For sure!Cool avatar - Mike Pence (Race Bannon from Johnny Quest) Our cartoons were so much cooler than kids have today.

View attachment 8239852

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

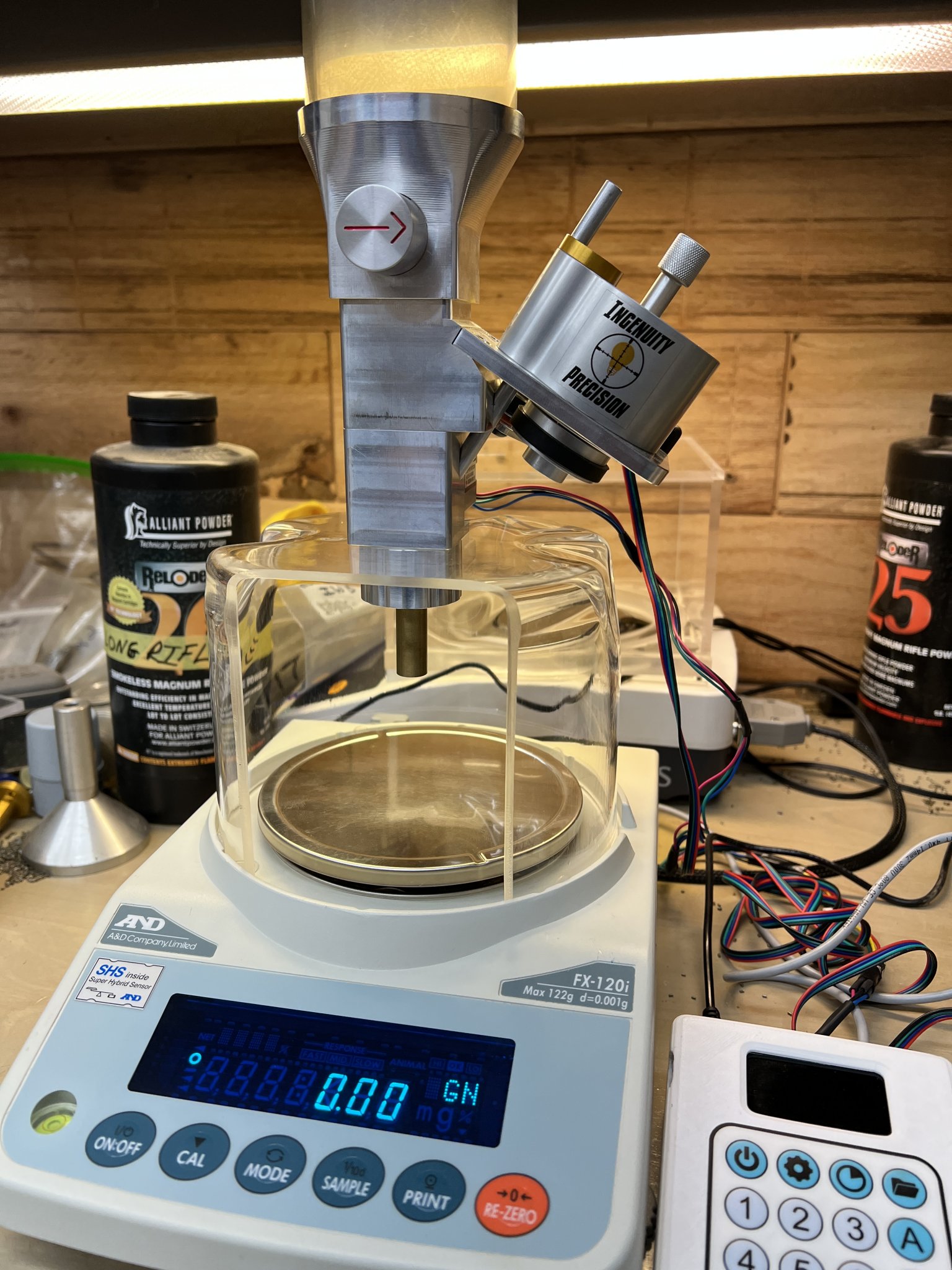

Ingenuity Precision trickler

- Thread starter NiteQwill

- Start date

- Status

- Not open for further replies.

If you were loading tiny calibers with small kernels, you might want less than 0.02 resolution.Paul... does your controller support grams too or only grains? Reason I ask is the fx120i has slightly better resolution if you run it in grams. (We're splitting kernels at this point, but it matters to some OCD types.)

I'm guessing it does support reading in grams since you have European distributors and plan on selling it in Europe, and most European reloading info is provided in grams.

Most of the time, this tens, on the side of overkill and I don’t know why anybody would want higher resolution than 0.02. It just creates problems and frustration with little practical improvement in velocity spread, especially if you’re shooting the big stuff with the large extruded powders, in which case it becomes a complete nuisance.

Thats darn slick! DC steppers are amazing. Talk about a innovator. So throwing the base charge manually and with the Creedmore scale $700 ish. Sold. TRX 925 is compatable yes?. Any problems losing the enclosure and welding some angle to get the manual measure over the cup/scale? It will take the right cup to get the measure and the trickler so theres no powder bounces outside the cup but I think its doable. Anti static procedures, grounding, mats needed?

This thing is so fast even with the Creedmore scale I think I will just run two cups and fill a block with charged brass on its bench not seat each charged piece of brass to save time. That lets me have my traditional check of comparing all the powder charges in the loading block visually to make sure there not a problem in the making. Makes me feel better. Then I will move the block to the bench with the press and seat. That way I can focus on one task and station at a time. The trickler can work while I pour the powder in the brass to save a little time.

This thing is so fast even with the Creedmore scale I think I will just run two cups and fill a block with charged brass on its bench not seat each charged piece of brass to save time. That lets me have my traditional check of comparing all the powder charges in the loading block visually to make sure there not a problem in the making. Makes me feel better. Then I will move the block to the bench with the press and seat. That way I can focus on one task and station at a time. The trickler can work while I pour the powder in the brass to save a little time.

Last edited:

What do you guys think of the new breeze shield? Just got first articles in today.

I'm excited for this thing!What do you guys think of the new breeze shield? Just got first articles in today.View attachment 8241893

Not crazy about it. I really like the look of the other oneWhat do you guys think of the new breeze shield? Just got first articles in today.View attachment 8241893

How stable is it? That's my only concern with any shield. The opening seems kind of big doesn't it, or is that just the picture making it look that way?What do you guys think of the new breeze shield? Just got first articles in today.View attachment 8241893

opening is 3.5" wide x 4" tall. I could make the opening smaller and still have plenty of room for the cup to go in and out.How stable is it? That's my only concern with any shield. The opening seems kind of big doesn't it, or is that just the picture making it look that way?

Factory one has windows 4.5" wide x 3.5" tall.

I'd make window slightly smaller if I was making my own, less potential for draft. Can we see the new prototype cup inside the breeze shield?

How stable is it? That's my only concern with any shield. The opening seems kind of big doesn't it, or is that just the picture making it look that way?

I agree, the number one concern I have is how stable it will be sitting on top and loaded with powder. The pic makes it look gigantically tall, but I suspect its just the pic and angle it was taken at. Short video of you using it with a semi-well known powder cup may make it a lot easier to judge size, etc.

Other questions:

1. Can the shield and dispenser both "spin" independently to sit in any direction wanted? For example, can the trickler be facing the user (6:00), and the opening be on the right side (3:00)?

2. Is the dispenser just sitting on top? Are they locked together in any way?

3. Any cable management planned?

The good thing about a shield is that it can be easily upgraded or changed later, by the original manufacturer or by aftermarket guys. I'll take whatever, and roll with the trend.

As you make the aperture smaller, you run the risk of the boomers with shaky hands complaining that they bump into it while inserting the cup. That's been a frequent complaint with the supertrickler because of the small space between the platen and the large tube.

As you make the aperture smaller, you run the risk of the boomers with shaky hands complaining that they bump into it while inserting the cup. That's been a frequent complaint with the supertrickler because of the small space between the platen and the large tube.

I guess there are two ways to go, one is to build structure on top of the scale vs simply slide the scale under a built structure.

Prototype would definitely need to be tested for stability, but so would any structure-on-scale concept. The OEM windshield on the Fx120i is obviously non-structural.

I do think that prototype gives the visual impression of being top-heavy, but its just a simple picture so its hard to say more.

One of the main features I would request if at all possible is the ability for 100% visual confirmation of the powder chamber being 100% empty.

Prototype would definitely need to be tested for stability, but so would any structure-on-scale concept. The OEM windshield on the Fx120i is obviously non-structural.

I do think that prototype gives the visual impression of being top-heavy, but its just a simple picture so its hard to say more.

One of the main features I would request if at all possible is the ability for 100% visual confirmation of the powder chamber being 100% empty.

1. Yes the shield and dispenser can be positioned any way you like in rotation. I.E. you can turn it where the cup is forward.I agree, the number one concern I have is how stable it will be sitting on top and loaded with powder. The pic makes it look gigantically tall, but I suspect its just the pic and angle it was taken at. Short video of you using it with a semi-well known powder cup may make it a lot easier to judge size, etc.

Other questions:

1. Can the shield and dispenser both "spin" independently to sit in any direction wanted? For example, can the trickler be facing the user (6:00), and the opening be on the right side (3:00)?

2. Is the dispenser just sitting on top? Are they locked together in any way?

3. Any cable management planned?

2. There is a hand nut on bottom the bolts them together.

3. The cables in production will be like the grey on in the picture. There will be three of those coming from the control box which you could tape or loom together to the rear of the scale for a cleaner management. They will also be 2' long for the guys that use their setup at the range in another enclosed box.

This thing is so fast even with the Creedmore scale I think I will just run two cups and fill a block with charged brass on its bench not seat each charged piece of brass to save time.

If you are going to run two cups, they must weigh exactly the same amount to get accurate results. This typically requires some ability to adjust the weight of the heavier of the two cups to make them match. Just keep that in mind.

If you are going to run two cups, they must weigh exactly the same amount to get accurate results. This typically requires some ability to adjust the weight of the heavier of the two cups to make them match. Just keep that in mind.

Yep. That's why I run cheapie stainless shot glasses on my motorized Harrell / IP trickler setup. They're tall enough you don't get any splash out with the really fast bulk drop of the Harrell's, and they're very easy to lightly sand to weight match. Alternating with 2 weight matched cups means the next charge is ready and waiting for me as soon as I stuff a bullet in the previous case.

The stainless shot glasses don't build up a static charge either since they're conductive.

For the window, maybe a Reuleaux triangle shape would be a good blend between usable opening space (vertical and horizontal) but areas that typically aren't "usable" (like the top corners on a square window) have material to block some draft.

Last edited:

That's why I run cheapie stainless shot glasses

Great idea. Just want to make sure I understand correctly.

You are using a standard stainless shot glasses that I can likely get at a liquor store and you don’t have splash problems?

What size? 1 oz, 2 oz?

Thanks for the video. It looks very stable, and I think the opening is a good size.

The adjustable drop tube is a nice feature to allow it to accept multiple different cup sizes.

I also like that it has the retaining nut holding the shield to the dispenser. This allows the entire unit to be removed easily for cleanup, storage, etc.

Last edited:

Great idea. Just want to make sure I understand correctly.

You are using a standard stainless shot glasses that I can likely get at a liquor store and you don’t have splash problems?

What size? 1 oz, 2 oz?

I think I'm using 2.5oz ones, but I'd have to verify when I get home. The ones I use have a small rolled lip at the top so they're easy to hold on to. Got them from Amazon, very inexpensive, been using them with my home brew automated Harrell's setup + AT V1 trickler (now with IP trickler) for 7 years now. Just do a search for stainless shot glass or stainless tumbler and look for something about 2.5" tall.

Tried all kinds of baffles and things to slow down the powder drop to avoid kernels splashing out and the easiest and most reliable solution that didn't slow down the bulk drop was a taller cup. Zero kernels bounce out of the cup now even if I'm dumping 85gr out of the Harrell's at full speed.

I think I'm using 2.5oz ones, but I'd have to verify when I get home.

Thanks! I’ve been using a silicone 1 cup kitchen measuring cup that I coated the interior with a hobby dry lube to keep powder from sticking. I haven’t yet messed with trying to get two cups measuring the same yet. I think the stainless cups would be better.

Thanks! I’ve been using a silicone 1 cup kitchen measuring cup that I coated the interior with a hobby dry lube to keep powder from sticking. I haven’t yet messed with trying to get two cups measuring the same yet. I think the stainless cups would be better.

No powder sticking or static buildup issues with the stainless shot glasses in 7 years of use. I think you'll like them. I tried all sorts of cups including the fancy 419 and PVA cups and the only thing that left the scale free of stray kernels at the end of a loading session was the taller stainless shot glasses.

Bad thing is they don't have a handle, so they might not play nice with the new draft shield Paul is showing above as you have to get your hand in there to grab the cup directly... depends how large the access window and your hands are. Based on the video above a handle will make things much easier. You could probably build a weighted base with a handle for them. I don't think just adding a handle to the shot glass would work, it would probably tip over. They probably need a bit of extra weight and a larger footprint on the bottom.

I use the one that comes with Stranahan's Single Malt. Works great and Stranahans is a great american single malt so win win.Great idea. Just want to make sure I understand correctly.

You are using a standard stainless shot glasses that I can likely get at a liquor store and you don’t have splash problems?

What size? 1 oz, 2 oz?

I think the design is excellent as is! I like using a tall SS shot cup to prevent kernels bouncing out.

Yea I dont care what the box looks like. Im fine with whatever you come up with as long as its functional. A cup that stops kernels from bouncing out to go along with the new thrower is more of a priority for me.

That is certainly an option, and you can even use some carbon loaded filament for conductivity to help dissipate static.

I'm a bit sensitive on the static issue having owned an rcbs chargemaster. All that plastic in the base and draft shield close to the scale pan on the chargemaster can build up static charges and result in significantly skewed dispensed charge weights and cause problems during load development and make you pull down a bunch of ammo and waste a lot of time... ask me how I know. That's why I like to see conductive materials used for the powder cup and anywhere near the scale pan.

Sorry, I told you the wrong stainless shot glass.... Mine is the one that comes with tincup whiskey like akh223's. Either way it's free with the whiskey.Great idea. Just want to make sure I understand correctly.

You are using a standard stainless shot glasses that I can likely get at a liquor store and you don’t have splash problems?

What size? 1 oz, 2 oz?

Lovin my Tincup 10 year even more now lol.Sorry, I told you the wrong stainless shot glass.... Mine is the one that comes with tincup whiskey like akh223's. Either way it's free with the whiskey.

Enabling autothrow should buy you a little more time to get the dump made manually.Hey quick question guys.

is there a way to make the IP not start trickling when I set an empty cup back on so I can make a manual throw and then it kick on? I tried the disable autothrow no luck

Am I making sense ? Included a picture of my set up if it helps

View attachment 8244257

My new electronics allow you to set the distance from target weight before the powder meter comes on.

Will the unit be made available through one of those (preferably the one in Spain, which one is it?) or do I have to order it directly from you then? German customs can be quite slow.I haver many dealers abroad. UK, Sweden, Spain in that area.

My Dealers are lining up to get their hands on it just as you. Most of them have already contacted me ready to start distributing ASAPWill the unit be made available through one of those (preferably the one in Spain, which one is it?) or do I have to order it directly from you then? German customs can be quite slow.

Awesome to hear, would you mind naming one or two so that I can get in contact and order when ready?My Dealers are lining up to get their hands on it just as you. Most of them have already contacted me ready to start distributing ASAP

Who are your dealers? The fellas that have been cheering you on over here would like to give you our cash.My Dealers are lining up to get their hands on it just as you. Most of them have already contacted me ready to start distributing ASAP

Maybe I missed this but is Paul taking orders for the new bulk dropper? I already have the IP trickler.

No not yet. Maybe close to end or year , December ishMaybe I missed this but is Paul taking orders for the new bulk dropper? I already have the IP trickler.

Will the mechanical/electronics of this thing have a restricted or optimal temperature operating range?

Asking because: the ATV4 motor would seize up in my garage on 100 degree days because of thermal expansion; and the ST vibratory motor is highly temperature sensitive below about 70 degrees - it speeds up as it heats up with continued operation, which alters its performance; or if you have settings that work at 90 degrees ambient, they don’t work at 65 degrees ambient (need different settings for seasonal temp variation if not in climate controlled environment.)

Mentioning because these are the things you don't think of when you're developing/testing in the same environment

Asking because: the ATV4 motor would seize up in my garage on 100 degree days because of thermal expansion; and the ST vibratory motor is highly temperature sensitive below about 70 degrees - it speeds up as it heats up with continued operation, which alters its performance; or if you have settings that work at 90 degrees ambient, they don’t work at 65 degrees ambient (need different settings for seasonal temp variation if not in climate controlled environment.)

Mentioning because these are the things you don't think of when you're developing/testing in the same environment

Last edited:

What, you can't afford a climate controlled 69 degree, polished concrete floor, automated reloading room?Will the mechanical/electronics of this thing have a restricted or optimal temperature operating range?

Asking because: the ATV4 would seize up on my garage on 100 degree days because of thermal expansion; and the ST vibratory motor is highly temperature sensitive below about 70 degrees - it speeds up as it heats up with continued operation, which alters its performance.

Mentioning because these are the things you don't think of when you're developing/testing in the same environment

I kid.

But, yes, very good thoughts. I'm interested to know as well.

Mentioning because these are the things you don't think of when you're developing/testing in the same environment

Unfortunately, it can be hard for a designer/inventor to envision all the ways their machine may be used. They have to make assumptions both consciously and unconsciously regarding many different aspects of the machine. The designer is so ingrained to the way they have designed it; that it is very hard for them to see the other ways their product will be used. This goes for using the product “correctly” and “incorrectly”.

I am continually shocked by how many different ways people will devise to use a product that the designer never thought about.

I say this to point out that the working temp envelope is a very valid question. We see people bringing their Autotricklers / Supertricklers to the range and reloading with them in the outdoor elements at events.

The follow on question from these customers will be “can it run off a battery pack”.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 588

- Replies

- 8

- Views

- 700

- Replies

- 178

- Views

- 9K

- Replies

- 23

- Views

- 790