Last year I had a custom .300WM built along with a GAP-10G2 from G.A. Precision. After going through a few boxes of ABM ammo (@ $58/box), I decided to get into reloading. In December I started acquiring everything I would need to start reloading for the GAP-10 which is chambered in 6.5 Creedmoor. I purchased both the Lyman and Berger reloading manual and read it as much as I could along with most of the sticky threads here on the Hide. Today I shot my very first reloads while conducting my very first optimal charge weight (OCW) test. I was using new Hornady brass, Federal GM210M primers, H4350, and Berger 130gr AR Hybrid OTM Tactical. My equipment list and process is as follows:

Using a Forster Co-Ax single stage press I ran the Hornady brass through a Redding Type-S Full length sizing die with .287" titanium nitride bushing and carbide button

I then trimmed the brass to the shortest Hornady case in the box (1.912") using a L.E. Wilson micrometer case trimmer.

I then uniformed the primer pockets, deburred the flash holes, and chamfered/deburred the case necks.

I then cleaned out the cases with an air compressor and primed them using the priming station on the Forster press.

Using the Berger manual, I used a Redding Match Grade 3BR powder measure to drop my charges.

I weighed each charge using a Frankford Arsenal DS-750 digital scale.

Using a Redding competition seating die, I seated each bullet .010" off the lands. (Determined using a Hornady OAL gauge)

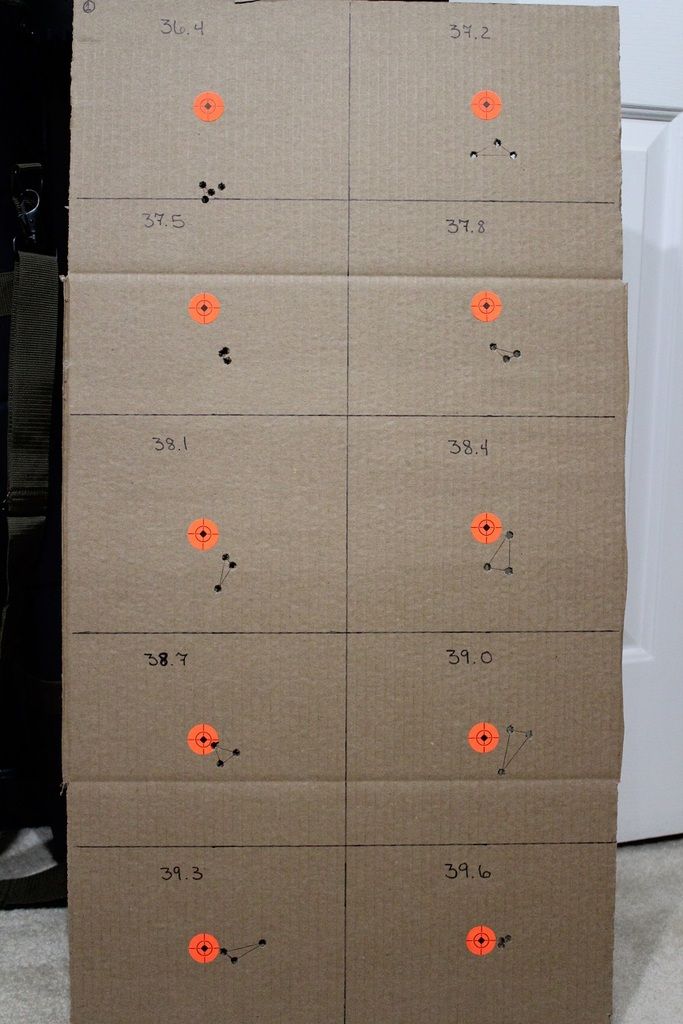

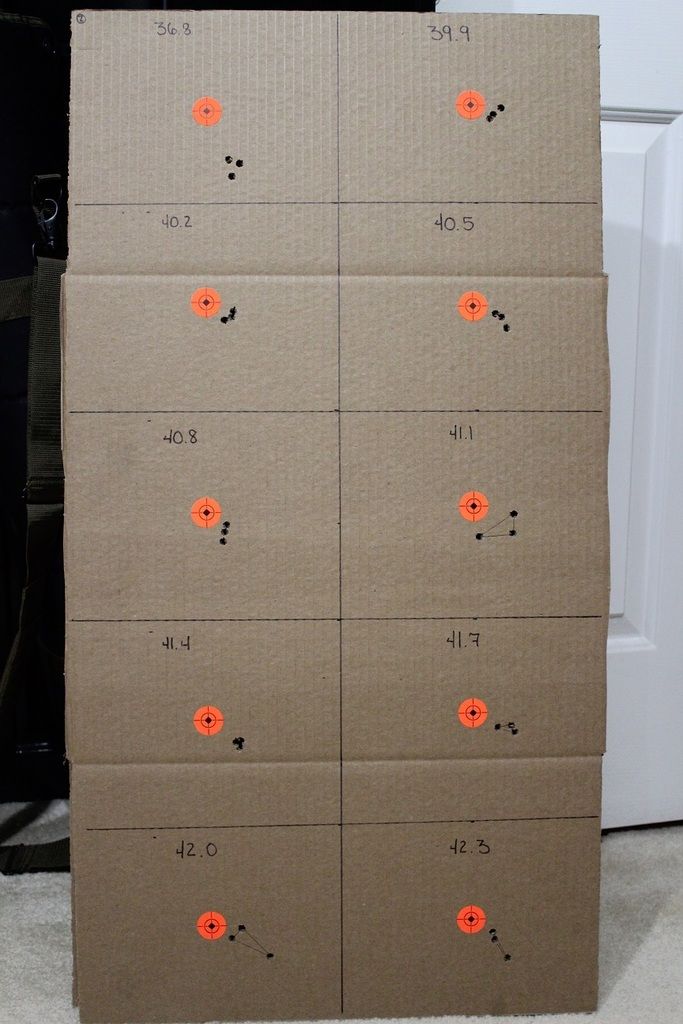

The OCW test was shot at 100 yards and conducted "round robin" style. The temperature was 70* with a headwind less than 4mph. I do not have a chrono yet so I can not give you velocities.

What do you guys think? The targets in the upper left of each cardboard were used as sighters as I didn't expect them to do very well being below book minimum. I had a lot of fun loading up these rounds and I cant wait to get back to the bench to reload them! Thanks for all the guidance you guys have given me so far on this journey.

Using a Forster Co-Ax single stage press I ran the Hornady brass through a Redding Type-S Full length sizing die with .287" titanium nitride bushing and carbide button

I then trimmed the brass to the shortest Hornady case in the box (1.912") using a L.E. Wilson micrometer case trimmer.

I then uniformed the primer pockets, deburred the flash holes, and chamfered/deburred the case necks.

I then cleaned out the cases with an air compressor and primed them using the priming station on the Forster press.

Using the Berger manual, I used a Redding Match Grade 3BR powder measure to drop my charges.

I weighed each charge using a Frankford Arsenal DS-750 digital scale.

Using a Redding competition seating die, I seated each bullet .010" off the lands. (Determined using a Hornady OAL gauge)

The OCW test was shot at 100 yards and conducted "round robin" style. The temperature was 70* with a headwind less than 4mph. I do not have a chrono yet so I can not give you velocities.

What do you guys think? The targets in the upper left of each cardboard were used as sighters as I didn't expect them to do very well being below book minimum. I had a lot of fun loading up these rounds and I cant wait to get back to the bench to reload them! Thanks for all the guidance you guys have given me so far on this journey.