Can u make the Tactical stock for a Left hand Tikka T3 Lite 30-06 .. that can use AI mag ..

i wrote u a PM .

i wrote u a PM .

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

VTB,

Could you make one for a Blaser Tac 2? They are mag fed so it is a different setup than a regular R93.

Thanks,

Sig

VTB,

Would you be interested in making light varmint/heavy varmint benchrest stocks?

Example:

McMillan Benchrest Stocks, McMillan Benchrest Series Stocks, McMillan Fiberglass Stocks, Synthetic Stocks

Can you do an adjustable cheek on the hunting stock and will the hunting stock take a barrel that is 1.2 inches in diameter (Carbon Fiber proof research)

Sent from my SM-N900V using Tapatalk

If there is a need and you'll provide the specs.

But let's be honest: we won't be able to make something overhemeting lighter than 20 oz and price for our stock in the US will be twice than mcmillan - why anyone will buy it?

At the same time need for this type of stock in Russia is close to 0.

The only player in this game right now is Scoville.

Gun Stocks - Best Stocks for Prone, Benchrest and long-range 6mm, 6ppc, 6mm BR Norma, 6BR, 6.5-284, .308, 600 and 1000 yard varmint & competition guns. Photos, prices, bedding tips, and stock maker (McMillan, Kelbly, Shehane) info.

This is an old article when they were listed at $800. Today the wait time is well over one year, if you can get a hold of him, and the price is excess of $1000.

PPC with Pedigree

Weight is always a concern in benchrest, every ounce counts. In regards to demand, you have a great point. I don't think the market is more than 50-100 stocks annually.

Trigger Guard not necessary.TireMan, hello

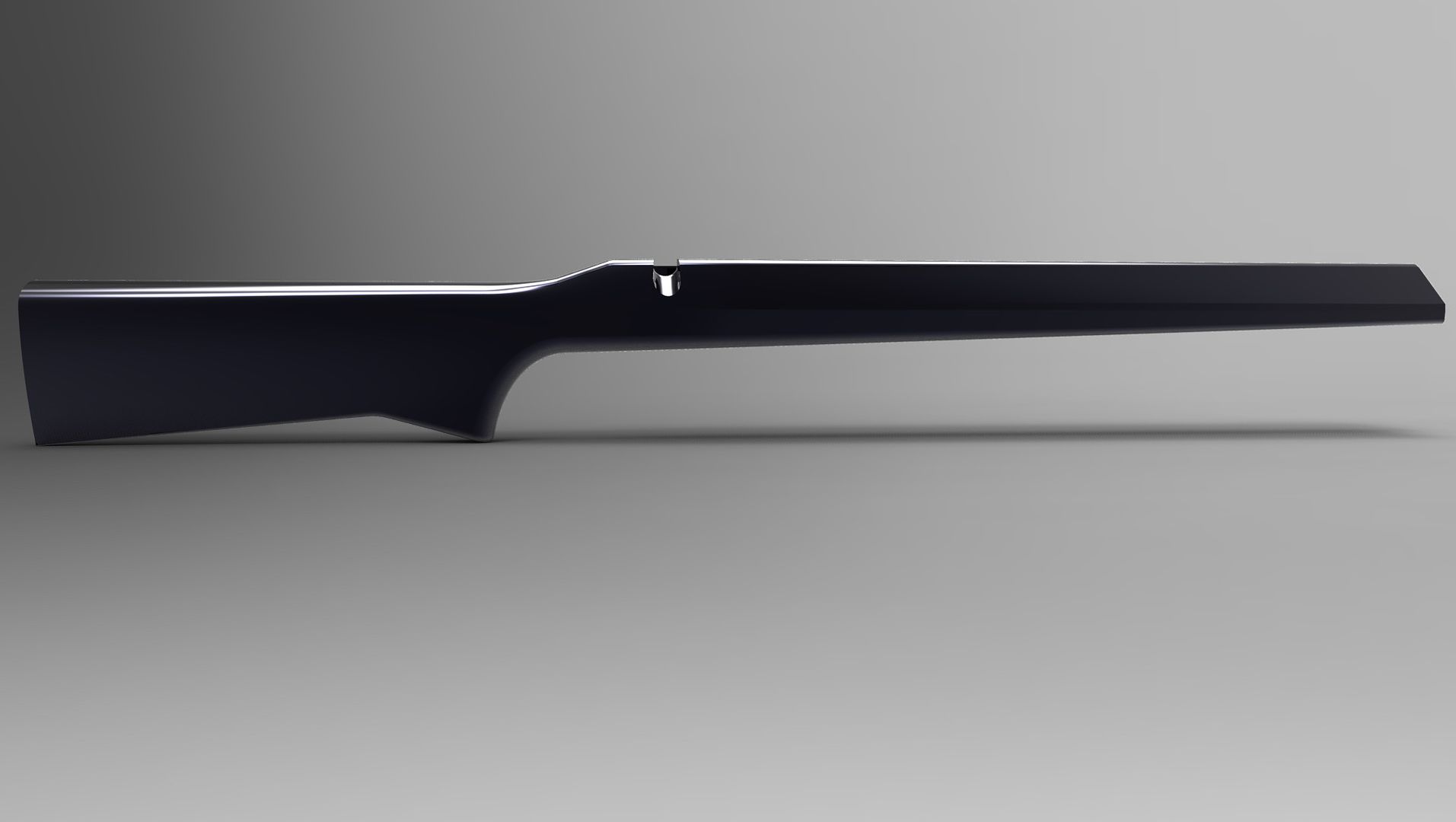

Here is the BR stock model we already have:

We can make molds for it but questions are:

1. We cook action channel area as monocoque. So for rem700 action channel is just plane cylinder 35mm in diameter. We can make different inlets to fit different action diameters. So the question is - which diameters of actions we should make to fill the US market? This would not be for a Remington 700 action. Almost exclusively for BAT and Kelby actions, with a few other varieties. 1.5" wide, and 1.720" tall actions. BAT BR actions run 1.350" (34.29 mm) round

2. Which barrel channel diameter should we make? Would 35mm be enough? The barrel would be 1.25" (31mm) Heavy Varmint or 1.20" Light Varmint tapering down to .900 and .875 respectively. I think your 35mm would work.

3. What weight should the stock be? Under 22oz (623 grams) is ideal. Under 400 grams would change the game tremendously. If this is possible...please let me know.

4. Should we cook triggerguard from carbon together with the stock?

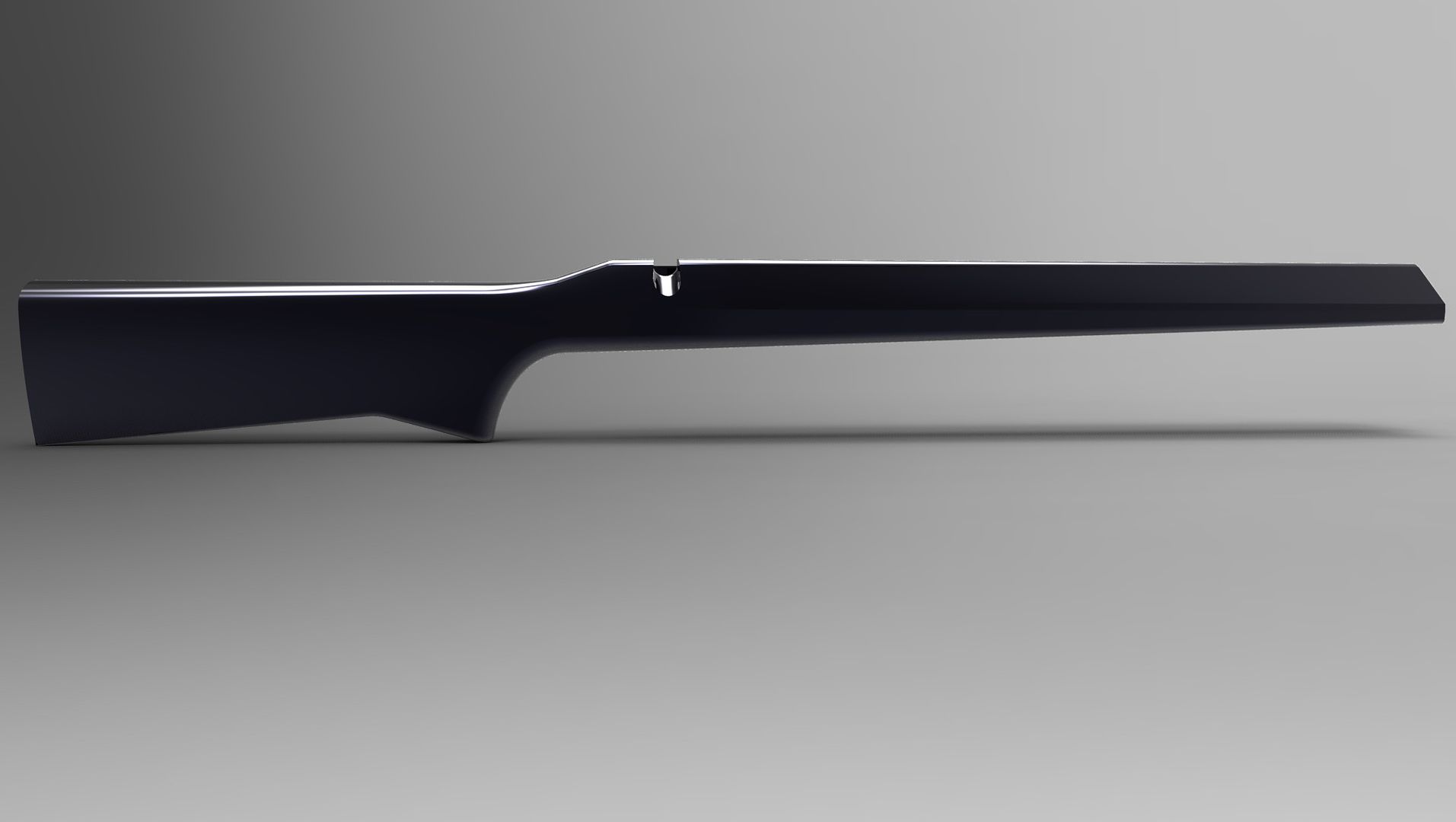

Fresh pics - Tikka T3 with SA DBM for AICS mags.

Pillars installed,

3 studs

13,5" LOP

weight (without DBM): 820 grams / 29 oz

test fitting it on 6,5x55 tikka T3 super varmint (will be used with stock DBM for LA mags)

Well that sucks! Hunting for a new vendor???????Hello guys.

With deep regret i should announce that i'm personally won't do any carbon stocks anymore.

The reason for it our production partners raised the price for materials and labor cost and inbound cost for 1 stock is around 1200Eur (almost $1550). It means that sales price (incl. trigger guard and shipment) can't be cheaper than +15%, i.e. $1800.

Which moves it out of the reasonable price range for any shooter.

I want to thank you all for the warm words you said during the life of the project and that moral support you've provided.

Thank you, Guys. When i hear your warm words it means that we're doing right thing.

Anyway we, as a company, we'll stay on the SH and will concentrate on the CNC'd handguards for HK MR series of rifles.

Hello guys.

With deep regret i should announce that i'm personally won't do any carbon stocks anymore.

Unfortunately making firearm parts and components in china is heavily regulated, and illegal to make unless you have permission from the government, or know people that can already do this because they have obtained permission already. You need to have good connections.I have friends that entered the carbon fiber mountain bike rim business with Chinese factories, they used the locals to make the molds. If you took your molds to China you'd be in business within 12 months with easy access to Euro and North American markets.