I have been less than happy using the normal type torque wrenches on firearm scope rings, scope bases, and barrel securement bolts (like on the LMT). Now I have found a GREAT solution thanks to a passing remark made by someone on the LMT thread: a mini torque wrench intended for use on delicate and small bicycle components.

The problems with "normal" torque wrenches are big.

They rarely come in the right torque range. Usually "inch pound" torque wrenches available at tool supply places work from a fairly high minimum setting, usually 25 in lb or so, to way too high a maximum setting, usually 200 in lb or so. This means that they can't be used on things like scope ring torn bolts - right where not applying too much torque is critical, but applying too little is inviting movement under recoil.

They also tend to be physically large, since they have to handle up to the maximum limit of 200 to 225 in lb. This physical size is accompanied by high weight. Both work against getting ACCURATE readings near the bottom end of the scale. Any experienced mechanic or gunsmith will know what I am talking about: the weight and size of the tool itself makes it very hard to apply a "pure" torque, and very hard to detect the click and movement at low torque settings.

Finally, they use a torque setting method that most enlightened people would call "stone age" - requiring you to peer at an engraved set of settings and tiny engraved print, locking and unlocking the wrench, relaxing it before storing each time, and no obvious indication when the darn thing is properly set OR relaxed.

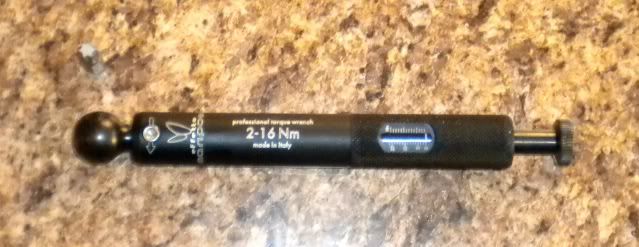

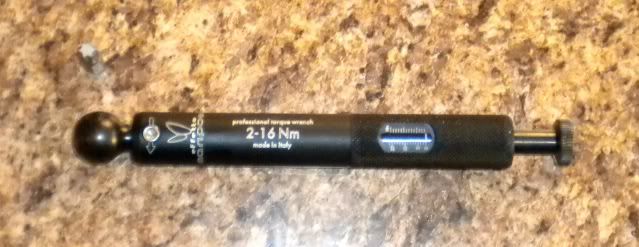

Reently, someone mentioned a torque wrench, made in Italy, intended for use on high end, fragile bicycle racing components - things like alloy clamps on carbon fiber seat posts, for example. It is called "Effetto Mariposa" - Italian for something like "Correct Force". No nose in the air names here!

This wrench is alloy, except for key contact parts, and is therefore lightweight. It is also short - only about 6 inches long, because its working range is more tuned to bicycles, and as it turns out, firearms. It works in the range 2 to 16 Newton meters which equates to 18 to 140 in lb. The 18 in lb is just about right for scope ring torx bolts (16 would be ideal, but 18 is fine in practice), and the 140 in lb is right on for the LMT barrel to receiver torx bolts. In between, the available range covers the 65 in lb needed to secure most scope rails, and a host of other bolts and fasteners on firearms.

It's also refreshingly easy to use. It is mechanical, has a viewing window that CLEARLY displays the setting, shows you obviously if it is set or relaxed, and operates very understandably: screw a knob clockwise to increase torque and counterclockwise to decrease it.

Here's a photo:

and here's a photo that shows you the wrench in size comparison to both an LMT and the wrench that LMT ships with the rifle to handle those 2 small torx barrel bolts:

Note also the storage box that the wrench comes in. It's very trick: the form is cut to prevent you placing the wrench back in for storage until the wrench has been relaxed! You cannot forget! This is a big plus, as leaving any torque wrench "set" to anything above a really minimal level hurts its accuracy over time and repetition.

Note that for travel to matches, hunting trips, etc, the wrench itself, with only the red rubber strip of tool heads, all easily fit into an accessory compartment magazine-sized or smaller, or with your cleaning kit, for convenient transport and ready availability when needed.

So: small, accurate (every bit as accurate as a "regular" torque wrench), light, easier to use, more accurate to use due to being the right size and weight for the job.

SUPER product.

The price may strike you as "high" if you have not priced GOOD torque wrenches lately, but at $185, INCLUDING the tool heads, it's properly priced to eb competitive.

If oyu have reservations, ask yourself: If I strip those LMT barrel bolt threads, or those Nightforce ring cap bolts, or those tiny rail base screws, how much money will it cost me to replace the affected parts (like the receiver on the LMT, for example).

I didn't like coughing up the money, but I did. Glad I did now that I have one.

Jim G

The problems with "normal" torque wrenches are big.

They rarely come in the right torque range. Usually "inch pound" torque wrenches available at tool supply places work from a fairly high minimum setting, usually 25 in lb or so, to way too high a maximum setting, usually 200 in lb or so. This means that they can't be used on things like scope ring torn bolts - right where not applying too much torque is critical, but applying too little is inviting movement under recoil.

They also tend to be physically large, since they have to handle up to the maximum limit of 200 to 225 in lb. This physical size is accompanied by high weight. Both work against getting ACCURATE readings near the bottom end of the scale. Any experienced mechanic or gunsmith will know what I am talking about: the weight and size of the tool itself makes it very hard to apply a "pure" torque, and very hard to detect the click and movement at low torque settings.

Finally, they use a torque setting method that most enlightened people would call "stone age" - requiring you to peer at an engraved set of settings and tiny engraved print, locking and unlocking the wrench, relaxing it before storing each time, and no obvious indication when the darn thing is properly set OR relaxed.

Reently, someone mentioned a torque wrench, made in Italy, intended for use on high end, fragile bicycle racing components - things like alloy clamps on carbon fiber seat posts, for example. It is called "Effetto Mariposa" - Italian for something like "Correct Force". No nose in the air names here!

This wrench is alloy, except for key contact parts, and is therefore lightweight. It is also short - only about 6 inches long, because its working range is more tuned to bicycles, and as it turns out, firearms. It works in the range 2 to 16 Newton meters which equates to 18 to 140 in lb. The 18 in lb is just about right for scope ring torx bolts (16 would be ideal, but 18 is fine in practice), and the 140 in lb is right on for the LMT barrel to receiver torx bolts. In between, the available range covers the 65 in lb needed to secure most scope rails, and a host of other bolts and fasteners on firearms.

It's also refreshingly easy to use. It is mechanical, has a viewing window that CLEARLY displays the setting, shows you obviously if it is set or relaxed, and operates very understandably: screw a knob clockwise to increase torque and counterclockwise to decrease it.

Here's a photo:

and here's a photo that shows you the wrench in size comparison to both an LMT and the wrench that LMT ships with the rifle to handle those 2 small torx barrel bolts:

Note also the storage box that the wrench comes in. It's very trick: the form is cut to prevent you placing the wrench back in for storage until the wrench has been relaxed! You cannot forget! This is a big plus, as leaving any torque wrench "set" to anything above a really minimal level hurts its accuracy over time and repetition.

Note that for travel to matches, hunting trips, etc, the wrench itself, with only the red rubber strip of tool heads, all easily fit into an accessory compartment magazine-sized or smaller, or with your cleaning kit, for convenient transport and ready availability when needed.

So: small, accurate (every bit as accurate as a "regular" torque wrench), light, easier to use, more accurate to use due to being the right size and weight for the job.

SUPER product.

The price may strike you as "high" if you have not priced GOOD torque wrenches lately, but at $185, INCLUDING the tool heads, it's properly priced to eb competitive.

If oyu have reservations, ask yourself: If I strip those LMT barrel bolt threads, or those Nightforce ring cap bolts, or those tiny rail base screws, how much money will it cost me to replace the affected parts (like the receiver on the LMT, for example).

I didn't like coughing up the money, but I did. Glad I did now that I have one.

Jim G