Chamber Reamer Design

Setting Up Dummy Round and Determining Freebore Length and Diameter

Freebore Length

Figuring free bore

Figuring free bore

For a close reference, seat the bullet to your desire position in a case, lock a calipers at bore diameter and slide the seated bullet into the caliper jaws (it will stop on the ogive at bore diameter). Then with a second calipers measure from the case-head to the caliper jaws. Compute out the desired case-length of a reamer and subtract that from your measurement. This will give you a ballpark spec for your desired lead/throat.

Donovan Moran

Dave Tooley

Gastonia, NC

"What Donavan is talking about is how getting a starting point when designing a new reamer. I usually set my calipers .001" under bullet size. Scribe a ring at the junction of the ogive and body. Seat the bullet to the OAL length I want. Then measure from the base of the case to that ring. That has always gotten me within .010" of the OAL length I wanted. If magazine length is a factor I always error on the short side about .015". Determining an exisiting barrel's freebore is about impossible as you know none of the other dimensions, being OAL case length and few others. But you can get come up with a number from the base of the case to ogive/body junction on the bullet."

Dave Tooley

[I have a similar technique to mark the ogive-bearing surface junction (also known as the bullet shoulder) on VLD bullets. I use a Sinclair comparator insert of the appropriate size to mark the ogive-bearing surface junction. For .338 Lapua Magnum, use the .33 insert. For the .308 Winchester, use the .30 insert. I insert the bullet into the comparator and gently rotate the bullet inside the comparator to inscribe a ring at the ogive-bearing surface junction.

Then insert the marked bullet into a brass case with the neck loosened just enough to hold the bullet snug. Adjust your bullet to the desired length. It is generally a good idea to position the back end of the bearing surface-boat tail junction just in front of the neck-shoulder junction of your case to avoid inconsistent tension from a case "donut". This will also give you greater case capacity. You can then measure from the base of the case to the inscribed ring (the shoulder) on the bullet to get the cartridge base to ogive (CTBO) and from the end of the case neck to the inscribed ring on the bullet shoulder to get your freebore measurement. The results are very comparable to the technique above.]

rxs0

Chambering the 6BR and 6 Dasher - The right reamer makes all the difference -- Dave Kiff

Chambering the 6BR and 6 Dasher

"First and foremost, we can give you a reamer with the throat set ideally from your dummy round, with freebore measured from the bullet ogive.

For the 100-107gr VLDs, a .115" -.120" freebore will allow you to get the base of the bullet up out of the doughnut area. This will save you lots of aggravation over the life of the barrel."

Dave Kiff

[By seating the bullet in front of the "donut" zone at the shoulder-neck junction, you avoid inconsistent neck tension that the "donut" can apply to the bullet.]

rxs0

"I like about half of the boat-tail of a VLD bullet hanging out of the neck below the junction with the case shoulder."

James A. Boatright, Well Guided Bullet

"Most people hate dealing with the brass ridge or "doughnut" that can build up at the neck-shoulder junction. This interferes with bullet seating and is a pain in the behind to eliminate. By setting the freebore so the bottom of the bearing surface,max diam. bullet shank) is .050"+ above the doughnut zone, you can pretty much ignore it."

Forum Boss

http://forum.accurateshooter.com/index.php?topic=430289.msg4316264#msg4316264

How to determine freebore for a reamer

How to determine freebore for a reamer [Archive] - Benchrest Central Forums

"You can get a close approximation by taking a 1" micrometer and setting it to .001" smaller than bullet diameter. Slide it down the seated bullet and then measure from the end of the case neck to where the micrometer stops."

Mike Bryant

Neck dimension

The way I determine freebore length is to seat a bullet where you want it. Take a micrometer and set it at .001" smaller than bullet diameter, slide the mike down the seated bullet and then measure from the end of the neck to where the front edge of the micrometer stops on the bullet. That will be what I specify for the freebore length.

Mike Bryant

Determining Reamer Freebore

pbike

determining reamer freebore [Archive] - Benchrest Central Forums

"Charles,

You may be right. Last time I talked to Kiff about this he said that its easiest to think of the freebore as a measurement from the boltface.

Seat the bullet in the case to the length you want it seated, ie where is the boattail or flatbase in the neck. open calipers to the size of the bore, and make a mark (scratch) on the bullet then measure from the base of the cartridge.

Kiff and JGS show their reamer prints with the freebore measurement from the base."

Paul

RiflShootr

Bullet seating depth?

There is a pretty simple way to determine how much freebore to have built into the reamer. First size a case and trim to length. Measure the case to see how much under maximum length you are and remember that number.

Take the longest bullet that you plan to use and seat it into the case to where the boattail/body junction of the bullet is approximately .020-.030 above the neck/shoulder junction of the case.

Then take a magic marker and color the bullet. Next, set your calipers @ .242 [in general, set your calipers .001" under bullet diameter] and while holding the round perpendicular to the jaws, rotate the round gently to scribe a line around the bullet.

Now measure the distance from the scribed line to the mouth of the case, and subtract the amount that the case was under maximum length and that number is the freebore you need.

If you wish to do so, scribe the line on the shortest bullet without seating, and measure from that line to the base of the bullet's bearing surface, and subtract the freebore number. The remainder is the amount that will be in the case neck for that bullet. This number may vary some depending on the difference in ogive shape of the 2 bullets if there is any, but it will be fairly close and give you a pretty good idea of what you will have.

Next step.....call Dave Kiff @ Pacific Tool and order your reamer.

Freebore Diameter

http://www.snipershide.com/shooting...74-30-06-chamber-reamer-help.html#post1152324

"From experience don't get too tight with the freebore diameter. I spent the last week getting carbon out of a barrel that restricted the freebore to the point of causing pressure problems. At one time I went .0005" over nominal bullet diameter but that gets you in trouble as not all bullets are dead on size wise. I go .001" to .002" over depending caliber. The more volume the case has the larger I go."

Dave Tooley

Freebore Diameter Question

http://forum.accurateshooter.com/index.php?topic=3769659.0

Throat Diameter

throat diameter

Chamber Throats 101

http://www.bellmtcs.com/FAQ/ChamberThroats101.htm

"Chamber Throats 101

I suggest you keep this, copy it, and pass it on.

First, consider what happens to that perfect (as perfect as the bullet makers make 'em), shiny bullet when you pull the trigger. It leaves the case, meets the rifling at the nose end of the bullet, and the rifling engrave into the bullet as it passes down the barrel. While the nose of the bullet centers itself in the tapered ends (leade) of the rifling, the butt end of the bullet is centered only as completely as the tolerances of the cylindrical section (if there is one) of the throat and the chamber neck allow.

In essence the throat is like a forming die in as much as the bullet takes on a different shape than it had when it left the manufacturer's plant, or your cast bullet mold and sizer. It is assumed, naturally, that the bullet was made in precision, close tolerance forming dies where tolerances are kept down to the 1/10ths of a thousandth.

The forming die in your barrel's chamber, the throat, is the only dimension in the chamber that allows being held to extremely close tolerances, simply because the bullet is the only component in the system that is held to very close tolerances.

What Kind of Tolerances Are Typically in Chambers and Throats?

Typical reamers from the reamer companies, one in particular, as standard are .001" larger than bullet diameter for that given caliber. Back when when I was still buying reamers, I would always pay the extra fare for them to take their throat reamer off the shelf back to the grinder and spin usually .001" off the reamer's diameter to get it down to within a 10th or so of bullet dia. for the given caliber.

SAAMI specs. for chamber throats are commonly .001" larger than bullet size, while some are as much as .005" larger than the bullet. No Joke!

What is a shot out barrel? One that has had a lot of rounds run through it, eroding the throat. Did the throat get smaller in diameter? No, it got larger, enough larger that it no longer guides and supports the bullet as it engraves into the rifling.

It allows the base of the bullet to deviate off the axis of the bore and go into the rifling at random angles, ie., cockeyed, distorting the bullet and throwing it out of balance. Remember, some bullets are spinning at over 200, 000 (yep, count the zeroes) RPM. You know what a little imbalance does to a tire on your car, and it sure isn't spinning anything like this!

The Effects of Bullet "Cant" on Accuracy

Harold Vaughn in his book, Rifle Accuracy Facts, studied the effects of bullet "cant" extensively and verified that how the bullet enters the rifling has a very dramatic and predictable effect on accuracy. This is excellent reading by a foremost and nationally recognized ballistics scientist..... not a "magazine expert" who long ago sold his soul to magazine advertisers and can't tell the truth for fear of offending an advertiser.

Harold also discusses throat diameter and alignment with the bore and states that nearly every factory chamber he has studied was deficient in this regard. What I find most interesting is that I learned this by hands on experience only, but as a scientist Harold put the hard numbers to the experiments he performed and validates what I preach about chamber throats. Contact Precision Shooting Magazine for a copy, or email me.

What about the chamber neck helping guide the bullet? Chamber necks, due to variations in brass thickness, usually have to have something on the order of at least .003" clearance to be reasonably safe-----we're not talking about turning case necks to match tight necked chambers, another story. Typical neck clearances are more like .005 to .007," so the chamber neck and case neck really can't do anything positive. They can hold the base of the bullet pointed in the general direction, but the forces exerted on the bullet are far greater than a .012-.015" thick brass case neck can overcome!

Only the steel in the chamber throat can positively align the bullet, yet with the tolerances you typically find in most all factory barrels and the majority of custom barrels chambered with off-the-shelf reamers the throat will be substantially larger than bullet diameter-----------the same condition as a shot out barrel!

Unless you specify throat diameter, much of the time you are buying a barrel that is to a significant degree "shot out" before you fire the first shot through it.

New reamers will likely be the worst, older reamers that have the throat section worn down will be closer to size.

Stop and think about this. You read all kinds of stuff about seating depth, overall cartridge length, seating the bullet into the rifling, or backed off so many thousandths from the rifling, but tell me this, how many times have you read or heard anything about THROAT DIAMETER ?????? I don't waste much time reading magazines any more. Maybe times have changed, but I have seen throat diameter mentioned only a very few times in all my 52 years, 47 of which reading magazines.

Side Note:

(I co-authored the chapter on chamber throats in the 1995 Precision Shooting Annual. In that same publication was a chapter about barrel lapping in which the author MONITORED THE GROWTH OF THE THROAT DIAMETER in the process of fire lapping his barrel. If your throat is too large to start with and you fire lap the barrel, you WILL end up with a still larger throat DIAMETER. I want you to burn DIAMETER into your mind. Give second thoughts to firelapping a barrel without rechambering it to a longer cartridge to get into fresh rifling with a new throat.)

I take all of this into account, when I rechamber a barrel and use techniques and tolerances that give the bullet its best opportunity to slip straight down the tube with the least distortion.

Ok, So what do you have in any given barrel? Sit tight. Follow along. I want to guide you into a mindset that will open doors for you. It will reveal some of the mysteries of the chamber throat.

When you get done with reading this, you will know what you are looking at when you peer down the breech end of your barrels.

Contenders and Encores are great for looking into. With the barrel off the frame you don't have to look very far into the chamber to see the rifling. And you can readily roll it around and examine the circumferences of the various cuts at the neck and throat.

Go pick up a barrel. Larger bore sizes are better to start with, easier to see details. You need a light source, but not too much light. In a well lighted room, looking through the barrel at a piece of white paper works very well.

Ok. You are looking down into the chamber, looking right at the ends of the rifling. Between you and the rifling is a big dark hole. Between the big dark hole and the rifling is the throat. It is the area the same as the grooves in the barrel, minus the rifling. The throat is merely the area in the barrel where the rifling are cut away so the bullet can stick out of the case.

In case you picked up a .22 Long Rifle, technically .22 LR does not have a throat since the bullet is the same approx. dia. as the brass case, thus the chamber is cut the same diameter all the way from the rim to a point past the bullet. This diameter, by the way, will be anywhere from .001" to .008" larger than bullet diameter!

You can check for these basic elements:

1) Relative length of the throat

2) The geometry of the throat

3) The DIAMETER of the throat, relative to the groove diameter of the barrel

4) The alignment of the throat with the bore, or more correctly the grooves of the barrel.

Quickly, you can see if the throat looks long compared to the throat in other barrels, or if it is short. Some are so short as to be virtually non-existent, but rather a chamfer on the ends of the rifling.

Geometry of the throat. Is it a cylinder where the riflings are cut away, or is it a cone. Most of the more recent factory barrels in .357 Mag, .357 Maximum, and .44 Magnum have a cone approximately .4" long. If you look down the wall of the chamber you can see where it begins to change from chamber wall to a long taper that ends on the tops of the rifling. What you want is a cylinder that will support a significant length of the bullet's shank as it engraves. The only tapered part of the throat should be just on the ends of the rifling.

Remember what I was saying about the base of the bullet? The case mouth can't hold it in alignment, and in the .357's for example, the base of the bullet can move about .012" in any direction off the centerline of the barrel. So what does it do when it meets the rifling? It has every chance in the world to go in cockeyed.

Ok, now we're getting down to the more critical part. Look between the ends of the rifling. If you see a line connecting the ends of the rifling, it means that the throat portion of the reamer was larger than the groove diameter of the barrel, and this diameter can be a thousandth or more larger than bullet diameter. For years the .44 Mag factory barrels had .440" groove diameters! And the eight groove .35 cal. barrels run as small as .356." So you really can't determine the actual diameter of the throat, but you can determine a size relationship between the two.

If you slug the barrel with a dead soft lead slug and mike it, you can get a better idea of the throat diameter. There are other methods to measure it as well, but we won't go into that here. I simply want to point out the relationships you are looking at.

If for example you slug a .30 cal. barrel and it mikes a true .308" diameter, then find a line connecting the ends of the rifling in the throat, think about it, the throat is larger than .308" in diameter.

The ideal is to have the correct groove diameter, .308" in our example, and the rifling cut away with little or no discernable line connecting the ends of the rifling, meaning the throat is matched to the bullet diameter, .308."

You usually will find a line connecting the ends of the rifling. Move the barrel around so that you can follow the entire circumference of this line connecting the ends of the rifling. Does it look the same all the way around? Or is it fainter or non-existent in part of its circumference, and pronounced on the other part.

To the extent it does not appear uniform all the way around, it is off center from the grooves. If it is off center, how does the bullet get a straight shot in?

Barrels that are more difficult to see the throat: .22 Mag, usually a short abrupt cone and most of the .22 centerfires where the short abrupt throats are also larger than groove diameter and hard to see.

If you have any connections at a hospital, get one of their laproscopes and stick it down into the throat area. You'll REALLY be able to see what I have described here. It'll blow you away.

The quality of the throat, based on the 4 criteria I listed earlier, can spell the difference between a barrel that shoots well and one you dump all kinds of money into trying to make it shoot, then "take it on the chin" when you get rid of it hoping the next barrel will be a good one.

There are other factors to look at also, such as the crown, but we are limiting this discussion to just the throat.

If you have a problem barrel, what you find in the throat may determine whether you continue working with it or cut your losses.

Save yourself some money and grief. Start paying close attention to the throat. While a borescope helps a lot, you can do a lot for yourself with the "naked eye" now that you know what you are looking for."

Mike Bellm

Chamber and Reamer

http://benchrest.com/showthread.php?75751-Chamber-and-Reamer

Determining Throat Angle

"A throat with an overly abrupt taper can also cause bullet deformation. Just how this deformation takes place is a guess, but it most likely due to a very slight amount of in-bore canting. This will cause a center of gravity offset from the bore center line, which can cause dispersion. We minimize these effects by cutting the chamber and throat concentric with the bore and we reduce the slope of the throat to about one half of standard throats."

Harold R. Vaughn, Rifle Accuracy Facts

Throat angle

Throat angle

"From experience, good and bad I never go past 2 degrees."

Dave Tooley

"We normally go with a 1.5 degree lead angle, unless the customer wants something different."

Chambering the 6BR and 6 Dasher

Dave Kiff

Leade Angle

leade angle

[Use 1 degree 30 minutes (1.5 degrees) for .338 LM, 300 Win Mag, and .308 Winchester reamers.]

rxs0

"The parameter that most affects accuracy is the leade angle and 1½° seems close to ideal. It is also desirable to have a close case fit in the chamber, tight freebore to bullet diameter fit, and the right freebore length for your bullet characteristics vs. seating depth.

Your chamber should have ~.002 diametral clearance at both the case shoulder and body and your sizing die should be able to return it to that condition. Fortunately, a lot of this has already been determined. The only things I usually need to tell Dave Kiff are: cartridge, brass type, freebore length and neck diameter. Otherwise, PT&G match reamers are near perfect. You could also load a dummy cartridge and send it with desired neck clearance. That would accomplish all of the above.

Decide whether you want turned necks or no-turn. Determine the neck wall thickness of the brass you intend to use (they vary). Determine the diametral clearance you want. I use .004-005" for .308. Measure the bullets you will use. They vary a little. Add it all up. That is the chamber dimension.

.308" bullets

.004" Diametral clearance

.014" neck wall thickness (2X)

.0005" for carbon

Ø.3405"

My tactical .308 has a Ø.342" neck to allow for some variation in factory ammo, if necessary. I think that most Palma chambers are ~Ø.343".

Your bullet choice will determine the freebore length. I size the freebore to allow bullet seating so that the shank (bearing surface) is just forward of the neck-shoulder junction. You could also specify the leade angle but 1½° is the overwhelming choice. There is also some body diameter variation based upon the brass manufacturer. Lapua and Norma tend to be larger in the body than Winchester or Remington, for instance. Other than those, chambers are fairly standard. Any of the reamer grinders can assist you with these parameters. I have found Dave Kiff at PT&G very helpful and I'm not alone in that opinion."

http://forum.accurateshooter.com/index.php?topic=3796201.0#top

Steve Blair

"This is what I would do. First I would see if I could locate some high mileage brass that was at the end of its useful life, having been sized and fired numerous times so as to be work hardened to the probable maximum. This brass will have appreciably more spring back than new brass, and will be the basis of a worst case sizing situation. Next I would purchase a bushing FL die, and size the cases so that they have a .002 bump from their fired shoulder to head length. (At this point, it is not important that the case "headspace" be in reference to any standard or the rifle to be built.) Next I would carefully measure the sized cases, and using the largest one, spec the body dimensions of the reamer for .002 clearance .200 from the head, and half that much at the shoulder (diameter). For the neck diameter, I would do a clean up turn on some new brass and spec the neck diameter to give .003 clearance on a loaded round, and in reality I would probably turn necks a little thinner so as to have a clearance of .005. Lots of knowledgeable shooters have figured out that more clearance works better, starting with around .003, or a little less at 6mm, and increasing as the caliber gets larger.....something about a cleaner bullet release. With the body diameters and neck diameter settled, I would make up some loaded rounds with my preferred bullets. loaded to the length that I wanted so that Dave could put them on the optical comparitor to come up with an appropriate throat length so that I can load all the way to a soft seat if I wanted, without any interference problems, and with enough bullet in the case necks. The other thing that I would pay some attention to would be freebore diameter, which I would spec. at .0003 over the measured maximum diameter of the largest diameter bullet that I planned on shooting."

http://forum.accurateshooter.com/index.php?topic=3788516.15

Boyd Allen

"From my experience when I changed,in a 7'08) from a 3 degree lead to a 1 1/2 degree lead I got a little more than 100 fps increase in velocity with the same pressure signs. This was the same barrel and same components and the bullet was seated into the rifleing. The more easily the projectiles transition into the rifleing the less distortion would seem plausible to me."

http://forum.accurateshooter.com/index.php?topic=1465516.0

DTubb

There has been much hullabaloo about reamer design over the years I've been designing them; first one in 1980 for an XP-100 used in the pistol silhouette game

BPCR Match Reamer Design Issues by Dan T

"There has been much cussing and dis-cussing concerning reamer design over the years I've been designing them. The first was designed in 1980 for an XP-100 used in the pistol silhouette game. I still have that JGS wildcat beauty based on RWS 5.6 x 50 brass. Can you say 7-TCU on steroids?

I've put this reamer primer together as a result of seeing too many friends spend good money, time and effort to have a top quality BPCR built only to have it all for naught due to an inappropriate chamber for top-notch match accuracy.

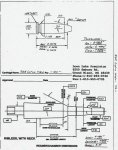

Most of the hubbub was and still is focused on the chamber's front-end: case-stop step-down, freebore and leade angle. For those of you not familiar with those terms, here is a picture as one is said to be worth a 1,000 words.

Reamer/Chamber Front-end Diagram

Much has also been made of chamber-body design. But, it is trivial in my opinion, as well as from experience, compared to the chamber's front-end. For the chamber body we just want a snug brass fit that does not interfere with round loading or case extraction and at the same time does not contribute to out-of-alignment issues when a round is chambered. There is, however, one area to focus on, especially for BPCR, and that is designing the chamber for the brass to be used given the range of original chamber dimensions and reloading dies for a given cartridge, can you say, no SAMMI spec? Simple, no? So, let's get to the meat of the matter.

The design parameters concerning front-end chamber specs focus on the three above mentioned chamber sections:

Case-stop Step-down: Angle, starting diameter & ending diameter

Freebore: Length and diameter, cylindrical or tapered

Leade angle: Angle and starting diameter, ending diameter is bore diameter

Let's address each design parameter in turn and then put the whole package together by addressing what it is we should be trying to accomplish with front-end reamer design.

First, let's discuss the case-stop step-down. It is the transition from the chamber's neck diameter down to either the freebore start or leade angle start. Not too much to discuss except that some BPCR reamers out there have only a case-stop step-down at a shallow angle that acts like a leade. It starts at the chamber-neck diameter and ends at the barrel's bore diameter; not my choice for a top performing match chamber as there is way to much slop and bullet bump-up that must be squeezed-down as the bullet hits the bore/groove diameters. From research to date, it seems that style of reamer was used to "butcher" the paper patch match chambers of original rifles and have somehow come to be accepted as match chambers in this day and age. That is unfortunate, to say the least. This discussion is focused on match chambers, not hunting or military; which have different optimization focuses. I believe the straight, shallow taper from full chamber-neck diameter down to barrel-bore diameter contributes to increased base distortion and contributes little to better bullet-to-bore alignment. And, since the bullet's base edge is the "steering" part of the bullet that can't possibly be an accuracy enhancer. For a hunting or military chamber this design might be appropriate though.

In my mind, minimizing the distance between the chamber's neck-diameter and the barrel's bore/groove diameters will help improve the bullet's base-edge symmetry because there will be a minimum of bullet bump-up that must be swaged down again, and never symmetrically, I might add, as the bullet enters the barrel's bore/groove. It seems we want the bullet to enter into the bore/groove diameters with minimum distortion, especially on the base edge. My current designs have a 45 degree angle from the chamber-neck diameter to the beginning of the leade angle. That typically means there is only about 0.023" of unsupported bullet before the leade angle begins. With 20-1 alloy my guess is that not much bump-up occurs in that narrow gap, a good thing for the bullet's base.

The second area of discussion concerning the chamber's front-end has to do with freebore. Freebore is typically a cylindrical, but sometimes tapered, section that is barrel-groove diameter or slightly larger. If there is freebore in the chamber design the back of it is where the case-stop step-down ends. The front of the freebore is where the leade angle starts. Most freebores are from about 0.050" all the way up to 0.500" long. Most are in the 0.150" range. For match cartridges that are a bit short on case capacity, like the 35-40 Maynard, a freebore can add a little more powder capacity due to being able to seat the bullet out further. But, at this time I'm inclined to say that a better strategy is to design a bullet that seats out into the bore for increased powder capacity. Some also call this "throating" the chamber and is often done after the barrel has been chambered, especially by bench rest shooters shooting jacketed bullets and smokeless powder. After working with various freebore configurations over the years I no longer included them in typical BPCR match chamber designs. That being said, it should also be stated that front-end chamber design and bullet design go hand-in-hand. Most of my current bullet designs are specified so that they seat substantially into the bore for enhanced bullet-to-bore alignment.

The final discussion point is about leade angle, a much debated design parameter. I will admit to going from 1/2 degree all the way to 3 degrees per side for grease-grooved and grease-grooveless bullets. Paper Patched chamber design is another discussion for now. After numerous reamers and much testing I've settled on 3 degrees per side, 6 degrees included to support the best possible bullet-to-bore alignment for the current crop of Paul Jones bullets I've been designing and Paul and David have been making molds for.

Now for the piece de resistance; addressing the whole front-end design package as a single entity by describing what it is we should be trying to accomplish with front-end reamer design. That design goal is; the best bullet-to-bore alignment possible with minimum bullet distortion especially on the base edge.

Some of you might ask, "How can we determine if a design accomplishes said goal?" Well, my friends, that is so simple you will fall off you computer chair when I tell you.

So, here it is. Make a dummy round (brass and bullet only) for your favorite load. Next, measure the bullet roll-out when the case neck is supported and the dial indicator is just behind the tip of the bullet. Write down the roll-out. Now, chamber the round and then carefully extract it. Measure the roll-out again. Is there any reduction in roll-out? If not, either your loading OAL is not what it should be or your chamber does not enhance bullet-to-bore alignment. For chambers and bullets currently in use, if a dummy round has its bullet purposely seated to create 10 thou roll-out; after chambering said round the roll-out will be reduced to between 2 and 3 thou. It's just that simple.

I guess one last issue should be discussed, chamber-neck diameter. For match chambers, "tight" necks seem to produce the best accuracy and they certainly are easier on brass due to reduced expansion and contraction every time the brass is subjected to the high pressures generated when the powder ignites. Current reamer designs allow for not neck-tuning the brass. But, slight neck-turning (just enough to remove high spots) to improve case-neck thickness consistency for more even bullet release can be done with no deleterious affects. The current design rule is simple: loaded round plus 1 to 1.5 thousandths clearance per side, 2 to 3 thousandths included. Also, the chamber neck's are cylindrical so the bullet has enhanced support as it starts its journey from case to target. One final issue to consider, the tighter the cartridge fit in the chamber-neck area, the less the bullet can bump-up as a result of its initial whack on the base from the rapid rise in pressure. From research to date, match chambers from the BPCR era were very tight and top marksmen were meticulous about their brass quality.

Happy pondering; think "Tight and well supported with enhanced concentricity from case to bore for our meticulously hand-cast bullets." Now that I think about it the true purpose of a BPCR match chamber is to deliver the bullet into the bore with minimum distortion and perfect alignment."

Cheers,

DanT

Case-Stop Step Down

[Case-stop step-down, use 45 degrees for .338 LM, 300 Win Mag, and .308 Winchester reamers.]

rxs0

"I also specify chamber over-all-length at .010" longer than max case length."

http://forum.accurateshooter.com/index.php?topic=3763294.msg35942477#msg35942477

fdshuster

Neck Diameter

"I would load at least 20 rounds and measure them all twice at 90 degrees to the first measure to the 1/10th of a thou, and add 0.003 to the largest dimension you get. If you end up in no man's land split between even thou, then round up rather than down."

http://forum.accurateshooter.com/index.php?topic=3751247.0

RonAKA

http://forum.accurateshooter.com/index.php?topic=3816085.msg36231611#msg36231611

"Between the end of the case neck and the bottom of the angled transition to the freebore, is an area where powder fouling can build up. If shorter cases are followed by longer ones, the longer ones are forced over the thickness of the fouling that was left in front of the shorter ones, crimping th e case mouth slightly. This points to the need for frequent trimming, and close control of shoulder bump. Additionally the corner that is formed at the larger diameter point of the angled transition is hard to clean, because brush bristles are bent by the smaller freebore diameter so that they miss the corner. IMO a good deal of this can be avoided by trimming for more clearance to the end of the chamber, which does not cause accuracy problems, and is only an issue if bullet and throat length combine to create a situation where there is less than the desired amount of bullet shank in the case neck. In the past, I thought that keeping this gap to a minimum was important. I have since learned better. (Search for Jack Neary on Youtube and watch all six segments.)

Getting to the carbon ring, what I have seen in a bore scope is a deposit at the very start of the freebore. This material is not the same as easier to remove powder fouling, and once it gets a foothold, generally requires the use of one of the abrasive cleaners too remove it. Not all barrels form carbon rings to the same degree, and certainly there are differences between powders. Sometimes the most accurate powder may not give the easiest to clean bore, but for competiton, unless the fouling becomes an accuracy problem in fewer shots than are allowed between cleanings, this is not an issue. On the other hand, for something like varmint shooting, a powder that gives good accuracy measures easily, and is relatively clean burning is probably a better choice than one that gives slightly better accuracy and requires more frequent cleaning."

Boyd Allen

Why You Will Not Get Accurate Dies If You Use Your Chamber Reamer

Chamber Reamer Myths | Reloading Dies For A Custom Fit

Voyeur's Guide to Barrel Chambering

Voyeur?s Guide to Barrel Chambering On Rifleman?s Journal « Daily Bulletin

ELR Resources Chamber Reamer Library

Information - Cartridges

.338 Lapua Magnum Development

Ordnanace Developements

The Well Guided Bullet

Interior Ballistics

An Introduction to Rifle Chambers

An Introduction to Rifle Chambers | Bison Ballistics

Saami Prints

SAAMI | Sporting Arms and Ammunition Manufacturers' Institute

CIP Prints

http://www.cip-bobp.org

http://www.poliisi.fi/intermin/images.nsf/files/AE55118F4B9B6506C2256FBE0032C6DE/$file/TABIcal.pdf

Misc

300WSM Reamer Design

The .300 WSM — Next Big Thing in F-Open Competition?

By Steve Blair

http://bulletin.accurateshooter.com/2013/11/the-300-wsm-next-big-thing-in-f-open-competition/

The specs of the front end (neck, leade, and throat) can be used in the design of the 300WM.

300WSM Reamer

I shoot 230 Hybrids with a .280" freebore and Ø.337" neck for .012" case neck. I recommend .200-.210" freebore and .339-.340" neck for 215 Hybrids with .013" case neck thickness. My Norma brass is fully turned at .013" case neck. Regardless any other factor, use a 1.5° leade angle.

http://forum.accurateshooter.com/index.php?topic=3823632.msg36275886#msg36275886

Steve Blair

Steve Blair's 300 WSM Match Reamer for 230 gr Berger Hybrid bullets and Norma brass

http://forum.accurateshooter.com/index.php?action=dlattach;topic=3799713.0;attach=896037

http://forum.accurateshooter.com/index.php?topic=3799713.msg36141929#msg36141929

Steve Blair

"Leade angle should be 1½°. My reamer is a PT&G .300 WSM Match with Ø.337" neck and .280" freebore. The feebore is solely for Berger 230 grain Hybrids."

Steve Blair

http://forum.accurateshooter.com/index.php?topic=3799713.msg36141484#msg36141484

"After the first firing, and assuming that the headspace is sized correctly (.001-.002"), there should be no case stretch. My .284 Shehane cases, also with 35° shoulder, do not stretch. My Warner Tool sizing die sizes the body .0015" and I have it shimmed to push the shoulder .0015-.002 back. My Norma brass is Ø.5525" at the body base and that is a pretty close fit to the chamber. Winchester brass is a little smaller. If the chamber is too small, the "Dreaded Click of Death®" will result unless custom sizing dies are used.

You will see on the SAAMI print that all chamber dimensions are nominal +.002". The nominal body diameter is Ø.5563 at the base, the same as my reamer. It is a minimum chamber.

I run the Shehane at comparable pressures to those of the WSM and get 5-8 loadings before primer pockets are too loose to use. When I buy a new barrel, I determine the largest lot size I will need within the barrel's anticipated life. For the .300 WSM, that would be 400 rounds to shoot the Berger SW Nationals and the National Championship. I acquire and prep the cases, which are enough to burn out the barrel before they are consumed. I expect about 1400-1600 rounds from the barrel using H1000 or IMR 7828 SSC, maybe a little less with H4831 SC.

BTW, here is the link to the .300 WSM. The lower drawing is, of course, the chamber."

http://www.saami.org/PubResources/CC_Drawings/Rifle/300 Winchester Short Magnum.pdf

http://forum.accurateshooter.com/index.php?topic=3799713.msg36141929#msg36141929

Steve Blair

300 WSM reamer spec?

« Reply #10 on: 08:57 AM, 12/04/12 »

Quote

From a 34" barrel, I expect to see ~2950 fps with either H1000 or IMR 7828 SSC, H4831 SC ~2900.

http://forum.accurateshooter.com/index.php?topic=3799713.msg36141993#msg36141993

Steve Blair

300 WSM Freebore

http://benchrest.com/showthread.php?84021-300-WSM-Freebore