Shooters, I just finished up another SPS package for a customer. It turned out really well as did the others. Now, with out coming off like a big baby, I hate doing these SPS packages for a few reasons.

So much of the chamber has to be "pushed forward" to get a nice clean chamber. With that being said, if the original chamber is not concentric with the bore, the new one will not be either.

In addition, the threads must be picked up so the new threads in the barrel match the original.

Furthermore, were still working with a factory barrel/bore which can be less than stellar, the threads, bore, and chamber are never concentric with (any combination) of each other.

Dialing in the bore also has its own specific challenges and can sometimes take an hour or two to get set up in the lathe just to start making cuts. I never get that good feeling that everything will turn out the way it should like when I'm doing a barrel from scratch.

Now, with that being said, this rifle came together after quite some time and it really shoots well!

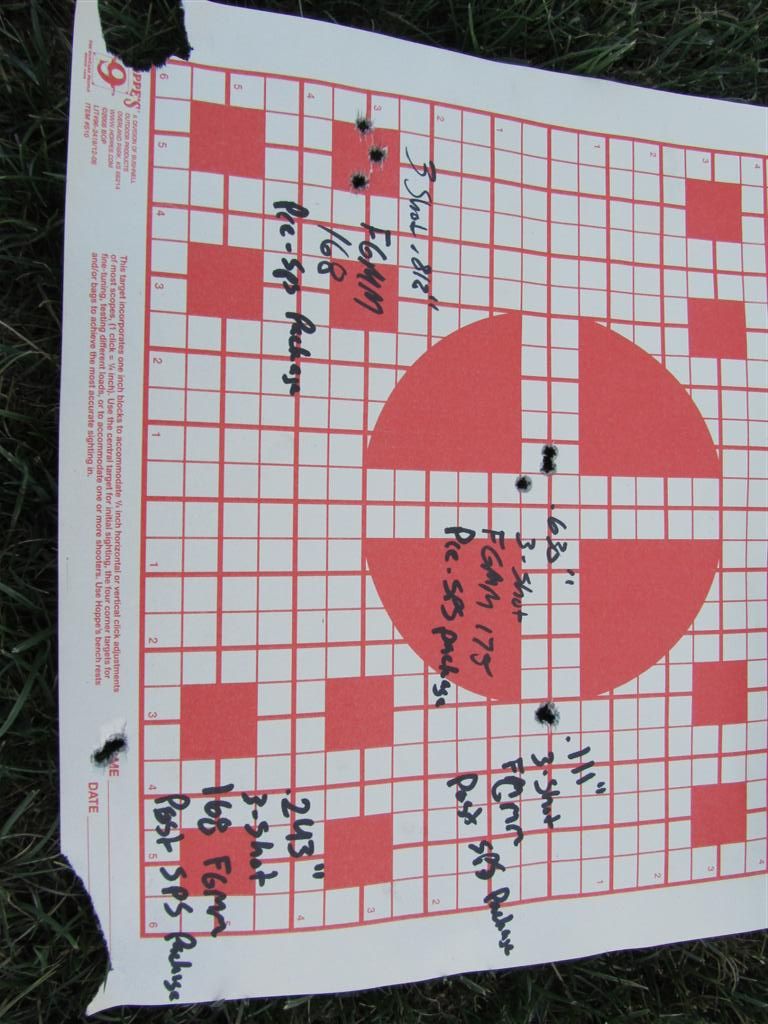

I test fired the rifle just as I received it from the customer but with my optics and a cleaned barrel.

Federal Gold Metal Match 168 and 175 ammo was used in each 3 shot group. Ammo is expensive and you get the point with the 3 shot groups, so 5 shot groups would have added 8 more rounds fired....$$$$

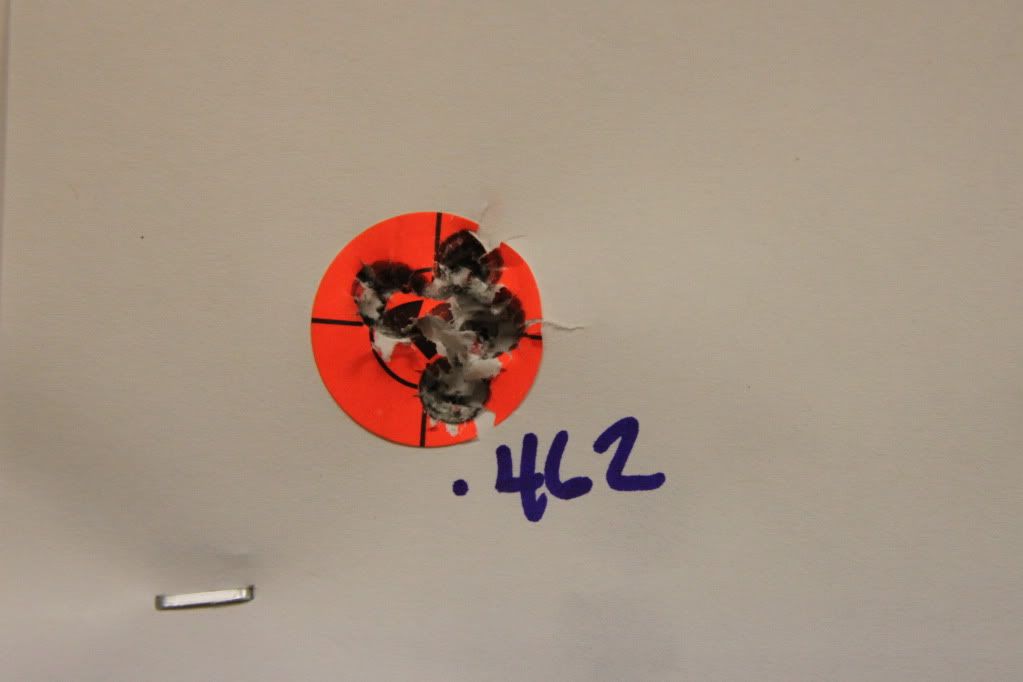

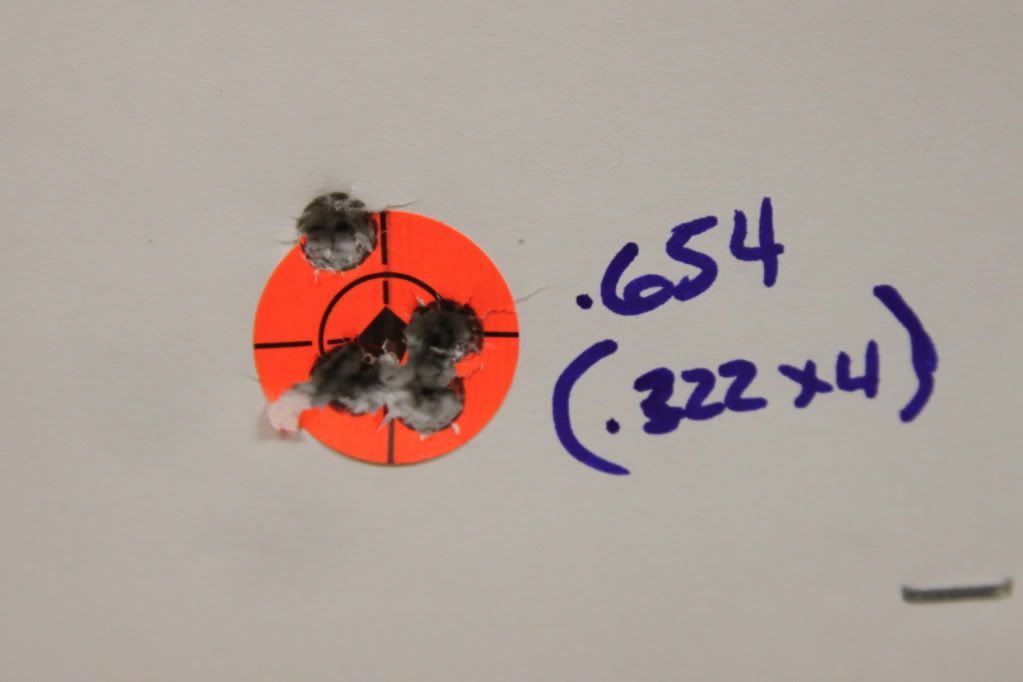

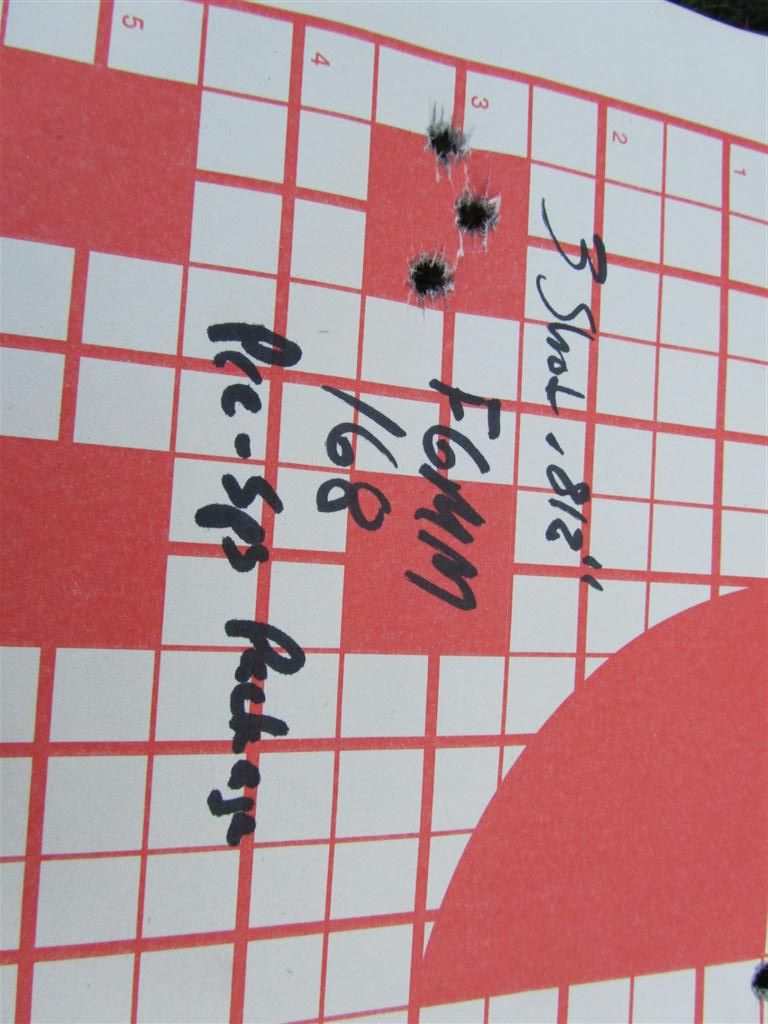

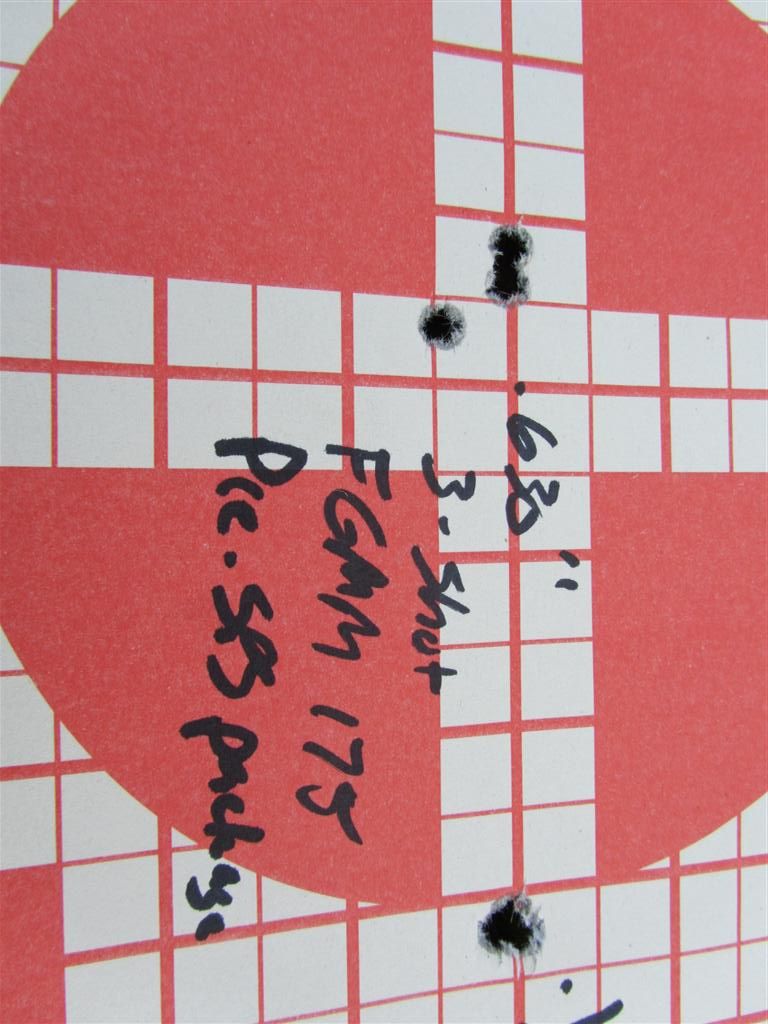

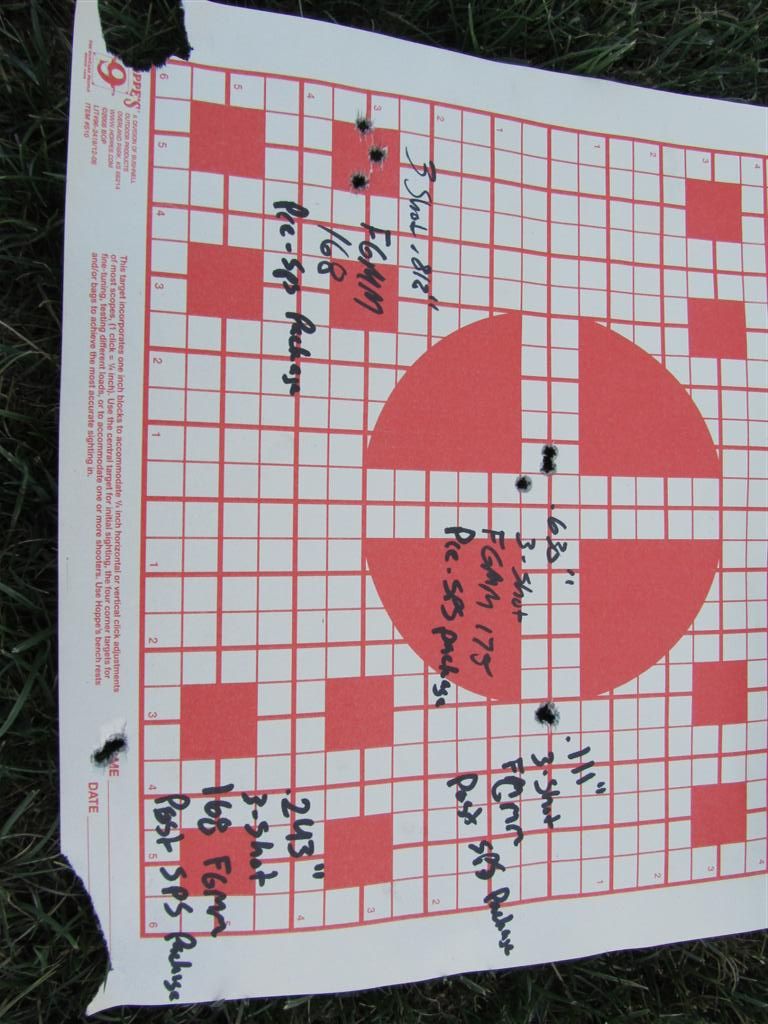

The Pre-SPS package groups measure....

168 FGMM- .812"

175 FGMM- .630"

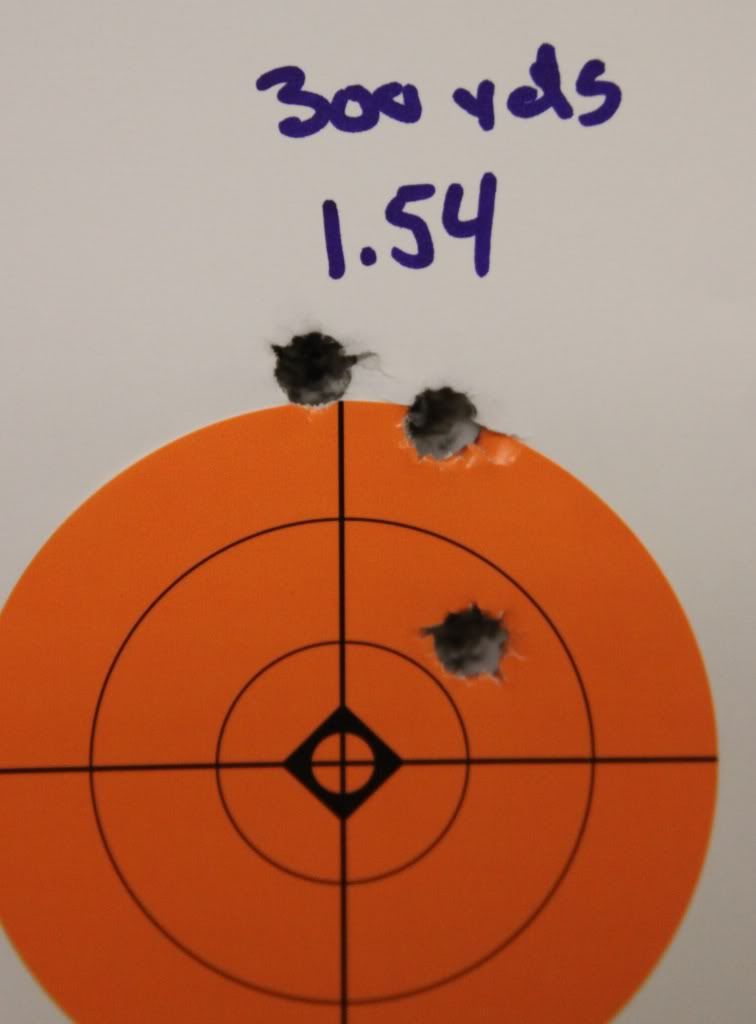

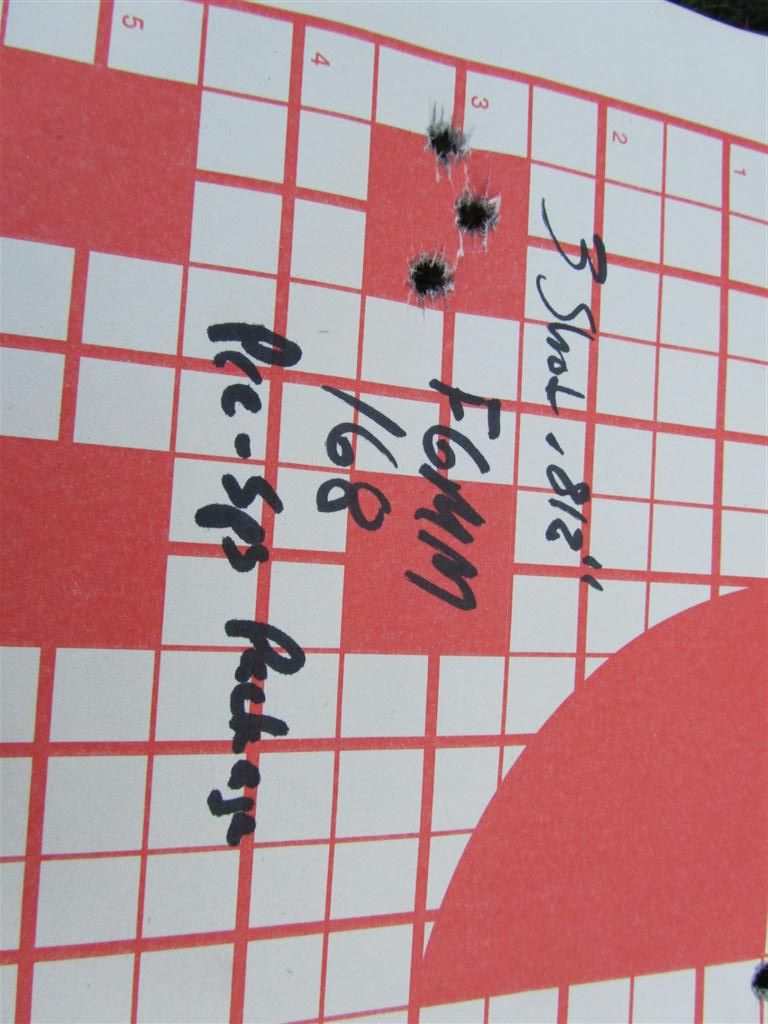

The Post-SPS package groups measure....

168 FGMM- .243"

175 FGMM- .111"

These rifles get the same attention that my custom builds get. The processes and techniques used are highly precise and no stone is left unturned when doing these packages.

Here are some pictures....

Pre-SPS Package FGGM 168 3 shot Group

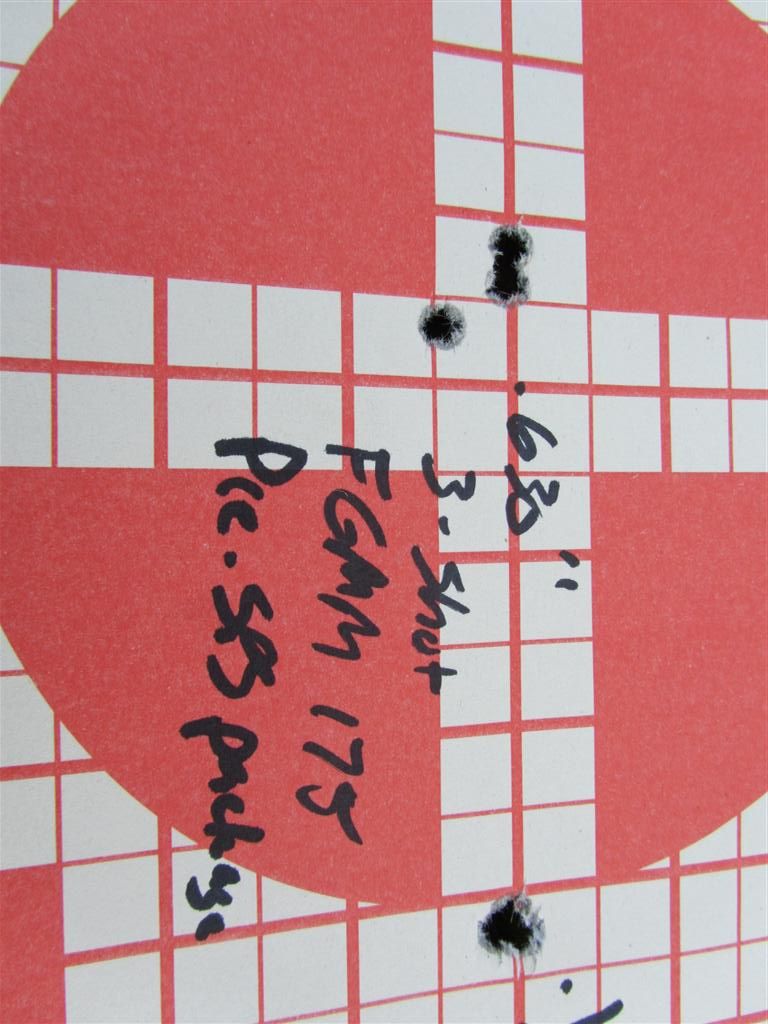

Pre-SPS Package FGMM 175 3 shot group

Post-SPS Package FGMM 168 3 shot group

Post-SPS Package FGMM 175 3 shot group

Mark

So much of the chamber has to be "pushed forward" to get a nice clean chamber. With that being said, if the original chamber is not concentric with the bore, the new one will not be either.

In addition, the threads must be picked up so the new threads in the barrel match the original.

Furthermore, were still working with a factory barrel/bore which can be less than stellar, the threads, bore, and chamber are never concentric with (any combination) of each other.

Dialing in the bore also has its own specific challenges and can sometimes take an hour or two to get set up in the lathe just to start making cuts. I never get that good feeling that everything will turn out the way it should like when I'm doing a barrel from scratch.

Now, with that being said, this rifle came together after quite some time and it really shoots well!

I test fired the rifle just as I received it from the customer but with my optics and a cleaned barrel.

Federal Gold Metal Match 168 and 175 ammo was used in each 3 shot group. Ammo is expensive and you get the point with the 3 shot groups, so 5 shot groups would have added 8 more rounds fired....$$$$

The Pre-SPS package groups measure....

168 FGMM- .812"

175 FGMM- .630"

The Post-SPS package groups measure....

168 FGMM- .243"

175 FGMM- .111"

These rifles get the same attention that my custom builds get. The processes and techniques used are highly precise and no stone is left unturned when doing these packages.

Here are some pictures....

Pre-SPS Package FGGM 168 3 shot Group

Pre-SPS Package FGMM 175 3 shot group

Post-SPS Package FGMM 168 3 shot group

Post-SPS Package FGMM 175 3 shot group

Mark