snug both closing AND opening the bolt.

LC Brass at a variety of charge weights. Settled on 24.0g of N140 with 77gr SMKs. No other pressure signs so I'm guessing similar to the poster above that the brass is slightly thicker or sprung back a hair more or something...

LC Brass at a variety of charge weights. Settled on 24.0g of N140 with 77gr SMKs. No other pressure signs so I'm guessing similar to the poster above that the brass is slightly thicker or sprung back a hair more or something...

This my friend is gold!! Thank you for all the precise info....hard to find now days. Also nice shooting for us all to see.So I have been lurking for a while now, I have made a few posts here and there, but nothing with much contribution yet. Now it is time to put up some meaningful data for all of you. I have noticed it can be hard to find load data on the Hornady 147 Gr ELD-M for the 6.5 Creedmoor. So I did some research and bought a few powders that interested me for this. I chose 4 different powders, loaded up 50 rounds of each, took it to the range and here are the results for anyone who is interested.

The powders I tested were RL16, RL26, H4831 SC, H4350. After testing all four I had great results with all of the in different ways. I will let you all be the judge of what might work for you. This data will hopefully help anyone trying to choose a good powder for the 147 ELD-M.

Use Caution when using any of these loads, be sure start low and work your way up. All these loads below, start high and get over recommended charges. Don't be a fool and blow up your tool.

The Rifle

View attachment 6905571

View attachment 6905576

Action - Defiance Deviant

Barrel - 26" Krieger 1:8 MTU

Break - Area 419 Hellfire

Trigger- Timney Calvin Elite 2 Stage

Chassis - MDT ESS

Rings - ARC M10 Medium

Scope - Minox ZP5 5-25x56

The Ammo

Bullet - Hornady 147 Gr ELD-M

Brass- Virgin Lapua Small Rifle 6.5 CM

Primer - CCI 450

OAL - 2.263

.020 Off the lands

Testing was done at my local range at 100m. Temperature was 22c with 30km wind gusting to 60km. Altitude was 805m above sea level. Sorry but all you guys from the USA will have to convert that from Canadian on your own eh.

Test #1 - RL16

Charge Muzzle Vel. SD ES Group Size "

40.3 2658 9.8 26 1.637

40.6 2687 8.1 18 .998

40.9 2707 6.0 13 .495

41.2 2721 5.6 15 .926

41.5 2749 8.1 22 .754

41.8 2771 6.6 15 .852

42.1 2788 4.5 12 .802

42.4 2808 9.8 26 .735

42.7 2835 6.7 14 1.040

43.0 2851 6.3 14 .926

View attachment 6905572

Test #2 - RL26

Charge Muzzle Vel. SD ES Group Size "

45.3 2715 4.7 12 .757

45.6 2759 8.7 22 .563

45.9 2776 9.5 25 .855

46.2 2794 6.4 16 .834

46.5 2817 5.1 13 .896

46.8 2844 9.2 21 .529

47.1 2855 6.9 19 1.093

47.4 2881 9.6 25 .905

47.7 2904 11 30 .739

48.0 2917 9.4 23 .826

View attachment 6905573

Test #3 - H4831 SC

Charge Muzzle Vel. SD ES Group Size "

42.5 2614 9.0 25 .516

42.8 2631 6.7 16 .555

43.1 2642 11 28 .826

43.4 2665 7.0 18 .668

43.7 2682 6.2 15 .915

44.0 2696 7.6 15 .507

44.3 2714 5.9 14 .437

44.6 2733 5.0 12 .878

44.9 2746 10.8 27 .607

45.2 2760 4.5 10 1.010

View attachment 6905574

Test #4 - H4350

Charge Muzzle Vel. SD ES Group Size "

40.0 2657 7.9 21 .971

40.3 2690 11 30 .888

40.6 2688 8.7 21 .799

40.9 2706 4.0 10 .799

41.2 2719 2.4 6 1.159

41.5 2737 4.7 12 .467

41.8 2750 4.4 11 .742

42.1 2769 9.9 25 .494

42.4 2792 2.6 7 .556

42.7 2806 7.4 19 .806

View attachment 6905575

After doing these tests I thought I would have a clear winner but now I just want to test these all more thoroughly. So this test has turned into phase 1 now. I will see what kind of fine tuning I can do to these in the future. I will keep you all posted when phase 2 is completed and I will post the results for you all.

Thanks you. Good to know people are still getting some use out of this.This my friend is gold!! Thank you for all the precise info....hard to find now days. Also nice shooting for us all to see.

Similar threads

- Replies

- 13

- Views

- 3K

- Replies

- 14

- Views

- 2K

- Replies

- 6

- Views

- 905

- Replies

- 38

- Views

- 2K