And done. Not woodworker at all but it's level, doesn't move and most importantly was sturdy enough to remove the PSA barrel....

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Innovative and very nicely done ??I bought a portable building 10x24 and insulated the crap out of it. Climate controlled with a large window unit/heat pump. Very cool in summer and toasty in the winter. I got the wood for the inside from an old privacy fence and metal from an old barn at my parents place. Floor from Lowes. Built a stout table and mounted my press. Still doing final touches. Its got a couch, recliner, TV with WiFi. Cool little man cave for sure!!View attachment 7008541

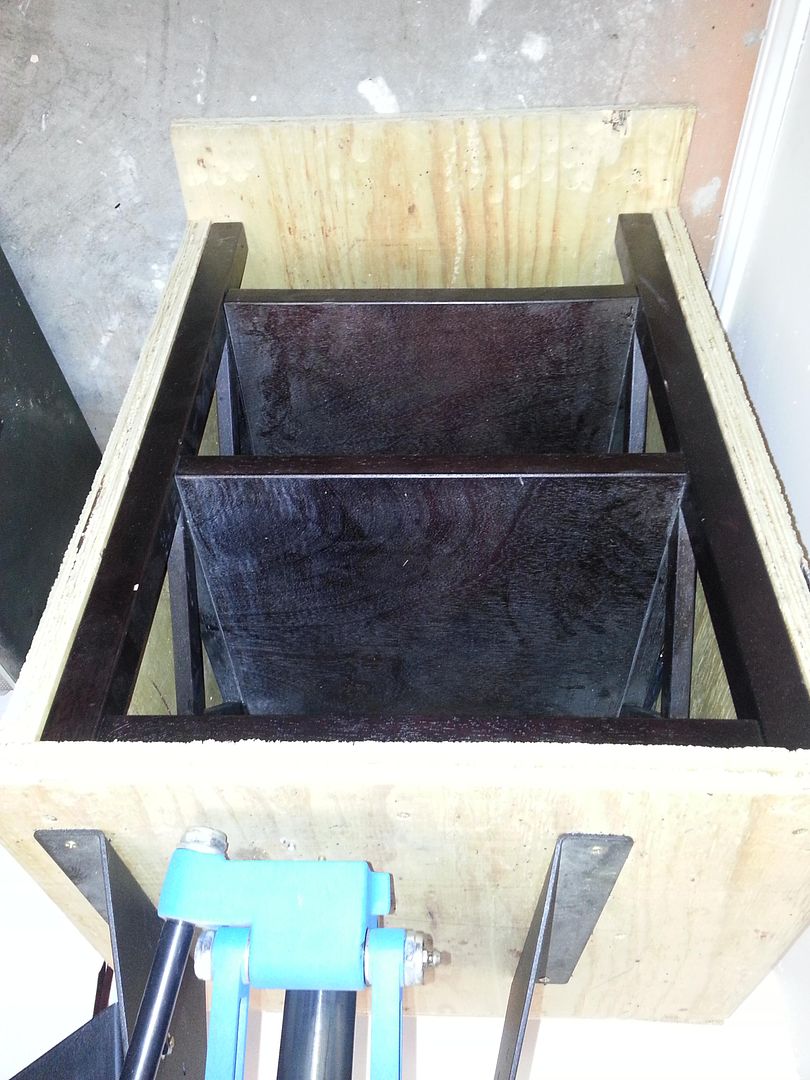

Yes they are, two of them side by side, with a 3/4” 4x8 sheet of ply ripped down the center and then laid on top of each other. Then fastened to the bench from the bottom side. Very sturdy so far.

My wife has always been my hero but she was especially so today. We moved her elliptical out of the gun room so I have sole possession. With coupon in hand I headed to Harbor Freight for a second Yukon workbench. Also stopped by Sam's Club for another 48" LED shop light. The second workbench is dedicated to the annealer, tumbler. storage of the drier and associated paraphernalia. The original Yukon workbench will be used for gun maintenance, cleaning etc... The reloading bench can now be used exclusively for what it was built for. A place for everything and everything in it's place. My OCD is soothed...for now...

And that floor mat is 1/13th of a tile off..... aarrrrrrgtgggggg.My OCD is NOT!! Those case are not lined up or even facing the same direction, left front wheel is not in line with cabinet...shit sorry, I actually HAVE OCD!!

Excellent suggestion!!!!!This is going to sound odd, but you can pick up unused or incorrectly spec'd stainless doors from your local elevator installers for scrap steel prices. I got four of them, and I'm welding up some legs with wheels right now. They make perfect table tops.

I'd be interested in hearing more about this. I grew up in the North and when I started reloading I had my stuff in a basement. Now that I moved back down South (was stationed down there), the wife and I just bought a house and basements aren't a thing. Right now I'm taking up one of the upstairs bedrooms, but soon enough I know I'll get kicked out. I had planned on using space in the garage or adding on a 3rd bay, but neither one is an ideal option. Purchasing an outbuilding and insulating/climate controlling it was the next best idea. How does the powder and primers fair? Any corrosion on the parts?I bought a portable building 10x24 and insulated the crap out of it. Climate controlled with a large window unit/heat pump. Very cool in summer and toasty in the winter. I got the wood for the inside from an old privacy fence and metal from an old barn at my parents place. Floor from Lowes. Built a stout table and mounted my press. Still doing final touches. Its got a couch, recliner, TV with WiFi. Cool little man cave for sure!!View attachment 7008541

I have had it for about three years now. No issues with corrosion. Powders and primers are still good. Realistically its no different than being in the house. The window unit/heat pump works great. The ac pulls moisture out in the summer, its shaded pretty good in the summer. The heat pump for winter works well also. Like I said its very insulated. I will get more pics up also.I'd be interested in hearing more about this. I grew up in the North and when I started reloading I had my stuff in a basement. Now that I moved back down South (was stationed down there), the wife and I just bought a house and basements aren't a thing. Right now I'm taking up one of the upstairs bedrooms, but soon enough I know I'll get kicked out. I had planned on using space in the garage or adding on a 3rd bay, but neither one is an ideal option. Purchasing an outbuilding and insulating/climate controlling it was the next best idea. How does the powder and primers fair? Any corrosion on the parts?

That looks great. We have just over 1.5 acres, mostly wooded. Unfortunately its all down a huge slope from the house, but I have enough room that I could probably add something just a little bit shorter than that on the garage side. Ideas are forming and its definitely cheaper than building a 3rd garage bay onto the house.I have had it for about three years now. No issues with corrosion. Powders and primers are still good. Realistically its no different than being in the house. The window unit/heat pump works great. The ac pulls moisture out in the summer, its shaded pretty good in the summer. The heat pump for winter works well also. Like I said its very insulated. I will get more pics up also. View attachment 7037019View attachment 7037022View attachment 7037028

Its great. Inside dimensions are 10*20. There is a sandbox in front and a swing set for our kids now. I can load and hang with them. They will watch cartoons out there while I tumble and sort brass. My kids are 2 and 4, they think its the coolest place!!That looks great. We have just over 1.5 acres, mostly wooded. Unfortunately its all down a huge slope from the house, but I have enough room that I could probably add something just a little bit shorter than that on the garage side. Ideas are forming and its definitely cheaper than building a 3rd garage bay onto the house.

"I know a guy" who is working on improving storage for his stuff, and he started with 'cabinet rails' that he got from IKEA. He just used them in a different way, to mount plywood panels onto the wall.

This way the panels are both held securely, 'invisibly', and removable. They can be removed so that they are adaptable/changeable as well as when the layout is finally finished, they will be covered with a "speaker cabinet fabric".

I'll see if I can get a few pictures, next time I'm there.

Here's a few pics I was able to get:I'm very curious about what you are trying to explain. Pics would be nice.

I finally finished my 4th bench in my reloading room which is a dedicated gun building bench. Just needs to be stained and cleared but that will have to wait till spring when I can leave the windows open.

1. Dillon XL650 bench

2. Co-Ax / Chargemaster bolt rifle bench

3. Roch Chucker depriming and brass prep bench

4. Gun building/cleaning bench

I went with Inline Fabrications Ultramount with Quick Change baseplate system. Its an amazing setup!! I have 5 baseplates with different tools mounted on each. They have a huge drop down of pre made plates for all kinds to tools, trimmers, presses, vises, etc. Waiting on a second shipment from them with my wall mounting system. Also have a nice sturdy old dinning room table as kind of a 5th bench for whatever I need it for.

Trim it 2Terry H what is the case trimmer in the lathe?

Your going to need more storage?View attachment 7063543

Here is my very first set up, have never reloaded before. Just finished it last night, it's nothing special but I'm happy with it for sure.

View attachment 7063543

Here is my very first set up, have never reloaded before. Just finished it last night, it's nothing special but I'm happy with it for sure.

ive got a wall cabinet on the way!Your going to need more storage?

thank you!Looks great! Especially for a new reloader. I actually prefer a smaller bench like yours for reloading. Keeps you from having to much crap on the bench.

View attachment 7063543

Here is my very first set up, have never reloaded before. Just finished it last night, it's nothing special but I'm happy with it for sure.

its made by "Gladiator" lowes, Home depot carry them. its their 6ft benchThat is sweet! Who is the manufacturer of the bench? I'm looking for one about that size.

safe's set in place last night and one bolted in and half of the other one before my back gave out(back surgery). hope to finish tonight and get all my shit under lock and key again. will finish the cage this weekend. have to put together my cabinets before i can put the roof on the cage.

Sweet jebus, Im pretty sure my whole reloading area would fit INSIDE your two safes.

Very nice sir! Its going to look sweet when done!

Welcome to the Armory.. Well done.got plenty done this weekend, safe's are set in place and bolted down, storage cabinets are put together and the security cage is all together except for one panel.

Well I've been planning my reloading setup for 3 years and scrimping along the way. This weekend will be the day(s) I jump in!Does anyone else spend twice as much time cleaning and organizing as actually reloading?