Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6 ARC Gas Guns

- Thread starter steve101610

- Start date

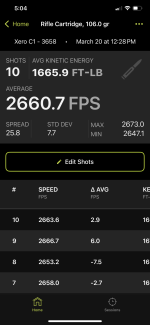

Chrono data from 18 inch Odin Works barrel (Geissle BCG, OW Bolt, JP H2 Silent capture spring, OW adjustable gas block):

I got 2490 fps in an 18" AR with 26.7 gr N140. That's a near max load. I tried Staball Match with no luck, really slow. Didn't want to go CFE or LVR. Not fast, but those bullets are fantastic.

Edit, sorry the 106 TAP, not A-Tips.

Last edited:

Adding my load I recently used at a quantified precision gas gun match. Shot with a proof 18” SS barrel. It did me well at the match

Hornady brass

Remington 7 1/2 BR primers

Berger 108 BT

29.2 gr CFE223

2580 fps with SD of 12

When I was shooting Berger 105 hybrids it was 27.8 gr of CFE223 for 2520 fps

Hornady brass

Remington 7 1/2 BR primers

Berger 108 BT

29.2 gr CFE223

2580 fps with SD of 12

When I was shooting Berger 105 hybrids it was 27.8 gr of CFE223 for 2520 fps

What mags are yall running? I am having trouble with bolt locking back on last mag. I keep adding gas and it just stays the same.

What mags are yall running? I am having trouble with bolt locking back on last mag. I keep adding gas and it just stays the same.

ASC running great for me

Thats what I am running. With a KGM R30k The gun shoots soft with very little recoil and muzzle jump. Cycles fine, getting a good 3-4 o clock ejection but the damn thing wont lock back.ASC running great for me

If I remember right (not home currently) I think I’m running Grendel duramags and have no issue with them too. I have two 20 rounders and a 10

Thats what I am running. With a KGM R30k The gun shoots soft with very little recoil and muzzle jump. Cycles fine, getting a good 3-4 o clock ejection but the damn thing wont lock back.

Weird. No issues with mine locking back.. I'm running a mega match billet ambi receiver set, rubber city bcg....

After reading tons and tons of info, i think the go to is Geiselle and Duramag magazines. Granted i bought 4 of the 15 rounders duragmags. Ive only put around 200 through my rifle but, i have not had any issues. Heard a lot of people were having accuracy issues with adj gas blocks on short dwell time barrels. Ive been playinig with the 107SMK and TAC powder and some more loaded up to try out. Im over book max now by around 1-2 grains. SDs are what i would consider normal for gas guns in the 9-15 range.

Noveske 18”

Ddc enticer-L

Last load tested:

107smk

TAC 27.5gr

CCI BR4

Hornady brass

2520 FPS

SD12

ES 30

Noveske 18”

Ddc enticer-L

Last load tested:

107smk

TAC 27.5gr

CCI BR4

Hornady brass

2520 FPS

SD12

ES 30

Last edited:

Nice group! I've got an ar in 6arc that I haven't shot yet. Hoping for a little warmer weekend to put it through it's trials. Have new brass & dies, but going to start with Hornady 108 gr ELD match ammo. The warm weather better get here soon, foot surgery with a minimum 8 weeks on crutches. Sucks getting old.

106 A Tip

29.0 lvr

Ruag green fire primer

Hornady brass

Group was .86 MOA out of a 20 inch Grendel Hunter barrel.

Performance at 1000 yards was excellent. Made a first round impact on my 2/3 IPSC and went 12/15 on it afterward. Then came back the next day to get the target and someone had driven down and stolen it off the range. Which is odd and the first time that’s ever happened lol

29.0 lvr

Ruag green fire primer

Hornady brass

Group was .86 MOA out of a 20 inch Grendel Hunter barrel.

Performance at 1000 yards was excellent. Made a first round impact on my 2/3 IPSC and went 12/15 on it afterward. Then came back the next day to get the target and someone had driven down and stolen it off the range. Which is odd and the first time that’s ever happened lol

Attachments

Lots of good stuff here. I’m currently collecting load data, and planning on testing a bunch of different bullets and powders. I’m looking to find an accurate load for long range type things, and a consistent load for plinking and flat range LARPer stuff with my buddies. Have virgin starline in 6ARC and have converted a bunch of virgin starline 6.5G, as well as a ton of once fired Hornady.

Have 10 plus pounds of 2520, 8208, AR COMP. 2 or 3 pounds of a half dozen other powders as well. Will be sharing the results in here as I go

Have 10 plus pounds of 2520, 8208, AR COMP. 2 or 3 pounds of a half dozen other powders as well. Will be sharing the results in here as I go

Last edited:

Mostly shoot Berger 108 but this is a killer fast round Seekins 18” Proof CF, Garmin XeroLots of good stuff here. I’m currently collecting load data, and planning on testing a bunch of different billets and powders. I’m looking to find an accurate load for long range type things, and a consistent load for plinking and flat range LARPer stuff with my buddies. Have virgin starline in 6ARC and have converted a bunch of virgin starline 6.5G, as well as a ton of once fired Hornady.

Have 10 plus pounds of 2520, 8208, AR COMP. 2 or 3 pounds of a half dozen other powders as well. Will be sharing the results in here as I go

7/16/23

84F 56% 29.88 in

Hornady 58 gr VMAX

A2230

Hornady brass x 5

205M FGMM

BTO 1.6650

COL 1.4900

32.2 3468, 3466, 3474, 3476 SD 4.6 0.5” x 3 no pressure

32.5 3507, 3506, 3497, 3506 SD 4.6 1” mild pressure

Mostly shoot Berger 108 but this is a killer fast round Seekins 18” Proof CF, Garmin Xero

7/16/23

84F 56% 29.88 in

Hornady 58 gr VMAX

A2230

Hornady brass x 5

205M FGMM

BTO 1.6650

COL 1.4900

32.2 3468, 3466, 3474, 3476 SD 4.6 0.5” x 3 no pressure

32.5 3507, 3506, 3497, 3506 SD 4.6 1” mild pressure

Nice! I have a ton of 58 vmax and A2230. Have to try them out!

I’ve been running a similar load with Benchmark in my 6 ARC, and I’ve found that staying a bit under max charge really helps keep SDs tight. I also tried the 105 Hybrids with Varget, and they performed pretty well even with the jump, but I had to tweak the powder charge a bit for consistency.

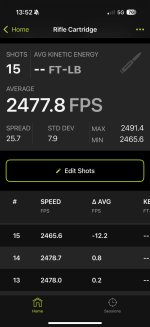

Hi All - just starting to load for my 6 ARC 18" Proof barrel with an adjustable JP Gas block.

Question 1, what speeds are a good target range with 105-108gr bullets to try to get to for general steel at 800-1K? The Hornady factory ammo I've shot through it so far seems to run in the mid to high 2500s with devcent accuracy at range. The 106gr TAP is just under 2600 and the Hornady Match 108 ELDM is about 2570. Is that the sort of speeds I should stick to or do people push it faster? My plan is to use LeverRevolution primarily but I have lots of TAC and Varget as well. My very initial test with Lever however produced underwhelming SDs and average accuracy.

Question 2, I plan to shoot 99% of the time suppressed. Would you guys suggest to do the load Dev also suppressed? Or do the laod development without the can and then tweak as necessary once I get some good loads?

Thanks!!

Question 1, what speeds are a good target range with 105-108gr bullets to try to get to for general steel at 800-1K? The Hornady factory ammo I've shot through it so far seems to run in the mid to high 2500s with devcent accuracy at range. The 106gr TAP is just under 2600 and the Hornady Match 108 ELDM is about 2570. Is that the sort of speeds I should stick to or do people push it faster? My plan is to use LeverRevolution primarily but I have lots of TAC and Varget as well. My very initial test with Lever however produced underwhelming SDs and average accuracy.

Question 2, I plan to shoot 99% of the time suppressed. Would you guys suggest to do the load Dev also suppressed? Or do the laod development without the can and then tweak as necessary once I get some good loads?

Thanks!!

Last edited:

I would do the load development with the suppressor since taking it off would change the barrel harmonics.Hi All - just starting to load for my 6 ARC 18" Proof barrel with an adjustable JP Gas block.

Question 1, what speeds are a good target range with 105-108gr bullets to try to get to for general steel at 800-1K? The Hornady factory ammo I've shot through it so far seems to run in the mid to high 2500s with devcent accuracy at range. The 106gr TAP is just under 2600 and the Hornady Match 108 ELDM is about 2570. Is that the sort of speeds I should stick to or do people push it faster? My plan is to use LeverRevolution primarily but I have lots of TAC and Varget as well. My very initial test with Lever however produced underwhelming SDs and average accuracy.

Question 2, I plan to shoot 99% of the time suppressed. Would you guys suggest to do the load Dev also suppressed? Or do the laod development without the can and then tweak as necessary once I get some good loads?

Thanks!!

I’m still waiting on my 6 arc barrel so I don’t have any real world data for you re: speed targets for the bullets in question but side note that if you have any on hand CFE 223 gets pretty good velocity for 6 arc gas guns compared to almost anything except leverevolution maybe.

This has probably been posted multiple times so SIAP but the below pic is a good general guide for speed targets with different length barrels:

This chart really helps - thanks!I would do the load development with the suppressor since taking it off would change the barrel harmonics.

I’m still waiting on my 6 arc barrel so I don’t have any real world data for you re: speed targets for the bullets in question but side note that if you have any on hand CFE 223 gets pretty good velocity for 6 arc gas guns compared to almost anything except leverevolution maybe.

This has probably been posted multiple times so SIAP but the below pic is a good general guide for speed targets with different length barrels:

View attachment 8652099

And that explains a lot and creates more questions now. My first test with loading for the 6 ARC, I was getting much higher speeds than I expected, along with early pressure signs that I didn't expect. Npw the trick is to figure out why...

Below are the results from my first test run. I was getting really fast speeds even at low powder charges. So I wonder what is causing that big of a difference in speeds between mine and the chart above.

Chrono is a Garmin X1

Yep, that's what I'm thinking as well.18" id try for somewhere around the 2500-2600fps in that grain weight. I personally would start with the suppressor on....last thing you want to do is develop a load and stick a can on then induce excess pressure.

You’re welcome and that’s a good question especially considering you are getting normal velocities (without pressure signs) from factory loads right? If so then just tweak your hand loads to match the velocity/COAL of factory loadsThis chart really helps - thanks!

And that explains a lot and creates more questions now. My first test with loading for the 6 ARC, I was getting much higher speeds than I expected, along with early pressure signs that I didn't expect. Npw the trick is to figure out why...

Below are the results from my first test run. I was getting really fast speeds even at low powder charges. So I wonder what is causing that big of a difference in speeds between mine and the chart above.

View attachment 8652960

Chrono is a Garmin X1

Correct. The Factory loads were Chrono'd and came right into the <2600 fps range.You’re welcome and that’s a good question especially considering you are getting normal velocities (without pressure signs) from factory loads right? If so then just tweak your hand loads to match the velocity/COAL of factory loads

Edit to add: I had wanted to work up to max load with Lever, since I'd read where numerous people say the SDs are not great until you get close to max case density in the case and then the SDs come right down. But that didn't seem to pan out for me. I might try some Varget and Tac next as well

If i were you i wouldnt invest any money in TAC, pretty terrible numbers and sensitivity. If i didnt have a 8#er to burn up id probably try to get some H4895, N135, or xbr 8208. Varget will probably be too slow unless youre ok with running compressed loads. I did my load work up in 50-60* weather and now im damn near 60fps faster and hitting pressure in 85* weather.Correct. The Factory loads were Chrono'd and came right into the <2600 fps range.

View attachment 8653026

Edit to add: I had wanted to work up to max load with Lever, since I'd read where numerous people say the SDs are not great until you get close to max case density in the case and then the SDs come right down. But that didn't seem to pan out for me. I might try some Varget and Tac next as well

+1 on this. Id also add that 4895 and 8208 are both extremely hard to find in stock. N135 is widely available and probably the cheapest of the 3 you listed. Its great for 223/5.56 as well. N140 isnt too bad eitherIf i were you i wouldnt invest any money in TAC, pretty terrible numbers and sensitivity. If i didnt have a 8#er to burn up id probably try to get some H4895, N135, or xbr 8208. Varget will probably be too slow unless youre ok with running compressed loads. I did my load work up in 50-60* weather and now im damn near 60fps faster and hitting pressure in 85* weather.

Ok, I’ll be the odd ball. All things about tac aside, it gives me the best accuracy and same speed as lever with 105/108 hornady bullets. It’s one of my top powder picks

loading 109 ELDM's to 2.300 in ASC mags, 29gr of lever RUAG greenfire SRP's in a dillon 550 with hornady dies. Run them through a SGT of arms belt buster die on my single stage. resize, trim/deburr/chamfer, dry tumble for 15 minutes. prime/charge/seat. out of my 20 inch grendel hunter barrel with no suppressor I get 2650fps and the drop actually out performs my 6.5 AR10 shooting 147 ELDMs. I love my 6arc such a handy and capable rifle.

TAC gets a lot of shit but its versatility & performance for the money is amazing. Being a double base ball powder its not good for accuracy loads but it kicks ass for an all around load (decent accuracy/sd’s and good speed) from 223 to 6 arc to 308. I love using it with 77 smk’s in my 5.56 loads so I burn through a lot of it.Ok, I’ll be the odd ball. All things about tac aside, it gives me the best accuracy and same speed as lever with 105/108 hornady bullets. It’s one of my top powder picks

I save my more temp stable extruded powders like 8208, n140, and Ar-Comp for accuracy loads (various calibers) plus with the exception of n140 they are more expensive and seldom in stock.

Also in my dillon TAC meters so accurately through the powder dispenser I'm getting the same throw every time. I tried tac in my 6arc and the accuracy was there but it was about 100fps behind what lever could get me. I'm shooting usually past 800 yards to 1200 with my 6arc so I like to have that extra bit of speed to beat the wind.TAC gets a lot of shit but its versatility & performance for the money is amazing. Being a double base ball powder its not good for accuracy loads but it kicks ass for an all around load (decent accuracy/sd’s and good speed) from 223 to 6 arc to 308. I love using it with 77 smk’s in my 5.56 loads so I burn through a lot of it.

I save my more temp stable extruded powders like 8208, n140, and Ar-Comp for accuracy loads (various calibers) plus with the exception of n140 they are more expensive and seldom in stock.

I agree, TAC is one of my favorite powders. all my 5.56 loads use TAC. with 70gr SMK & 80gr ELDVT in the 6arc i shot the most accurate 10 shot group I've ever shot with the rifle.

Yeah good point on how well it meters…its just a smidge too fast burning to get the last little bit of speed in 6arc cases.Also in my dillon TAC meters so accurately through the powder dispenser I'm getting the same throw every time. I tried tac in my 6arc and the accuracy was there but it was about 100fps behind what lever could get me. I'm shooting usually past 800 yards to 1200 with my 6arc so I like to have that extra bit of speed to beat the wind.

I agree, TAC is one of my favorite powders. all my 5.56 loads use TAC. with 70gr SMK & 80gr ELDVT in the 6arc i shot the most accurate 10 shot group I've ever shot with the rifle.

What brand of 6arc brass are you using and Have you worked up any 6arc loads with cfe223? If so I’d be curious how they compared speed wise with your lever loads.

Yeah good point on how well it meters…its just a smidge too fast burning to get the last little bit of speed in 6arc cases.

What brand of 6arc brass are you using and Have you worked up any 6arc loads with cfe223? If so I’d be curious how they compared speed wise with your lever loads.

CFE 223 was so dirty in my 5.56 I haven't bothered with it in my 6arc. like looney toons level of smoke and carbon. but quite honestly the hornady book data for lever max charge is like 200fps faster and way over pressure with every lot I've tried of lever so I usually knock them down like a grain and a half. I'm using hornady brass because starline belts if you go anywhere near book max. I anneal every firing but hornady brass has given me the best results but I still have yet to try alpha.

105 Berger Hybrid, 27.0gr N140, converted Starline Grendel case, Ginex primer. 2.255col.

This is my 600yard match load. I just chrono'ed an entire 3x20 match this past weekend and shoot a 597-27X in some pretty tough wind conditions. Typical 5 rounds groups are about 0.75moa from a Satern 20in barrel.

I have found that 27.0gr N140 works extremely well with all the 105-108gr bullets I have available (Bergers, SMKs, ELDMs).

This is my 600yard match load. I just chrono'ed an entire 3x20 match this past weekend and shoot a 597-27X in some pretty tough wind conditions. Typical 5 rounds groups are about 0.75moa from a Satern 20in barrel.

I have found that 27.0gr N140 works extremely well with all the 105-108gr bullets I have available (Bergers, SMKs, ELDMs).

Attachments

was out doing the first firing with my new Peterson brass. Used a mild of the road load with target and some 108 eld-m pills

never had a double digit before.

I built a Mega mono upper and billet lower that I have had laying around since 2013 into my ARC

never had a double digit before.

I built a Mega mono upper and billet lower that I have had laying around since 2013 into my ARC

Attachments

Picked up 500 of the 100gr Sierra Tipped Game Kings from Raven Rock.

Only had a chance to try 20 rounds so far, best group was 0.676moa at 200 yards using 27.0gr N140 2.25COL. The other groups measured in between 1-1.5 moa.

For 20 cents per bullet I think these have a lot of potential.

Only had a chance to try 20 rounds so far, best group was 0.676moa at 200 yards using 27.0gr N140 2.25COL. The other groups measured in between 1-1.5 moa.

For 20 cents per bullet I think these have a lot of potential.

Attachments

Picked up 500 of the 100gr Sierra Tipped Game Kings from Raven Rock.

Only had a chance to try 20 rounds so far, best group was 0.676moa at 200 yards using 27.0gr N140 2.25COL. The other groups measured in between 1-1.5 moa.

For 20 cents per bullet I think these have a lot of potential.

Did you get the black oxide coated overruns? I wonder if they'd shoot with the same loads as the uncoated variety.

That's a good deal, I shot the regular uncoated variety some as well as the 90gr TGKs, but availability was pretty variable. They did shoot well though, and are supposed to be on the tougher side, which should help penetration given their lighter weight. I did shoot one deer with them, a snap heart shot and it exited, but it was a pretty small deer.

Yes I bought the black oxide 100gr TGKs. They are certainly accurate enough for deer hunting. Over the next few weeks I am going to do some load development and see if I can get them consistently under 1 MOADid you get the black oxide coated overruns? I wonder if they'd shoot with the same loads as the uncoated variety.

That's a good deal, I shot the regular uncoated variety some as well as the 90gr TGKs, but availability was pretty variable. They did shoot well though, and are supposed to be on the tougher side, which should help penetration given their lighter weight. I did shoot one deer with them, a snap heart shot and it exited, but it was a pretty small deer.

View attachment 8673422

View attachment 8673423

New to the forum, but I've been reloading for 6ARC for a couple years and learned a lot in the course of troubleshooting that I think other folks may find useful. To start off I'll share some of what I've learned about 6ARC brass now that there's a reasonable selection available.

Here's garage-grade cross sections of Starline, Hornady, Alpha, and Peterson brass. Ignore the wiggles near the shoulder on some of the cases, that's just where I got overly aggressive with the hack saw. I was most interested in the shape of the web.

It's plainly obvious that there's significant differences in the internal case design between the manufacturers. To see why it might matter, we need to look at what the case needs to do in that region.

SAAMI chamber specification drawing have the chamber walls running practically to the breech face, but of course that's not how most rifles are constructed. In most modern rifles the "breech face" is recessed in a bolt and there's a gap between the end of the bolt and face of the barrel. Additionally, semi-autos often have a pronounced cone, chamfer, radius, or some mixture of all three blending the barrel face into the chamber to ensure reliable feeding. Having a case web high enough and/or case walls thick enough to resist chamber pressures that far up the case (until chamber wall support begins) is critical. If the case expands where it isn't supported you can end up with anything from a case that's impossible to resize in a normal die to, in an extreme scenario, and case failure and blowout. To make sure we're all on the same page here's an annotated cutaway of a 5.56 AR (original from here: https://www.coltforum.com/threads/windham-weaponry-ar15-cut-away.49104/)

This chart shows case wall thickness of the four above cases as a function of the height from the case base, with the grey dashed line being the difference between the SAAMI maximum chamber diameter and the actual chamber diameter of my loosest 6ARC AR barrel (divided by two to go from diameter to radius and multiplied by 10 to make it visible on the same scale):

I've called that grey dashed line the "chamber gap" because it's a measure of where and by how much the chamber is oversized relative to the specification. Anywhere that dashed line is greater than zero is an area where the chamber is not providing support and the case needs to resist pressure on its own. Note the 10x scaling: at 0.02" height the chamber is only 0.001" over spec but quickly gets out of control below that.

The region where this chamber is oversized and the region where the wall of the Starline brass has gotten thin have a lot of overlap. Starline brass shot in this barrel expanded to partially fill that gap and would never resize properly with a standard die. Instead a "belt" just above the extractor groove would form on sizing (many Grendel and ARC reloaders know exactly what I'm talking about). The sizing die was squeegee-ing the over-expanded brass down the case instead of squeezing it in radially.

I had much, much less of this issue with Hornady brass. You can see why: the web on Hornady brass starts much higher and has a large radius fillet blending into the case wall, which also starts much thicker. The Peterson brass is another big step beyond even that and should have absolutely no problems. The Alpha brass has a thicker web and wall than Starline, but has still reached it's beginning wall thickness where this chamber is not yet in spec. I haven't shot Alpha brass in this barrel, but I suspect the hardness of an Alpha case head combined with the extra wall thickness and only having an extra 0.001" to expand into would make it a non-issue. That said, the Alpha brass, like the Starline, seems optimized more for bolt actions. In a bolt action the unsupported region will be lower down on the case, below the web height. For instance, my Howa mini has an in-spec chamber down to only 0.145" up the case, ie right at the top of the extractor groove.

Here's garage-grade cross sections of Starline, Hornady, Alpha, and Peterson brass. Ignore the wiggles near the shoulder on some of the cases, that's just where I got overly aggressive with the hack saw. I was most interested in the shape of the web.

It's plainly obvious that there's significant differences in the internal case design between the manufacturers. To see why it might matter, we need to look at what the case needs to do in that region.

SAAMI chamber specification drawing have the chamber walls running practically to the breech face, but of course that's not how most rifles are constructed. In most modern rifles the "breech face" is recessed in a bolt and there's a gap between the end of the bolt and face of the barrel. Additionally, semi-autos often have a pronounced cone, chamfer, radius, or some mixture of all three blending the barrel face into the chamber to ensure reliable feeding. Having a case web high enough and/or case walls thick enough to resist chamber pressures that far up the case (until chamber wall support begins) is critical. If the case expands where it isn't supported you can end up with anything from a case that's impossible to resize in a normal die to, in an extreme scenario, and case failure and blowout. To make sure we're all on the same page here's an annotated cutaway of a 5.56 AR (original from here: https://www.coltforum.com/threads/windham-weaponry-ar15-cut-away.49104/)

This chart shows case wall thickness of the four above cases as a function of the height from the case base, with the grey dashed line being the difference between the SAAMI maximum chamber diameter and the actual chamber diameter of my loosest 6ARC AR barrel (divided by two to go from diameter to radius and multiplied by 10 to make it visible on the same scale):

I've called that grey dashed line the "chamber gap" because it's a measure of where and by how much the chamber is oversized relative to the specification. Anywhere that dashed line is greater than zero is an area where the chamber is not providing support and the case needs to resist pressure on its own. Note the 10x scaling: at 0.02" height the chamber is only 0.001" over spec but quickly gets out of control below that.

The region where this chamber is oversized and the region where the wall of the Starline brass has gotten thin have a lot of overlap. Starline brass shot in this barrel expanded to partially fill that gap and would never resize properly with a standard die. Instead a "belt" just above the extractor groove would form on sizing (many Grendel and ARC reloaders know exactly what I'm talking about). The sizing die was squeegee-ing the over-expanded brass down the case instead of squeezing it in radially.

I had much, much less of this issue with Hornady brass. You can see why: the web on Hornady brass starts much higher and has a large radius fillet blending into the case wall, which also starts much thicker. The Peterson brass is another big step beyond even that and should have absolutely no problems. The Alpha brass has a thicker web and wall than Starline, but has still reached it's beginning wall thickness where this chamber is not yet in spec. I haven't shot Alpha brass in this barrel, but I suspect the hardness of an Alpha case head combined with the extra wall thickness and only having an extra 0.001" to expand into would make it a non-issue. That said, the Alpha brass, like the Starline, seems optimized more for bolt actions. In a bolt action the unsupported region will be lower down on the case, below the web height. For instance, my Howa mini has an in-spec chamber down to only 0.145" up the case, ie right at the top of the extractor groove.

My 6ARC experience is solely in AR15s using Starline and Hornady brass....New to the forum, but I've been reloading for 6ARC for a couple years and learned a lot in the course of troubleshooting that I think other folks may find useful. To start off I'll share some of what I've learned about 6ARC brass now that there's a reasonable selection available.

Here's garage-grade cross sections of Starline, Hornady, Alpha, and Peterson brass. Ignore the wiggles near the shoulder on some of the cases, that's just where I got overly aggressive with the hack saw. I was most interested in the shape of the web.

View attachment 8674134

It's plainly obvious that there's significant differences in the internal case design between the manufacturers. To see why it might matter, we need to look at what the case needs to do in that region.

SAAMI chamber specification drawing have the chamber walls running practically to the breech face, but of course that's not how most rifles are constructed. In most modern rifles the "breech face" is recessed in a bolt and there's a gap between the end of the bolt and face of the barrel. Additionally, semi-autos often have a pronounced cone, chamfer, radius, or some mixture of all three blending the barrel face into the chamber to ensure reliable feeding. Having a case web high enough and/or case walls thick enough to resist chamber pressures that far up the case (until chamber wall support begins) is critical. If the case expands where it isn't supported you can end up with anything from a case that's impossible to resize in a normal die to, in an extreme scenario, and case failure and blowout. To make sure we're all on the same page here's an annotated cutaway of a 5.56 AR (original from here: https://www.coltforum.com/threads/windham-weaponry-ar15-cut-away.49104/)

View attachment 8674158

This chart shows case wall thickness of the four above cases as a function of the height from the case base, with the grey dashed line being the difference between the SAAMI maximum chamber diameter and the actual chamber diameter of my loosest 6ARC AR barrel (divided by two to go from diameter to radius and multiplied by 10 to make it visible on the same scale):

View attachment 8674174

I've called that grey dashed line the "chamber gap" because it's a measure of where and by how much the chamber is oversized relative to the specification. Anywhere that dashed line is greater than zero is an area where the chamber is not providing support and the case needs to resist pressure on its own. Note the 10x scaling: at 0.02" height the chamber is only 0.001" over spec but quickly gets out of control below that.

The region where this chamber is oversized and the region where the wall of the Starline brass has gotten thin have a lot of overlap. Starline brass shot in this barrel expanded to partially fill that gap and would never resize properly with a standard die. Instead a "belt" just above the extractor groove would form on sizing (many Grendel and ARC reloaders know exactly what I'm talking about). The sizing die was squeegee-ing the over-expanded brass down the case instead of squeezing it in radially.

I had much, much less of this issue with Hornady brass. You can see why: the web on Hornady brass starts much higher and has a large radius fillet blending into the case wall, which also starts much thicker. The Peterson brass is another big step beyond even that and should have absolutely no problems. The Alpha brass has a thicker web and wall than Starline, but has still reached it's beginning wall thickness where this chamber is not yet in spec. I haven't shot Alpha brass in this barrel, but I suspect the hardness of an Alpha case head combined with the extra wall thickness and only having an extra 0.001" to expand into would make it a non-issue. That said, the Alpha brass, like the Starline, seems optimized more for bolt actions. In a bolt action the unsupported region will be lower down on the case, below the web height. For instance, my Howa mini has an in-spec chamber down to only 0.145" up the case, ie right at the top of the extractor groove.

That being said, I have experienced the "belting" issue that you mention using both Starline and Hornady brass when I was using a RCBS Small Base sizing die. After a few hundred rounds, I decided to buy a Lee sizing die and the issue completely disappeared. I have read that many others have had the same experience.

Another brass related issue I have noticed is split necks. My Starline brass started to have splits around the 3rd firing....1 out of 100 cases I estimate. On the 4th firing, it was about 5 per 100.

I look forward to seeing your firing results from the Alpha brass. I just need to have a few too many beers one night so I can motivate myself to order some!

I have 50 pieces of Alpha brass. Currently waiting on a AR barrel but once I get it and work up some loads I will definitely share my resultsMy 6ARC experience is solely in AR15s using Starline and Hornady brass....

That being said, I have experienced the "belting" issue that you mention using both Starline and Hornady brass when I was using a RCBS Small Base sizing die. After a few hundred rounds, I decided to buy a Lee sizing die and the issue completely disappeared. I have read that many others have had the same experience.

Another brass related issue I have noticed is split necks. My Starline brass started to have splits around the 3rd firing....1 out of 100 cases I estimate. On the 4th firing, it was about 5 per 100.

I look forward to seeing your firing results from the Alpha brass. I just need to have a few too many beers one night so I can motivate myself to order some!

My 6ARC experience is solely in AR15s using Starline and Hornady brass....

That being said, I have experienced the "belting" issue that you mention using both Starline and Hornady brass when I was using a RCBS Small Base sizing die. After a few hundred rounds, I decided to buy a Lee sizing die and the issue completely disappeared. I have read that many others have had the same experience.

Another brass related issue I have noticed is split necks. My Starline brass started to have splits around the 3rd firing....1 out of 100 cases I estimate. On the 4th firing, it was about 5 per 100.

I look forward to seeing your firing results from the Alpha brass. I just need to have a few too many beers one night so I can motivate myself to order some!

I have a few different sizing dies and have had the issue with both an RCBS small base and a Hornady, which although not labeled "small base" certainly seems to be. I'll share pin gauge measurements of the dies when I have a chance to write up my findings.

I haven't had any issues with split necks up to 7 firings, but I also flame anneal after every firing.

My 6ARC experience is solely in AR15s using Starline and Hornady brass....

That being said, I have experienced the "belting" issue that you mention using both Starline and Hornady brass when I was using a RCBS Small Base sizing die. After a few hundred rounds, I decided to buy a Lee sizing die and the issue completely disappeared. I have read that many others have had the same experience.

Another brass related issue I have noticed is split necks. My Starline brass started to have splits around the 3rd firing....1 out of 100 cases I estimate. On the 4th firing, it was about 5 per 100.

I look forward to seeing your firing results from the Alpha brass. I just need to have a few too many beers one night so I can motivate myself to order some!

I havent had a single split neck and no belting issues with hundred of Starline firings on my 6 ARC brass. Sounds like your overworking the necks..

I use a 6ARC LE Wilson SS FL Bushing die to size my necks along with 21st Century mandrel. I have the LE Wilson die setup to bump shoulders back 0.003 and squeeze the neck down 0.005 under loaded neck diameter than run the mandrel through to open the neck up 0.002 to give me a final neck tension of 0.003.. This works the necks the least.

Have you measured your fired necks and recorded the number, then measure your neck again on the same case after running it in your sizing die and recorded the number and then measured the neck of that same case after loading a round?

Similar threads

- Replies

- 34

- Views

- 3K

- Replies

- 5

- Views

- 719

- Replies

- 31

- Views

- 849

- Replies

- 30

- Views

- 4K

- Replies

- 31

- Views

- 5K