I got them a Lowe’s, about $250 for both.Where did you source the counter tops? Are they economical?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building the Perfect Reloading Room

- Thread starter sirhrmechanic

- Start date

Here is the start of a new bench. I used 2x4s with joist hangers 16" OC and 3/4" plywood on top. I mounted my New MEC on the top with the mounting bolts going through two 2x4s turned flat screded into the joist and one 2x4 turned upright and screwed to them & the joist. The press does not move at all.

I did have two Dillon 650s but I had to sell them. I will be getting a new Dillon 750 in the very near future.

I did have two Dillon 650s but I had to sell them. I will be getting a new Dillon 750 in the very near future.

Here is the start of a new bench. I used 2x4s with joist hangers 16" OC and 3/4" plywood on top. I mounted my New MEC on the top with the mounting bolts going through two 2x4s turned flat screded into the joist and one 2x4 turned upright and screwed to them & the joist. The press does not move at all.

I did have two Dillon 650s but I had to sell them. I will be getting a new Dillon 750 in the very near future.

What did you use to finish the top? That's a nice looking heavy duty bench!

The bench I built. Notched construction, 4x4 legs, 2x3 framework, 3/4 birch plywood(double layer top) minwax gunstock stain, helmsman outdoor urethane, all fasteners from the inside to keep them hidden. Bottom shelf high enough to clear a Rubbermaid ruffneck tote and outlets.

Need to get a cluttered mess shot

Need to get a cluttered mess shot

Attachments

What are you guys using for bench lights? The room where I am building my reloading bench has overhead lighting but it is on the dim side. I don't want to mess around with installing new lighting since we plan to move in a years time. I was thinking about an adjustable architecture style desk lamp. What's on your bench?

8 foot LED Strip Lights. Standard 110 V connections. My shop is 13 feet wide 24 Deep and I ran three 24 foot runs (3 section), and a couple extras in closet space. No dark spots, and plenty of light. Also wired it to timer/motion sensor switch so all I do is walk in and light come on and when I leave with hands full of gun bags don't have to shut it off.

I use an A&D fx120 and have zero issues with the LEDsDo you use a digital scale and if so which one and do the lights cause interference?

Do you use a digital scale and if so which one and do the lights cause interference?

IIRC that was only an issue with florescent/halogen lamps. I have not had any issues with LED fixtures and my Lyman DPS 3 or gen5. Though I do hate the touch screen gen 5 as I prefer real buttons.

Wow. .....now that is a set up right there!

Home office is painted and ready to make into my reloading space. Built in cabinet and shelving will make some nice storage. One lonely 8lb h4350 needs some buddies. This will probably be a long road but I'm excited to get things into the A/C.

Attachments

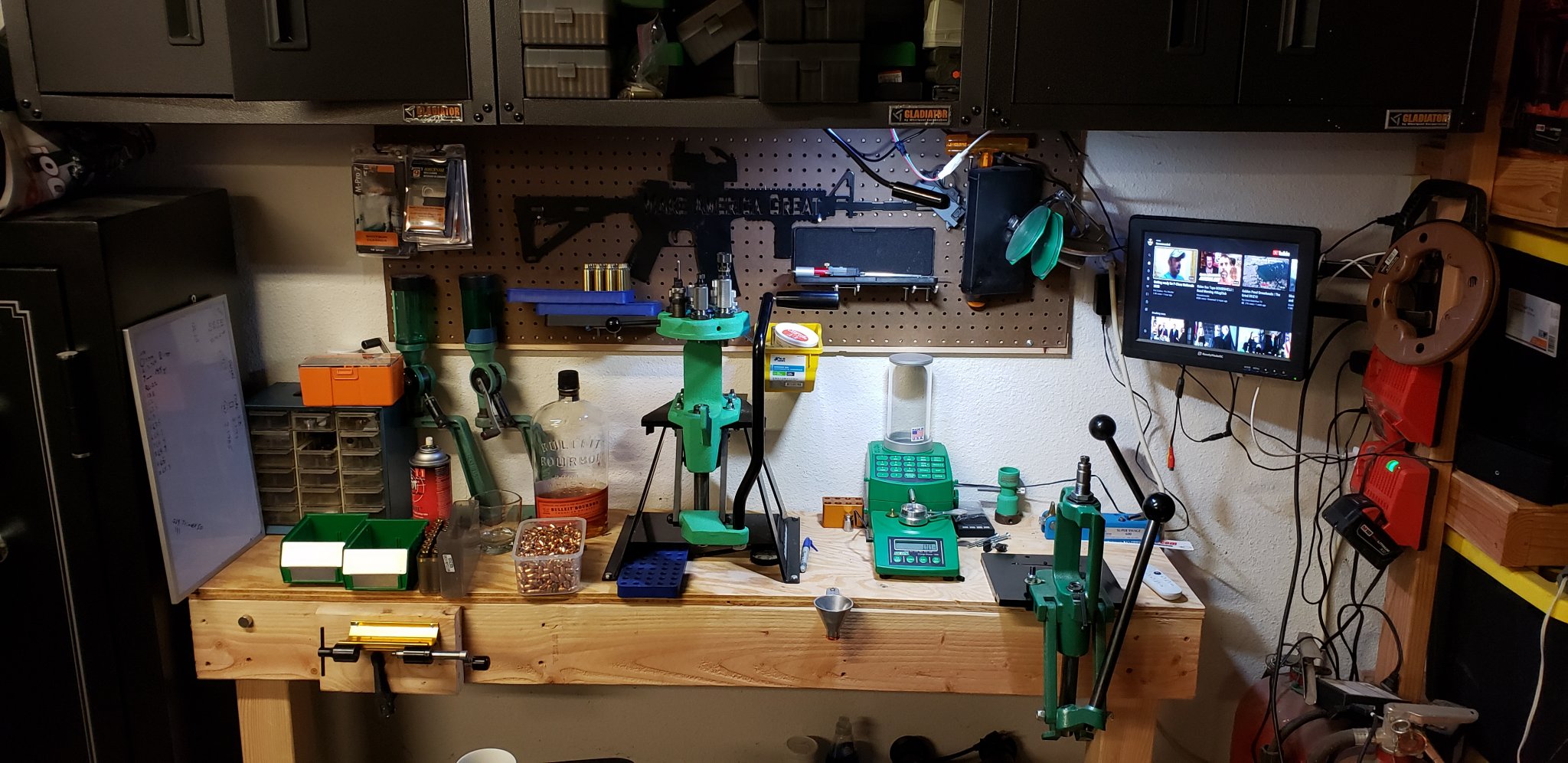

What brand of workbench is that? I'm looking for another bench something like this one.After following this thread for a while, I've incorporated a couple of ideas I gleaned here into my own setup. Here's my bench in it's mostly-final form....

View attachment 7156014

This is my first design. Been loading with this set up for the past 3 years and it's time to remodel. Glad I found this thread as I plan to glean a few ideas for use in my new set up.

Thanks. Benches are steel angle with a pan in there to hold the rebar and mesh with concrete and there’s garage floor epoxy on the top of the concrete on the benches and island. For the Island I cut a colum down and weld a small base and anchor bolted it to the floor and made up the top of it like the benches. A bit of fabricating , but was fun.

Thanks. Benches are steel angle with a pan in there to hold the rebar and mesh with concrete and there’s garage floor epoxy on the top of the concrete on the benches and island. For the Island I cut a colum down and weld a small base and anchor bolted it to the floor and made up the top of it like the benches. A bit of fabricating , but was fun.

WOW!

My old reloading room is towards the top of page 5 on this thread. Was just looking at it. It‘s been fun

@1badbarrel - i would try to get you to adopt me, but Im kinda old for that. Plus I have a kid.

Thats a heck of a set-up.

I try to not be envious and your pics make it tough.

Thats a heck of a set-up.

I try to not be envious and your pics make it tough.

My goodness.....

How many rounds do you reload a year? Are you running a business out of there or do you only reload, eat, sleep, shoot?

Building out a new room for reloading, gun cleaning and light 'smith work. I have space. Looking for opinions, mostly on the reloading part:

I have a couple of tumblers. They are pretty loud. I want to make a cabinet and put the tumblers behind doors, on drawer slides, to cut down on the noise. I have one of those Dillon media separator tubs. In the same cabinet a shelf to hold the separator. When finished tumbling, open the door, pull out the tumbler drawer, tip the contents into the separator, spin it around, dump the brass out into a "catcher pan". Dump the media back into the tumbler, roll it back into its home and close the door. Store fresh media in 5-gal buckets under the separator. Advantage: I don't have to pick the tumbler up off the floor and I don't have to listen to it. thoughts?

I have a nice Sartorius scale and autothrow/trickler. I also have another nice scale. I want to put them both on a table by themselves with a rock solid top - I'm thinking about one of those white quartz counter tops with filtered AC, bright lighting, and all their associated stuff. Thoughts? What about static?

I like a smooth workflow but I am a bit messy. For precision rifle, same as everyone else I have several steps. Tumble the brass. Anneal. Lube and size. Retumble. Expand necks. Trim. Prime. Throw powder. Seat bullets. Package and label. I'm thinking about fixing the base tools for each step to the bench and storing the tools for that stage (for example, sizing dies) next to the primary tool (the single-stage press). I have two tumblers and I will go back and forth a little.

I also have a progressive, I'm planning to mount that near the single-stage with its caliber kits overhead.

I want to clean guns in this area but not on these benches - cleaning cradle and stuff will go on a cleaning bench. I have noticed that bolt guns, semis, shotguns, and pistols need different cleaning cradles and maintenance tools but almost all of the long guns get cleaned from the breech and throw patches into a patch catcher. I'm thinking there will be a vice on this bench. I will use that to clean pistol barrels and lots of other stuff. When I clean a gun, I usually take it down to the frame. I also do light 'smithing - file here, grind there, fit stocks, install scopes, fit and tune triggers, remove and install barrels, that sort of thing. I will use the cleaning table and its vice for that sort of work.

I'm thinking that bench tops should be white so I don't lose things. I understand that Formica stains? Thoughts?

I like open shelves and closed-door cabinets. My lovely wife tells me that I have enough brass. We all know better but I need to store it somewhere. I have one or two rounds of loaded ammo, that needs to go somewhere and that crap is heavy. And I have powder and primers. I have a three-shelf cabinet I made out of 3/4-inch plywood, I will probably put powder and primers in that. This ain't my first rodeo but I am not the smartest guy in the room so please give me your thoughts.

I have a couple of tumblers. They are pretty loud. I want to make a cabinet and put the tumblers behind doors, on drawer slides, to cut down on the noise. I have one of those Dillon media separator tubs. In the same cabinet a shelf to hold the separator. When finished tumbling, open the door, pull out the tumbler drawer, tip the contents into the separator, spin it around, dump the brass out into a "catcher pan". Dump the media back into the tumbler, roll it back into its home and close the door. Store fresh media in 5-gal buckets under the separator. Advantage: I don't have to pick the tumbler up off the floor and I don't have to listen to it. thoughts?

I have a nice Sartorius scale and autothrow/trickler. I also have another nice scale. I want to put them both on a table by themselves with a rock solid top - I'm thinking about one of those white quartz counter tops with filtered AC, bright lighting, and all their associated stuff. Thoughts? What about static?

I like a smooth workflow but I am a bit messy. For precision rifle, same as everyone else I have several steps. Tumble the brass. Anneal. Lube and size. Retumble. Expand necks. Trim. Prime. Throw powder. Seat bullets. Package and label. I'm thinking about fixing the base tools for each step to the bench and storing the tools for that stage (for example, sizing dies) next to the primary tool (the single-stage press). I have two tumblers and I will go back and forth a little.

I also have a progressive, I'm planning to mount that near the single-stage with its caliber kits overhead.

I want to clean guns in this area but not on these benches - cleaning cradle and stuff will go on a cleaning bench. I have noticed that bolt guns, semis, shotguns, and pistols need different cleaning cradles and maintenance tools but almost all of the long guns get cleaned from the breech and throw patches into a patch catcher. I'm thinking there will be a vice on this bench. I will use that to clean pistol barrels and lots of other stuff. When I clean a gun, I usually take it down to the frame. I also do light 'smithing - file here, grind there, fit stocks, install scopes, fit and tune triggers, remove and install barrels, that sort of thing. I will use the cleaning table and its vice for that sort of work.

I'm thinking that bench tops should be white so I don't lose things. I understand that Formica stains? Thoughts?

I like open shelves and closed-door cabinets. My lovely wife tells me that I have enough brass. We all know better but I need to store it somewhere. I have one or two rounds of loaded ammo, that needs to go somewhere and that crap is heavy. And I have powder and primers. I have a three-shelf cabinet I made out of 3/4-inch plywood, I will probably put powder and primers in that. This ain't my first rodeo but I am not the smartest guy in the room so please give me your thoughts.

Building out a new room for reloading, gun cleaning and light 'smith work. I have space. Looking for opinions, mostly on the reloading part:

I have a couple of tumblers. They are pretty loud. I want to make a cabinet and put the tumblers behind doors, on drawer slides, to cut down on the noise. I have one of those Dillon media separator tubs. In the same cabinet a shelf to hold the separator. When finished tumbling, open the door, pull out the tumbler drawer, tip the contents into the separator, spin it around, dump the brass out into a "catcher pan". Dump the media back into the tumbler, roll it back into its home and close the door. Store fresh media in 5-gal buckets under the separator. Advantage: I don't have to pick the tumbler up off the floor and I don't have to listen to it. thoughts?

I have a nice Sartorius scale and autothrow/trickler. I also have another nice scale. I want to put them both on a table by themselves with a rock solid top - I'm thinking about one of those white quartz counter tops with filtered AC, bright lighting, and all their associated stuff. Thoughts? What about static?

I like a smooth workflow but I am a bit messy. For precision rifle, same as everyone else I have several steps. Tumble the brass. Anneal. Lube and size. Retumble. Expand necks. Trim. Prime. Throw powder. Seat bullets. Package and label. I'm thinking about fixing the base tools for each step to the bench and storing the tools for that stage (for example, sizing dies) next to the primary tool (the single-stage press). I have two tumblers and I will go back and forth a little.

I also have a progressive, I'm planning to mount that near the single-stage with its caliber kits overhead.

I want to clean guns in this area but not on these benches - cleaning cradle and stuff will go on a cleaning bench. I have noticed that bolt guns, semis, shotguns, and pistols need different cleaning cradles and maintenance tools but almost all of the long guns get cleaned from the breech and throw patches into a patch catcher. I'm thinking there will be a vice on this bench. I will use that to clean pistol barrels and lots of other stuff. When I clean a gun, I usually take it down to the frame. I also do light 'smithing - file here, grind there, fit stocks, install scopes, fit and tune triggers, remove and install barrels, that sort of thing. I will use the cleaning table and its vice for that sort of work.

I'm thinking that bench tops should be white so I don't lose things. I understand that Formica stains? Thoughts?

I like open shelves and closed-door cabinets. My lovely wife tells me that I have enough brass. We all know better but I need to store it somewhere. I have one or two rounds of loaded ammo, that needs to go somewhere and that crap is heavy. And I have powder and primers. I have a three-shelf cabinet I made out of 3/4-inch plywood, I will probably put powder and primers in that. This ain't my first rodeo but I am not the smartest guy in the room so please give me your thoughts.

BAX,

For gun cleaning/maintenance station, I prefer an island bench that I can move around and not have to re position the firearm. Another thing I'd consider is the double sliding doors on all my cabinets. This gives easier access when you have to share your floor space for storage and keeps out most of the dust. IMO there are only two materials I'd consider for bench tops, stainless or unfinished wood butcher block of a light color. Neither will cause a static problem and both will make it easy to see what you drop.

"yes" on the island!BAX,

For gun cleaning/maintenance station, I prefer an island bench that I can move around and not have to re position the firearm. Another thing I'd consider is the double sliding doors on all my cabinets. This gives easier access when you have to share your floor space for storage and keeps out most of the dust. IMO there are only two materials I'd consider for bench tops, stainless or unfinished wood butcher block of a light color. Neither will cause a static problem and both will make it easy to see what you drop.

Today I use a Sinclair cleaning cradle that is attached to cart. I can roll the cart around without moving the weapon from the cradle. I think I will keep the cart but install the cradle (and, perhaps, the vice) on a fixed island table. The cart top /14-inch hardboard over is 5/8-inch plywood secured to the sides with steel 90-degree angle. I drilled the angle, threaded the holes, and ran several screws to secure it - might be #12 or 1/4-inch, I forget. Its sturdy. I like the top design, I can easily replace the hardboard.

You said, "stainless or unfinished wood butcher block of a light color". I agree on the static issue. Today, I use a large rubber pad I got from Brownells, no static. Stainless has no give., things dropped onto it dent or break and it is tough to drill holes in it and that creates other usage problems. However, it does not burn and that has value and my rubber pad would address the "give" issue. When you said "unfinished butcher block" are you thinking just sanded? No varnish? That will absorb solvent etc. Can you expand on that thought?

I am thinking about fire. I have an extinguisher and smoke detectors. I keep powder and primers in a sturdy wood cabinet. I'm planning to use as many steel shelves as I can afford. Walls are drywall over 2x4 studs and insulation, floor and ceiling are concrete. Wiring installed by a pro with outlets about 3 feet off the floor. But there will still be wood, plastic, and paint in the space. What sort of things would be reasonable?

The sanded/unfinished butcher block top would be susceptible to solvents and lubes, however, one can always put down a mat to absorb those problems. Unfinished was suggested for the anti-static properties. Stains are desirable 'character marks' in a man cave! Stainless wouldn't be forgiving as you stated but nothing I can think of would fall far enough to be damaged by the stainless. Whatever you go with, I'd suggest an aluminum angle edge that would prevent small things from rolling off to impact the floor. Sounds like you've put a lot of thought into the project. I look forward to seeing your finished project!"yes" on the island!

Today I use a Sinclair cleaning cradle that is attached to cart. I can roll the cart around without moving the weapon from the cradle. I think I will keep the cart but install the cradle (and, perhaps, the vice) on a fixed island table. The cart top /14-inch hardboard over is 5/8-inch plywood secured to the sides with steel 90-degree angle. I drilled the angle, threaded the holes, and ran several screws to secure it - might be #12 or 1/4-inch, I forget. Its sturdy. I like the top design, I can easily replace the hardboard.

You said, "stainless or unfinished wood butcher block of a light color". I agree on the static issue. Today, I use a large rubber pad I got from Brownells, no static. Stainless has no give., things dropped onto it dent or break and it is tough to drill holes in it and that creates other usage problems. However, it does not burn and that has value and my rubber pad would address the "give" issue. When you said "unfinished butcher block" are you thinking just sanded? No varnish? That will absorb solvent etc. Can you expand on that thought?

I am thinking about fire. I have an extinguisher and smoke detectors. I keep powder and primers in a sturdy wood cabinet. I'm planning to use as many steel shelves as I can afford. Walls are drywall over 2x4 studs and insulation, floor and ceiling are concrete. Wiring installed by a pro with outlets about 3 feet off the floor. But there will still be wood, plastic, and paint in the space. What sort of things would be reasonable?

bax, On this question, I'd go industrial. When I was active duty, I recall red knee high steel cans with a foot lever to lift the lid for dirty rags and other combustibles that had to be cleaned out every day/shift to mitigate potential fire hazards.

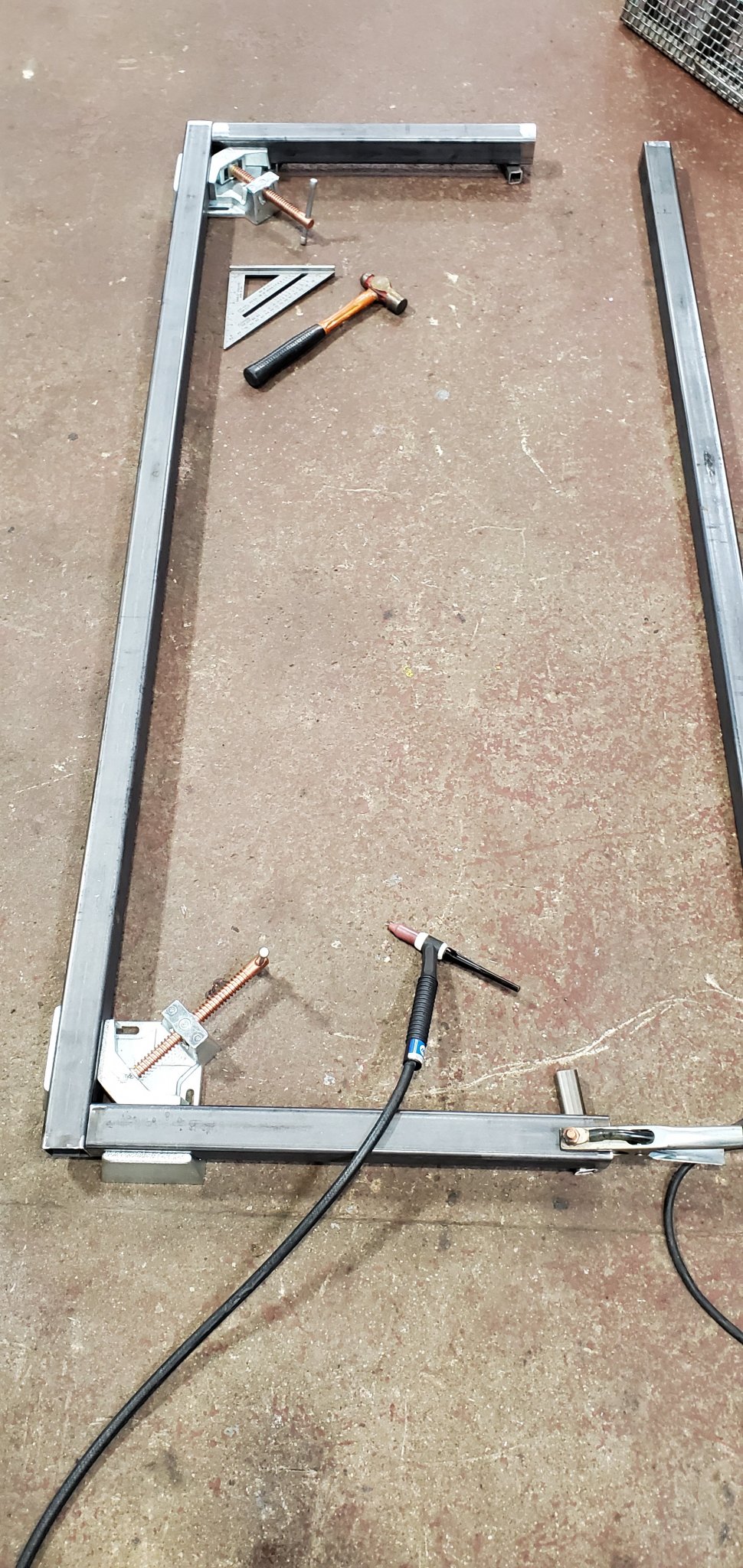

While it will be small compared to a lot of your setups, got to start somewhere.

Back legs and shelf tomorrow as well as paint.

6' long, 30" deep, 40" tall, back legs will go up 5' with a 9" shelf off that. Will pick up butcher block counter top Sunday hopefully.

Back legs and shelf tomorrow as well as paint.

6' long, 30" deep, 40" tall, back legs will go up 5' with a 9" shelf off that. Will pick up butcher block counter top Sunday hopefully.

Just finished putting this together as my old bench was starting to have issues with the weight. This frame is all 4x4s so it should do much better. I keep all of my equipment in cabinets or drawers when not in use. While it may not be the "perfect reloading room" as the thread title implies, it works for me. Bench holds 56 20mm ammo cans and the extra stuff. Wood, hardware, and tool boxes came to about $1200 (bench was $632) and the bench is 96" wide, 42" deep and the height of the top shelf is 43.5"

Last edited:

I'm jealous of all your storage under the benchJust finished putting this together as my old bench was starting to have issues with the weight. This frame is all 4x4s so it should do much better. I keep all of my equipment in cabinets or drawers when not in use. While it may not be the "perfect reloading room" as the thread title implies, it works for me. Bench holds 56 20mm ammo cans and the extra stuff. Wood, hardware, and tool boxes came to about $1200 (bench was $632) and the bench is 96" wide, 42" deep and the height of the top shelf is 43.5"

Thanks,

Those cylinders are what is left over from my days of technical diving. I sold half of the cylinders and that is what remains. I keep telling myself that I will make some more deep dives but I just never seem to get back to it. Probably need to take these tanks out to our storage unit and get them out of the way.

I made the bench a bit higher than others so that it could hold a large portion of my ammo. My old bench also had three shelves but the the 20mm ammo cans would only fit on the bottom shelf so this is much better. Each can in the front holds the same ammo directly behind it so I don't need to dig through the pile to find what I need. Some are two cans while other cartridge's are in four cans. I keep my powders, tumblers and other stuff in that 18 section gym locker and on the other wall, I have more stuff like my AMP annealing machine an other odds and ends. The tool boxes hold mostly primers and bullets and the top of the tool box on the left is all new brass and the top of the one on the right holds my progressive press and three single-stage presses.

Those cylinders are what is left over from my days of technical diving. I sold half of the cylinders and that is what remains. I keep telling myself that I will make some more deep dives but I just never seem to get back to it. Probably need to take these tanks out to our storage unit and get them out of the way.

I made the bench a bit higher than others so that it could hold a large portion of my ammo. My old bench also had three shelves but the the 20mm ammo cans would only fit on the bottom shelf so this is much better. Each can in the front holds the same ammo directly behind it so I don't need to dig through the pile to find what I need. Some are two cans while other cartridge's are in four cans. I keep my powders, tumblers and other stuff in that 18 section gym locker and on the other wall, I have more stuff like my AMP annealing machine an other odds and ends. The tool boxes hold mostly primers and bullets and the top of the tool box on the left is all new brass and the top of the one on the right holds my progressive press and three single-stage presses.

I fully plan on stealing as many ideas from all the pictures that I can fit into my own reloading room when and If I ever get that chance to do so .

Frame of the bench is finished. Didn't get a chance to buy the butcher block.

Need to run some electrical for overhead light and a couple outlets.

Need to run some electrical for overhead light and a couple outlets.

Here is my miniature bench In the garage. Still have some changes to make but you get the idea.

Damn, tagging in a bit late here.

I'd been looking for butcher block and got disgusted at the price. Found an alternate I think is going to come out really well- reclaimed bowling lane.

A place near me has 6' sections for $300... can't go wrong with 1 1/2-inch thick maple. Should have it in about a week.

I'd been looking for butcher block and got disgusted at the price. Found an alternate I think is going to come out really well- reclaimed bowling lane.

A place near me has 6' sections for $300... can't go wrong with 1 1/2-inch thick maple. Should have it in about a week.

Only paid $250 for mine from home depot including the screws I bought using the mil discount. But, if I had the choice, the maple, even if I had to rip it, plane it, joint it, etc... I would prefer it over the birch. So not bad.

Later than I planned to finish it, deer camp got it in the way.

Lots still to buy, but it's now at a point where I can at least prep brass.

Lots still to buy, but it's now at a point where I can at least prep brass.

Still a work in progress but figured I’d throw mine up looking to add some more shelving as well as some cabinets to the bottom. Ended up 12’ by 21.5” with the L extending around 30” if I remember right. 4x4 posts 2x8 tabletop with 3/4 plywood cover and went with 4 coats of polyurethane for ease of cleanup.

Similar threads

- Replies

- 66

- Views

- 3K

- Replies

- 103

- Views

- 5K