What are your load details for 300 yards plus if you don’t mind sharing?While not as old as most here, this is my 100k serial tc hawken with target sights I installed. I built this wedge for quick elevation stops and it works like magic. I scribe the wedge once I validate the load and range. I am very repeatable at 300yards and before long should be solid into the 600's.

View attachment 8284671View attachment 8284672

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front stuffers and pumpkin slinger picture thread…

- Thread starter sirhrmechanic

- Start date

There are a couple C Sharps on GunBroker that I have been watching. While I really do like the 1874 but the 1885 Highwall is such a great looking rifle I'd like to add one to my collection. 45-70 is pretty practical in general Id still like to play with the smaller calibers also.

I'm definitely going to be playing with black powder.

I'm definitely going to be playing with black powder.

I have a love/hate relationship with black powder, I love most of the rifles that use it but hate cleaning it.There are a couple C Sharps on GunBroker that I have been watching. While I really do like the 1874 but the 1885 Highwall is such a great looking rifle I'd like to add one to my collection. 45-70 is pretty practical in general Id still like to play with the smaller calibers also.

I'm definitely going to be playing with black powder.

If I were to get a high wall I’d probably get it in .405 Winchester as it’s the only way to get a USA made rifle in that cartridge as all the 1895’s are now made by Miroku. They make a very nice gun as I have several made by them but there is something about a quintessential American cartridge being chambered in an American made rifle.

There is a Winchester highwall at the local gun shop in 38-55 serial number is from 1900 and its a New Haven barrel. Also considering a C Sharps highwall.I have a love/hate relationship with black powder, I love most of the rifles that use it but hate cleaning it.

If I were to get a high wall I’d probably get it in .405 Winchester as it’s the only way to get a USA made rifle in that cartridge as all the 1895’s are now made by Miroku. They make a very nice gun as I have several made by them but there is something about a quintessential American cartridge being chambered in an American made rifle.

I have a bunch of muzzleloaders and don't mind cleaning just part of it. I definitely need to budget more time when I get black powder out.

80grs 2f swiss by weight under a lanolin lubed felt wad pushing a 495gr no excuses bullet.What are your load details for 300 yards plus if you don’t mind sharing?

I thought a side lock would be a pain to clean.....I was wrong. Some hot water and a bit of ballistol.....and done.

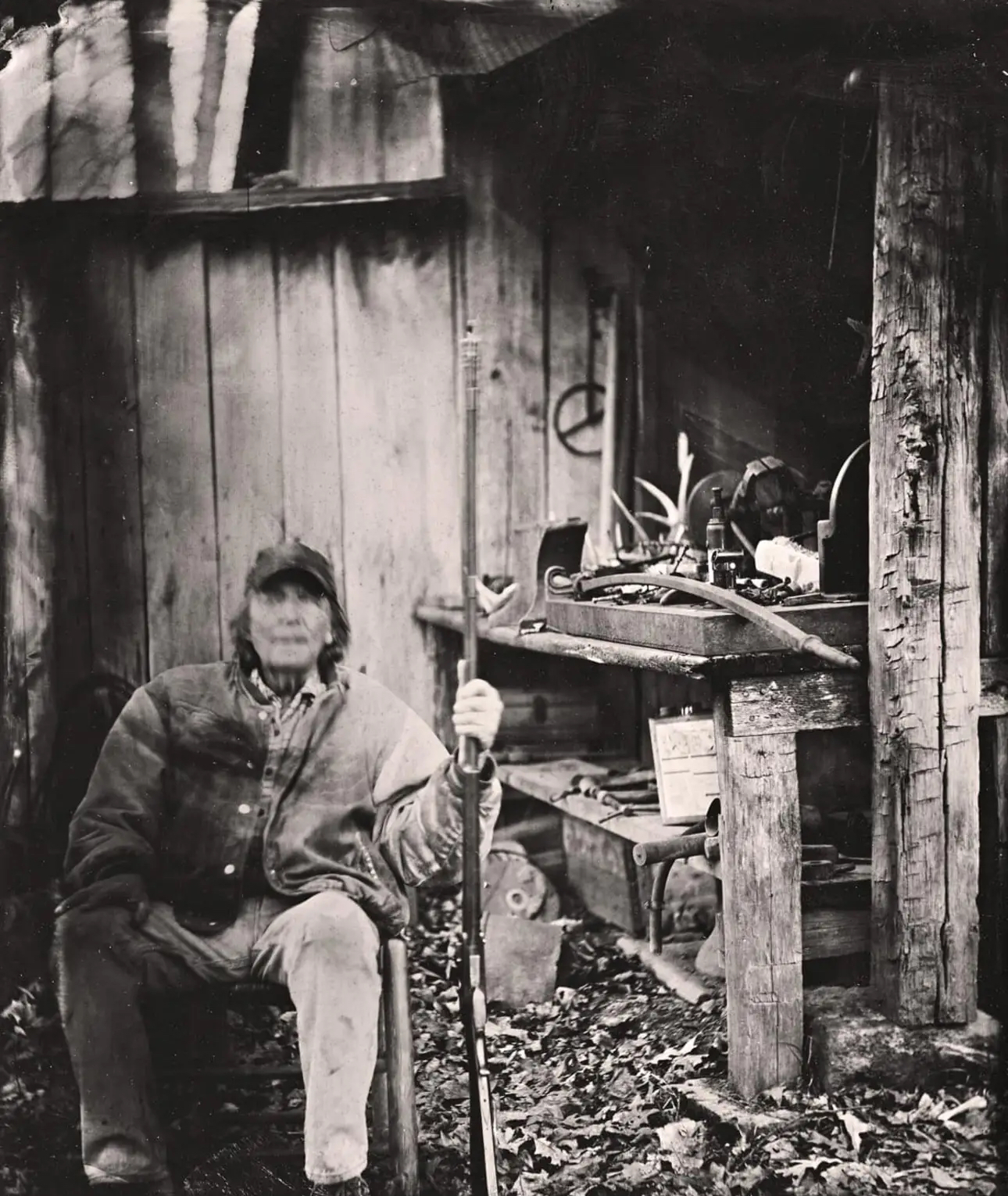

A sad day for those in the muzzle loading and Longrifles world. Herschel House passed on earlier today.

A legendary longrifle maker and edged blade forger, he taught nd mentored at least a couple of generations of contemporary longtime artisans.

RIP, sir.

Sirhr

A legendary longrifle maker and edged blade forger, he taught nd mentored at least a couple of generations of contemporary longtime artisans.

RIP, sir.

Sirhr

Just read his story…..America!A sad day for those in the muzzle loading and Longrifles world. Herschel House passed on earlier today.

View attachment 8319941

A legendary longrifle maker and edged blade forger, he taught nd mentored at least a couple of generations of contemporary longtime artisans.

RIP, sir.

Sirhr

I have three different Highwalls, and 5 different 1874s.There are a couple C Sharps on GunBroker that I have been watching. While I really do like the 1874 but the 1885 Highwall is such a great looking rifle I'd like to add one to my collection. 45-70 is pretty practical in general Id still like to play with the smaller calibers also.

I'm definitely going to be playing with black powder.

The Highwalls are good shooters and I like them a lot.

I absolutely love the Sharps 1874s. They've become an obsession.

Though there is one I kinda wish I hadn't acquired, it's a C. Sharps #3 Sporter chambered in 50-140. Beautiful rifle, and very accurate. Fires a 600-grain semi flat-nosed bullet. Gobbles up 1FG BP like you wouldn't believe.

My shoulder can handle the recoil of that rifle just fine. My brain cannot. Touching off a round sends my brain slamming into inside of my skull in a brutal fashion. After about three shots I have to sit a wait a few seconds before I can see anything but stars and sparkly lights. But then I look down range at my tight little groups, and I get excited and keep shooting more. Becomes a vicious cycle. By the time I finally call it quits, I'm as bleary as a punch-drunk fighter. I spend the rest of that day and part of the next with a pounding headache and a stiff neck. These days its job is just to sit and look pretty.

The 45-110 and the 45-70s are pure joy to shoot. Those you can shoot all day long with no negative consequence.

Back in 2020 I made the pilgrimage to Big Timber and visited both C. Sharps and Shiloh. That was an exciting day for me.

This was the first black powder rifle I ever shot. Now it's mine. Built by my Dad from a Dixie Gun works kit back in the ‘70s. He used the kit supplied stock for a pattern to make one from bird's eye maple. It needs a cleanup and the stock needs a rub down and some oil, but it's a beaut and shoots like a dream. .45 caliber.

Edit to the above. I believe it was called a Pennsylvania Dutch rifle, due to the two piece stock.

You know the funny thing about those flintlock stocks? They were shaped so that they come to the eye naturally, without adjustments.

You know the funny thing about those flintlock stocks? They were shaped so that they come to the eye naturally, without adjustments.

Video by my friend Ed Parry. Totally worth watching!

I have several Ed Parry rifles. They are magnificent!

Sirjr

.50 caliber flintlock. 38” swamped Colerain barrel. Curly sugar maple stock. Took me two years to finish building it; and got backwoods redemption this year in the deer woods. Patched round ball at 75 yards, ran 10 yards and flopped DRT.

Video by my friend Ed Parry. Totally worth watching!

I have several Ed Parry rifles. They are magnificent!

Sirjr

Excellent video. Thanks.

My current "Front Stuffer" project. It won't be quite as decorated... But it's gonna be epic!

Ed will do the inletting and shaping and stock work after I finish the metal.

Then I'll do the finishing, decorating and engraving.

Mine won't be quite as ornate.... Like not even close. But there will be some engraving and wire work and ivory inlays (Yes, ivory from Elephants that died before your gamgam was born) and other decor. But not quite like this King-ey thing.

Bet Louis XIV wishes he had one of these. Pussy. If he was not a pussy, he'd have kept his head.

I should have the metal work finished this weekend.

Sirhr

Ed will do the inletting and shaping and stock work after I finish the metal.

Then I'll do the finishing, decorating and engraving.

Mine won't be quite as ornate.... Like not even close. But there will be some engraving and wire work and ivory inlays (Yes, ivory from Elephants that died before your gamgam was born) and other decor. But not quite like this King-ey thing.

Bet Louis XIV wishes he had one of these. Pussy. If he was not a pussy, he'd have kept his head.

I should have the metal work finished this weekend.

Sirhr

Uum...someone put the Lock on the wrong side of that Exquisite Rifle !!

.50 caliber flintlock. 38” swamped Colerain barrel. Curly sugar maple stock. Took me two years to finish building it; and got backwoods redemption this year in the deer woods. Patched round ball at 75 yards, ran 10 yards and flopped DRT.

View attachment 8338840View attachment 8338841

It’s a pistol and a war hammer? That is awesome! Man, people really didn’t fuck around back then.My current "Front Stuffer" project. It won't be quite as decorated... But it's gonna be epic!

Ed will do the inletting and shaping and stock work after I finish the metal.

Then I'll do the finishing, decorating and engraving.

View attachment 8339299

View attachment 8339300

View attachment 8339301

View attachment 8339302

View attachment 8339303

Mine won't be quite as ornate.... Like not even close. But there will be some engraving and wire work and ivory inlays (Yes, ivory from Elephants that died before your gamgam was born) and other decor. But not quite like this King-ey thing.

Bet Louis XIV wishes he had one of these. Pussy. If he was not a pussy, he'd have kept his head.

I should have the metal work finished this weekend.

Sirhr

FAFO was a lot more terminal in the 18th Century than it is today!It’s a pistol and a war hammer? That is awesome! Man, people really didn’t fuck around back then.

Cheers,

Sirhr

The finest rifle I have ever owned by Jerry Kirklin, .54 swamped Getz 48" barrel

Interarms 54cal I bought in 1992. Had these 485gr maxi balls, 90gr of FFg Pyrodex. Every shot gave me a killer headache for a couple seconds. My old eyes couldn't really see the black front sight on a black target at 100yards but at 50 it was doable. Not a great group but tons of fun. 20 shots downrange was enough!

Thank you for showing this rifle. It is a work of art and … as a Range Officer, I prefer a wooden ramrod for the safety checkView attachment 8342121

View attachment 8342124

View attachment 8342125

The finest rifle I have ever owned by Jerry Kirklin, .54 swamped Getz 48" barrel

I have one of these same rifles. They're good shooters.Interarms 54cal I bought in 1992. Had these 485gr maxi balls, 90gr of FFg Pyrodex. Every shot gave me a killer headache for a couple seconds. My old eyes couldn't really see the black front sight on a black target at 100yards but at 50 it was doable. Not a great group but tons of fun. 20 shots downrange was enough!

View attachment 8344069

On a different note, if anyone knows a good source for 54cal miniballs please let us know. I've been casting my own, but sometimes I get lazy or want to conserve my supply of lead for other purposes.

I seem to be returning to my interest in blackpowder after being away for decades. Back in the 90s I remember Co2 powered unloaders handy for removing a stuck ball or unloading after a hunt. I have a screw that fits on a rod but would like the unloader. Checked Midway with no luck. Any ideas?

Last edited:

Dog,I have one of these same rifles. They're good shooters.

On a different note, if anyone knows a good source for 54cal miniballs please let us know. I've been casting my own, but sometimes I get lazy or want to conserve my supply of lead for other purposes.

I've been shooting No Excuses maxis in my 54cal. I like em. Talked to the owner this week for load data. Very helpful.

Thanks. I'll give them a try.Dog,

I've been shooting No Excuses maxis in my 54cal. I like em. Talked to the owner this week for load data. Very helpful.

N-SSA we use old fire extinguishers filled with compressed air.I seem to be returning to my interest in blackpowder after being away for decades. Back in the 90s I remember Co2 powered unloaders handy for removing a stuck ball or unloading after a hunt. I have a screw that fits on a rod bit would like the unloader. Checked Midway with no luck. Any ideas?

Have you tried track of the wolf?I seem to be returning to my interest in blackpowder after being away for decades. Back in the 90s I remember Co2 powered unloaders handy for removing a stuck ball or unloading after a hunt. I have a screw that fits on a rod bit would like the unloader. Checked Midway with no luck. Any ideas?

I think Dave2C on ALR forum might do one. I'm on site and can't access my login there on my phone, but that is a superb forum for matters muzzle loading.

Is the barrel going to be silver soldered to the hammer head?FAFO was a lot more terminal in the 18th Century than it is today!

Cheers,

Sirhr

I guess the better question is how is the hammer head attached to the barrel?

I was shooting this out at that farm yesterday. Rifle built by John Little, in .45 and built in 1976

Fine shooting flinter

Fine shooting flinter

My heavy bench target rifle built by Bill Large. It has a 32lb barrel in .50 caliber

Is the barrel going to be silver soldered to the hammer head?

I guess the better question is how is the hammer head attached to the barrel?

Have not decided. But the hammer part is stainless and that doesn’t silver solder well. My guess is I will probably pin it or run a screw through and polish the ends. But I’ll know more later today.

I never figured this stuff out until I’m building it. Have a blueprint just a photograph and an idea in my head of how to do the cuts. Cheers.

My current "Front Stuffer" project. It won't be quite as decorated... But it's gonna be epic!

Ed will do the inletting and shaping and stock work after I finish the metal.

Then I'll do the finishing, decorating and engraving.

View attachment 8339299

View attachment 8339300

View attachment 8339301

View attachment 8339302

View attachment 8339303

Mine won't be quite as ornate.... Like not even close. But there will be some engraving and wire work and ivory inlays (Yes, ivory from Elephants that died before your gamgam was born) and other decor. But not quite like this King-ey thing.

Bet Louis XIV wishes he had one of these. Pussy. If he was not a pussy, he'd have kept his head.

I should have the metal work finished this weekend.

Sirhr

It’s a pistol and a war hammer? That is awesome! Man, people really didn’t fuck around back then.

FAFO was a lot more terminal in the 18th Century than it is today!

Cheers,

Sirhr

ALR forum?

The gunbuilding forum has some amazing work shown.

Got a whole lot done in the shop today, including getting the head of my war hammer machined and ready for polishing.

Here all the facets and details are turned and machined on with lathe and milling machine. This was entirely manual. No blueprint. Just worked the dimensions as the looked and felt right. Having a DRO is invaluable on stuff like this! Used an assortment of mills, but mostly 1/4 carbide and a small ball-nose. And a bit of hand filing in the edges.

After turning on all the facets and edges, heated to red hot and bent the spike into a nice curve. Damn stainless bends hard, even when red hot! And I didn't want to break off at the 'thin' neck. But between getting it cherry and using a 'bending slot' in my anvil... it came out with a lovely curve!

A bit of light sanding on belt sander and with DynaFile. Then bead blasted and wire brushed. It's now ready for 'serious' polishing. Being stainless it will polish up like chrome. But that's going to be a lot of work. Barrel is inserted temporarily. Before polishing. I'll get the stock roughed on.

Once it's done, I'll have a bit of engraving done on it. But nothing like the Damascening on the 'original.' This will be more of a 'working man's' pistol war hammer club claw thingie. Not fit for a king. Well, maybe a poor king. Like in Lichtenstein or something.

Of course tomorrow I'll have to post pictures of my Asseghai project. I needed a bedside spear, it turns out. Doesn't everyone? Pix of that little beauty tomorrow!

Cheers,

Sirhr

Here all the facets and details are turned and machined on with lathe and milling machine. This was entirely manual. No blueprint. Just worked the dimensions as the looked and felt right. Having a DRO is invaluable on stuff like this! Used an assortment of mills, but mostly 1/4 carbide and a small ball-nose. And a bit of hand filing in the edges.

After turning on all the facets and edges, heated to red hot and bent the spike into a nice curve. Damn stainless bends hard, even when red hot! And I didn't want to break off at the 'thin' neck. But between getting it cherry and using a 'bending slot' in my anvil... it came out with a lovely curve!

A bit of light sanding on belt sander and with DynaFile. Then bead blasted and wire brushed. It's now ready for 'serious' polishing. Being stainless it will polish up like chrome. But that's going to be a lot of work. Barrel is inserted temporarily. Before polishing. I'll get the stock roughed on.

Once it's done, I'll have a bit of engraving done on it. But nothing like the Damascening on the 'original.' This will be more of a 'working man's' pistol war hammer club claw thingie. Not fit for a king. Well, maybe a poor king. Like in Lichtenstein or something.

Of course tomorrow I'll have to post pictures of my Asseghai project. I needed a bedside spear, it turns out. Doesn't everyone? Pix of that little beauty tomorrow!

Cheers,

Sirhr

Nice work!Got a whole lot done in the shop today, including getting the head of my war hammer machined and ready for polishing.

Here all the facets and details are turned and machined on with lathe and milling machine. This was entirely manual. No blueprint. Just worked the dimensions as the looked and felt right. Having a DRO is invaluable on stuff like this! Used an assortment of mills, but mostly 1/4 carbide and a small ball-nose. And a bit of hand filing in the edges.

View attachment 8346112

After turning on all the facets and edges, heated to red hot and bent the spike into a nice curve. Damn stainless bends hard, even when red hot! And I didn't want to break off at the 'thin' neck. But between getting it cherry and using a 'bending slot' in my anvil... it came out with a lovely curve!

View attachment 8346111

A bit of light sanding on belt sander and with DynaFile. Then bead blasted and wire brushed. It's now ready for 'serious' polishing. Being stainless it will polish up like chrome. But that's going to be a lot of work. Barrel is inserted temporarily. Before polishing. I'll get the stock roughed on.

View attachment 8346110

Once it's done, I'll have a bit of engraving done on it. But nothing like the Damascening on the 'original.' This will be more of a 'working man's' pistol war hammer club claw thingie. Not fit for a king. Well, maybe a poor king. Like in Lichtenstein or something.

Of course tomorrow I'll have to post pictures of my Asseghai project. I needed a bedside spear, it turns out. Doesn't everyone? Pix of that little beauty tomorrow!

Cheers,

Sirhr

Man....Got a whole lot done in the shop today, including getting the head of my war hammer machined and ready for polishing.

Here all the facets and details are turned and machined on with lathe and milling machine. This was entirely manual. No blueprint. Just worked the dimensions as the looked and felt right. Having a DRO is invaluable on stuff like this! Used an assortment of mills, but mostly 1/4 carbide and a small ball-nose. And a bit of hand filing in the edges.

View attachment 8346112

After turning on all the facets and edges, heated to red hot and bent the spike into a nice curve. Damn stainless bends hard, even when red hot! And I didn't want to break off at the 'thin' neck. But between getting it cherry and using a 'bending slot' in my anvil... it came out with a lovely curve!

View attachment 8346111

A bit of light sanding on belt sander and with DynaFile. Then bead blasted and wire brushed. It's now ready for 'serious' polishing. Being stainless it will polish up like chrome. But that's going to be a lot of work. Barrel is inserted temporarily. Before polishing. I'll get the stock roughed on.

View attachment 8346110

Once it's done, I'll have a bit of engraving done on it. But nothing like the Damascening on the 'original.' This will be more of a 'working man's' pistol war hammer club claw thingie. Not fit for a king. Well, maybe a poor king. Like in Lichtenstein or something.

Of course tomorrow I'll have to post pictures of my Asseghai project. I needed a bedside spear, it turns out. Doesn't everyone? Pix of that little beauty tomorrow!

Cheers,

Sirhr

That's fucking beautiful

Bit of oddball wood and some stain and a bit of lathe time and I have the Assegai is ready for some handle finish.

This will look good next to the Vickers.

Sirhr

This will look good next to the Vickers.

Sirhr

Last edited:

I found this Lyman Great Plains Rifle (.54) sitting in an auction getting no love at all. I was able to snag it for the minimum bid this morning.

I found this Lyman Great Plains Rifle (.54) sitting in an auction getting no love at all. I was able to snag it for the minimum bid this morning.

View attachment 8361436

Those are great rifles! Furniture is nice. I have one that I got like yours... dirt cheap and no love.

There are a whole lot of folks who strip them down, redo the stocks... brown or brighten the barrels. They can be made to look like completely hand-made contemporary or vintage plains rifles with minimal work!

Or shoot the hell out of it like it is!

Cheers and great snag!

Sirhr

Thanks. I think I'll shoot the hell out of it. Then, maybe I'll have an idea of what it should have done to it.Those are great rifles! Furniture is nice. I have one that I got like yours... dirt cheap and no love.

There are a whole lot of folks who strip them down, redo the stocks... brown or brighten the barrels. They can be made to look like completely hand-made contemporary or vintage plains rifles with minimal work!

Or shoot the hell out of it like it is!

Cheers and great snag!

Sirhr

When I came home from breakfast this morning, this gun was sitting on the front porch in a pieced together box big enough to qualify as a coffin. They made the box by taking two shorter boxes and spicing them together end-to-end. When I separated the two halves, packing peanuts went EVERYWHERE. (And didn't that put me in a wonderful mood.) Then came a layer of bubble wrap, followed by a layer of tissue paper.I found this Lyman Great Plains Rifle (.54) sitting in an auction getting no love at all. I was able to snag it for the minimum bid this morning.

View attachment 8361436

The bad news is that there were a lot more scuffs and light scratches on the stock than were visible in the auction house pictures.

The good news is that a few drops of Tung oil rubbed into the wood with my fingers has rendered them all invisible. The stock looks almost pristine now. Almost. The metal all looks good. The lock and triggers function as they should. The nipple looks recently replaced, and I have no problem with that.

Now I only have one concern: When I checked how far the ramrod is going down the barrel, it seems a tad too shallow by about an inch. So, I'll need to set up my bench and make sure things are truly clear before I do anything else.

But first I have a bunch of packing peanuts to clean up.

When I came home from breakfast this morning, this gun was sitting on the front porch in a pieced together box big enough to qualify as a coffin. They made the box by taking two shorter boxes and spicing them together end-to-end. When I separated the two halves, packing peanuts went EVERYWHERE. (And didn't that put me in a wonderful mood.) Then came a layer of bubble wrap, followed by a layer of tissue paper.

The bad news is that there were a lot more scuffs and light scratches on the stock than were visible in the auction house pictures.

The good news is that a few drops of Tung oil rubbed into the wood with my fingers has rendered them all invisible. The stock looks almost pristine now. Almost. The metal all looks good. The lock and triggers function as they should. The nipple looks recently replaced, and I have no problem with that.

Now I only have one concern: When I checked how far the ramrod is going down the barrel, it seems a tad too shallow by about an inch. So, I'll need to set up my bench and make sure things are truly clear before I do anything else.

But first I have a bunch of packing peanuts to clean up.

Another forum I’m on had an entire thread on loaded muzzleloaders at auctions and it is surprisingly common.

Yeah, I've heard of it happening enough times that I thought it prudent to be one of the first things I checked.Another forum I’m on had an entire thread on loaded muzzleloaders at auctions and it is surprisingly common.

Turns out it wasn't loaded. I was able to confirm that by removing the cleanout screw from the "snail" (the piece the nipple screws into.), putting a small cotton ball just inside the muzzle, and then blasting some compressed air into the cleanout port. The cotton went flying.

The cleanout screw was corroded into the snail, so I dabbed a drop of PB Blaster onto it and went to watch TV for a while. When I came back to it, it came loose with some firm but gentle torque.

Tomorrow I'll cast some solid conicals and some miniballs. I have a couple molds for each. Then maybe on Monday I'll get to learn what works with it.

Something followed me home today. Not quite a Pumpkin Chunker, but a Remington Rolling Block #4. It will need some TLC and probably a barrel liner.

Well, I made time tonight to clean the No. 4. Who knows when the last time it was cleaned. Two cycles of brush and patches until almost white. This was done using Hoppes #9

The next step will be to shoot it Saturday using CCI Standard Velocity before I decide to have the barrel re-lined. As I was pushing patches through, I could feel how rough the bore is.

It’s Defenitely an early production with a serial number of 800XX.

I’m also looking to source a butt plate to replace the missing one.

Not looking at draw filing out the pitting because the patina looks good to me. I am considering using BLO to revitalize the wood though.

The next step will be to shoot it Saturday using CCI Standard Velocity before I decide to have the barrel re-lined. As I was pushing patches through, I could feel how rough the bore is.

It’s Defenitely an early production with a serial number of 800XX.

I’m also looking to source a butt plate to replace the missing one.

Not looking at draw filing out the pitting because the patina looks good to me. I am considering using BLO to revitalize the wood though.