The crown profile doesn't matter, cut it flat but make sure its square and even, this is notI could certainly be mistaken, but I thought that the main reason for barrel crowns was to clean up and protect the end of the ID of the barrel. Plus they look good. My understanding is that if you can perfectly part the barrel to the desired length, and never bang it into anything, neither of which are guaranteed by a long shot, that a crown would not make it more accurate?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Does my gunsmith suck?

- Thread starter Ohioguy47

- Start date

Since most gunsmith work involves using machine tools, as long as what he does doesn't involve him using them, he should be good. But as a machinist, he's sloppy...!That looks sloppy, most smiths with solid reputations pay attention to the little details.

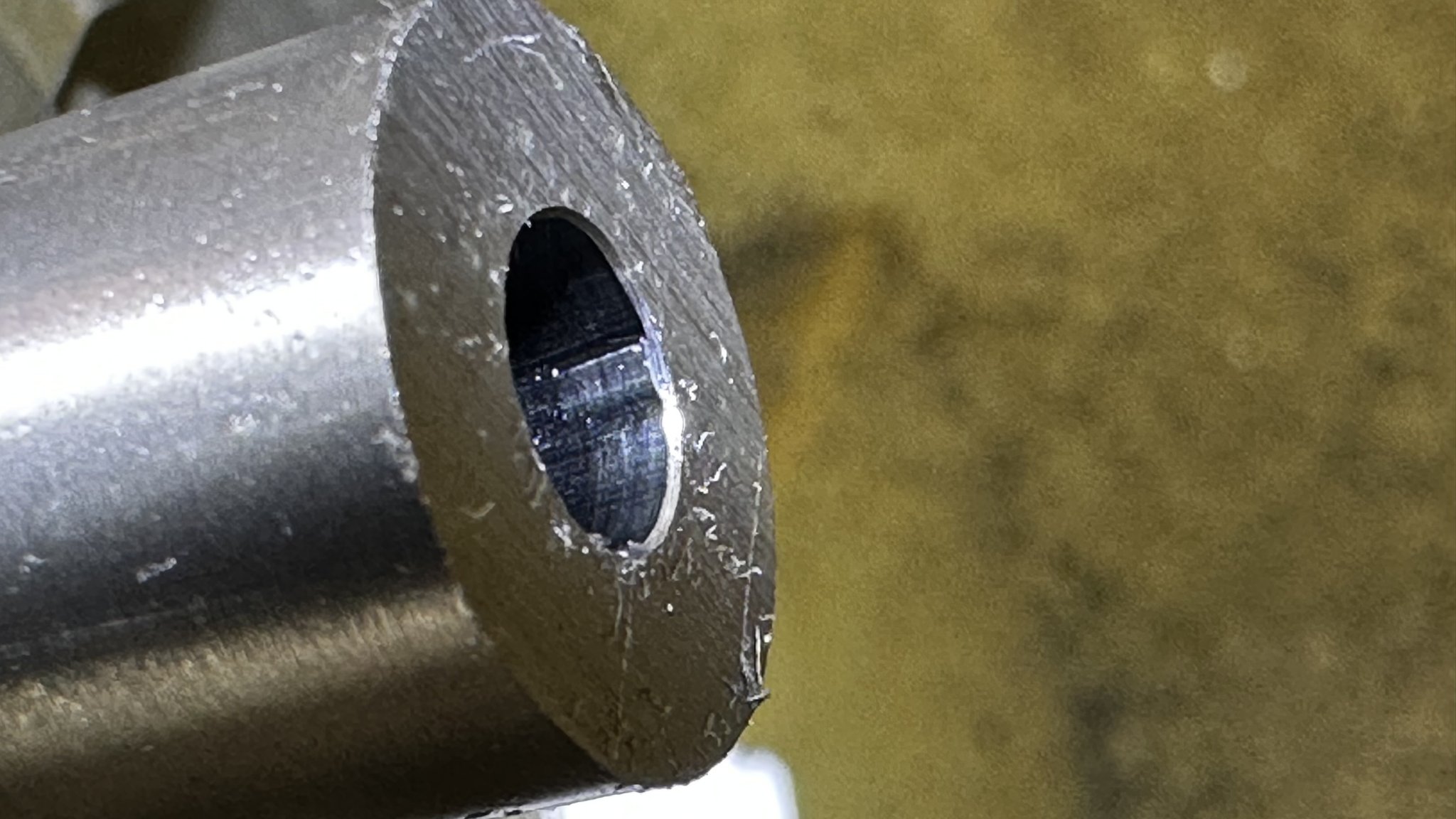

The undercut looks too deep. It's usually around the minor diameter of the threads. Whether it's a safety issue depends on the actual dimensions.Genuinely curious,

Is that bevel or whatever you’d call it between the shoulder and threads normal? Most I’ve seen come straight down at base of threads or even have a slight shoulder there. Seems it would create a weak spot thinning the barrel like that if not needed

View attachment 8283493

He might have a hard time hitting him with that barrel.Don’t fire him, shoot him.

It's a thread relief and it shouldn't be much more than .005" to .010" smaller than the minor diameter of the thread. It gives the machinist space to pull out the threading tool when retracting and also, in the case of a rifle barrel, a way for the muzzle device to index on the face of the barrel. When I do them on hydraulic rams I use a radiused tool to create my thread relief to reduce stress risers. That one looks ugly!Genuinely curious,

Is that bevel or whatever you’d call it between the shoulder and threads normal? Most I’ve seen come straight down at base of threads or even have a slight shoulder there. Seems it would create a weak spot thinning the barrel like that if not needed

View attachment 8283493

Signs your "gunsmith" is about to fuq your barrel up...His lathe says Grizzly on it.

You put a 9" dildo on the end of there and the old lady will be making your breakfast for a week.No self respecting gunsmith uses a Dremel. The really good ones use a Foredom because Dremels are too slow. If it doesn't have a foot control for speed it isn't a real flexible shaft grinder. I use mine for everything from gunsmithing, to dental work, to tune ups, and in the kitchen.

View attachment 8283361

If I put a 9” dildo on anything I’d be out of the house and replaced within a week.You put a 9" dildo on the end of there and the old lady will be making your breakfast for a week.

This was the first thing I noticed... what the actual fuck is that??The undercut looks too deep. It's usually around the minor diameter of the threads. Whether it's a safety issue depends on the actual dimensions.

I use a narrow grooving tool when I need a relief cut, and go maybe ten thou deeper than the minor thread diameter.

This clown cut damn near to the bore...

If I am tracking with your post, the barrel pictured would have started life as a new blank?Hello! I recently had a local gunsmith spin me up a barrel for my first full custom build.

. . . and your gunsmith would have done all the breech/chamber work and muzzle work to the barrel you have?

If this is the case, I would be very unhappy with the work even if it shoots tiny groups.

Any full custom build and for sure, your FIRST full custom build should be something to be proud of.

The performance as well as the physical appearance of the workmanship should be on par with your expectations and money spent. Unless your budget was yesterday's lunch money, I do not think you got what you paid for.

Not sure what brand of blank you/he supplied, but Krieger, Bartlien and a handful of other top tier makers consistently produce perfect barrel blanks that are expensive (rightfully so) and take months to get. Seeing that surface finish and visible dimensional issues heaped upon one poor unsuspecting barrel blank is a damn shame.

If a shop was happy to let that work leave the premises, then I would have to assume they exhibited an equal amount of not giving a shit with any other work they attempted to perform on your rifle. It does not bode well for what your "first full custom build" will be compared to what it could have been.

.

Some of us shoot 4 moa at 100 yards, and half moa at 1000 yards…most people here wouldn't consider 1 moa good

If you are in Ohio, you have many excellent alternatives that could deliver stellar work.

Area419 and Short Action Customs just for starters.

Butt load of their work shown by proud customers all over the internet.

PS: I would not bring them the barrel shown in your photos.

They could possibly throw up.

Any unscheduled puking during business hours takes a mop with Pine-Sol and we all know time is money for a small business. . . .

.

Area419 and Short Action Customs just for starters.

Butt load of their work shown by proud customers all over the internet.

PS: I would not bring them the barrel shown in your photos.

They could possibly throw up.

Any unscheduled puking during business hours takes a mop with Pine-Sol and we all know time is money for a small business. . . .

.

If you are in Ohio, you have many excellent alternatives that could deliver stellar work.

Area419 and Short Action Customs just for starters.

Butt load of their work shown by proud customers all over the internet.

PS: I would not bring them the barrel shown in your photos.

They could possibly throw up.

Any unscheduled puking during business hours takes a mop with Pine-Sol and we all know time is money for a small business. . . .

.

Is this why a PITA fee often appears in the itemized billing invoice?

Pain

In

The

Ass

Not being concentric could limit your choices of muzzle devices and silencers. If you do decide to use a silencer, be sure to check it with some type of alignment rod.Hello! I recently had a local gunsmith spin me up a barrel for my first full custom build. It appears that the muzzle crown was poorly done with the initial taper not being concentric. Before i spend all the money on components breaking it in and developing a load, i want to know if this will affect to accuracy. I want this to be a half minute or better gun. Hoping to use your guys experience on whether this is a no go and needs redone or if she's good to shoot. Appreciate the help

I'd probably buy a Strider knife and cut the tires on his 4X4 if that happened to Me...

But that's just me

On a more serious note pm me maybe I can use my skills and help you a little...

Mike R.

But that's just me

On a more serious note pm me maybe I can use my skills and help you a little...

Mike R.

Last edited:

@Ohioguy47, my dude that's an offer from arguably one of the best smiths in the country....maybe even on Earff...I'd PM him.

Whatever the tolerance was on that machine work, he definitely used both ends of it simultaneously.

Sub par work.

I'm not a machinist, but I do own 2 Dremels. To me that looks like a dull cutting tool. The threads look all galled. No defined edges.

I'd have a competent and vetted Smith check it and clean it up.

I'm fairly certain I've cut off bolts with a hack saw crooked. And used hand files to create a smoother better looking thread.

Jesus! My eyes are shit these days but I swear the threads midway look split like someone hit the wrong number on the thread dial at some point. And all that galling? Yikes!View attachment 8283853

Sub par work.

I'm not a machinist, but I do own 2 Dremels. To me that looks like a dull cutting tool. The threads look all galled. No defined edges.

I'd have a competent and vetted Smith check it and clean it up.

I'm fairly certain I've cut off bolts with a hack saw crooked. And used hand files to create a smoother better looking thread.

Can't stress this enough. PM him now.@Ohioguy47, my dude that's an offer from arguably one of the best smiths in the country....maybe even on Earff...I'd PM him.

Hello! I recently had a local gunsmith spin me up a barrel for my first full custom build. It appears that the muzzle crown was poorly done with the initial taper not being concentric. Before i spend all the money on components breaking it in and developing a load, i want to know if this will affect to accuracy. I want this to be a half minute or better gun. Hoping to use your guys experience on whether this is a no go and needs redone or if she's good to shoot. Appreciate the help

Is the hack who did this in Bradford by any chance?

Yep he "spun it up" alright ! A term used by uneducated people in the ways of machining, trying to sound impressive, or macho, or.. but just the opposite occurs when I hear the term, and used often here...it's so unimpressive you deserve what you get, and I won't cut you any slack.

Chamber, thread, chamfer, might get you some help. Spun up, gets nothing, but irritation from me...like nails on a chalk board.

Your "gunsmith" has no talent for machining and the whole project should be turned over to someone who is competent...someone who will not spun it up!

Chamber, thread, chamfer, might get you some help. Spun up, gets nothing, but irritation from me...like nails on a chalk board.

Your "gunsmith" has no talent for machining and the whole project should be turned over to someone who is competent...someone who will not spun it up!

Last edited:

You sound all spun up.Yep he "spun it up" alright ! A term used by uneducated people in the ways of machining, trying to sound impressive, or macho, or.. but just the opposite occurs when I hear the term, and used often here...it's so unimpressive you deserve what you get, and I won't cut you any slack.

Chamber, thread, champher, might get you some help. Spun up, gets nothing, but irritation from me...like nails on a chalk board.

Your "gunsmith" has no talent for machining and the whole project should be turned over to someone who is competent...someone who will not spun it up!

In my experience the people you pay with liquor always deliver quality work.I can’t say much as I pay my “gunsmith” with liquor or other random shit but I think it should just be put back in the lathe and cleaned up with files and polished. I bet it will shoot just fine.

Most of the finishing is just to look pretty for pictures.

Yep he "spun it up" alright ! A term used by uneducated people in the ways of machining, trying to sound impressive, or macho, or.. but just the opposite occurs when I hear the term, and used often here...it's so unimpressive you deserve what you get, and I won't cut you any slack.

Chamber, thread, champher, might get you some help. Spun up, gets nothing, but irritation from me...like nails on a chalk board.

Your "gunsmith" has no talent for machining and the whole project should be turned over to someone who is competent...someone who will not spun it up!

Cool. Thanks for the 4am education lesson.Yep he "spun it up" alright ! A term used by uneducated people in the ways of machining, trying to sound impressive, or macho, or.. but just the opposite occurs when I hear the term, and used often here...it's so unimpressive you deserve what you get, and I won't cut you any slack.

Chamber, thread, champher, might get you some help. Spun up, gets nothing, but irritation from me...like nails on a chalk board.

Your "gunsmith" has no talent for machining and the whole project should be turned over to someone who is competent...someone who will not spun it up!

Yep he "spun it up" alright ! ....

Chamber, thread, champher, might get you some help. Spun up, gets nothing, but irritation from me...like nails on a chalk board.

Your "gunsmith" has no talent for machining and the whole project should be turned over to someone who is competent...someone who will not spun it up!

Chamfer

I worked with a Mexican friend that called it a “champer”Chamfer

So which is correct?My favorite is fillets and watching people struggle between fill-et vs fill-ay

A fill-et is a delightfully, rounded corner... applied to an internal edge.a fill-et is a delightful, rounded corner.

a fill-ay is a succulent cut of meat.

but whatever you do, never ask for a fillet when you really want a fillet

A round is a delightfully, rounded corner... applied to an external edge.

Just sayin'

I think what you're seeing is the remnants of very poor surface finish of the cylinder prior to threading.Jesus! My eyes are shit these days but I swear the threads midway look split like someone hit the wrong number on the thread dial at some point. And all that galling? Yikes!

Here’s a fun one I got in a few months back. Customer wanted me to bed the barreled action to a new laminate wood stock and do finish assembly(trigger, internal magazine etc). It was a trued 700 action with a Shilen ratchet barrel. I should have looked it over closer. I would have refused it.

First thing I noticed. The recoil lug was not in the 6 oclock position. Bedding stud screwed into the front receiver screw hole for reference.

In fixing that I thought id check on the receiver threads. Yowza! Fortunately he he slathered a bucket of anti-seize on it, so it actually came apart. It unscrewed with very little torque, maybe 20-30 lbs.

Since that was crappy, I scoped the throat and found the land tops scored to bits from a bad reamer pilot or chips getting in between.

Further down the rabbit hole I noticed a ding in the crown and abrasive marks across the crown and some distance down the lands and groove. Note the circumferential marks in the bore. It wiped the high/driven side off the ratchet rifling right off.

I chopped 3/8” off and put it in the lathe to re-crown, and realized I hadn't chopped enough.

The bolt handle had been re-attached crooked, and was in hard contact with the receiver when the bolt was closed, so the handle was relieved slightly. He had put corse lapping compound on the bolt body and lapped it to the receiver producing one of the sloppiest and binding nightmares Ive ever felt. The guy had removed a ton of material off the action face so the lug pocket in the stock needed to be moved back to accommodate the new lug position.

Apparently this was done by a gunsmith in Wyoming. Older dude. First name is Matt I believe . Maybe he was great back in the day, kinda doubt it, but he definitely isn't now.

New crown

I dont know why the customer didn't have the old guy fit the stock. I told him there were no guarantees how this rifle would shoot, and I wouldn’t continue to work on it to make it shoot if it needed more work.

First thing I noticed. The recoil lug was not in the 6 oclock position. Bedding stud screwed into the front receiver screw hole for reference.

In fixing that I thought id check on the receiver threads. Yowza! Fortunately he he slathered a bucket of anti-seize on it, so it actually came apart. It unscrewed with very little torque, maybe 20-30 lbs.

Since that was crappy, I scoped the throat and found the land tops scored to bits from a bad reamer pilot or chips getting in between.

Further down the rabbit hole I noticed a ding in the crown and abrasive marks across the crown and some distance down the lands and groove. Note the circumferential marks in the bore. It wiped the high/driven side off the ratchet rifling right off.

I chopped 3/8” off and put it in the lathe to re-crown, and realized I hadn't chopped enough.

The bolt handle had been re-attached crooked, and was in hard contact with the receiver when the bolt was closed, so the handle was relieved slightly. He had put corse lapping compound on the bolt body and lapped it to the receiver producing one of the sloppiest and binding nightmares Ive ever felt. The guy had removed a ton of material off the action face so the lug pocket in the stock needed to be moved back to accommodate the new lug position.

Apparently this was done by a gunsmith in Wyoming. Older dude. First name is Matt I believe . Maybe he was great back in the day, kinda doubt it, but he definitely isn't now.

New crown

I dont know why the customer didn't have the old guy fit the stock. I told him there were no guarantees how this rifle would shoot, and I wouldn’t continue to work on it to make it shoot if it needed more work.

Similar threads

- Replies

- 9

- Views

- 374

- Replies

- 27

- Views

- 2K

- Replies

- 134

- Views

- 10K