What sizing die is everyone using for the 6XC II chamber? I dont see any list. Are they custom order?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6XC Loads

- Thread starter Mormegil87

- Start date

Most of the 6XC dies you see for sale nowadays are appropriate for the 6XC II. I have both a Forster and a Tubb 6XC die (stock specs) and they both work perfectly for all of my 6XC II rifles using any brass (Norma, Alpha, and Peterson are what I've used so far). I also have a custom-made 6XC II die based on my reamer spec, but in retrospect that was totally unnecessary.

Do you know your measurement for a loaded round with 6xc Alpha SRP brass? I'm asking because my gunsmith uses a reamer that has the right body diameter but the neck on the reamer is only .273 and Alpha recommends a .274-.276 neck. I would like to have at least .003 clearance for the neck in the chamber.Most of the 6XC dies you see for sale nowadays are appropriate for the 6XC II. I have both a Forster and a Tubb 6XC die (stock specs) and they both work perfectly for all of my 6XC II rifles using any brass (Norma, Alpha, and Peterson are what I've used so far). I also have a custom-made 6XC II die based on my reamer spec, but in retrospect that was totally unnecessary.

My loaded necks measure 0.271 with Alpha SRP brass. I have the standard JGS 6XC II - LT reamer, which has 0.276 neck.

How’s the Peterson SRP necks measure loaded? How’s it hold up. Is all of the Peterson 6xc SRP brass the same. I heard the first lots were soft. I see Tubb carries it as well as other places and just want to know if it’s the same quality everywhereMy loaded necks measure 0.271 with Alpha SRP brass. I have the standard JGS 6XC II - LT reamer, which has 0.276 neck.

Loaded necks always measure 0.2710" with either Alpha SRP or Peterson SRP (unturned necks). This is with calipers that only go to 0.0005" increments.

I bought 800 of the first lot of Peterson 6XC SRP brass from Grafs before I heard about it's issues, thinking "oh man 40 cents each what an awesome deal let me click right away and buy this!".

Despite all I have heard and read about that first batch of brass being soft, having low capacity, etc, I am actually very pleased with it. The stuff shoots 0.3 MOA groups and lets met get DTACs to 3010 fps (accuracy node for me) without any pressure signs in my 6XC II chamber. I've won several PRS matches with it. I've got five or six stout firings on all of it and not a single pocket has loosened, case separation, neck split, etc. I do anneal in between each firing though.

I weighed 100 Peterson cases and found the standard deviation was three times higher than it was for Alpha brass (and that was actually two intermixed lots of Alpha). It sure doesn't show in shooting though.

I bought 800 of the first lot of Peterson 6XC SRP brass from Grafs before I heard about it's issues, thinking "oh man 40 cents each what an awesome deal let me click right away and buy this!".

Despite all I have heard and read about that first batch of brass being soft, having low capacity, etc, I am actually very pleased with it. The stuff shoots 0.3 MOA groups and lets met get DTACs to 3010 fps (accuracy node for me) without any pressure signs in my 6XC II chamber. I've won several PRS matches with it. I've got five or six stout firings on all of it and not a single pocket has loosened, case separation, neck split, etc. I do anneal in between each firing though.

I weighed 100 Peterson cases and found the standard deviation was three times higher than it was for Alpha brass (and that was actually two intermixed lots of Alpha). It sure doesn't show in shooting though.

Again I ask as someone looking hard at building a 6xc. Why does it seem that so many are going against the specific recommendations of the creator of the round? I understand some items suggested bring direct money back to SSS. But that’s the least of the variations I see.

1)Suggested reamer does not cost more or less than other reamers.

2) suggested LTP Peterson brass does not cost more or less than other brass. Actually cheaper through SSS. LRP lasting just as long as SRP per the people I shoot with.

3) suggested powders and FPS recommendations not adhered too. My understanding form SSS (2950) was this was to extend barrel life with maximum accuracy

4) Neck turning when the Peterson and suggested reamer eliminate the need.

I don’t own this cartridges. I do shoot with some that do. Just trying to do my do diligence before purchase. Thanks.

1)Suggested reamer does not cost more or less than other reamers.

2) suggested LTP Peterson brass does not cost more or less than other brass. Actually cheaper through SSS. LRP lasting just as long as SRP per the people I shoot with.

3) suggested powders and FPS recommendations not adhered too. My understanding form SSS (2950) was this was to extend barrel life with maximum accuracy

4) Neck turning when the Peterson and suggested reamer eliminate the need.

I don’t own this cartridges. I do shoot with some that do. Just trying to do my do diligence before purchase. Thanks.

Again I ask as someone looking hard at building a 6xc. Why does it seem that so many are going against the specific recommendations of the creator of the round? I understand some items suggested bring direct money back to SSS. But that’s the least of the variations I see.

1)Suggested reamer does not cost more or less than other reamers.

2) suggested LTP Peterson brass does not cost more or less than other brass. Actually cheaper through SSS. LRP lasting just as long as SRP per the people I shoot with.

3) suggested powders and FPS recommendations not adhered too. My understanding form SSS (2950) was this was to extend barrel life with maximum accuracy

4) Neck turning when the Peterson and suggested reamer eliminate the need.

I don’t own this cartridges. I do shoot with some that do. Just trying to do my do diligence before purchase. Thanks.

Same questions I had and couldn’t find the answers to. At least enough to sway me.

I ordered dies and reamer from Tubb. Figured it was easier to just do everything according to his specs/recommendations.

As you said, the cost isn’t any greater than any other 6mm round. Might as well go with tubb’s recommendations.

Yea, I don't understand it. I can't find anyone out side SSS that can answer my questions or provide a critical evaluation of an alternative that holds merit. I'm not married to the idea of the 6xc, it just continually checks the most boxes with me. I would easily entertain others if I could get non fan boy imputes. So for now, Ive got the action, stock, trigger, barrels (04), DBM, and what not just collecting dust till i find a 6mm to go with. Not in a rush, but would like to get started.

I am very new to the 6xc however I ordered a bartlein barrel from area 419 last week and had it chambered for 6xc. When I spoke with Craig from area 419 he told me their chambers are set up for Alpha SRP with berger 105 hybrids. I ordered Alpha brass and hybrids and will have the barrel installed this friday. Craig said he had thousands of rounds down range with their barrels and chambers and actually gave me load data for it over the phone. I will update next week once I get some ammo loaded up for it.

I am very new to the 6xc however I ordered a bartlein barrel from area 419 last week and had it chambered for 6xc. When I spoke with Craig from area 419 he told me their chambers are set up for Alpha SRP with berger 105 hybrids. I ordered Alpha brass and hybrids and will have the barrel installed this friday. Craig said he had thousands of rounds down range with their barrels and chambers and actually gave me load data for it over the phone. I will update next week once I get some ammo loaded up for it.

Thanks for the heads up. Can you expand on why your going against the inventors suggested reamer, brass, bullets, etc. Again just looking for information, not judging.

because they are just suggestions. they work. but so do dozens of other combos. Tubb is good, but he doesnt know the ONLY way to do 6XC. if he did, then why do we have a 6XC II, RBT DTACs, ATR. those are all second gen products.Thanks for the heads up. Can you expand on why your going against the inventors suggested reamer, brass, bullets, etc. Again just looking for information, not judging.

also, the way Tubb comes off, it is as if there is no other way. I guess when you won what he has and build what he has, you can do that.

105 v 115. H4350 v H1000. Norma v Peterson v Alpha. They all shoot 2950-3050 with moderate loads and good barrel life

Thanks for the heads up. Can you expand on why your going against the inventors suggested reamer, brass, bullets, etc. Again just looking for information, not judging.

The reason I personally went the area 419 route was that 1. They had a barrel blank in stock, and could have it to me in two weeks. 2 Craig at area 419 has had thousands of rounds through said barrels and those chambers are cut to what alpha brass suggests and knows its works. I guess I didn’t look at 6xc any differently then I would have if I was doing a 6BR or 6creed. Order a barrel get it spun up and then find a load it likes. Like I said I’m no pro of any of these cartridges I’m learning as I go as well. I’ll let you know how the barrel shoots first thing next week as soon as I get some load development done.

Sir, what would you say the SD is with that load?I have been using RL 16 in my 6XC all season and am very happy with the results, which are the same for three consecutive barrels now. Accuracy no worse than H4350 and H4831sc (which were both excellent), and I have not experienced any practical issues with the often-mentioned fact that the powder burns "dirtier" than others. Just clean your brake after each match and follow same barrel cleaning as with other powders.

Speed is better though. I found a node with 105 hybrids at 3160 fps (39.8 gr RL 16) that I cannot reach without mild pressure signs using H4350. I tested RL 16 up to 3230 fps just to explore where pressure would show up and had just barely flattened primers but no sticky bolt. This is with the 105s loaded so that the BT/bearing surface junction is about 1/3 of the way from the neck/shoulder junction, so keep in mind that my safe loads may be significantly higher than yours and follow appropriate safe load workup on your own rifle.

With uncoated DTACs I can push velocity to 3070-3080 before seeing pressure signs, but it shoots best at 2980 fps which is a node that I can also reach easily with H4350 or H4831sc.

My setup is:

6XC II chamber

28" Bartlein 7.4 twist

Peterson small primer brass

CCI 450s

115 DTACs (uncoated) or 105 hybrids

98Vandal I hope you find this useful.

I got a 6xc(II) [bartlein 26" 1:7], running 105 hybrids, 38.7gr of H4350 on Alpha munitions brass and CCI 200 Large pocket primers and I get about 3050 fps on average, but my SD is about 15, which I'm not happy with... If you were on my shoes, where would you start troubleshooting the high SD number? The reason I'm doing 38.7 is because when I did ladder testing 38.7 seemed promising, but now I wonder if I should go back to ladder testing to reconfirm 38.7 is a good node....

Thanks in advance!

My testing this last week had me comparing RL 16 and H4350. The bullets I tested were 1. 105 gr Berger Hybrid 2. 108 gr Hornady ELD-M 3. 110 gr Sierra Match King. I loaded charges from 38.2 gr to 39.6 gr (I increased charge weight by 0.2 gr per round tested and covered 8 rounds per powder with this test). All bullets were seated identically off the lands (0.010") to best represent as much control as one can during such a comparison/experiment.

Across the spectrum RL 16 proved to be the more energetic propellant when compared to identical charges of H4350; my results across the board favored RL 16 with a 1.45% to 1.91% increase in velocity (variance was greatest with lowest charge weight and least with greatest charge weight). In addition to a velocity increase, I actually observed a slight edge to the RL 16 in accuracy (I'm certainly not snapping the chalk line on this and considering it to be the final answer on accuracy but I am contributing to the conversation). I also fully recognize that the inventor of the cartridge did significant research, development, and testing in the creation of the 6 XC cartridge and his data is freely available for all to benefit from but enjoy the opportunity for we shooters to build upon an amazing cartridge in the pursuit of capturing its full potential.

Of note, I didn't get my 115 gr DTACs tested but will do so in the near future. The 115 gr DTAC appears to be the "Gold Standard" and I look forward to what that test will provide in both quantitative and qualitative data.

Across the spectrum RL 16 proved to be the more energetic propellant when compared to identical charges of H4350; my results across the board favored RL 16 with a 1.45% to 1.91% increase in velocity (variance was greatest with lowest charge weight and least with greatest charge weight). In addition to a velocity increase, I actually observed a slight edge to the RL 16 in accuracy (I'm certainly not snapping the chalk line on this and considering it to be the final answer on accuracy but I am contributing to the conversation). I also fully recognize that the inventor of the cartridge did significant research, development, and testing in the creation of the 6 XC cartridge and his data is freely available for all to benefit from but enjoy the opportunity for we shooters to build upon an amazing cartridge in the pursuit of capturing its full potential.

Of note, I didn't get my 115 gr DTACs tested but will do so in the near future. The 115 gr DTAC appears to be the "Gold Standard" and I look forward to what that test will provide in both quantitative and qualitative data.

I would guess that DT pushes H4350 due to the temp swings here in the Lone Star state. Yes, you leave a bit of speed on the table, but you avoid pressure issues and redoing your load every weather swing. That is a big issue down here for us year long volume shooters. Not so much when I was on the east coast.

I have been using RL 16 in my 6XC all season and am very happy with the results, which are the same for three consecutive barrels now. Accuracy no worse than H4350 and H4831sc (which were both excellent), and I have not experienced any practical issues with the often-mentioned fact that the powder burns "dirtier" than others. Just clean your brake after each match and follow same barrel cleaning as with other powders.

Speed is better though. I found a node with 105 hybrids at 3160 fps (39.8 gr RL 16) that I cannot reach without mild pressure signs using H4350. I tested RL 16 up to 3230 fps just to explore where pressure would show up and had just barely flattened primers but no sticky bolt. This is with the 105s loaded so that the BT/bearing surface junction is about 1/3 of the way from the neck/shoulder junction, so keep in mind that my safe loads may be significantly higher than yours and follow appropriate safe load workup on your own rifle.

With uncoated DTACs I can push velocity to 3070-3080 before seeing pressure signs, but it shoots best at 2980 fps which is a node that I can also reach easily with H4350 or H4831sc.

My setup is:

6XC II chamber

28" Bartlein 7.4 twist

Peterson small primer brass

CCI 450s

115 DTACs (uncoated) or 105 hybrids

98Vandal I hope you find this useful.

What powder charge are you using with the DTACs?

I've just finished testing the 115 gr DTACs with H4350 and RL 16 and, again, RL 16 pushed them faster by 0.21% (39.0 gr) to 3.27% (38.4 gr). At 39.6 grs (the farthest that I'm willing to go at this point), RL 16 pushed the bullet at 3035 fps while H4350 achieved 2968 fps. I appreciate the work of people like paproctor8 as his insight and detail has provided me a foundation to work with. I am unlikely to try and push the bullets much faster than what many of the more seasoned members and DT recommend. I'm finding great accuracy with what I've accomplished thus far and am still doing a bit more tweaking before I settle on a final load. Regardless, I really appreciate all the dialogue/feedback this thread has generated as it prevented me from starting from zero.

I would guess that DT pushes H4350 due to the temp swings here in the Lone Star state. Yes, you leave a bit of speed on the table, but you avoid pressure issues and redoing your load every weather swing. That is a big issue down here for us year long volume shooters. Not so much when I was on the east coast.

Yes and people are figuring out that you don’t need to be pushing every bullet as fast as possible.

Ask @JC Steel how fast he’s pushing his bullets.

Yes and people are figuring out that you don’t need to be pushing every bullet as fast as possible.

Ask @JC Steel how fast he’s pushing his bullets.

I like to run SLOW!!

Stay way away from pressure, accurate, never have problems(knock on wood), and the slower the bullet the more I get to watch them fly through the air. Which in some matches is a big advantage.

Sry to bring up an old thread, but has anyone used a 20” barrel 6xc using 105’s?

Yes, my daughters rifle is a 20" 7.5 twist 6XC. She's running Berger 105 VLD hunting bullets @ 2915 w/ 36.0 gr. of 4064 and it's a hammer!

I like to run SLOW!!

Stay way away from pressure, accurate, never have problems(knock on wood), and the slower the bullet the more I get to watch them fly through the air. Which in some matches is a big advantage.

Thinking about doing the same on my comp rifle.

Go heavy and slow, save some barrel life and no need to worry about the warm days.

Last match i used molly coated Berger 105 gr BT going 3100 fps, had a hard time spotting trace at most stages.

was really windy, 5-7ms and changing all the time with long distances to the plates(90% where at 600 yards plus, furthest at 1361 yards).

going to try get my hands on some 115 gr DTAC, would be nice with a mild load going 2900 fps or so.

Thinking about doing the same on my comp rifle.

Go heavy and slow, save some barrel life and no need to worry about the warm days.

Last match i used molly coated Berger 105 gr BT going 3100 fps, had a hard time spotting trace at most stages.

was really windy, 5-7ms and changing all the time with long distances to the plates(90% where at 600 yards plus, furthest at 1361 yards).

going to try get my hands on some 115 gr DTAC, would be nice with a mild load going 2900 fps or so.

I'm running the 115's at 2,923 with 38.2 grains of H4350 out of a 26" Kreiger barrel. I think the ES was 9 and SD 4.1, great accuracy. I've ran them as fast as 3,000, but didn't see the point for what I'm doing. Honestly I haven't dropped a charge in a case that didn't produce single digit SD's. Phenomenal round once I got everything figured out.

I'm going to run that load at a match Saturday, then play around at 38 even and see if I can get them running consistently around 2,900 and be done with it.

Yes, my daughters rifle is a 20" 7.5 twist 6XC. She's running Berger 105 VLD hunting bullets @ 2915 w/ 36.0 gr. of 4064 and it's a hammer!

Have you ever tried running 110 class bullets out of her 20" ? Could you load hotter with the 105 or that was near its max?

Looking to do an 18.5" in 6xc running 110smks hopefully at at least 2800. Only lose .1mil wind to those running above 3000fps. Not concerned about drop.

Have you ever tried running 110 class bullets out of her 20" ? Could you load hotter with the 105 or that was near its max?

Looking to do an 18.5" in 6xc running 110smks hopefully at at least 2800. Only lose .1mil wind to those running above 3000fps. Not concerned about drop.

I've never tried running anything else in her rifle but the same load in my 26" rifle is 3000 fps @ sea level. My normal match load in my 26" barrel with 105 or 115's is H4350 from 38 to 40 gr.

I've never tried running anything else in her rifle but the same load in my 26" rifle is 3000 fps @ sea level. My normal match load in my 26" barrel with 105 or 115's is H4350 from 38 to 40 gr.

Thanks. Looks like about a 85fps drop over 6" for her load in your gun. Feeling pretty good I should get 2800 with a 110 in an 18.5"

Thanks. Looks like about a 85fps drop over 6" for her load in your gun. Feeling pretty good I should get 2800 with a 110 in an 18.5"

I think you'll get there!

Anyone here have a .090 freebore with 1-30 lead angle in a 6XC II and shoot 105 Hybrids? I'm looking for the approximate OAL and base to Ogive measurements. Barrel is in process and trying to make some break-in loads while I have time.

Math says it should be around 2.01 to 2.1 to the bearing surface but looking for actual numbers from actual barrels.

Thanks in advance!

Math says it should be around 2.01 to 2.1 to the bearing surface but looking for actual numbers from actual barrels.

Thanks in advance!

Bennet, you have any data on 105 hybrids and distance to lands using Area 419s reamer? Have a barrel coming with same reamer and trying to get ahead of curve with some break in loads. Trying to get the oal of 105s touching and at ogive (using Hornady comparator #2 for the .243).The reason I personally went the area 419 route was that 1. They had a barrel blank in stock, and could have it to me in two weeks. 2 Craig at area 419 has had thousands of rounds through said barrels and those chambers are cut to what alpha brass suggests and knows its works. I guess I didn’t look at 6xc any differently then I would have if I was doing a 6BR or 6creed. Order a barrel get it spun up and then find a load it likes. Like I said I’m no pro of any of these cartridges I’m learning as I go as well. I’ll let you know how the barrel shoots first thing next week as soon as I get some load development done.

And if you've found any loads specific to that reamer, I'd be interested also.

Thanks!

Still wondering if anyone is running A-tips in their XC with RL16 or H4350? Looking to get a rough idea of where to start.

Anyone had luck with SMK 107’s or 110’s in their 6XC? I have a 26” 1:7 twist barrel, and I’ve only ran 115’s. Ordered 100 each of the 107’s and 110’s to test out.

Loaded up some A-Tips today to find a node. I was specifically looking for something a bit slower based of some of the recommendations Jake Vibbert has made in his podcast in regards to shooting slower loads.

Found a nice one at around 2830 with 37.0-37.4 grains of RL16. Going to try getting out this weekend to narrow down the charge weight even further.

37.1, 37.3 and 37.5 of RL16 with a COAL of 2.750 and 2.760. Hopefully have everything locked down by the end of the day on Tuesday.

Found a nice one at around 2830 with 37.0-37.4 grains of RL16. Going to try getting out this weekend to narrow down the charge weight even further.

37.1, 37.3 and 37.5 of RL16 with a COAL of 2.750 and 2.760. Hopefully have everything locked down by the end of the day on Tuesday.

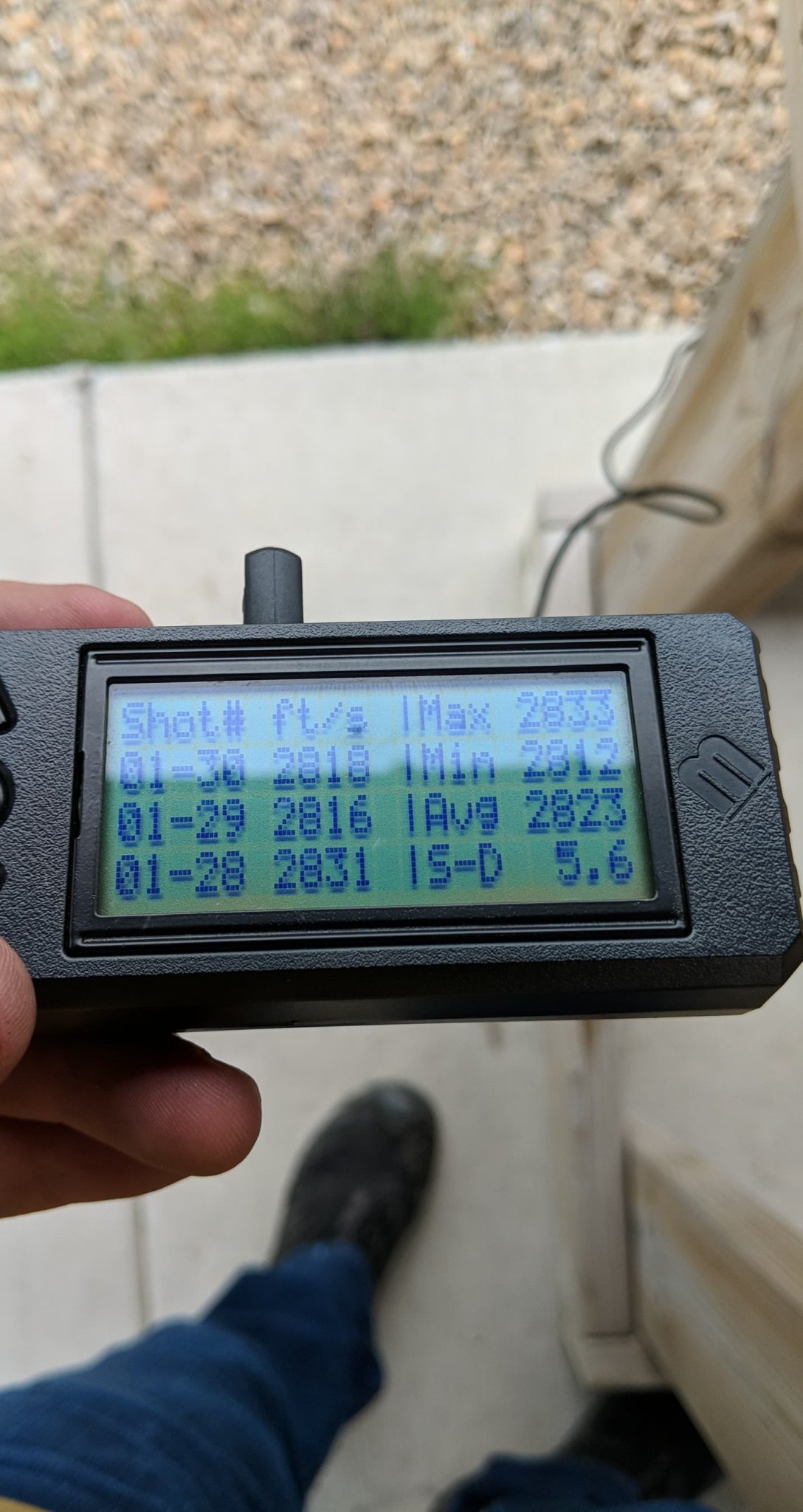

Think I've settled on:

Hornady A-TIPS

Alpha SRP

37.3 RL16

2.760 COAL

0.329" group

2830 Average

ES 11

SD 5.6

Final testing and sight in on Wednesday

Hornady A-TIPS

Alpha SRP

37.3 RL16

2.760 COAL

0.329" group

2830 Average

ES 11

SD 5.6

Final testing and sight in on Wednesday

Anybody tried much slower powders to get case fill ratio up? I have no prob running mine slow. Just trying to fill the void per say.

Thanks

Thanks

I did a little bit larger test than I normally. But I have the last two matches of the season, in the next two weekends so I wanted some good numbers.

1 String, 30 Rounds

Brass:. Alpha 6XC SRP

Primers: Federal Gold Medal Match

Powder: RL16

Charge: 38.3

Bullet: Hornady A-Tips

Jump: 0.025"

ES: 21

SD: 5.6

Average: 2823

I know it's slow but I'll be damned if it doesn't work really well.

1 String, 30 Rounds

Brass:. Alpha 6XC SRP

Primers: Federal Gold Medal Match

Powder: RL16

Charge: 38.3

Bullet: Hornady A-Tips

Jump: 0.025"

ES: 21

SD: 5.6

Average: 2823

I know it's slow but I'll be damned if it doesn't work really well.

Similar threads

- Replies

- 0

- Views

- 129

- Replies

- 5

- Views

- 187