Guess I shouldn't have said anything lol, no email for me yet. I wonder if they ran out and production will have to catch back up.Cool, there's a chance I could get mine shipped out today then. We shall see.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AutoTrickler V4

- Thread starter adamjmac

- Start date

Ironically, I just got my email, they said if I paid by 11/15 it would go out on the next export. I'll probably have it before thanksgiving! For those that didn't read my earlier post, mine was not a conversion, I reserved it on 3/12 at 2:15pm Atlantic time.Guess I shouldn't have said anything lol, no email for me yet. I wonder if they ran out and production will have to catch back up.

Got mine in Monday. Setup was easy with the included instructions. Before I messed with the speeds it was throwing a charge in 26ish seconds. After some tuning I got it down to 10-15. This is going to cut my reloading time down considerably.

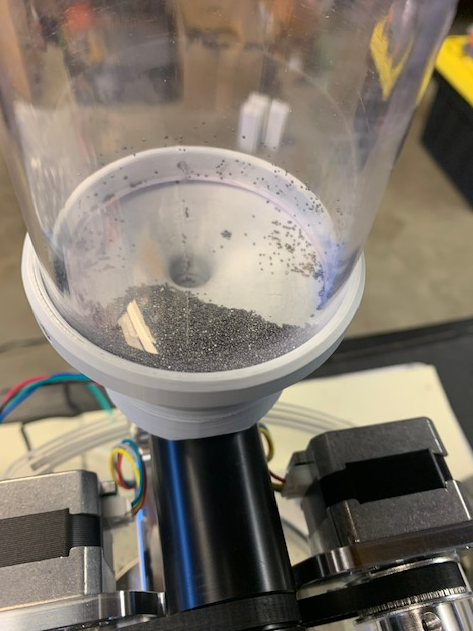

Just got mine in and decided to torture test it, so I pulled out a ~15 year old can of W231 that’s been sitting in the shed. After cleaning the can off, and after the calibration (had to depress the front slightly to get the small tube to start to flow, as covered in directions), it metered excellently. The only thing I’ve noticed is the flake powders do tend to ‘stick’ to things, and sneak inside of crevices at the joint of the hopper tube and hopper base. I got a fair bit stuck around the bottom of the plastic hopper tube material, wedged between it and the plastic bottom piece. I was able to flex the plastic tube enough to get most of it out.

Emptying it wasn’t too big of a deal; I would just suggest you do it by lifting off the device from the scale vs. rotating the whole scale and needing to deal with leveling/etc again. I found that following the instructions worked quite well. I just added some taps here and there, and overall it worked as expected.

I love the all-in-one nature of this vs. my v2 and v3s, and so for me - upgrading from a v3 would be a solid YES. That said, I don’t think it’s much faster than my v3 was, just less to move around/deal with on the bench. I am very happy with it, and if it can handle a really old flake powder like that, there isn’t much I’m worried about with my other powders.

[Sidenote]

I do wish there was a ‘pay more’ price to skip all the FDM 3d-printed stuff and just have it machined, I’d gladly pay the extra. I may fire up my CAD software and then head out to the shop and kick off the CNC mill and lathe to one-off, but I don’t like spending all that time figuring out designs/fixturing/etc.

In function, it likely won’t matter that much with most powders, but I don’t like the look of the FDM grey parts, nor the stair-stepping on the parts that flow, especially with static at play.

Emptying it wasn’t too big of a deal; I would just suggest you do it by lifting off the device from the scale vs. rotating the whole scale and needing to deal with leveling/etc again. I found that following the instructions worked quite well. I just added some taps here and there, and overall it worked as expected.

I love the all-in-one nature of this vs. my v2 and v3s, and so for me - upgrading from a v3 would be a solid YES. That said, I don’t think it’s much faster than my v3 was, just less to move around/deal with on the bench. I am very happy with it, and if it can handle a really old flake powder like that, there isn’t much I’m worried about with my other powders.

[Sidenote]

I do wish there was a ‘pay more’ price to skip all the FDM 3d-printed stuff and just have it machined, I’d gladly pay the extra. I may fire up my CAD software and then head out to the shop and kick off the CNC mill and lathe to one-off, but I don’t like spending all that time figuring out designs/fixturing/etc.

In function, it likely won’t matter that much with most powders, but I don’t like the look of the FDM grey parts, nor the stair-stepping on the parts that flow, especially with static at play.

Last edited:

What was your email reservation date and time?Got mine yesterday

View attachment 7743713

Last edited:

That’s because the are manufacturing the super trickler.For what it's worth, I reached out to Area419 for an updated tray/replacement for all the 3d printed parts for the v4, and they said no plans at this time. If people are interested, you may want to reach out.

Thanks! I’m March 12 at 4:22 so hopefully in a few weeks.@Slim Reaper

I placed my order between March 12 1:58pm and 3:07pm Atlantic

I got mine 2 days ago. I only put it together, I haven't put powder in it yet. But I did find out that a 1/4x20 bolt fits in the threaded hole in the back. Put some Teflon tape on it so it won't move and use it instead of shims.

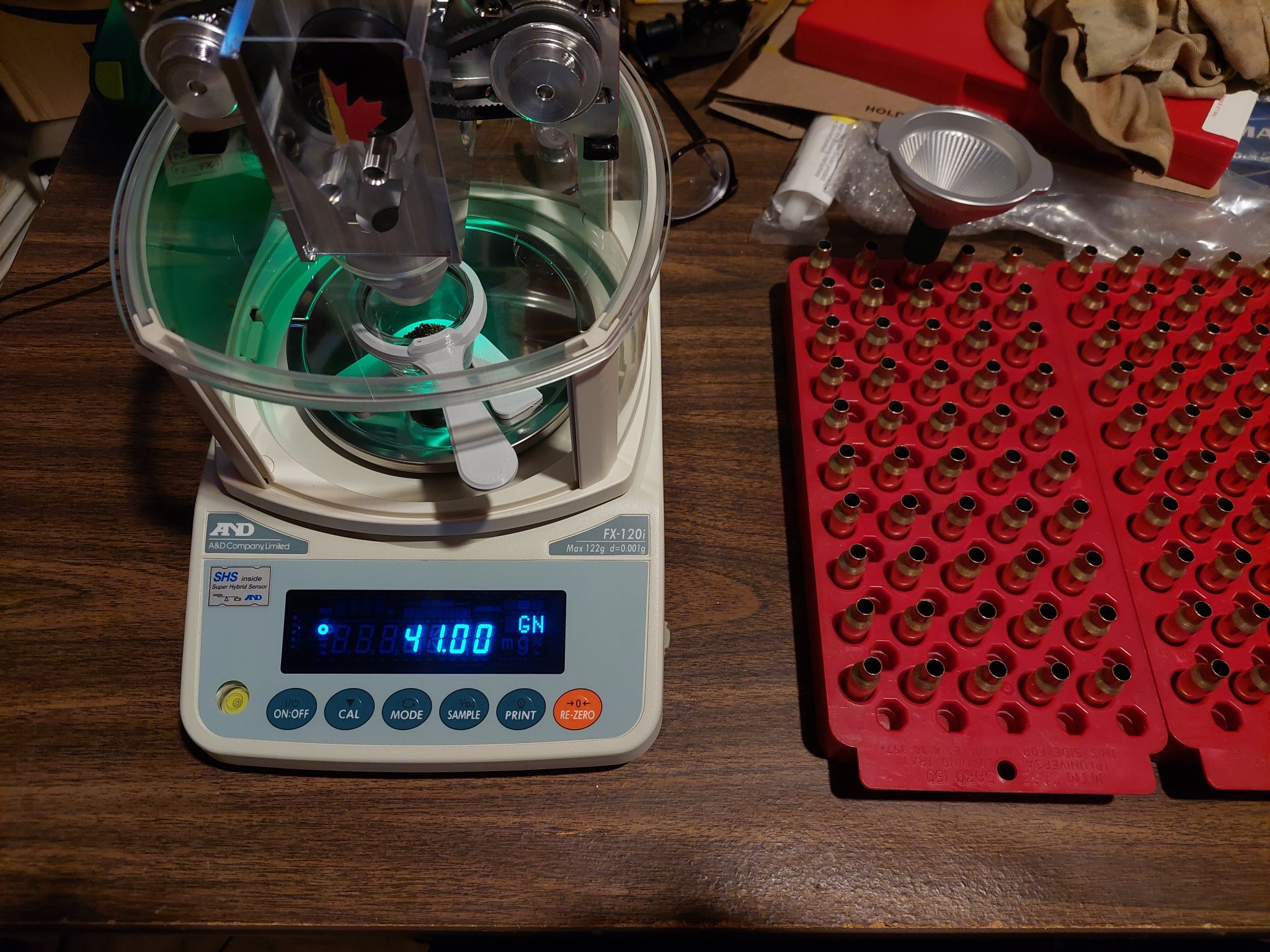

Dropped 200 loads today for the first time. H4350 41 grains, after calibration and no shimming, I was getting +-.02 accuracy, many hitting it right on the nose @ 41.0. If it hit 40.98 it would stop dispensing. Occasionally, when the large drop tube reversed it would over throw. This was done on a crappy table and not on a proper bench. Still for the most part right on the money. I never owned a scale that if you breathed next to it would change the measured weight, always returning to what it was before breathing on it though...

I finally got some free time last weekend to setup my V04. Swapping it out from the V03 was surprisingly quick and easy. All throughout this past week I spent time after work making a variety of my most common precision loads (.223REM, .308WIN, 6.5x47L, .338LM Improved, and .300NM) to get feel for how much better V04 is over V03. For the most part it's faster and more reliable to use, especially with big kernel powders like N570. But on the flipside I see a regression with small spherical powders like TAC and AA2520, with the dispenser spraying quite a bit around the platter.

Edit: yes, I realize the Area419 platter doesn’t line up with the V04 drop. I made sure the scoop was directly under the drop when I ran these.

After about 30 drops of AA2520 - crap everywhere

My field expedient solution to this was just just tape some paper to better guide it into the funnel. It doesn't eliminate the problem, but it does fix the problem to a satisfactory level. This is probably one of those cases where an extended drop tube like the one Area419 makes would be a better solution.

The angle of the bottom of the reservoir seems flatter than the V03, so it prematurely runs empty. Easy fix - just add more powder than needed, but a little annoying.

All in all it's a great upgrade, but I hope Area419 makes a set of metal upgrades for this model like they did for the previous.

Edit: yes, I realize the Area419 platter doesn’t line up with the V04 drop. I made sure the scoop was directly under the drop when I ran these.

After about 30 drops of AA2520 - crap everywhere

My field expedient solution to this was just just tape some paper to better guide it into the funnel. It doesn't eliminate the problem, but it does fix the problem to a satisfactory level. This is probably one of those cases where an extended drop tube like the one Area419 makes would be a better solution.

The angle of the bottom of the reservoir seems flatter than the V03, so it prematurely runs empty. Easy fix - just add more powder than needed, but a little annoying.

All in all it's a great upgrade, but I hope Area419 makes a set of metal upgrades for this model like they did for the previous.

Last edited:

I ordered the 419 platter and cup after my March order of the V3. Well, I converted my order to the V4 and now own the platter that doesn't line up with the V4 drop and the cup is too far from the drop and allows the powder to spill out. I like the slot the cup slides into so I took a jigsaw to the platter and cut the excess back and front off along with the pin on the bottom. I of course lined the plate up first so the platter cup hole and cup lined up perfectly with the drop. The front curve of the platter follows the curve of the base plate cover. Using 2 sided 3M fender tape it stays on the base plate cover plus this also gets the 419 cup up closer to the funnel drop so no spillage at all. Slides in and out perfectly. As long as you zero the scale-out in the same spot you're using, it's accurate. I'll never have a V3 so I didn't mind cutting it.

Yeah, we are going to need some pictures....I ordered the 419 platter and cup after my March order of the V3. Well, I converted my order to the V4 and now own the platter that doesn't line up with the V4 drop and the cup is too far from the drop and allows the powder to spill out. I like the slot the cup slides into so I took a jigsaw to the platter and cut the excess back and front off along with the pin on the bottom. I of course lined the plate up first so the platter cup hole and cup lined up perfectly with the drop. The front curve of the platter follows the curve of the base plate cover. Using 2 sided 3M fender tape it stays on the base plate cover plus this also gets the 419 cup up closer to the funnel drop so no spillage at all. Slides in and out perfectly. As long as you zero the scale-out in the same spot you're using, it's accurate. I'll never have a V3 so I didn't mind cutting it.

I use the v4 and AA2520 without any spills at all.I finally got some free time last weekend to setup my V04. Swapping it out from the V03 was surprisingly quick and easy. All throughout this past week I spent time after work making a variety of my most common precision loads (.223REM, .308WIN, 6.5x47L, .338LM Improved, and .300NM) to get feel for how much better V04 is over V03. For the most part it's faster and more reliable to use, especially with big kernel powders like N570. But on the flipside I see a regression with small spherical powders like TAC and AA2520, with the dispenser spraying quite a bit around the platter.

Edit: yes, I realize the Area419 platter doesn’t line up with the V04 drop. I made sure the scoop was directly under the drop when I ran these.

View attachment 7744638

After about 30 drops of AA2520 - crap everywhere

View attachment 7744639

My field expedient solution to this was just just tape some paper to better guide it into the funnel. It doesn't eliminate the problem, but it does fix the problem to a satisfactory level. This is probably one of those cases where an extended drop tube like the one Area419 makes would be a better solution.

View attachment 7744644

The angle of the bottom of the reservoir seems flatter than the V03, so it prematurely runs empty. Easy fix - just add more powder than needed, but a little annoying.

All in all it's a great upgrade, but I hope Area419 makes a set of metal upgrades for this model like they did for the previous.

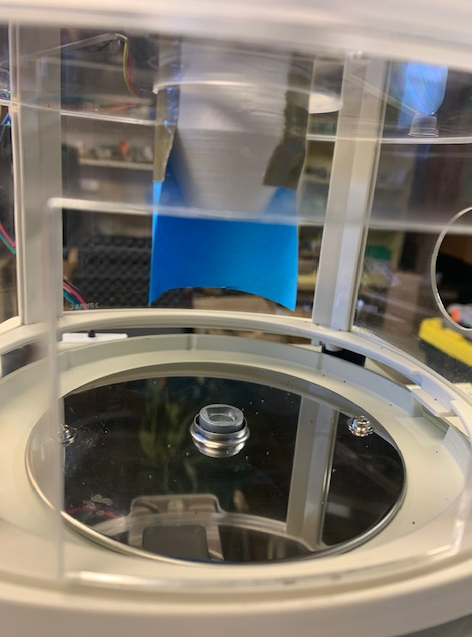

Have you tried it without the area 419 parts? I’ve the used the original parts only … I’ve stuck on the piece of plastic that lines up the cup. If you follow the instructions, the cup will be a little offset from the drop tube. It essentially lines up so the powder is hitting the wall of the cup. I think this was something that Adam mentioned in his YouTube a while back as being important for the v4.

It’s all good. The added paper guard solved the issue. But hearing that it’s not a problem for you, I’ll take the drop spout off today and see if the interior needs to be cleaned up. Something causing turbulence in the flow could explain the splashing (it’s dropping in a cone shaped spray pattern). I assumed it had more to do with the trickle nature of the flow in the V04 vs the volume drop in V03.

I knew that was coming.Yeah, we are going to need some pictures....

Here is the front view showing the funnel and cup clearance.

Overhead view. The base plate cover can be rotated so you can adjust where the powder falls into the cup. But I get no spillage with it centered.

Looks damn fine work!I knew that was coming.

Here is the front view showing the funnel and cup clearance.

View attachment 7744976

Overhead view. The base plate cover can be rotated so you can adjust where the powder falls into the cup. But I get no spillage with it centered.

View attachment 7744978

View attachment 7744980

View attachment 7744982

View attachment 7744985

I am finding the V4 to be much better at throwing extruded powders. I will be using the V3 for fine ball powders only.

I used the V04 to load some big .338LM Improved tonight and another nice new feature stood out: no need to double drop large charges. With the V03 if I wanted to drop 106gr I’d have to tweak it to drop something like 50gr twice. No biggie if you’re dropping big charges most of the time, but adjusting from throwing 18gr here, 38gr there, and then having to drop closer to 50gr is a bit of a pain. More importantly it could be a bit slow with added trickling.

The V04 does it in one go. And to then turn around and drop 38gr for a 6.5mm is a piece of cake.

The V04 does it in one go. And to then turn around and drop 38gr for a 6.5mm is a piece of cake.

What powder are you using?I used the V04 to load some big .338LM Improved tonight and another nice new feature stood out: no need to double drop large charges. With the V03 if I wanted to drop 106gr I’d have to tweak it to drop something like 50gr twice. No biggie if you’re dropping big charges most of the time, but adjusting from throwing 18gr here, 38gr there, and then having to drop closer to 50gr is a bit of a pain. More importantly it could be a bit slow with added trickling.

The V04 does it in one go. And to then turn around and drop 38gr for a 6.5mm is a piece of cake.

Okay, cause I am having a little trouble with H1000. Maybe I will keep that in my ATv3 and use the v4 for extruded powders only.N570 , RL33, and LRT

LRT is a ball powder and meters just fine. If you scroll up a bit you’ll see where I was getting a lot of spill with ball powders, but that turned out to be because of a mod I made to my scale that raised the cage a bit.

I don’t shoot H1000 so I can’t really test that on my end.

I don’t shoot H1000 so I can’t really test that on my end.

I just got mine this week and need to load up some 300wm with h1000. What is the problem?Okay, cause I am having a little trouble with H1000. Maybe I will keep that in my ATv3 and use the v4 for extruded powders only.

It is consistently throwing .5 to two grains over.I just got mine this week and need to load up some 300wm with h1000. What is the problem?

Assuming you ran the calibration...It is consistently throwing .5 to two grains over.

Where is the slider on the app set?

Is it shimmed in the back at all? If not maybe shim the front?

I haven't ran H1000 but ran stabal without issue.

Any chance you'd be willing to share the stl?made a cover for the output

SURE, send me your emailAny chance you'd be willing to share the stl?

I'm using the V4 again today. Charging 500 cases of 308 Winchester, at 250 now. Using Reloader 15, 41 grains.

Drops are 80% @ 40.98, 18% @ 41 and 2% 41.02, getting a very minor amount of kernels bouncing out of the pan.

A few drops here and there @ 41.04.

Update:

I'm @ 400 drops now and did some timing...

Most drops are between 22 and 25 seconds. Some as low as 17, and the high is 34.

Also, there is some powder kernels sticking around the small drop tube at the bushing. I've wiped them off and they return. Must be some static building up around that bushing.

Drops are 80% @ 40.98, 18% @ 41 and 2% 41.02, getting a very minor amount of kernels bouncing out of the pan.

A few drops here and there @ 41.04.

Update:

I'm @ 400 drops now and did some timing...

Most drops are between 22 and 25 seconds. Some as low as 17, and the high is 34.

Also, there is some powder kernels sticking around the small drop tube at the bushing. I've wiped them off and they return. Must be some static building up around that bushing.

Last edited:

Ahh...I see. Great idea.live in the desert, wind blowing dust and crawling spiders

The time it takes to drop a charge seems excessively long. Is there any way you can tune it to go faster?I'm using the V4 again today. Charging 500 cases of 308 Winchester, at 250 now. Using Reloader 15, 41 grains.

Drops are 80% @ 40.98, 18% @ 41 and 2% 41.02, getting a very minor amount of kernels bouncing out of the pan.

A few drops here and there @ 41.04.

Update:

I'm @ 400 drops now and did some timing...

Most drops are between 22 and 25 seconds. Some as low as 17, and the high is 34.

Also, there is some powder kernels sticking around the small drop tube at the bushing. I've wiped them off and they return. Must be some static building up around that bushing.

View attachment 7747683

I left it on the setting of 5 (default), you can bump that up at the cost of accuracy it says... I'll have to try

The large tube drops most of the powder in about 5 seconds, to about 39 grains in this case. Then the small tube takes over and that's where the time gets extended.

The large tube drops most of the powder in about 5 seconds, to about 39 grains in this case. Then the small tube takes over and that's where the time gets extended.

The time it takes to drop a charge seems excessively long. Is there any way you can tune it to go faster?

Any ideas on a dust/storage cover for the v4 setup? Would like to protect it a bit when not in use.

I’m using a food processor cover for my v3 that I got off of Amazon. Not sure if it’s going to fit the v4.Any ideas on a dust/storage cover for the v4 setup? Would like to protect it a bit when not in use.

Crutello Food Processor Cover with Storage Pockets for Small 2.5-5 Cup Processors, Fits Various Brands https://smile.amazon.com/dp/B08PPT9GKH/ref=cm_sw_r_cp_api_glt_fabc_B9B248SM8MJ93PC00D7B?_encoding=UTF8&psc=1

CE has the complete V3 kit going like hot cakes today. They say you’ll get before Christmas. Thier website has popups that alert you when someone adds something to thier cart. I was on and had like 6 pop ups for the v3 kit being sold.

What I have noticed is that when the trickler starts to get close to the target weight, it is inconsistent slowing down. Out of 10 throws, the speed would slow down pretty linear only on average 2 or 3 times. The rest, the speed would not slow down until .02 before the target weight. And with extruded powders, this means an overthrow every time. This is disappointing.

I tried to use a custom speed set-up in the menu. I slowed the trickler tube down to 3 from the default setting of 4. I also changed the transition from the large to small tube down to 1.0 grains from the default setting of almost 2.5 grains. And although these changes resulted in perfect throws when the trickler slowed with a linear pattern, it did nothing when the trickler slowed at or very near (.02gr) from the target from it's full speed.

Why does this happen? If the trickler would start to slow down around a half of a grain from the target weight (with a linear pattern all of the time instead of just a few times out of 10), then over throws would be a lot less then 7 or 8 tries out of 10.

I'm not sure why this happens. When the trickler slows properly, it really works great. With exact throws every time. And that's saying a lot for extruded powders. When it doesn't, it is frustrating because the over throw is .04 to .10 of a grain. Far from the precision I am looking for.

I'm hoping I can work through this issue somehow with the custom settings and not to have to resort back to my tweezers like the V3 with extruded powders. Or this whole exercise of an "upgrade" will have been wasted.

I will report back. (BTW, the powder I used was IMR4198.)

I tried to use a custom speed set-up in the menu. I slowed the trickler tube down to 3 from the default setting of 4. I also changed the transition from the large to small tube down to 1.0 grains from the default setting of almost 2.5 grains. And although these changes resulted in perfect throws when the trickler slowed with a linear pattern, it did nothing when the trickler slowed at or very near (.02gr) from the target from it's full speed.

Why does this happen? If the trickler would start to slow down around a half of a grain from the target weight (with a linear pattern all of the time instead of just a few times out of 10), then over throws would be a lot less then 7 or 8 tries out of 10.

I'm not sure why this happens. When the trickler slows properly, it really works great. With exact throws every time. And that's saying a lot for extruded powders. When it doesn't, it is frustrating because the over throw is .04 to .10 of a grain. Far from the precision I am looking for.

I'm hoping I can work through this issue somehow with the custom settings and not to have to resort back to my tweezers like the V3 with extruded powders. Or this whole exercise of an "upgrade" will have been wasted.

I will report back. (BTW, the powder I used was IMR4198.)

Last edited:

That is the same issue I am having.What I have noticed is that when the trickler starts to get close to the target weight, it is inconsistent slowing down. Out of 10 throws, the speed would slow down pretty linear only on average 2 or 3 times. The rest, the speed would not slow down until .02 before the target weight. And with extruded powders, this means an overthrow every time. This is disappointing.

I tried to use a custom speed set-up in the menu. I slowed the trickler tube down to 3 from the default setting of 4. It didn't help. Why does this happen? If the trickler would start to slow down around a half of a grain from the target weight, with a linear pattern, then over throws would be a lot less then 7 or 8 tries out of 10.

I'm not sure why this happens. When the trickler slows properly, it really works great. With exact throws every time. And that's saying a lot for extruded powders. When it doesn't, it is frustrating because the over throw is .04 to .10 of a grain. Far from the precision I am looking for.

I'm hoping I can work through this issue somehow with the custom settings. I will report back.