One could definitely do what you are thinking and loading accordingly for desirable pressures.Would .05” really affect the fps that much? I’m guessing 50fps at most.

And please, this is an honest question. In no way trying to be a jackass or argue. I’m genuinely trying to learn before I experiment and accidentally blow off some digits

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6mm max

- Thread starter nrspence

- Start date

There is some further optimization that be done with the mags feed lips etc and duramag is supposedly working on it.So what mags are available to run a 2.29" OAL round in an off the shelf lower? Seems like if you don't have that available to you then you're stuck using lighter/lower BC projectiles and/or running the heavies slower due to the lost case capacity, thereby giving up any benefits.

ETA: It's stated in the article, duh, haha

However, to gain additional performance in 6mm MAX, the designers chose to use the already-available .350 Legend magazine design, which provides for a slightly longer 2.30" COAL and uses follower and feed-lip geometry already designed for the case body.

Can anyone with 350L AR mags confirm this OAL is doable?

All reports so far say the metal 350L mags seem to work pretty well

They have been available since December I believeSo when will barrels and ammo be available?

They have been available since December I believe

From where? Nothing comes up on google or ammoseek for ammo, also not seeing any barrels in stock anywhere.

From where? Nothing comes up on google or ammoseek for ammo, also not seeing any barrels in stock anywhere.

Click shop

Are there any lightweight barrel options? Who's blanks are they using and is the machining in house or someone else?

I'm haven't seen any of that barrel info. I was a little disappointed they did not have the barrel weight on the website.Are there any lightweight barrel options? Who's blanks are they using and is the machining in house or someone else?

They do reply to emails I would just use the contact form on the website

Talked to Brian at BC yesterday. He said barrels available next week. Most everything else is in stock to purchase. I hope next week he decides to ship barrels too.

Looks like 30˚ to me. Once you go higher, you need 2 separate actions with the forming dies in the production process, which increases costs.I might have missed it, but does anyone know what the shoulder angle is?

The owners have made statements on other forums that the drawings are not going to be released till SAAMI approval or submission not sure which. The goal is SAAMI certification

Last edited:

Or buy a bag of brass from Brian and find out.The owners have made statements on other forums that the drawings are not going to be released till SAAMI approval or submission not sure which. The goal is SAAMI certification

The 6 Max has less a little less recoil and is a little flatter shooting than the 6ARC, you don't loose any mag capacity and it uses the same AR15 bolt , the cartridge feeds and extracts well and all at 55,000 psi which means decent barrel life all in the AR15 sized platform. IMHO, the 6 MAX is very comparable to the 6mm ARC and 22 ARC, but just checks a few more boxes and is just better ****overall**** than similar cartridges I think it would be great 5.56 NATO replacement cartridge. I bet Hornady wishes they had thought of it. I hope it catches on.

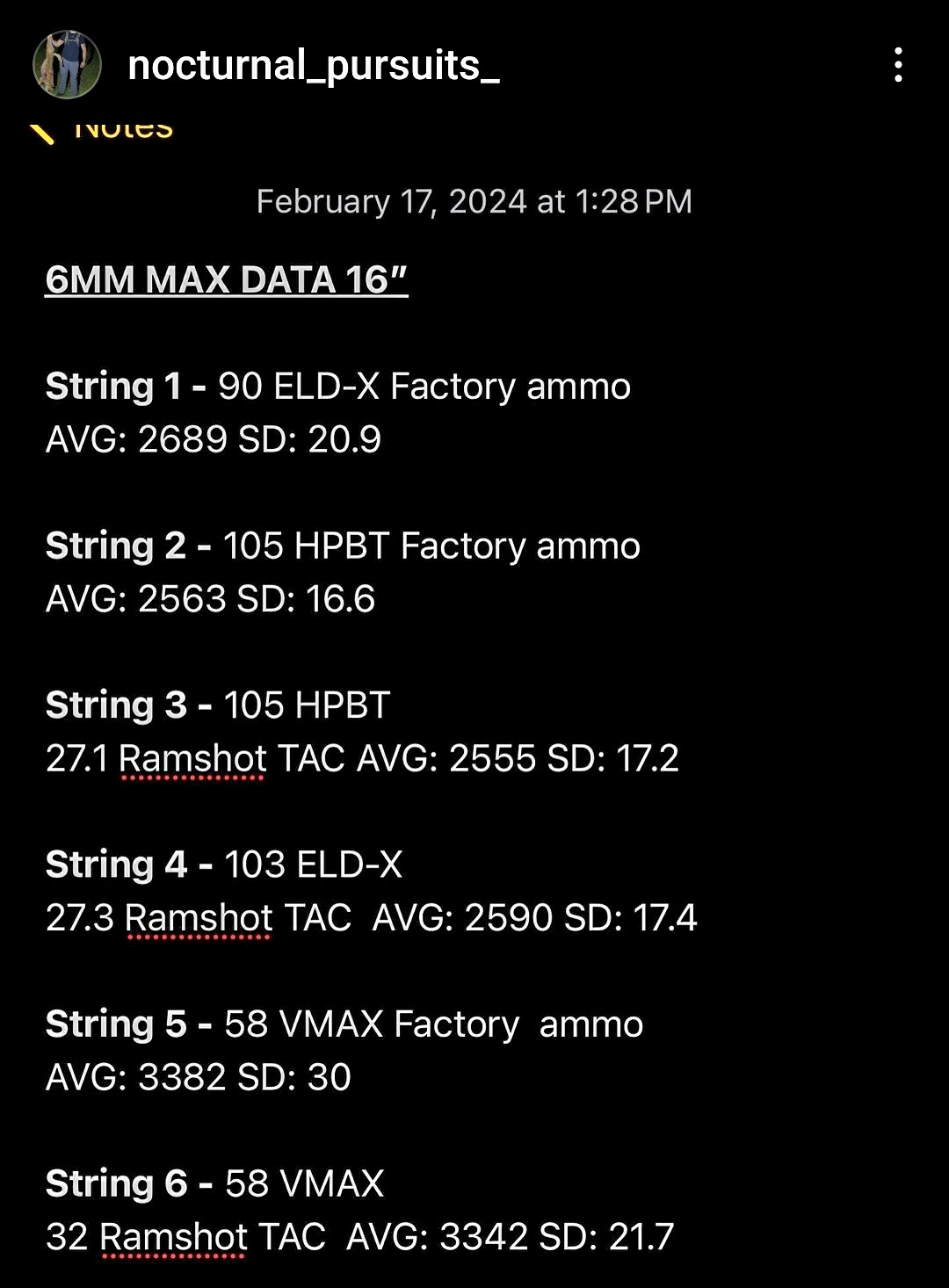

I agree with some of this (magazine capacity being the main one so far with 20rds), but I’m seeing some information that conflicts with the performance differences, specifically the "flatter and less recoil" parts. I’m looking at 6mm ARC load data and 6mm Max load data and not seeing why it would have less felt recoil or be flatter, since the charge weights are within fractions of a grain under the same bullets, with very similar muzzle velocities. The main difference there is working pressure is 3,000psi higher in the 6mm Max, but velocities might be slower even using the same charge weights.The 6 Max has less a little less recoil and is a little flatter shooting than the 6ARC, you don't loose any mag capacity and it uses the same AR15 bolt , the cartridge feeds and extracts well and all at 55,000 psi which means decent barrel life all in the AR15 sized platform. IMHO, the 6 MAX is very comparable to the 6mm ARC and 22 ARC, but just checks a few more boxes and is just better ****overall**** than similar cartridges I think it would be great 5.56 NATO replacement cartridge. I bet Hornady wishes they had thought of it. I hope it catches on.

They use the same powders and almost identical charge weights, but the pressures are higher with 6mm Max:

90gr ELD-M 6mm Max (source: Precision Ballistics Reload Data)

24” Bartlein test barrel

H4895 27.0gr 2819fps 53,536psi

CFE223 30.5gr 2944fps 53,000psi

90gr ELD-M 6mm ARC 18” Noveske (source: Hornady’s 11th Edition, pages 239-244)

H4895 27.4gr 2700fps (24” would average 2837fps with the same load.)

CFE223 30.9gr 2800fps (24” would average 2943fps.)

Trajectory and Free Recoil energy

So once the bullets leave the muzzle, they will fly with equally-flat trajectories. For a 10lb AR-15, both will generate 4.3ft-lbs of free recoil energy. If there is a difference in recoil energy due to the 6mm Max’s higher chamber pressure, it will be academic and imperceptible to the shooter, all other components of the rifle being equal (6mm Dasher and 6mm ARC have almost the same free recoil energy). Their propellant mass, bore volume, and projectile weight will be the primary factors in free recoil energy felt by the shooter. In my experience shooting 6mm AR and 95gr or lighter 6.5 Grendel, the rifles feel like a light-loaded .223 Rem AR-15. None of them have much recoil to speak of and are very easy to self-spot with.

Hornady doesn’t list their pressure data, but they are staying under 52,000psi for the AR-15 loads, so we’re looking at either differences in propellant burn efficiency or a few thousand psi variance between test apparatuses. Since the PPC-based case uses a short, fatter propellant column, I suspect that has more to do with it because the 6mm Max guys seem to have used a reputable independent lab for their pressure testing, and the test protocol descriptions look good to me.

The real constraints

The physical dimensional constraint is the longer COL that requires different mags that will push the compatibility with the AR-15 lower receiver when you look at it from a production standpoint, especially for 25-30rd mags.

Can I make a magazine that allows 2.300” COL? Yes, of course. Can I crank out tens of thousands of them that will allow compliant factory ammunition to feed through them without binding the meplats on the front wall of the magazines for an economical price? So far, the answer to that with cartridges using shorter 2.260” COL has been a mixed bag. It also likely is factoring into why the Geissele 6mm ARC mags are so pricey. 6.8 SPC PRI mags are pricey as well. Keep in mind that with 6mm Max, we’re stretching the edge of COL just to get 100-105gr bullets in there, with powder column intrusion, whereas the 6mm ARC handles the 110gr A-Tip, 109 Berger, 108 ELD-M, 107 SMK, etc. with optimum projectile base placement relative to the SNJ (shoulder-neck junction).

If you need to use a 2.300” +/- 0.015” COL for factory ammunition, you need a wider variance length for your mag space. This means you need a larger magazine well for the AR-15, which has always been our main constraint when trying to get more performance out of the small frame receiver set. Once we depart from the existing magazine well and receiver set, we wipe out some of the important compatibility with parts supply in the market, and require re-design of the bolt carrier, its travel, the recoil system mechanical engineering for LRBHO, firing pin placement relative to hammer swing, magazine well geometry, and ground-up magazine development.

Financial constraints

You basically have to convince whoever is financing the effort that 50-100fps more muzzle velocity and 0.240” changes to component lengths is worth investing at least $1 million, likely more, for a huge gamble in potential ROI. Magazine development is very costly, as is pyramid testing.

Now if we could go back in time to 1957, I think .350 Legend or 25 Remington (.417” case head) parent cases make far more sense than the .222 Remington, and engineers within Ordnance Board proposed the 25 Remington parent with a slightly-longer receiver when they were having Stoner run around in circles with studies while trying to fast-track the M14 into production, the goal being to push any hopes of the AR-15 being adopted aside.

Right now, we do have some very significant improvements in performance out of the existing AR-15 receiver set, BCG, and Fire Control Group. The main thing I like about the 6mm Max for a military consideration is the compactness of the cartridge stack, while still bringing 8-10grs more powder under 65-75gr bullet weights when compared with the 5.56x45. That would cover down really well for both a carbine and a more nimble DM system, while still having small magazines that fit within the existing STANAG form factor for 30rd box mags. We haven’t seen a production 30rd mag yet for 6mm Max yet though, or what that would look like.

The demos where they are getting 20” 5.56 velocity out of a 10.5” 6mm Max kinda sells the cartridge for military applications, although there was pretty insane flame emanating from the suppressor in broad, cloudless daylight. It would need some flash suppressant in the propellant to help mitigate signature, like we have done over the decades with 5.56x45 and 7.62x51 in extensive continued development by ARDEC and Lake City.

Last edited:

From SOLGW : Great news on the mag front is that the caliber is designed to use our existing fantastic Duramag SS 350 legend magazines but we are putting out 6mm Max marked 20rd mags for the SOLGW team. Yesterday we also tested prototypes for a 30rd version which exceeded expectations for such an early prototype.

Also some more info on the 6mm MAX

Also some more info on the 6mm MAX

Last edited:

BC Precision is out of stock on their initial batch of SOLGW 6Max barrels, so someone is buying them... Anyone see or hear anything about initial end-user results?

BC Precision is out of stock on their initial batch of SOLGW 6Max barrels, so someone is buying them... Anyone see or hear anything about initial end-user results?

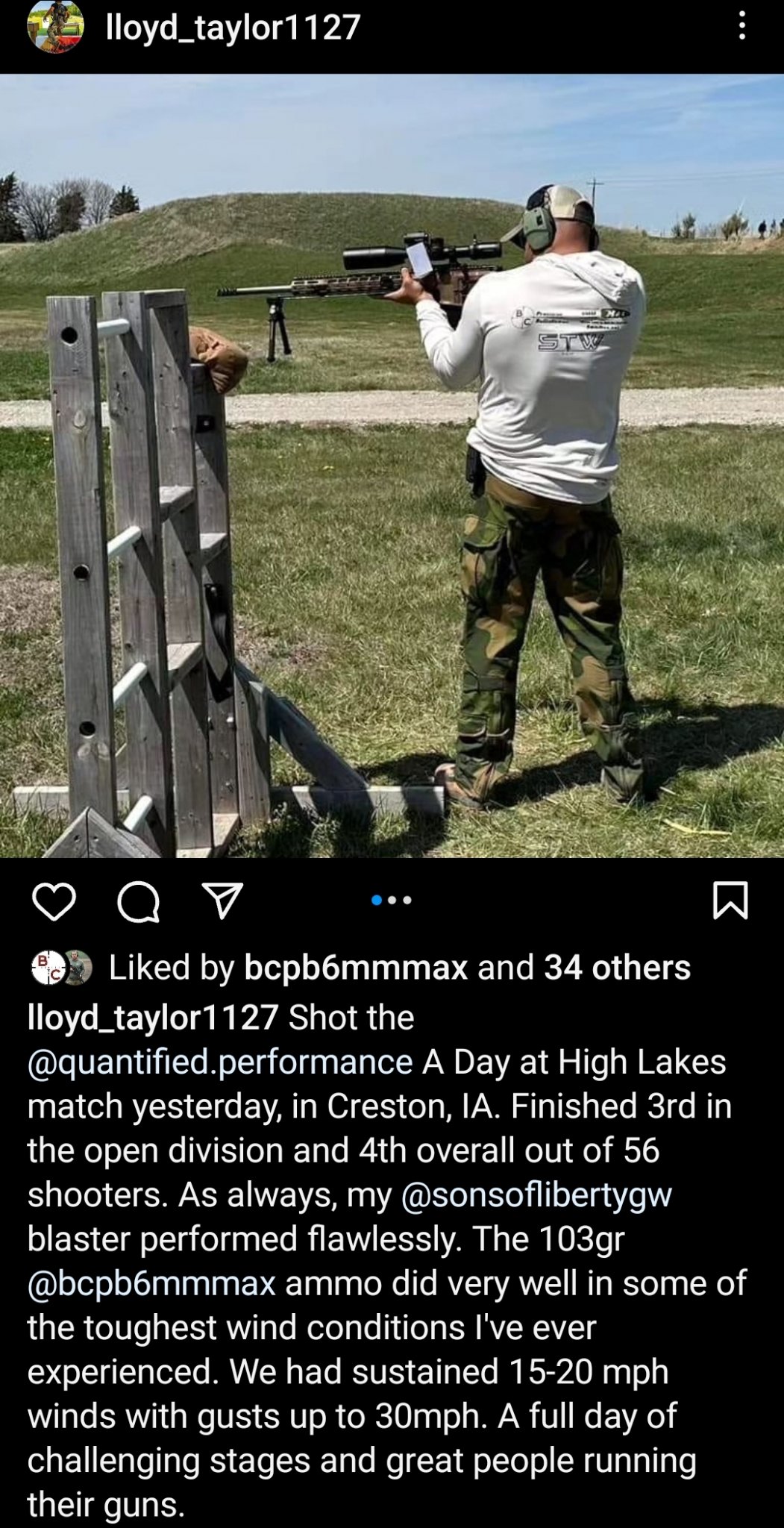

I think a couple of guys are going to shoot them in the next quantified match. I believe 2 people podiumed with them in the last match

I’m already thinking 22 max in an ar. Any one else see the fun of that?

I am periodically nagging them to do testing in a Howa Mini. This could be a killer youth rifle cartridge.

I am periodically nagging them to do testing in a Howa Mini. This could be a killer youth rifle cartridge.

This is what I’m thinking. I would love to buy a barrel for my mini-fix.

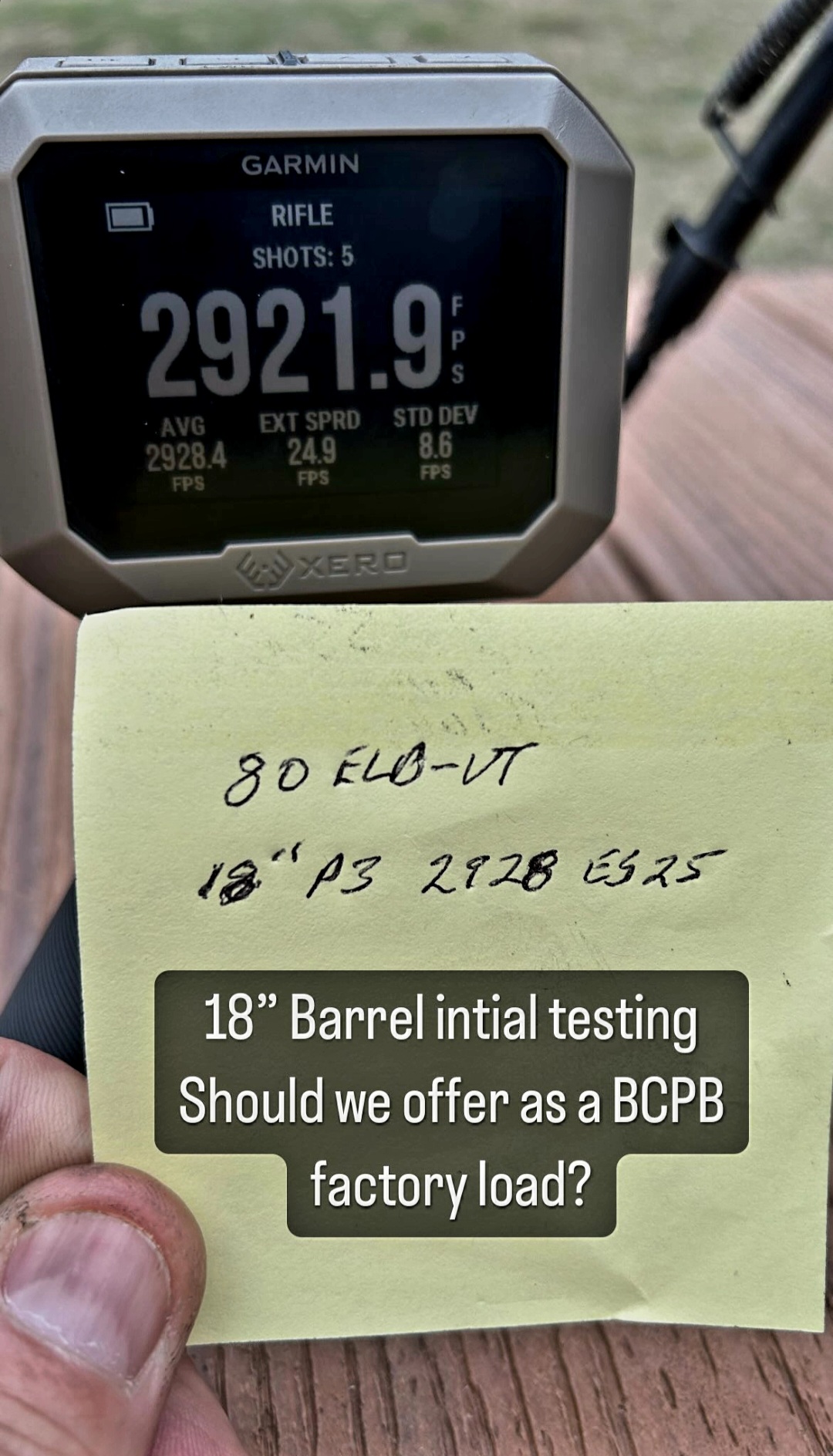

Don't have any details but looks like someone is testingThis is what I’m thinking. I would love to buy a barrel for my mini-fix.

I am having a couple of them made for my mini fix right now, the lead time is 6 to 8 months though. I am having to have a reamer made w/go-no gauges first which will take up to 8 weeks.

Who is going to spin barrels for you?

This is such a better fit for the mini fix than the ARC. From my understanding from tag firearms the ARC is requiring a whole new Bolt assembly instead of just a bolt face change for the 6ARC mini fix.

The reamer and gauges are being made by Pacific Tool and Gauge and Helix 6 Barrel will be spinning the barrel up for me. I had to provide the 2 mini fix 224 Valkyrie barrels I have so they can reuse the barrel extension. I don’t know if the barrel extension can be bought separately so I am sacrificing my 224 barrels.

i feel the same way, the 6 MAX is a better solution for the mini fix. it’s an expensive way to do it Overall but I am interested in the caliber. I hope I can get some better velocities out of a bolt gun, time will tell.

****Correction and clarification - PT & G is not licensed by BC Precision to make reamers and go/no gauges for the 6mm MAX cartridge.

Mike, over at BC Precision has informed me that they are working with Carbon Six barrels to make their barrels for the 6 Max.

i feel the same way, the 6 MAX is a better solution for the mini fix. it’s an expensive way to do it Overall but I am interested in the caliber. I hope I can get some better velocities out of a bolt gun, time will tell.

****Correction and clarification - PT & G is not licensed by BC Precision to make reamers and go/no gauges for the 6mm MAX cartridge.

Mike, over at BC Precision has informed me that they are working with Carbon Six barrels to make their barrels for the 6 Max.

Last edited:

Definitely happy to see it in a micro action rifle like that.Don't have any details but looks like someone is testing

View attachment 8390521

I need another caliber like I need another hole in my head, but this one has the gears turning.

I love…love…my 6.8 rifles, but a common/standard .223/5.56mm bolt like I have with my 300BLK rifles and uppers is pretty damn tempting.

I want to wait to see more data on how this works on hogs (especially vs. my beloved 6.8) before I rebarrel one of my uppers, but definitely tracking. Ironically I just sold my 350 Legend barrel and accessories, even though the attraction was the standard bolt face…that one just didn’t give me anything I wasn’t already getting with my 300 BLK guns, and I already have a 450 BM upper for straight wall cartridge needs.

I suspect this won’t be enough to get me to switch from 6.8…especially for the distances I typically shoot…but it’s gonna be interesting to follow this round’s development.

I love…love…my 6.8 rifles, but a common/standard .223/5.56mm bolt like I have with my 300BLK rifles and uppers is pretty damn tempting.

I want to wait to see more data on how this works on hogs (especially vs. my beloved 6.8) before I rebarrel one of my uppers, but definitely tracking. Ironically I just sold my 350 Legend barrel and accessories, even though the attraction was the standard bolt face…that one just didn’t give me anything I wasn’t already getting with my 300 BLK guns, and I already have a 450 BM upper for straight wall cartridge needs.

I suspect this won’t be enough to get me to switch from 6.8…especially for the distances I typically shoot…but it’s gonna be interesting to follow this round’s development.

So, I've been thinking all this time the 6MAX as a 1000yd beater of the 77SMK (.224) Zombies n shit...I need another caliber like I need another hole in my head, but this one has the gears turning.

I love…love…my 6.8 rifles, but a common/standard .223/5.56mm bolt like I have with my 300BLK rifles and uppers is pretty damn tempting.

I want to wait to see more data on how this works on hogs (especially vs. my beloved 6.8) before I rebarrel one of my uppers, but definitely tracking. Ironically I just sold my 350 Legend barrel and accessories, even though the attraction was the standard bolt face…that one just didn’t give me anything I wasn’t already getting with my 300 BLK guns, and I already have a 450 BM upper for straight wall cartridge needs.

I suspect this won’t be enough to get me to switch from 6.8…especially for the distances I typically shoot…but it’s gonna be interesting to follow this round’s development.

To think in terms of hog killing...oh boy! Load some 70-75gr Hammer Bullets, hunters or tipped hunters...pump that velocity and pop & bang flop! I know it would be a great out to 300yd load. Canyon buster no question.

That’s impressive, a Kudu isn’t exactly a small nor fragile animal!

I think with the right bullet the 6mm Max would be a very good choice for a new standard military cartridge . I think *** overall*** it just checks the most boxes for an AR15 sized platform. If 6mm Max really takes off ( probably around 2 years down the line) maybe Ridgeline Defense will also get into shorter barrel offerings or complete uppers. If so, I'll take a 11.5" inch suppressed and a 16" inch suppressed in 6mm Max, until then it's 5.56 shooting 70 and 77gr for bad guy ammo.

Last edited:

He mentioned something at the end of the video above.Anyone have insight on the next batch of barrels?

Where the heck are the barrels? SOLGW seems to dribble out a dozen or so once every couple of months.

BC Precision had some heavy-barrel (.875 gas block) 18" last week when I looked.Where the heck are the barrels? SOLGW seems to dribble out a dozen or so once every couple of months.

They had some on April 17th at a distributor. I'm on the waitlist for a 16", but was Out of stock in less than 30 minutes. They had some 18" barrels for the rest of the day...they were OOS by the morning of the 18th.

Last edited:

More going up on max website in 7 days when he gets back from AfricaWhere the heck are the barrels? SOLGW seems to dribble out a dozen or so once every couple of months.

Should we read into the font choice on those ammo boxes or no?

What are you seeing that I'm not?

Should we read into the font choice on those ammo boxes or no?

The "X" in "Max"?....