Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Get 25% Off Access To Frank's Online Training

Use code FRIDAY25 and SATURDAY25 to get 25% off access to Frank’s online training. Want a better deal? Subscribe to get 50% off.

Get Access Subscribe

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building the Perfect Reloading Room

- Thread starter sirhrmechanic

- Start date

The corner of a (big) walk-in closet. Modest but adequate so far. I do most of my gunsmithing in another room, so this area is just for reloading. I do wish the desk was bench height, but it was already here and I didn't see any reason to rebuild.

Im planning on building another bench along the right wall so I can add another press and maybe some case-prep stuff, to keep it separate from the loading bench. I also want to add a quick change track to the new bench so I can move stuff around as I please.

Great looking setup! Better looking pup!

Mike

This setup is working out pretty well for me, a lot better than my last one that was a mobile bench that I had to work from both sides.

It's probably not as fast as a progressive but I'm able to go from an unprepped case to a finished round in the time it's taking the Chargemaster to throw 42 grains of 4350, about 25 seconds.

I'm pretty much sick of my RCBS presses that I got from my uncle though. I got them from him 10 years ago and I have no idea how long he had them before that. I'm thinking I need to try a COAX.

It's probably not as fast as a progressive but I'm able to go from an unprepped case to a finished round in the time it's taking the Chargemaster to throw 42 grains of 4350, about 25 seconds.

I'm pretty much sick of my RCBS presses that I got from my uncle though. I got them from him 10 years ago and I have no idea how long he had them before that. I'm thinking I need to try a COAX.

We are just about wrapped up on an extensive remodel on a house we purchased in February (about 3 weeks left), but because my wife definitely does not suck, she gave me one of the rooms for a gun room/reloading room. It is almost done!

"Fill'em and Kill'em" Yes ! great. Love it. @scott_gresham

Those hinged stool seats are wicked nice.

Those hinged stool seats are wicked nice.

"Fill'em and Kill'em" Yes ! great. Love it. @scott_gresham

Those hinged stool seats are wicked nice.

Thanks! Those were actually left over from our kitchen remodel. My wife had bought three of those for under our bar in the kitchen, and they didn't work well with the size of the bar overhang, so I lucked into them!

I gotta get me one of those Molon Labe pillows lolThanks! Those were actually left over from our kitchen remodel. My wife had bought three of those for under our bar in the kitchen, and they didn't work well with the size of the bar overhang, so I lucked into them!

those pillows were super cheap. Cafepress I think.I gotta get me one of those Molon Labe pillows lol

My reloading area is in the living portion of our home. I used a bench I had built for years when I was shooting pistol comps and LRP rifle stuff, but the bench just didn’t fit in. We live in a renoed country home that was built in 1895 but the basement is not suitable for precision equipment (damp). I stopped pistol comps about 4 years ago and decided to downsize a bit. I wanted to be able to continue to load pistol and rifle but on a smaller bench. I wanted the bench to look like a piece of furniture and fit in with the rest of the room.

I followed this thread and others looking for ideas. I finally came across the bench that Terry H built, and with his permission, stole his design. Hired a retired cabinet maker who is also a shooter, and put together a plan, settled on a price, materials, etc... A few months later, I’m kind of “moved in”.

Solid White Oak construction, 100 lb rated slides, 5/4” top with T track (I have multiple presses mounted on aluminum plate), 3/4” Maple drawers, etc... It’s built Hell for stout and HEAVY.

I followed this thread and others looking for ideas. I finally came across the bench that Terry H built, and with his permission, stole his design. Hired a retired cabinet maker who is also a shooter, and put together a plan, settled on a price, materials, etc... A few months later, I’m kind of “moved in”.

Solid White Oak construction, 100 lb rated slides, 5/4” top with T track (I have multiple presses mounted on aluminum plate), 3/4” Maple drawers, etc... It’s built Hell for stout and HEAVY.

And of course, the obligatory pic with one of the rifles sitting on it...?

^^^ That is gorgeous! That's not a reloading bench. That's a reloading Cabinet!

Beautiful way to integrate into the house... and build a bench for the ages.

Love the concept and the execution. Well done!

Cheers,

Sirhr

Beautiful way to integrate into the house... and build a bench for the ages.

Love the concept and the execution. Well done!

Cheers,

Sirhr

My reloading area is in the living portion of our home. I used a bench I had built for years when I was shooting pistol comps and LRP rifle stuff, but the bench just didn’t fit in. We live in a renoed country home that was built in 1895 but the basement is not suitable for precision equipment (damp). I stopped pistol comps about 4 years ago and decided to downsize a bit. I wanted to be able to continue to load pistol and rifle but on a smaller bench. I wanted the bench to look like a piece of furniture and fit in with the rest of the room.

I followed this thread and others looking for ideas. I finally came across the bench that Terry H built, and with his permission, stole his design. Hired a retired cabinet maker who is also a shooter, and put together a plan, settled on a price, materials, etc... A few months later, I’m kind of “moved in”.

Solid White Oak construction, 100 lb rated slides, 5/4” top with T track (I have multiple presses mounted on aluminum plate), 3/4” Maple drawers, etc... It’s built Hell for stout and HEAVY.

View attachment 6911334View attachment 6911335View attachment 6911336View attachment 6911337View attachment 6911338View attachment 6911339

That turned out fantastic!!

My Sophisticated Redneck reloading rig for when it’s 100 and holy shit it’s hot in the garage. Gave my wife a choice, I can build something permanent in the house or I can do this. God bless her for putting up with me and this is where I landed. Gorilla platform $29, left over wood $0, left over tech screws $0, left over wood screws $0, reloading in the AC........priceless?

Yep, this is what I want my reloading room to look like! Mine is in my living room right now lolI recently built a new haven for my daily operations.

Here's some pictures in no particular order. There is simply too much going on in this room to get pictures of everything.

Didn’t want you fellas to worry that the new bench was for show. Hotter than Haiti’s here this afternoon so I bumped shoulders and trimmed some 260 brass.

I built a walk in safe room in my basement, that seconds as my reloading room. I have a ton of photos from start to finish if anyone is interested. cost less than $1000 to build the 10x10 room.

How wide is your reloading cave? Nice placeI recently built a new haven for my daily operations.

Here's some pictures in no particular order. There is simply too much going on in this room to get pictures of everything.

I'm interested in what door you used for your 10x10.

Right now a Metal exterior door. with digital deadbolt and digital keypad. as you probably know, safe doors are crazy expensive!

Right now a Metal exterior door. with digital deadbolt and digital keypad. as you probably know, safe doors are crazy expensive!

A heavy metal fab shop might be able to fix you up real nice for a fraction of the cost of a retail pre-hung 'Vault' door. Only issue is that the onus is on you to design things unless your fabricator is good at design and working on-the-fly. Also, check craigslist for such things. I know a guy that got a smokin' deal on an older 1600lb vault door/jam that was reclaimed from some former jewelry store's demolition. *Insanely* cheap. It was serious overkill, but for the price, it was impossible to beat.

A heavy metal fab shop might be able to fix you up real nice for a fraction of the cost of a retail pre-hung 'Vault' door. Only issue is that the onus is on you to design things unless your fabricator is good at design and working on-the-fly. Also, check craigslist for such things. I know a guy that got a smokin' deal on an older 1600lb vault door/jam that was reclaimed from some former jewelry store's demolition. *Insanely* cheap. It was serious overkill, but for the price, it was impossible to beat.

Funny you mention this, I actually have a buddy who is designing one for me. He owns a metal shop. Gonna be sweet!

Started reloading about a year ago. Here is my reloading bench progression from then to now.

How do you like that Hornady Iron press?Started reloading about a year ago. Here is my reloading bench progression from then to now.

View attachment 6922505

View attachment 6922504

How do you like that Hornady Iron press?

I’ve only been reloading for a year and this is the only press I have ever used so please keep that in mind.

I like it so far but do have trouble with long straight wall revolver cartridges (.460S&W) with keeping the case aligned when entering the sizing die. In talking with Hornady about this minor issue they confirmed that with the tolerances they use because it was designed as a “precision rifle press”, this could be a problem. Other than that I had to monkey with the auto prime to get it to feed consistently but again, more of an inconvenience than issue.

The selling point for me was the open front which is awesome. A little pricey but it is one heavy duty press!

After find this thread,and seeing the you tube video,now i need to redo mine.i found a gladiator garageworks 6 ft,with attached 6 ft power strip that has at least 6-8 outlets.got it for 150 on a returned clearance.i have twin 650’s mounted and with that i am pressed for space.8 foot would be perfect.but so would kicking the wifes car out of the garage

Hi, I know it might be a bit late... But I believe you can get a set of plans for a really great reloading bench/storage combo from American Reloading Organisation (?) not entirely sure of the name, but you can google it. It’s an industry organisation, but the plans are free and it looks like a REALLY good bench.padom Awesome! I think I'm gonna try and build a 48" replica of this. I may bother you for additional photos come spring time.

I got the plans, bought the lumber, never built the bench... Kids came & took over my life!

Now that they both shoot, I might re-visit this & put them to work reloading for me...

Wow, what a thread !!!

Since I've only been a part of the forum for a few days, I saved the reloading room thread for a whole day to absorb. I've moved too frequently during my youth and 20+ years in the military to setup a nice reloading area. Now that I'm 63, full time retired and have a home across the street from the mortuary my next move shouldn't be far. Since I'm counting on modern medical science to help keep me reloading and shooting till I'm 150, I'll get going on my reloading area. I have a few thoughts to offer for consideration that I didn't see in the thread. The first would be that if there is any overhead or same floor plumbing the time will come when floor level water will happen. I suggest that all benches and cabinets have water resistant plates under them to hold them up 3/4" to 1-1/2". The simplest and most economical way is to use outdoor composite decking boards to cut, mill, shape, stack in whatever way is needed to get everything that can wick water or rust off the floor. Bench legs, wood or metal need this protection and if you have press board cabinets or closets you can imagine that they quickly become trash once water gets to them. Second, build modular, I mean that whatever you put in should be small enough it can be taken out without having to demolish it or the building. You can still make it in bolt together sections that have the appearance and utility of a very large work area. Keep in mind door widths and the ability to move around tight corners, narrow hallways and stairwells. Make the bench tops removable, if your laminating add blind nuts so it can be bolted down from underneath. If using butcher block or some other thick solid you can add wood-to-bolt threaded adapters. Half or more of the weight can easily be in these tops. Third, consider not wasting space on swinging cabinet doors use sliders. They are much lighter in weight and don't require the movement of tall or large objects such as bikes and stools or progressive equipment. Things are uncertain in life, many a retired person thought that they were in their last home only to find out their beloved spouse is deciding they need to live closer to the kids and grand kids.

Since I've only been a part of the forum for a few days, I saved the reloading room thread for a whole day to absorb. I've moved too frequently during my youth and 20+ years in the military to setup a nice reloading area. Now that I'm 63, full time retired and have a home across the street from the mortuary my next move shouldn't be far. Since I'm counting on modern medical science to help keep me reloading and shooting till I'm 150, I'll get going on my reloading area. I have a few thoughts to offer for consideration that I didn't see in the thread. The first would be that if there is any overhead or same floor plumbing the time will come when floor level water will happen. I suggest that all benches and cabinets have water resistant plates under them to hold them up 3/4" to 1-1/2". The simplest and most economical way is to use outdoor composite decking boards to cut, mill, shape, stack in whatever way is needed to get everything that can wick water or rust off the floor. Bench legs, wood or metal need this protection and if you have press board cabinets or closets you can imagine that they quickly become trash once water gets to them. Second, build modular, I mean that whatever you put in should be small enough it can be taken out without having to demolish it or the building. You can still make it in bolt together sections that have the appearance and utility of a very large work area. Keep in mind door widths and the ability to move around tight corners, narrow hallways and stairwells. Make the bench tops removable, if your laminating add blind nuts so it can be bolted down from underneath. If using butcher block or some other thick solid you can add wood-to-bolt threaded adapters. Half or more of the weight can easily be in these tops. Third, consider not wasting space on swinging cabinet doors use sliders. They are much lighter in weight and don't require the movement of tall or large objects such as bikes and stools or progressive equipment. Things are uncertain in life, many a retired person thought that they were in their last home only to find out their beloved spouse is deciding they need to live closer to the kids and grand kids.

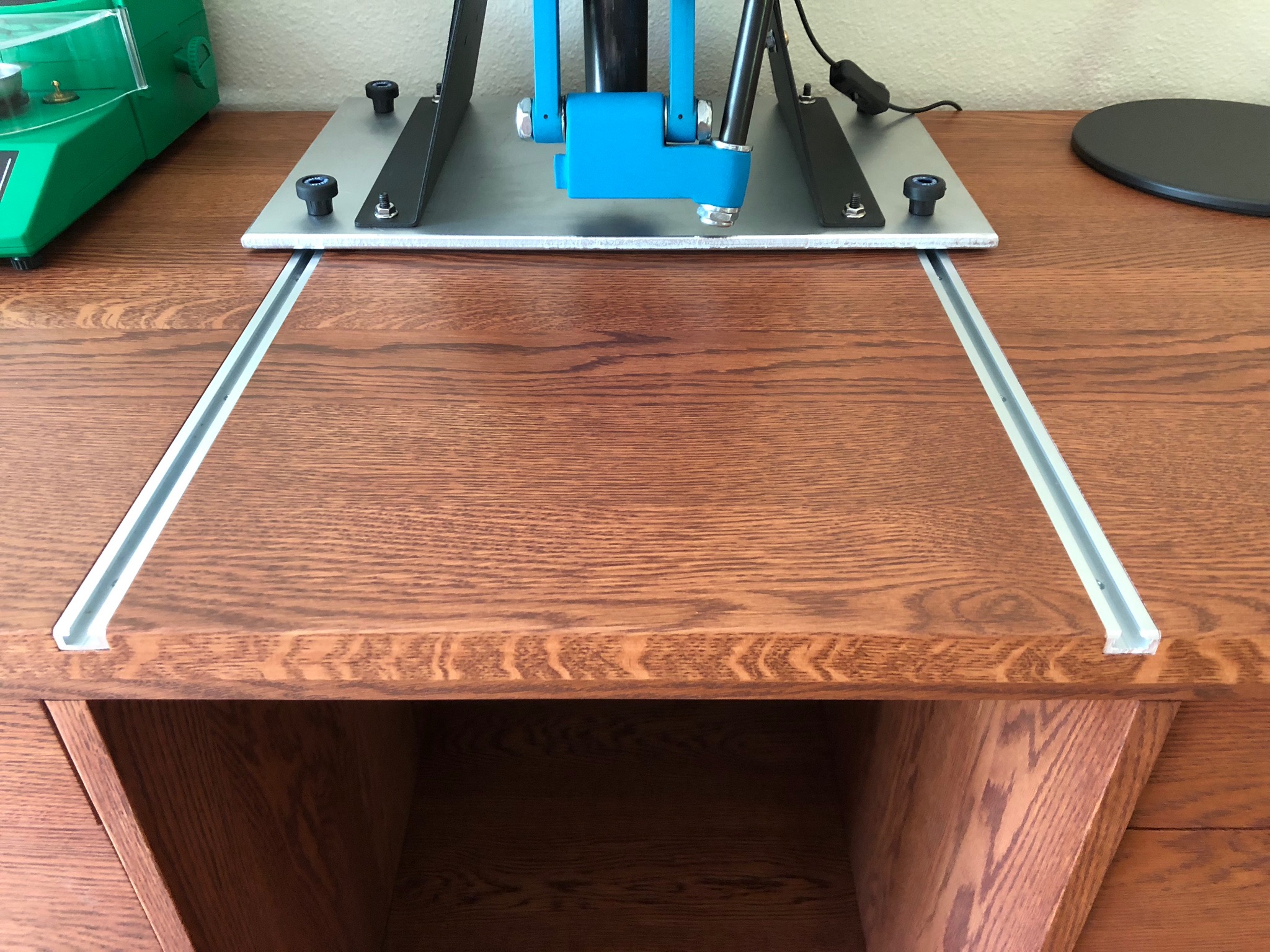

I don't know about perfect, but it works for me. I put some Rockler T-tracks in the top so I can easily swap out presses or equipment.

Attachments

-

IMG_3328.JPG471 KB · Views: 809

IMG_3328.JPG471 KB · Views: 809 -

IMG_3329.JPG429.2 KB · Views: 768

IMG_3329.JPG429.2 KB · Views: 768 -

IMG_3335.JPG458.2 KB · Views: 710

IMG_3335.JPG458.2 KB · Views: 710 -

IMG_3385.JPG582.5 KB · Views: 738

IMG_3385.JPG582.5 KB · Views: 738 -

IMG_6873-1.JPG255.7 KB · Views: 763

IMG_6873-1.JPG255.7 KB · Views: 763 -

IMG_3415-1.JPG265 KB · Views: 819

IMG_3415-1.JPG265 KB · Views: 819 -

IMG_3399-1.JPG266.6 KB · Views: 886

IMG_3399-1.JPG266.6 KB · Views: 886 -

IMG_3402.JPG693.8 KB · Views: 936

IMG_3402.JPG693.8 KB · Views: 936 -

IMG_6742-1.JPG253.1 KB · Views: 921

IMG_6742-1.JPG253.1 KB · Views: 921

I don't know about perfect, but it works for me. I put some Rockler T-tracks in the top so I can easily swap out presses or equipment.[/

Looks hell for stout and very practical. Nicely done ??

Looks hell for stout and very practical. Nicely done ??

Thanks, I honestly thought Hitlery would win so I wanted to stock up on reloading stuff, which meant I needed someplace to put it all. I had loads of wood and just needed the plywood, drawer glides and stools. Sketched it out on a pad and built it in place. It will be staying here when we move.

Defender3,

I like the bobble heads to keep you company and supervise.

Yes! Uncle Si keeps me straight while the Trumpster continues to annoy HH6.

Very nice raider! Clean, organized, and PLENTY of outlets ?.Here's mine newly organized

Sure you have enough light above that bench or do you wear sunglasses when you load? ?I don't know about perfect, but it works for me. I put some Rockler T-tracks in the top so I can easily swap out presses or equipment.

Sure you have enough light above that bench or do you wear sunglasses when you load? ?

The basement is like a blackhole, any light within 3 parsecs is absorbed. I needed to overcome the blackhole in combination with old eyes.

The basement is like a blackhole, any light within 3 parsecs is absorbed. I needed to overcome the blackhole in combination with old eyes.

How many of us have old, obsolete or multiples of equipment that could be sold at a club or range flee sale with some of the proceeds going to the club, range or kids shooting programs? I couldn't help but notice four different balance scales in one of the photos.

View attachment 6947631i put this in a wall in my basement gunroom. There's no window so this really makes it feel less like you're underground

I expected to see a game animal or target holder in the background.

It's just some wallpaper mural to make it feel less like a basementI expected to see a game animal or target holder in the background.

Well yah...I can't run out or be bothered to move over a step.Very nice raider! Clean, organized, and PLENTY of outlets ?.

I've got a question for you guys that have been reloading for a while. What is a good bench top height to be at? Background-

I built a new house this summer, now moved in, and I'm starting to eye up the future gun room. I have no reloading experience, so when it comes to building my bench I'm looking at tons of pictures and gathering ideas. My lack of experience means that I don't know how tall a bench needs to be. I'm about 5'9" for reference. Do any of you have a high bench that you sometimes stand and sometimes sit?

Your advice is appreciated.

I built a new house this summer, now moved in, and I'm starting to eye up the future gun room. I have no reloading experience, so when it comes to building my bench I'm looking at tons of pictures and gathering ideas. My lack of experience means that I don't know how tall a bench needs to be. I'm about 5'9" for reference. Do any of you have a high bench that you sometimes stand and sometimes sit?

Your advice is appreciated.

I've got a question for you guys that have been reloading for a while. What is a good bench top height to be at? Background-

I built a new house this summer, now moved in, and I'm starting to eye up the future gun room. I have no reloading experience, so when it comes to building my bench I'm looking at tons of pictures and gathering ideas. My lack of experience means that I don't know how tall a bench needs to be. I'm about 5'9" for reference. Do any of you have a high bench that you sometimes stand and sometimes sit?

Your advice is appreciated.

Your best bet, to get the correct height for you, is to go to the kitchen counter with your tape measure. Set your hands on the counter then raise them to what you think would be the most comfortable working height for you with elbows bent. Measure from the floor to the chosen height above the counter. Depending on your height and arm length you will probably end up at about 38 to 42 inches. I like mine at 40 inches. The kitchen counter would be to low for me to work at comfortably. Take into consideration what equipment you'll be using and the amount of travel up and down your arm will need to operate the press. You don't want to have to bend over on the down stroke of the lever when standing. For sitting you can adjust the height on a good office style stool to accommodate the finished height of the bench.

Kitchen counter height is good... And get yourself a stool with adjustable height. I worked off of desks, kitchen counters, card tables.... finally built my room at the same height as kitchen counters. I forgot the exact number, but there is a spec. And with a stool and standing... works great.

That said, I am average height. If you are short/tall.... work accordingly.

I understand Frank's reloading bench is built on a shoeshine box. But that's just him.

Cheers,

Sirhr

That said, I am average height. If you are short/tall.... work accordingly.

I understand Frank's reloading bench is built on a shoeshine box. But that's just him.

Cheers,

Sirhr

Take into consideration what equipment you'll be using and the amount of travel up and down your arm will need to operate the press

That is my problem right there. I don't have reloading experience. Thanks for the advice, great tips. I'll try to visit someone local who reloads so I can get an idea. Any other advice before I cut wood is welcomed! I have a clean slate room to work with so I have options.

Thanks fellas!

Similar threads

- Replies

- 103

- Views

- 5K