Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Autotrickler V3 - CE Products?

- Thread starter NiteQwill

- Start date

Adams card that comes in the package says "to the Kernel within 10 seconds".

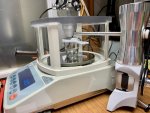

I have never in my life purchased something that has over performed like this thing has...

good lord. I did a comparison to my Lyman Gen 6 and the V3. The same weights thrown, I can throw 4 charges in the time it takes to throw one with the Gen6 and they are to the .01 grain of H4350.

LOL! Welcome to the FX-120AT brotherhood! (fun, ain't it?)

I just got mine today!! Had about 10 minutes to open it up and lay the parts out before i had to call it quits for the day. Definitely ready to throw some charges on it tomorrow. First class machining and 3D printing. Hopefully i can update you guys tomorrow on how great it is after i use it.

The plan tomorrow is to cut one of the draft shields in half And drill a hole in one for the trickler so i can set it all up with my 419 clear lid(that came in the package) and not have to screw with it anymore.

The plan tomorrow is to cut one of the draft shields in half And drill a hole in one for the trickler so i can set it all up with my 419 clear lid(that came in the package) and not have to screw with it anymore.

Instructions tell you specifically which one to use I believe. Do not use the one that comes with the scale.Came with two power cords , what one y’all using. Outlet is 110/120 volt .

Michigan, south to Ohio where it sat for 3 days, then west to Illinois for 2 days and then finally arrived in Houston early yesterday morning where it has been sitting ever since. I think someone wrote on the box, please deliver as slowly as possible. 50 miles to go and the wait is killing me!*sigh* mines been sitting in Olive Branch MS since 8pm Friday......

Man that sucks, it’ll be worth it I’m sure. Mine did make it to Alaska yesterday, FedEx must of felt their ears burning. Supposed to be delivered by end of day today. Almost 10 weeks from order to delivery.Michigan, south to Ohio where it sat for 3 days, then west to Illinois for 2 days and then finally arrived in Houston early yesterday morning where it has been sitting ever since. I think someone wrote on the box, please deliver as slowly as possible. 50 miles to go and the wait is killing me!

Rainy day, better go get some brass prepped for it!

Got mine setup and the hope drilled in the wind shield for the trickler.. took my time with everything and was very deliberate, it probably took me about 20 mins to fully set it up and start throwing powder.... this thing was definitely worth the wait!

Well just arrived, opening the boxes, step one is install the tilt adjustment screw. Except there is no threads or insert of any type in the trickler base. Or am I not seeing something in the kit. Anyone got a picture of their screw hole? Adjuster just drops in a hole.

Attachments

Sigh, figured there was supposed to be an insert.There should be a brass bushing that threaded?

If they can't get you a replacement quickly I can send you the base I'm not using since I have the Area 419 base.Sigh, figured there was supposed to be an insert.

If they can't get you a replacement quickly I can send you the base I'm not using since I have the Area 419 base.

Me too, did you find it a PIA to switch over? , the screws that hold the funnel were a 1/16 allen key, and hard to reach, alot different than the video I watched, but that was an earlier base I guess?

Just curious, how did you decide to put the funnel on? with the Autotrticker logo facing the scale or facing out?

Yes, it was a bit of a PITA. Not horrible, but more of a pain than I expected. I also had to put thicker rubber feet on the bottom so I could use it with the standard powder pan. The Area 419 pan sits lower so it isn't a problem if you use their pan.Me too, did you find it a PIA to switch over? , the screws that hold the funnel were a 1/16 allen key, and hard to reach, alot different than the video I watched, but that was an earlier base I guess?

Oh and funnel logo facing scale although if I'd thought about it I probably would have faced it out.

Last edited:

Anyone got a picture of their screw hole?

Sooooo many jokes....so....soo....many

Yes, it was a bit of a PITA. Not horrible, but more of a pain than I expected. I also had to put thicker rubber feet on the bottom so I could use it with the standard powder pan. The Area 419 pan sits lower so it isn't a problem if you use their pan.

Oh and funnel logo facing scale although if I'd thought about it I probably would have faced it out.

I couldn't agree more, I did take a second look at it ? but decided it was too much of a PIA to remove the screws.

I wonder if the holes were symmetrical? I'm guessing there were.

Or one of these threaded inserts would probably work.Sigh, figured there was supposed to be an insert.

Sooooo many jokes....so....soo....many

For now, works pretty good actually haha.

mother of all inventions!

Just a FYI in case someone is chasing their ass like I did for MONTHS. I had the area419 setup and my scale was so damn finicky. It would lose zero, wander all over hell, and if I weighed a powder charge in an hour if I weighed it again it was significantly different. I couldn't even get through a batch without it changing. Thought my scale was defective and I consider myself a decent troubleshooter. Well it was the tray from Area419. I went back to the OEM pan and it's been absolute bliss ever since. Area419 sent me a new one but still gave me problems. I know I'm a minority but my buddy read the solution somewhere and saved my sanity so I'm passing my experience on. I think AREA419 is a great company and don't mean any disrespect.

Just a FYI in case someone is chasing their ass like I did for MONTHS. I had the area419 setup and my scale was so damn finicky. It would lose zero, wander all over hell, and if I weighed a powder charge in an hour if I weighed it again it was significantly different. I couldn't even get through a batch without it changing. Thought my scale was defective and I consider myself a decent troubleshooter. Well it was the tray from Area419. I went back to the OEM pan and it's been absolute bliss ever since. Area419 sent me a new one but still gave me problems. I know I'm a minority but my buddy read the solution somewhere and saved my sanity so I'm passing my experience on. I think AREA419 is a great company and don't mean any disrespect.

Interesting , how old is your unit? and was this happening recently? I wonder if anyone else had the same problem? Did Area 419 offer any ideas?

Thank you! I was considering getting the 419 tray and cup but I will stick with the OEM. Saved me some money that paid of my Area419 funnel kit (Which is amazing.)Just a FYI in case someone is chasing their ass like I did for MONTHS. I had the area419 setup and my scale was so damn finicky. It would lose zero, wander all over hell, and if I weighed a powder charge in an hour if I weighed it again it was significantly different. I couldn't even get through a batch without it changing. Thought my scale was defective and I consider myself a decent troubleshooter. Well it was the tray from Area419. I went back to the OEM pan and it's been absolute bliss ever since. Area419 sent me a new one but still gave me problems. I know I'm a minority but my buddy read the solution somewhere and saved my sanity so I'm passing my experience on. I think AREA419 is a great company and don't mean any disrespect.

The hopper and lid from Area419 make a great addition, a little more expensive than an old H4350 lid but worthwhile.When your scrounging for more prepped brass..... dam this thing could get expensive in more ways than one.

Didn’t like the idea of not covering the trickler. Lid from an empty can of H4350.

Auto Trickler Hopper Funnel/Lid

Another highly customer requested upgrade for the Autotrickler V2 and V3! Introducing our billet aluminum hopper funnel with lid. Features- – 3″ Diameter funnel seals to Autotrickler hopper with an o-ring – Allows easier pouring from jugs into trickler hopper – O-ring between lid and funnel...

Modern solutions to modern problems. I like It! Plus I'm super cheap when it comes to certain thingsWhen your scrounging for more prepped brass..... dam this thing could get expensive in more ways than one.

Didn’t like the idea of not covering the trickler. Lid from an empty can of H4350.

This was last summer and fall. Other people have had the problem which is how my buddy came across the solution. It really was a miserable problem. Constantly chasing my ass and unsure of load consistency despite having paid a lot of money for the autotrickler so I could have confidence in my powder charges. Area419 said they had some reports and thought it may have to do with the part going into the hole of the scale. However the new one didn't fix the problem so I quickly put it in the drawer. Now I have 2 and I can't in good conscience sell them to someone and them end up with the frustrations I've had. Same with original powder holder that I no longer need after upgrading to V3.Interesting , how old is your unit? and was this happening recently? I wonder if anyone else had the same problem? Did Area 419 offer any ideas?

The V3 and autotrickler is a complete pleasure to use now. It's my favorite part of the process now.

Does it come with a copy of the instructions and assembly manual or do I need to print a copy from their web page?

Ordered mine 7/6. Am I looking at Sept for delivery??

What else do I need beside the clear lid. I ordered it for delivery with the ATV3.

Forgot, I think I read it is already programmed from CE products? Just assemble the parts? I downloaded the app already.

Ordered mine 7/6. Am I looking at Sept for delivery??

What else do I need beside the clear lid. I ordered it for delivery with the ATV3.

Forgot, I think I read it is already programmed from CE products? Just assemble the parts? I downloaded the app already.

Instructions come with for both the scale and the ATV3. It is already programmed. Just assemble and put it to work.Does it come with a copy of the instructions and assembly manual or do I need to print a copy from their web page?

Ordered mine 7/6. Am I looking at Sept for delivery??

What else do I need beside the clear lid. I ordered it for delivery with the ATV3.

Forgot, I think I read it is already programmed from CE products? Just assemble the parts? I downloaded the app already.

I see you are still playing with a full deckWhen your scrounging for more prepped brass..... dam this thing could get expensive in more ways than one.

Didn’t like the idea of not covering the trickler. Lid from an empty can of H4350.

Contacted Adam, he’s working on getting one shipped to replace the base. No drama, honest mistake.I see you are still playing with a full deck, did you get a resolution to not having threads? Mine is out for delivery!

Probably never have played with a full deck, don’t know why I’d start now.

What do you think Sixwhiskey? Worth the wait?View attachment 7403826What can Brown do for you! 12 weeks to the day.

Just finished playing with my AutotricklerV3....again...another 100 rounds of 300PRC at 78.5 grains of N565....then 20 rounds of 223 using Accurate 2230....found some on a shelf at Midsouth...and then 40 rounds of 300blk with Lil'gun. On the 300blk....I'm only using 12.0 grains of Lil'gun...so I turned the thrower off and just used the trickler....yea....a little slow...but I was cleaning up my mess around the shop while it spun up.

For those that don't have an AutotricklerV3 yet...and you are sitting there trying to justify the cost....and you are indecisive.... I'll tell ya...this is the single most piece of reloading equipment that exceeded my expectations....while the price was high...and I had to eat off brand Ramen....not even Top Ramen...but Bottom Ramen....it was well worth it. I'd say if I had to do it all over again...that'd I'd buy this first....I can't..because I don't think I would have really enjoyed V2 or V1.....the V3 is the entry point where all the cool shit is...the ease of use and setup....quality....it's ready for prime time. Plus....the V3 wasn't available when I first started reloading...we were still using scales with stone counter rocks....and complaining that the dinosaur stomping was causing the scales to drift.

Again...this thing rocks harder than Joe Dirt rocks a mullet.

For those that don't have an AutotricklerV3 yet...and you are sitting there trying to justify the cost....and you are indecisive.... I'll tell ya...this is the single most piece of reloading equipment that exceeded my expectations....while the price was high...and I had to eat off brand Ramen....not even Top Ramen...but Bottom Ramen....it was well worth it. I'd say if I had to do it all over again...that'd I'd buy this first....I can't..because I don't think I would have really enjoyed V2 or V1.....the V3 is the entry point where all the cool shit is...the ease of use and setup....quality....it's ready for prime time. Plus....the V3 wasn't available when I first started reloading...we were still using scales with stone counter rocks....and complaining that the dinosaur stomping was causing the scales to drift.

Again...this thing rocks harder than Joe Dirt rocks a mullet.

@Sixwhiskey what can brown do for me?....see where that Fragile sticker is on your box?....usually mine has a nice size 11 boot print right across it...and then some dents in the side like the neighbor kids have been using it for soccer practice. The V3 came to me double boxed and heavily padded...thank god....not a scratch on the unit...but the box was rather....well...it had some character.

I finally got to mess with it a little yesterday evening, loaded up a quick to 10 rounds to narrow down a velocity. Started at 39 and worked up to 43.5 in .5 increments. Took all of 10 minutes. Shot those, came back in and loaded 10 more from 41 to 42 to further narrow it down. So all total around 40 minutes with a new powder to find the velocity area I want to explore. I really didn't need to start as low as 39, but wanted to see how easy it was. To answer your question, yes it was worth the wait.What do you think Sixwhiskey? Worth the wait?

I will add to what b2lee said with, the scale is the most important part of the whole setup. If you are on a budget, I would start there. You could always drop a funnel down the hole with a long neck, use a lee powder dipper and a manual trickler and be faster than a beam scale and more accurate than my Chargemaster. Or if you already have a powder thrower, throw low and trickle on the FX-120. Don't get me wrong, the whole package is the 74 69 74 73 0d 0a , but I wish I had bought the scale years ago. So many frustrations would have been solved and so much powder, components and barrel life saved.

I have so more tweaking to do, right now I am consistently throwing low by about a kernel, but I have only loaded the 20 rounds.

p.s. if you know what the whole package is, congrats on being as big a geek as I am !

!

I have so more tweaking to do, right now I am consistently throwing low by about a kernel, but I have only loaded the 20 rounds.

p.s. if you know what the whole package is, congrats on being as big a geek as I am

p.s. if you know what the whole package is, congrats on being as big a geek as I am!

It's my favorite part of a woman

@Sixwhiskey what can brown do for me?....see where that Fragile sticker is on your box?....usually mine has a nice size 11 boot print right across it...and then some dents in the side like the neighbor kids have been using it for soccer practice. The V3 came to me double boxed and heavily padded...thank god....not a scratch on the unit...but the box was rather....well...it had some character.

When my UPS man showed up he said he something from Italy for me, I said "huh?" Well it says "fra-gee-lay"! He is a good kid and always takes care of us, but I was worried as well, especially since my son used to work for UPS. The stories he told.

So I am consistently .02 under. I am playing with some 4166 for a 308 load and I am guessing each kernel weighs around .03. So is it better to be over or under, or it doesn't matter as long as its consistent? Or it doesn't matter because 1 kernel isn't going to make a difference? It is just hard on my OCD.

.02 under as in you are setting the load for 94 and consistently getting 93.98? That is fine it is rated as .02 accurate so it is doing it's job. Unless you are dropping a fine powder it will rarely get dead on. Consistency is what makes me happy, my standard deviations have dropped below four.So I am consistently .02 under. I am playing with some 4166 for a 308 load and I am guessing each kernel weighs around .03. So is it better to be over or under, or it doesn't matter as long as its consistent? Or it doesn't matter because 1 kernel isn't going to make a difference? It is just hard on my OCD.

@bunny too Some powder charges fall on target easier than others almost like my desired powder charge falls on the half kernel sometimes.

However, there is a guy here on SH that sells reducers of 2 different sizes for the end of the trickler and you get both for $17 on ebay. Surprisingly they are freaking awesome. He says half the people swear by the bigger and 1/2 swear by the smaller. I realize I said game changer and I meant it. It makes it so the trickler has finer adjustment if that makes sense. It can be more horizontal and the slightest adjustment gets me on target. Plus I can adjust the drop 1/2 grain from target and the trickle hits the mark before the final slow motion that again grinds on my soul.

Before the reducer I was either 0.02 gr below OR way over. Drove my OCD batshit crazy.

However, there is a guy here on SH that sells reducers of 2 different sizes for the end of the trickler and you get both for $17 on ebay. Surprisingly they are freaking awesome. He says half the people swear by the bigger and 1/2 swear by the smaller. I realize I said game changer and I meant it. It makes it so the trickler has finer adjustment if that makes sense. It can be more horizontal and the slightest adjustment gets me on target. Plus I can adjust the drop 1/2 grain from target and the trickle hits the mark before the final slow motion that again grinds on my soul.

Before the reducer I was either 0.02 gr below OR way over. Drove my OCD batshit crazy.

That is excellent information!@bunny too Some powder charges fall on target easier than others almost like my desired powder charge falls on the half kernel sometimes.

However, there is a guy here on SH that sells reducers of 2 different sizes for the end of the trickler and you get both for $17 on ebay. Surprisingly they are freaking awesome. He says half the people swear by the bigger and 1/2 swear by the smaller. I realize I said game changer and I meant it. It makes it so the trickler has finer adjustment if that makes sense. It can be more horizontal and the slightest adjustment gets me on target. Plus I can adjust the drop 1/2 grain from target and the trickle hits the mark before the final slow motion that again grinds on my soul.

Before the reducer I was either 0.02 gr below OR way over. Drove my OCD batshit crazy.

Thank you ifgator,

-b

Last edited:

If you followed set up procedures it should have had you put the scale sensitivity to fast. Which is basically instant from what I can tell. That wont help when two or three clump together, when the trickler isnt leveled right or if there is a slight draft.That is excellent information!how would I find the reducers?I was think of sending Adam an email asking that he modify the APP so it has a "magnum" setting, a setting that would set the stepping motor in the trickler to a second between each step when it gets within a tenth of the desired charge; as I typically weigh magnum powders my kernels weigh about .06 grains a piece, it would not be uncommon (though not typical) for it to go from 94 grains (my setting) to 94.04 or .06 (or .08 etc.) within the amount of time it took the scale to register the weight. Drives me crazy too , I just dump the load back in the hopper and sigh.I will search ebay for the reducers, if you want to send me a link that would be cool too. Found and purchased, thank you for the information and help

Thank you ifgator,

-b

I did but even on fast the trickler runs for a tenth to a fifth of a second after a grain drops and the weight registers, this occasionally allows a second or third grain to drop. I have the trickler level on a four inch granite surface plate with three breeze blocks installed, even on the fast sensitivity setting I think there is a fraction of a second lag. When the kernels are that large it can make a difference.If you followed set up procedures it should have had you put the scale sensitivity to fast. Which is basically instant from what I can tell. That wont help when two or three clump together, when the trickler isnt leveled right or if there is a slight draft.

I run mine with a negative 1 degree angle and it usually undercharges by 0.02 and sometimes right on the target weight - it rarely goes over. This is using H4350 and CFE223 powders. To me negative 1 degree means the autotrickler is tilted back away from the scale.Try to run the trickler with a plus one degree angle instead of level?

That's actually where I'm at. Either right on or 0.02 heavy which is so much faster and better.I run mine with a negative 1 degree angle and it usually undercharges by 0.02 and sometimes right on the target weight - it rarely goes over. This is using H4350 and CFE223 powders. To me negative 1 degree means the autotrickler is tilted back away from the scale.

@bunny too I meant to find the link but I have surgery tomorrow and the day got away from me. I'd love to hear how you like the reducers. I'm not sure which I'm currently using but I've found the one I'm currently using is best for the Varget I've been using lately. The other is better for RL 26 and Vihtavouri 560. I realize this is very descriptive and helpful information

https://www.ebay.com/itm/Auto-Trick...529916?hash=item3b478d8ebc:g:zsAAAOSweLBaWTlN

Here is a link I found on Ebay.

Here is a link I found on Ebay.

I received my eBay reducers today. I have three now. The first I bought is from Dan636 on here. It is the same one made of brass in Elfster's videos. Very well machined and threaded both inside and out. The ones from Ebay are not threaded and are smooth on the inside. , I wrapped them with teflon and they screwed right in. The Ebay reducer is a set of two different sizes both of which are bigger than the brass one. All three seem to be good to go.

I also installed 3 panels as seen below, back, left and front. My setup sits on the far left of my bench and it made more sense to work from the right side. Eliminated all draft issues and so far I haven't bumped the trickler. In fact, it is a non-issue, I don't even think about it being there when I place the cup. The other thing I did was put the clear plastic cover back on the scale, that combined with the weight of the 419 lid made the top more stable.

I also installed 3 panels as seen below, back, left and front. My setup sits on the far left of my bench and it made more sense to work from the right side. Eliminated all draft issues and so far I haven't bumped the trickler. In fact, it is a non-issue, I don't even think about it being there when I place the cup. The other thing I did was put the clear plastic cover back on the scale, that combined with the weight of the 419 lid made the top more stable.

Last edited:

Similar threads

- Replies

- 0

- Views

- 194

- Replies

- 0

- Views

- 453

- Replies

- 56

- Views

- 2K