Hello everyone, im having an issue with hard extraction on my bergara 6.5 prc. Im shooting 57.5 grains of h1000 with a 147 eld-m and hornady brass. My first thought would be that pressure would cause the load to stick, but when I developed this load there were zero issues with it. Shot great, extracted great. Ive broken one extractor and since replaced it, and cleaned the chamber but still having the same problem. Anyone know what this could be?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hard extraction 6.5 prc

- Thread starter Tjn260

- Start date

pressure. Primer has mild crater and I can see an ejector mark right next to the H. You are also over book max for H1000. Small base die will fix it for a few loads.

Agree. I'm shooting 55.4 gr. of RL26 with a 143 ELD-X at 2,995 fps. It's a little above the velocity of the Hornady Precision factory load.

What's your velocity? You're a little over the Hornady max load with H1000 for the 147. Not judging!

What's your velocity? You're a little over the Hornady max load with H1000 for the 147. Not judging!

Thanks for the replies everyone, I think I found the culprit. While the load may be on the warmer side, I believe a carbon ring had formed in the neck area of the chamber. Ive been cleaning the chamber and after scrubbing the neck area my sticky extraction stopped. It was also doing the same thing with factory 143 eld-x. As for the ejector marks on the brass, this is the same brass I worked up to max with. Max was 58 grains h-1000 for this gun. 57.5 gets me 2890 fps and sd around 10. I appreciate the help gentlemen.

When you first developed the load, was it with virgin brass? If so, it's usually undersized and the first shot spends some of its energy expanding it to the chamber walls. Or maybe your headspace was larger previously -- same idea.

You could also be developing a 'carbon ring' in the throat, or your brass needs to be trimmed, or some other little thing that would increase pressure, but the bottom line is that you are over book max, which will not usually generate 'pressure signs' in pristine conditions, but it often doesn't take much to push it over the edge.

You could also be developing a 'carbon ring' in the throat, or your brass needs to be trimmed, or some other little thing that would increase pressure, but the bottom line is that you are over book max, which will not usually generate 'pressure signs' in pristine conditions, but it often doesn't take much to push it over the edge.

I used once fired hornady brass, full length sizing with .002 bump. I thought it was a little odd that even the max load had alot of carbon on the neck when factory ammo had none. I don't think that 57.5 is too insane given that its a very popular combo with the 147, and even 58 just had the ejector mark and the primer looked the same as 57.5. Don't get me wrong, I wouldn't run 58 because like you said there is less of a buffer zone if something happens to increase pressure. However 57.5 seems to be a safe and accurate load in this rifle.When you first developed the load, was it with virgin brass? If so, it's usually undersized and the first shot spends some of its energy expanding it to the chamber walls. Or maybe your headspace was larger previously -- same idea.

You could also be developing a 'carbon ring' in the throat, or your brass needs to be trimmed, or some other little thing that would increase pressure, but the bottom line is that you are over book max, which will not usually generate 'pressure signs' in pristine conditions, but it often doesn't take much to push it over the edge.

Good for you. I was actually going to suggest you take a look and see if you're getting that carbon ring scrubbed out. It often does cause these kinds of issues. I would suggest too that if you're going long periods between scrubbing the carbon ring out, to be sure to trim you cases to the same length each time after sizing. Doing so doesn't eliminate the issue, but does help extend how long to have to do that scrubbing.Thanks for the replies everyone, I think I found the culprit. While the load may be on the warmer side, I believe a carbon ring had formed in the neck area of the chamber. Ive been cleaning the chamber and after scrubbing the neck area my sticky extraction stopped. It was also doing the same thing with factory 143 eld-x. As for the ejector marks on the brass, this is the same brass I worked up to max with. Max was 58 grains h-1000 for this gun. 57.5 gets me 2890 fps and sd around 10. I appreciate the help gentlemen.

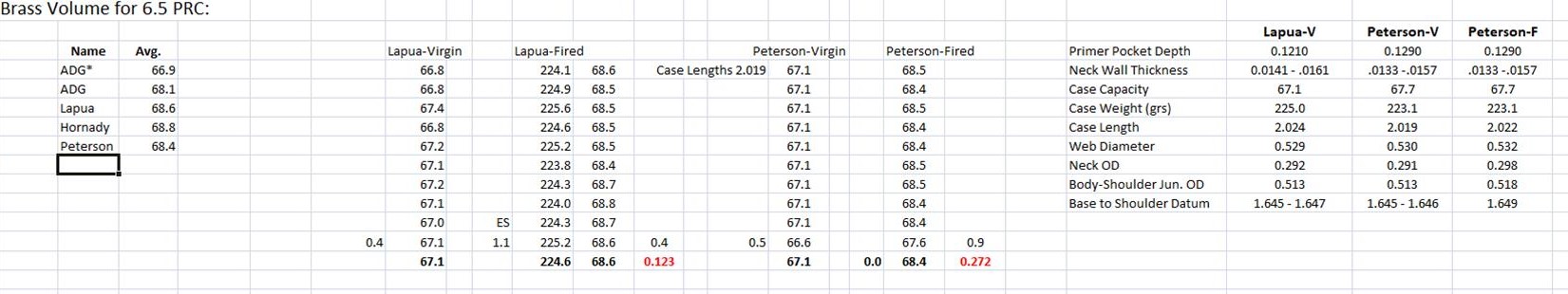

FYI: you might find the chart below of some help with regards to where you're at with pressure (and note the case fill depending on your case's OAL and assuming your barrel is 26").

Last edited:

Thanks for the chart! This lines up almost exactly with what I was seeing when working up my load. Given that max pressure for the 6.5 prc is 65,000 psi, looks like i may have a bit of wiggle room.Good for you. I was actually going to suggest you take a look and see if you're getting that carbon ring scrubbed out. It often does cause these kinds of issues. I would suggest too that if you're going long periods between scrubbing the carbon ring out, to be sure to trim you cases to the same length each time after sizing. Doing so doesn't eliminate the issue, but does help extend how long to have to do that scrubbing.

FYI: you might find the chart below of some help with regards to where your at with pressure (and note the case fill depending on your case's OAL and assuming your barrel is 26").

Thanks for the chart! This lines up almost exactly with what I was seeing when working up my load. Given that max pressure for the 6.5 prc is 65,000 psi, looks like i may have a bit of wiggle room.

You are seeing pressure signs and getting enough of a heavy bolt lift that you broke an extractor. Why on earth would think you have any wiggle room? You are above published max for the powder/bullet and you don't know if your chamber is sized to spec (reamers get small after use).

All you're accomplishing now is beating up your brass and your equipment - not to mention that if you take this load out on a hot summer day, you'll be well into the danger zone. Be smart about this and back it off into the published powder range. As @BridgerMT said, you don't need to be obsessed with pushing every bit of speed out of your rifle.

Not really trying to push all the speed I can get, thats just where the lowest SD was, also when these rounds started sticking, it was doing the same thing with factory ammo. As for the hot day, it was 95+ degrees when I tested those loads. The sticky bolt and broken extractor was from a carbon ring. I scrubbed it out and all is well again.You are seeing pressure signs and getting enough of a heavy bolt lift that you broke an extractor. Why on earth would think you have any wiggle room? You are above published max for the powder/bullet and you don't know if your chamber is sized to spec (reamers get small after use).

All you're accomplishing now is beating up your brass and your equipment - not to mention that if you take this load out on a hot summer day, you'll be well into the danger zone. Be smart about this and back it off into the published powder range. As @BridgerMT said, you don't need to be obsessed with pushing every bit of speed out of your rifle.

Around 300 rounds id sayhow many rounds between cleanings

View attachment 8032641

Should've clarified, the brass was fired in this 6.5 prc. Bought factory ammo amd used the 1x fired brass.

Makes sense, but it was having the same exact problems today using factory ammo. I thought myself that perhaps something was wrong with the sizing of the brass, because I had read about early 6.5 prc dies having problems with sizing. So I tried factory ammo, and boom, same exact problems. This brass is on its 3rd firing now and I haven't annealed so I expected it may be the brass, but trying factory ammo ruled that out.Hard bolt lift is a classic sign of high pressure. But you said hard extraction.

Hard extraction, most of the time, comes from the case web being swollen. Maybe you have a carbon ring.... under your case neck? An expanded web can come from using brass in a chamber that isn't compatible with your die. Your die won't squeeze the web back down enough and on a second or subsequent firing you get hard EXTRACTION. It's also possible that you overpressured the brass and blew the webs out. It's counter intuitive but spring back in the brass can have the brass expand wider at the base than your chamber once it's overpressured. If the die is not half thou or more under the chamber web diameter it won't squeeze the brass back. Similar to the first situation I described but caused by pressure instead of a previous chamber that was wider.

If you have a mic you can measure the web, .200" up from the rim. Look up the reamer print for a PRC. Compare your brass measurements to the reamer measurement.

With some rifles (like some of the Christensen Arms 6.5 PRC's) there's been reports of difficult extraction of Hornady brass after just a few firings (like around 3-4). What apparently was found is the way the chambers were cut and someone came up with a solution with a reamer that enlarged the chamber just a hair.

When I got my 6.5 PRC last year I thought I might run into that problem with the Preferred Barrel Blanks barrel I installed using some 1X fired Hornady brass I had bought since I couldn't find anything else at the time. But, I just never had that problem with any brass that's I've used (Hornaday, Lapua or Peterson). I always anneal and trim after every firing and use a Forster FL sizing die (none bushing) and expand necks with an expander mandrel.

I have taken various measurements to see what's going on with my brass and here what some of those numbers look like:

When I got my 6.5 PRC last year I thought I might run into that problem with the Preferred Barrel Blanks barrel I installed using some 1X fired Hornady brass I had bought since I couldn't find anything else at the time. But, I just never had that problem with any brass that's I've used (Hornaday, Lapua or Peterson). I always anneal and trim after every firing and use a Forster FL sizing die (none bushing) and expand necks with an expander mandrel.

I have taken various measurements to see what's going on with my brass and here what some of those numbers look like:

Cases don’t stick cuz the necks are dirty. Cases stick cuz the base does not spring back enough. Get a tighter sizing die.

If it happens that you continue to have hard extraction, take a look as this video about this shooter that used a JGS 6.5 PRC AW 2 reamer to solve the problem.When I bought the rifle there was zero brass available anywhere, but I lucked up and found a bunch of 143 eld-x at a lgs so I bought up a bunch of it to use until adg/peterson/lapua came back in stock.

That's what a lot of shooters were thinking a while back. But rather can get a custom die to get the brass sized smaller, the reamer I mention above was a solution apparently was a better fix.Cases don’t stick cuz the necks are dirty. Cases stick cuz the base does not spring back enough. Get a tighter sizing die.

Of course, it really depends on just what the issue really is.

It’s the same solution but mine is less invasive.That's what a lot of shooters were thinking a while back. But rather can get a custom die to get the brass sized smaller, the reamer I mention above was a solution apparently was a better fix.

Of course, it really depends on just what the issue really is.

Cases don’t stick cuz the necks are dirty. Cases stick cuz the base does not spring back enough. Get a tighter sizing die.

I mean it was doing it with factory ammo tooCases don’t stick cuz the necks are dirty. Cases stick cuz the base does not spring back enough. Get a tighter sizing die.

I mean it was doing it with factory ammo too

Did you measure the case dimensions before and after firing?

Haven't measured anything yet, the rifle always ran flawless with handloads and factory ammo until it just didn't one day. Will get a measurement of the brass today and compare it with factory. Cleaning the chamber really well fixed the issue but im curious to see how much the sizing die isn't actually sizing.Did you measure the case dimensions before and after firing?

Similar threads

- Replies

- 8

- Views

- 393

- Replies

- 5

- Views

- 802