Hello Everyone,

A brief explanation first, then some pictures.

I have made the significant investment to an HP MJF 5200 machine, along with automated postprocessing equipment, etc. It is a helluva setup and is producing some insanely nice prints. I'm running Nylon 11 (forgive the website saying it's Nylon 12 on a 4200 machine...that was before the new equipment, and I'm not savvy enough to fix by myself) which has great temp resistance, much more elongation and durability vs Nylon 12, and an awesome ever-so-slight soft surface feel vs 12 which doesn't feel as pleasant.

The 5200 is holding insane tolerances, most stuff within a few thou, and accounts for shrinkage internally. Our models we've made over the years fit perfect with FDM printing, which has 1-1.5% shrink with the specific nylon blend we have used the past few years.

Long story short, I have to make levers at 98.5-99.25%ish scale on the new machine for a perfect fit. I've had hundreds of scopes in my shop the past few years, but obviously don't have access to all of them now to ensure fitment is spot on.

THUS, order a standard lever here and request at checkout to send a "Pro Series" model:

mkmachining.com

mkmachining.com

Let me know how things fit. I'm scaling everything and keeping track of who gets what. If you have any fitment problems, I will quickly alter your scale and get another one out. Within a few weeks I'm expecting every single model we offer (hundreds of lever models) will be tested and ready to rock for Pro Series production.

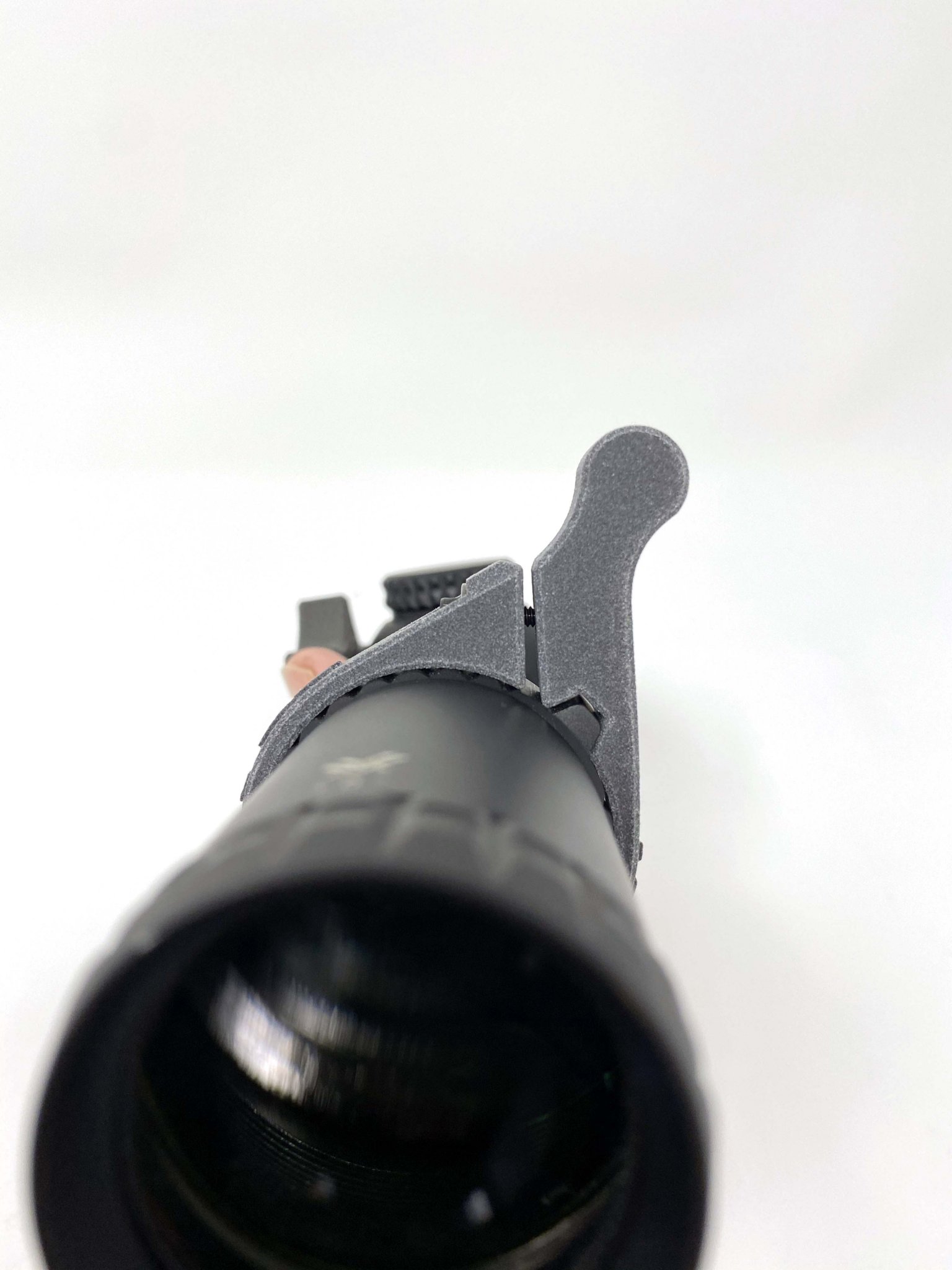

My desired fit holding finger tight on the mag ring:

My desired fit when tightened down, the small gap allows for mag ring tolerances, overtightening, etc. Gap should be no larger when secure a bit smaller is acceptable but there needs to be a gap:

Here are finished prints, dyed and polished. They look awesome, feel awesome, and are nice a tough:

Now for something you're really going to like. ARDs and Scope Caps are on the way. I believe you'll find these to have a more palatable price than other options, and perform much more nicely than the cheapo caps. ARDs will launch shortly, scope caps I've got a RFQ out on custom springs, but the design is finalized:

As you may guess, the possibilities off the new hardware are borderline limitless. Can I make your ideas for you? Yes. Do I want to make your ideas for you? Yes. Can this replace injection molding? Yes, in quantities well into the thousands.

Forgive the photo compression making one of the caps look purply and such. They're a nice satin black.

A brief explanation first, then some pictures.

I have made the significant investment to an HP MJF 5200 machine, along with automated postprocessing equipment, etc. It is a helluva setup and is producing some insanely nice prints. I'm running Nylon 11 (forgive the website saying it's Nylon 12 on a 4200 machine...that was before the new equipment, and I'm not savvy enough to fix by myself) which has great temp resistance, much more elongation and durability vs Nylon 12, and an awesome ever-so-slight soft surface feel vs 12 which doesn't feel as pleasant.

The 5200 is holding insane tolerances, most stuff within a few thou, and accounts for shrinkage internally. Our models we've made over the years fit perfect with FDM printing, which has 1-1.5% shrink with the specific nylon blend we have used the past few years.

Long story short, I have to make levers at 98.5-99.25%ish scale on the new machine for a perfect fit. I've had hundreds of scopes in my shop the past few years, but obviously don't have access to all of them now to ensure fitment is spot on.

THUS, order a standard lever here and request at checkout to send a "Pro Series" model:

Throw Levers -- Available for Over 70 Different Scopes

Upgrade your optic with one of our throw levers, speeding up magnification changes and target engagements without breaking the bank. Our levers are proudly printed in the USA from durable PETG polymer. They install in a minute or less, and come with a lifetime warranty. Available for over 70...

Let me know how things fit. I'm scaling everything and keeping track of who gets what. If you have any fitment problems, I will quickly alter your scale and get another one out. Within a few weeks I'm expecting every single model we offer (hundreds of lever models) will be tested and ready to rock for Pro Series production.

My desired fit holding finger tight on the mag ring:

My desired fit when tightened down, the small gap allows for mag ring tolerances, overtightening, etc. Gap should be no larger when secure a bit smaller is acceptable but there needs to be a gap:

Here are finished prints, dyed and polished. They look awesome, feel awesome, and are nice a tough:

Now for something you're really going to like. ARDs and Scope Caps are on the way. I believe you'll find these to have a more palatable price than other options, and perform much more nicely than the cheapo caps. ARDs will launch shortly, scope caps I've got a RFQ out on custom springs, but the design is finalized:

As you may guess, the possibilities off the new hardware are borderline limitless. Can I make your ideas for you? Yes. Do I want to make your ideas for you? Yes. Can this replace injection molding? Yes, in quantities well into the thousands.

Forgive the photo compression making one of the caps look purply and such. They're a nice satin black.