I am just amazed at the experience and talent there are here on SH. I recently purchased a new stock for my T3 in .223 Rem. Those who are familiar w/ a T3 know of the joke the recoil lug is! My question is this: should I or should I not worry about the recoil lug because it is a 223? Those that have a T3 know what I am talking about. There are several "lugs" throughout the length of the reciever and should that suffice for a "recoil lug" or do I bed the recoil lug permanently. The rifle will benefit either way but it needs to have a bedding job done. I hope I have said enough or I might need to post some pictures. Any thoughts would be appreciated.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Bedding a Tikka T3

- Thread starter Exhaust3

- Start date

Re: Bedding a Tikka T3

either bed it all or dont bed at all. Im not familiar with the Tikka rifles so im not to certain what the lugs look like. But even being a 223 it will benefit from a good STRESS free bedding job

either bed it all or dont bed at all. Im not familiar with the Tikka rifles so im not to certain what the lugs look like. But even being a 223 it will benefit from a good STRESS free bedding job

Re: Bedding a Tikka T3

I have a Tikka T3 300WM. I learned a lot about these stocks, trying to get it to shoot. Granted, my rifle generates a great deal more recoil than yours but some of this may still benefit you.

1st, remember this is a co-polymer stock, which is engineering speak for "nothing sticks to it".

Clean the entire stock with acetone, brake clean, something to remove the gun oil and mold release.

EVERYWHERE you're going to put bedding compound must be roughed up with very coarse sandpaper or a dremel tool.

Make mechanical locks for the bedding compound with the dremel or a small drill.

I HIGHLY recommend you bed some pillars in this stock. It was impossible for me to get repeatable torque until I did this. Also, my screws don't back out and fall out of the stock now.

Prep the area around the action screws as you have the rest of the stock and fill all the voids with Devcon, making sure to get all air bubbles out. Also build up the area around the screw hole in the tang as you will have to drill a clearance hole for the pillar and the plastic is not big enough.

Bed the stock recoil lug like it was in the original (more on this later). I would coat it with release, except the top, and then put a couple drops of super glue on the top, glue it for now to the action, and then insert it as part of the action.

When you've removed the action from the stock after bedding, grind away every vertical surface that will contact the action upon fore/aft movement in the stock, except the recoil lug. You want ONE recoil surface. The stock must not touch ANYWHERE except the 2 pillars, the surface of the bottom and sides of the action and the recoil lug.

Be aware that the foreend of this stock is VERY flexible and Devcon will squish under the chamber of the barrel and flex the forend down.. This will put stress on the barrel. I recommend that you remove this and leave clearance under the chamber area.

After this, it;s just like the other bedding jobs you've seen here on the Hide.

p.s. I ditched the stock recoil lug because it's a POS for a 300WM. If your .223 is leaving no indentations in the aluminum, you're gtg.

OR

You could buy a Manners T4

Good luck

John

I have a Tikka T3 300WM. I learned a lot about these stocks, trying to get it to shoot. Granted, my rifle generates a great deal more recoil than yours but some of this may still benefit you.

1st, remember this is a co-polymer stock, which is engineering speak for "nothing sticks to it".

Clean the entire stock with acetone, brake clean, something to remove the gun oil and mold release.

EVERYWHERE you're going to put bedding compound must be roughed up with very coarse sandpaper or a dremel tool.

Make mechanical locks for the bedding compound with the dremel or a small drill.

I HIGHLY recommend you bed some pillars in this stock. It was impossible for me to get repeatable torque until I did this. Also, my screws don't back out and fall out of the stock now.

Prep the area around the action screws as you have the rest of the stock and fill all the voids with Devcon, making sure to get all air bubbles out. Also build up the area around the screw hole in the tang as you will have to drill a clearance hole for the pillar and the plastic is not big enough.

Bed the stock recoil lug like it was in the original (more on this later). I would coat it with release, except the top, and then put a couple drops of super glue on the top, glue it for now to the action, and then insert it as part of the action.

When you've removed the action from the stock after bedding, grind away every vertical surface that will contact the action upon fore/aft movement in the stock, except the recoil lug. You want ONE recoil surface. The stock must not touch ANYWHERE except the 2 pillars, the surface of the bottom and sides of the action and the recoil lug.

Be aware that the foreend of this stock is VERY flexible and Devcon will squish under the chamber of the barrel and flex the forend down.. This will put stress on the barrel. I recommend that you remove this and leave clearance under the chamber area.

After this, it;s just like the other bedding jobs you've seen here on the Hide.

p.s. I ditched the stock recoil lug because it's a POS for a 300WM. If your .223 is leaving no indentations in the aluminum, you're gtg.

OR

You could buy a Manners T4

Good luck

John

Re: Bedding a Tikka T3

Here's some pics of my old stock. It's bedded for a Rem. 700 style lug, so it will look a little different. You can see where I ground away every vertical interference.

It also doesn't look all sexy like Roscoe's because my end mill is made by "DREMEL".

The black you see is where I put sharpie on the action to look for interference and it soaked into the Devcon.

Also note in the second photo the built up area surrounding the rear pillar. When you are done this will be TIGHT against the trigger assy. Be sure it just clears.

The third photo shows where I bedded the bottom plastic.

John

Here's some pics of my old stock. It's bedded for a Rem. 700 style lug, so it will look a little different. You can see where I ground away every vertical interference.

It also doesn't look all sexy like Roscoe's because my end mill is made by "DREMEL".

The black you see is where I put sharpie on the action to look for interference and it soaked into the Devcon.

Also note in the second photo the built up area surrounding the rear pillar. When you are done this will be TIGHT against the trigger assy. Be sure it just clears.

The third photo shows where I bedded the bottom plastic.

John

Re: Bedding a Tikka T3

I think because it's a 223 I will ditch the recoil lug and bed the thing. I will however machine some pillars (I have access to that type of thing!!) I couldn't wait until they came out with an aftermarket stock, so I had Joel Russo make me an A-3L.

I think because it's a 223 I will ditch the recoil lug and bed the thing. I will however machine some pillars (I have access to that type of thing!!) I couldn't wait until they came out with an aftermarket stock, so I had Joel Russo make me an A-3L.

Re: Bedding a Tikka T3

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Exhaust3</div><div class="ubbcode-body">I couldn't wait until they came out with an aftermarket stock, so I had Joel Russo make me an A-3L. </div></div>

Could have told me this to begin with... all that typing for nothing!

Post pics when you get it done.

John

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Exhaust3</div><div class="ubbcode-body">I couldn't wait until they came out with an aftermarket stock, so I had Joel Russo make me an A-3L. </div></div>

Could have told me this to begin with... all that typing for nothing!

Post pics when you get it done.

John

Re: Bedding a Tikka T3

Ive bedded a couple of T3's, I machined out the recoil lug recess so the lug was able to "float" on a base of devcon and set the lug into the devcon.

You need to do it this way in one go (entire bedding)

Set the action upside down with the recoil lug resting in its locating recess in the action, (everything except the lug is covered in release agent)

Then apply bedding to action and stock - holding the lug in place with a cocktail stick as you apply it.

Once the two are covered, set the stock into place on the action and continue as normal.

When everything is cured, you end up with a lug that is the correct height and bonded into the stock.

I have a mill, so its a bit easier.....

Ive bedded a couple of T3's, I machined out the recoil lug recess so the lug was able to "float" on a base of devcon and set the lug into the devcon.

You need to do it this way in one go (entire bedding)

Set the action upside down with the recoil lug resting in its locating recess in the action, (everything except the lug is covered in release agent)

Then apply bedding to action and stock - holding the lug in place with a cocktail stick as you apply it.

Once the two are covered, set the stock into place on the action and continue as normal.

When everything is cured, you end up with a lug that is the correct height and bonded into the stock.

I have a mill, so its a bit easier.....

Re: Bedding a Tikka T3

Hi first use release agent on the action then a trick is when you place the recoil lug into the action cutout place a small amount of super glue on the top of it then press it hard into the action slot making sure it is hard against the front of the slot. Make sure their is around 100 thou deepth under the action and all around the lug. have your pillars machined to have the radius of the action and drill through the stock for them make them slightly longet than they need to be. Now bolt them to the action apply the bedding compound around the pillars i make relief cuts in them to lock the to the stock and around the recoil lug to lock it in then make sure their is enough bedding compound in the stock and slide it in. the excess bedding compound needs cleaning off and when the compound dries the pillars are perfect to the action and the recoil lug is in the correct alighnment to the action. remove the screws give the action a crack with a soft faced hammer to release the super glue and free the action from the bedding. then file up overhanging bedding turn the stock over and spot face the pillars in a mill or drill press with a uni mill to the correct depth and the job is as good as you will get.

Hi first use release agent on the action then a trick is when you place the recoil lug into the action cutout place a small amount of super glue on the top of it then press it hard into the action slot making sure it is hard against the front of the slot. Make sure their is around 100 thou deepth under the action and all around the lug. have your pillars machined to have the radius of the action and drill through the stock for them make them slightly longet than they need to be. Now bolt them to the action apply the bedding compound around the pillars i make relief cuts in them to lock the to the stock and around the recoil lug to lock it in then make sure their is enough bedding compound in the stock and slide it in. the excess bedding compound needs cleaning off and when the compound dries the pillars are perfect to the action and the recoil lug is in the correct alighnment to the action. remove the screws give the action a crack with a soft faced hammer to release the super glue and free the action from the bedding. then file up overhanging bedding turn the stock over and spot face the pillars in a mill or drill press with a uni mill to the correct depth and the job is as good as you will get.

Re: Bedding a Tikka T3

Did any of you bed first part of the barell as factory stock seems to grip first inch or two of the barrel or did you bed free floated from the action end forward?

I found it annoying that stock can be tightened down even if action isn't seated onto recoil lug i found that out when looking at vent on the left side of the rifle being quite a bit above the stocks edge - it should be level with the edge when properly seated.

Did any of you bed first part of the barell as factory stock seems to grip first inch or two of the barrel or did you bed free floated from the action end forward?

I found it annoying that stock can be tightened down even if action isn't seated onto recoil lug i found that out when looking at vent on the left side of the rifle being quite a bit above the stocks edge - it should be level with the edge when properly seated.

Re: Bedding a Tikka T3

i free float all of my barrels but the one in the pic has the first inh bedded i never bed the barrel so when changing barrels the bedding is never effected but either can work.

i free float all of my barrels but the one in the pic has the first inh bedded i never bed the barrel so when changing barrels the bedding is never effected but either can work.

Re: Bedding a Tikka T3

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Sharac</div><div class="ubbcode-body">Did any of you bed first part of the barell </div></div>

Like a lot of things you'll find conflicting views on this. I bed mine to the back of the recoil lug so the entire barrel and chamber is free floated.

Part of the risk with bedding the chamber on a OEM Tikka stock is that, unless you bed like Roscoe's example, with tape around the barrel and absolutely no pressure on the action (example here: http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=1167022#Post1167022 ) the bedding compound under the chamber will put downward pressure on the fore stock deflecting it down making it a spring. Almost impossible to assure "no stress" on the barrel if done this way.

John

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Sharac</div><div class="ubbcode-body">Did any of you bed first part of the barell </div></div>

Like a lot of things you'll find conflicting views on this. I bed mine to the back of the recoil lug so the entire barrel and chamber is free floated.

Part of the risk with bedding the chamber on a OEM Tikka stock is that, unless you bed like Roscoe's example, with tape around the barrel and absolutely no pressure on the action (example here: http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=1167022#Post1167022 ) the bedding compound under the chamber will put downward pressure on the fore stock deflecting it down making it a spring. Almost impossible to assure "no stress" on the barrel if done this way.

John

Re: Bedding a Tikka T3

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Sharac</div><div class="ubbcode-body">as i think about it i think a better option is Manners stock... </div></div>

OOOhh... a good bedding job is OK. A good bedding job in a Manner's is just about unbeatable!

John

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Sharac</div><div class="ubbcode-body">as i think about it i think a better option is Manners stock... </div></div>

OOOhh... a good bedding job is OK. A good bedding job in a Manner's is just about unbeatable!

John

Re: Bedding a Tikka T3

Just purchased a Tikka T3 Varmint in .223. Just curious about bedidng these things. I have bedded several REM and SAVGs with devcon. I know about 1 recoil surface but am a little unclear about the Tikka recoil lug. I know that you do not want any pressure on the action. So, are you guys bedding it so that when the action screws are in and tightened down, the entire action is supported by the bedding and the recoil lug is simply snug against the underside of the action and not causing any vertical pressure?

Just purchased a Tikka T3 Varmint in .223. Just curious about bedidng these things. I have bedded several REM and SAVGs with devcon. I know about 1 recoil surface but am a little unclear about the Tikka recoil lug. I know that you do not want any pressure on the action. So, are you guys bedding it so that when the action screws are in and tightened down, the entire action is supported by the bedding and the recoil lug is simply snug against the underside of the action and not causing any vertical pressure?

Re: Bedding a Tikka T3

Redmist addressed that above...

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Redmist</div><div class="ubbcode-body">Ive bedded a couple of T3's, I machined out the recoil lug recess so the lug was able to "float" on a base of devcon and set the lug into the devcon.

You need to do it this way in one go (entire bedding)

Set the action upside down with the recoil lug resting in its locating recess in the action, (everything except the lug is covered in release agent)

Then apply bedding to action and stock - holding the lug in place with a cocktail stick as you apply it.

Once the two are covered, set the stock into place on the action and continue as normal.

When everything is cured, you end up with a lug that is the correct height and bonded into the stock</div></div>

You can also use a dab of the thin super glue to hold the lug to the action temporarily while you bed it. Either will work.

John

Redmist addressed that above...

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Redmist</div><div class="ubbcode-body">Ive bedded a couple of T3's, I machined out the recoil lug recess so the lug was able to "float" on a base of devcon and set the lug into the devcon.

You need to do it this way in one go (entire bedding)

Set the action upside down with the recoil lug resting in its locating recess in the action, (everything except the lug is covered in release agent)

Then apply bedding to action and stock - holding the lug in place with a cocktail stick as you apply it.

Once the two are covered, set the stock into place on the action and continue as normal.

When everything is cured, you end up with a lug that is the correct height and bonded into the stock</div></div>

You can also use a dab of the thin super glue to hold the lug to the action temporarily while you bed it. Either will work.

John

Re: Bedding a Tikka T3

Thanks. I must have missed that little bit about it. Makes sense and was the one question I had because I could see that if you did not have a small space between the lug and the action, it could easily apply unwanted pressure when the action scrws were tightened.

My current plans are to build a custom stock for my gun. I am going to start with an aluminum chasis similar to the Whidden blocks. This way I can build the stock out of any wood I chose as it will not be in contact with the action.

All good stuff here.

Cheers and thanks.

Thanks. I must have missed that little bit about it. Makes sense and was the one question I had because I could see that if you did not have a small space between the lug and the action, it could easily apply unwanted pressure when the action scrws were tightened.

My current plans are to build a custom stock for my gun. I am going to start with an aluminum chasis similar to the Whidden blocks. This way I can build the stock out of any wood I chose as it will not be in contact with the action.

All good stuff here.

Cheers and thanks.

Re: Bedding a Tikka T3

For you guys adding pillars, what length is your front and back pillar. I think I am going to need pillars and a bedding job.

How much of an effect would the stock contacting the barrel ahead of the action have on accuracy? First time to the range and had some flyers that I can't account for. Noticed afterwards that the stock was tight against the barrel on both sides for the first 3 inches of the barrel out of the action.

I have since floated the barrel but have not had a chance to shoot it again.

For you guys adding pillars, what length is your front and back pillar. I think I am going to need pillars and a bedding job.

How much of an effect would the stock contacting the barrel ahead of the action have on accuracy? First time to the range and had some flyers that I can't account for. Noticed afterwards that the stock was tight against the barrel on both sides for the first 3 inches of the barrel out of the action.

I have since floated the barrel but have not had a chance to shoot it again.

Re: Bedding a Tikka T3

Exhaust,

Are you having accuracy issues with your .223 Tikka?

What kind of groups is it shooting?

The reason I ask is that I have a bit of time running Tikkas (long before they became the cool kid on the block) and I have yet to see a .223 that needed bedding.

It has been my experience that plastic stocked T3s in heavy recoiling calibers such as .300 win mag or .338 can benefit from bedding, but .308 class cartridges and below seem to shoot extremely well in factory stocks.

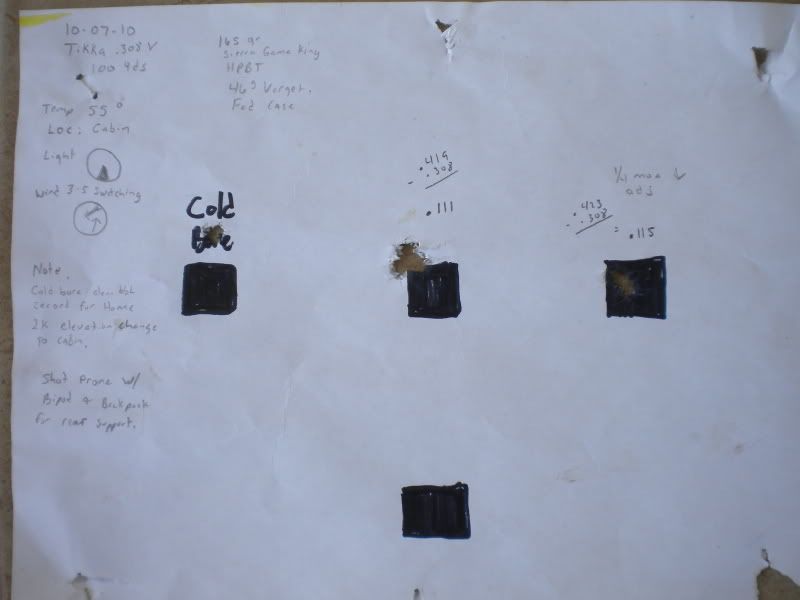

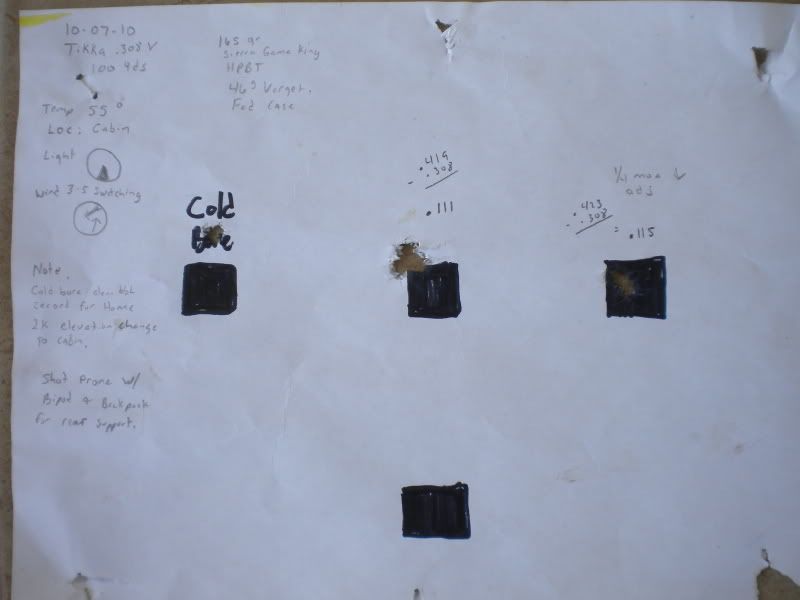

Here is a pic of a hunting load from a factory stocked T3 .308.

I would suggest before you take much creedence in "internet wisdom" about crappy Tikka stocks, you actually go out and shoot your T3 and see what kind of groups you are getting.

The same goes for those "crappy" plastic single stack magazines. Mine have never failed me in many thousands of rounds. They seem to work about as reliably as a Glock magazine.

Go shoot the rifle.

If you actually have an issue, then address it.

Believe it or not, the people at Sako/Tikka know how to build rifles.

Exhaust,

Are you having accuracy issues with your .223 Tikka?

What kind of groups is it shooting?

The reason I ask is that I have a bit of time running Tikkas (long before they became the cool kid on the block) and I have yet to see a .223 that needed bedding.

It has been my experience that plastic stocked T3s in heavy recoiling calibers such as .300 win mag or .338 can benefit from bedding, but .308 class cartridges and below seem to shoot extremely well in factory stocks.

Here is a pic of a hunting load from a factory stocked T3 .308.

I would suggest before you take much creedence in "internet wisdom" about crappy Tikka stocks, you actually go out and shoot your T3 and see what kind of groups you are getting.

The same goes for those "crappy" plastic single stack magazines. Mine have never failed me in many thousands of rounds. They seem to work about as reliably as a Glock magazine.

Go shoot the rifle.

If you actually have an issue, then address it.

Believe it or not, the people at Sako/Tikka know how to build rifles.

Re: Bedding a Tikka T3

+1 in general for Tikkas.

also if you do a entire bed and float the recoil lug how does one know the correct height to mount it at after machining out the area

Ive recently "beefed up " my t3 stock but have been waiting to do a bed job when i get some free time

+1 in general for Tikkas.

also if you do a entire bed and float the recoil lug how does one know the correct height to mount it at after machining out the area

Ive recently "beefed up " my t3 stock but have been waiting to do a bed job when i get some free time

Re: Bedding a Tikka T3

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: tikka'd</div><div class="ubbcode-body">+1 in general for Tikkas.

also if you do a entire bed and float the recoil lug how does one know the correct height to mount it at after machining out the area

Ive recently "beefed up " my t3 stock but have been waiting to do a bed job when i get some free time </div></div>

Leave the rear of the tang portion untouched and wrap tape around the barrel to give the correct height.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: tikka'd</div><div class="ubbcode-body">+1 in general for Tikkas.

also if you do a entire bed and float the recoil lug how does one know the correct height to mount it at after machining out the area

Ive recently "beefed up " my t3 stock but have been waiting to do a bed job when i get some free time </div></div>

Leave the rear of the tang portion untouched and wrap tape around the barrel to give the correct height.

Re: Bedding a Tikka T3

+1 on just shoot it stock first. I have two T3 lites (204 and 243) and they shoot a 5 shot ragged hole. Good tool, good price point.

+1 on just shoot it stock first. I have two T3 lites (204 and 243) and they shoot a 5 shot ragged hole. Good tool, good price point.

Re: Bedding a Tikka T3

BC has a pretty nice stock out now with lug integral to the bedding block. I had a few fliers in my .270 that I could not account for and did a skim bed in devcon and got some better action screws that could be torqued accurately. All fliers went away and it is more consistent that it was in the OEM stock. I have never had a problem with the OEM stock on my .223 and it has a couple thousand rounds through it.

BC has a pretty nice stock out now with lug integral to the bedding block. I had a few fliers in my .270 that I could not account for and did a skim bed in devcon and got some better action screws that could be torqued accurately. All fliers went away and it is more consistent that it was in the OEM stock. I have never had a problem with the OEM stock on my .223 and it has a couple thousand rounds through it.

Re: Bedding a Tikka T3

The T3 plastic stock is quality wise a bit better than other factory tupperware stock. As a stock material the injection moulded material used is just not as good as composites. Ergonomics? more like economics in mind when manufacturing that stock. Judging a stock by three shots fired from a non changing position is just useless. Performance of a stock/rifle combo in my view must be judged by several groups fired from several shooting positions, with and without bipod. After a month or two...fire another group without touching the scope, still the same poi? Most if not all injection moulded plastics relax or flow away if pressure in applied, what does that do for your action tension?

Ever thought why nobody makes a tennis racket or fishing rod out of injection moulded plastic? That would really show the material properties.

I've bedded a few T3 lately and think they are no different to other actions. As others have mentioned I also superglue the lug into the action and the bedding permanently glues the lug into place. The stocks I do don't need pillars and skim bedding is what suits them meaning the bedding job is done fairly quick.

By the way...nice work as usual Redmist

edi

The T3 plastic stock is quality wise a bit better than other factory tupperware stock. As a stock material the injection moulded material used is just not as good as composites. Ergonomics? more like economics in mind when manufacturing that stock. Judging a stock by three shots fired from a non changing position is just useless. Performance of a stock/rifle combo in my view must be judged by several groups fired from several shooting positions, with and without bipod. After a month or two...fire another group without touching the scope, still the same poi? Most if not all injection moulded plastics relax or flow away if pressure in applied, what does that do for your action tension?

Ever thought why nobody makes a tennis racket or fishing rod out of injection moulded plastic? That would really show the material properties.

I've bedded a few T3 lately and think they are no different to other actions. As others have mentioned I also superglue the lug into the action and the bedding permanently glues the lug into place. The stocks I do don't need pillars and skim bedding is what suits them meaning the bedding job is done fairly quick.

By the way...nice work as usual Redmist

edi