Just pulled the trigger on the whole A&D scale, auto throw, and trickler last night. Super boosted about it. Anybody got any tips on set up or operation that anyone would want to share? Easy set up? Tough? Dont see many videos on setup on YouTube. Thanks fellas

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just got an A&D auto throw kit! Help!

- Thread starter BLKWLFK9

- Start date

Real easy. Just follow the step by step instructions to program the scale, and plug in two cables for the auto throw and trickler. You'll fiddle with the Lee hopper and the sliding bar on the back of the scale to get it all tuned. Make sure you put a bend in the straw from the hopper to help slow down the kernels, and level the scale as best you can.

For upgrades, Area 419 has some amazing options. I went with their full package buying a few pieces at a time. I really like the new V plate, cup, and trickler base. The base has adjustable feet that you can tweak to mess with the feed rate. I also got a reducing insert to help reduce over throws. You just pop it in the end of the trickler. Lots of different options and upgrades out there, but I'm able to get charges accurate to a kernel within 6 seconds.

For upgrades, Area 419 has some amazing options. I went with their full package buying a few pieces at a time. I really like the new V plate, cup, and trickler base. The base has adjustable feet that you can tweak to mess with the feed rate. I also got a reducing insert to help reduce over throws. You just pop it in the end of the trickler. Lots of different options and upgrades out there, but I'm able to get charges accurate to a kernel within 6 seconds.

Congrats, you will be very happy with it. DO not look at the area 419 options  I have gotten just about all the upgrades from them. As stated above they are quality upgrades to the scale and well worth it.

I have gotten just about all the upgrades from them. As stated above they are quality upgrades to the scale and well worth it.

Here is a pretty good thread about the A&D scale: https://www.snipershide.com/shootin...upgrade-with-v2-auto-trickler-review.6365890/

Chad

Here is a pretty good thread about the A&D scale: https://www.snipershide.com/shootin...upgrade-with-v2-auto-trickler-review.6365890/

Chad

Even if you buy the 'pre-programed' scale, double check. I had 2 that weren't dead on.

Another huge vote for the 419 stuff. I have the base for the throw, trickler, the pyrex hopper, and their cup. All of which are a tremendous upgrade over the 3-D printed items and janky medicine cup it comes with. I'm 100% getting the clear Lexan lid as well. If I had one complaint, it would be the PITA that is bending over every load. You can guesstimate, but the one time you get it wrong it's gonna suck lol.

Set up is simple. The slowest part is for sure the auto throw arm from Lee. It' just takes some time messing with it and the speed of the auto trickler to get them working well together. I acutally canted my trickler up a tad using the 419 base the other day (could accomplish this other ways wit the factory base) and need to increase the throw from the Lee arm to speed things back up. I will say that after doing this I got virtually zero error over 100 rounds.

Don't get frustrated if it's not 100% perfect every single time. I've had days where it would start going over and get frustrated. Take some time and continue to tweak it and you'll be extremely happy with your purchase.

Another huge vote for the 419 stuff. I have the base for the throw, trickler, the pyrex hopper, and their cup. All of which are a tremendous upgrade over the 3-D printed items and janky medicine cup it comes with. I'm 100% getting the clear Lexan lid as well. If I had one complaint, it would be the PITA that is bending over every load. You can guesstimate, but the one time you get it wrong it's gonna suck lol.

Set up is simple. The slowest part is for sure the auto throw arm from Lee. It' just takes some time messing with it and the speed of the auto trickler to get them working well together. I acutally canted my trickler up a tad using the 419 base the other day (could accomplish this other ways wit the factory base) and need to increase the throw from the Lee arm to speed things back up. I will say that after doing this I got virtually zero error over 100 rounds.

Don't get frustrated if it's not 100% perfect every single time. I've had days where it would start going over and get frustrated. Take some time and continue to tweak it and you'll be extremely happy with your purchase.

I went with a cheap one from Amazon. As long as you have a reference (check weight) that you can relate your loads to, you're fine. I use the check weight before every reloading session to see if it's drifted or changed.

I think a check weight for the load you are using is a valuable way to monitor your scale.

For things like the 300WM a 5 gram weight, down to a 2 gram weight for .223 loads.

Your scale might require a full scale calibration weight but checking it's accuracy @ the target value adds confidence.

A really small sensitivity weight (10 milligram would be adequate) will prove the capability to sense small changes in measured value.

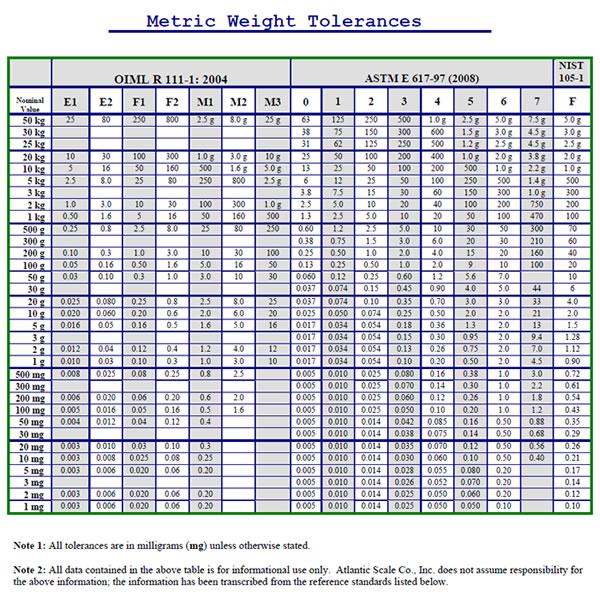

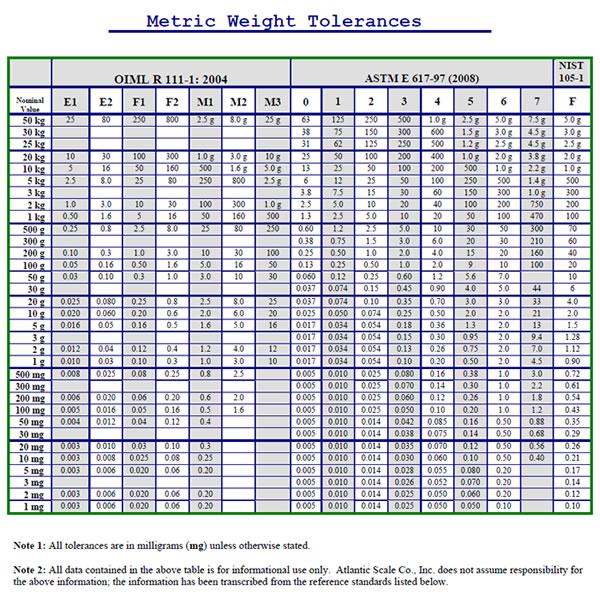

As far as the Quality of the weights look up weight classes and tolerances. The cheaper weights are usually Chrome/Nickel plated magnetic steel.

Usually just fine. Better weights will be made of nonmagnetic stainless. For those of you that spent the money to buy a high end milligram reading scale, why not a check weight good to a milligram? Price out tolerances

You really want 'Sameness'. Having a full scale calibration weight is fine but a check weight and sensitivity weight can prove long term

Sameness.

Now to the poster above me that went with the Amazon cheap check weight, that's just fine.

Get a container to protect the weight just like you spent a few hundred dollars for it.

Take care of it and it will be almost exactly the same 100 years from now?

Not saying it's 'on the money', just the same as the last time you used it.

One quality control technique for monitoring weights is to get a continuous set.

1,2,3,5 sequence or 1,2,2,5 sequence not a 1, 2, 5 sequence.

1g, 2g, 3g, 5g 10g. or 1g, 2g, 2g, 5g, 10g. Not a 1g, 2g, 5g, 10g.

By having more than one combination you can check for group and individual changes.

Have doubts about your 3 gram in a 1,2,3,5 set because you dropped it?

compare it to your 1g and 2g.

For things like the 300WM a 5 gram weight, down to a 2 gram weight for .223 loads.

Your scale might require a full scale calibration weight but checking it's accuracy @ the target value adds confidence.

A really small sensitivity weight (10 milligram would be adequate) will prove the capability to sense small changes in measured value.

As far as the Quality of the weights look up weight classes and tolerances. The cheaper weights are usually Chrome/Nickel plated magnetic steel.

Usually just fine. Better weights will be made of nonmagnetic stainless. For those of you that spent the money to buy a high end milligram reading scale, why not a check weight good to a milligram? Price out tolerances

You really want 'Sameness'. Having a full scale calibration weight is fine but a check weight and sensitivity weight can prove long term

Sameness.

Now to the poster above me that went with the Amazon cheap check weight, that's just fine.

Get a container to protect the weight just like you spent a few hundred dollars for it.

Take care of it and it will be almost exactly the same 100 years from now?

Not saying it's 'on the money', just the same as the last time you used it.

One quality control technique for monitoring weights is to get a continuous set.

1,2,3,5 sequence or 1,2,2,5 sequence not a 1, 2, 5 sequence.

1g, 2g, 3g, 5g 10g. or 1g, 2g, 2g, 5g, 10g. Not a 1g, 2g, 5g, 10g.

By having more than one combination you can check for group and individual changes.

Have doubts about your 3 gram in a 1,2,3,5 set because you dropped it?

compare it to your 1g and 2g.

I have an A&D 120fi on order and am waiting on it to show up. I am likely to get an auto throw/tricker setup soon.

But in the end, if you use the same scale, same calibration weight and use the same process consistently then you should be throwing the same weight of powder as you did during load development. I think that is the important factor. Until you know more info about your calibration weight, you will not know what the actual value is of your throw. Even then, it will be +/- based upon the scales ability as well as the accuracy of the weight/process you used to calibrate your calibration weight! In the end, I guess it's just about "consistency", "precision" and "predictability" of what you throw than it is about its ultimate "accuracy". But accuracy would be nice as well.

I ordered an inexpensive weight set off Amazon. The inexpensive set I bought does not have certification paperwork, so you are sort of at the mercy of the advertised level (+/- a specific amount) of accuracy of the weight. Otherwise the set (with tractability) would have been as expensive or more expensive than the scale itself. The set I picked had good reviews and a number or others had checked the weights against those with certifications and they mostly measured well. But even then, there is no guarantee that my experience will be the same as theirs.

I plan to take my cheap set to a local friend who has access to a metrology lab with more accurate scales that have been calibrated via certified weights. I am not looking for "offical" certified tractability, but rather just numbers as measured by good equipment/weights. Hopefully this will tell me how far off calibration weights (and thrown powder weights) are from reality. My goal is that that hopefully my 50g weight is very very close to 50g. I hesitate to even mention what I bought as I have yet to receive it and have it measured. It might be crap.

I don't have my scale in hand yet, I assume that it expects a set weight for it's calibration procedure. Such as a "50g" weight. I guess the idea is that when you calibrate with a weight, you are telling the scale "this is 50.000g". For weights without certification paperwork, the issue is that you just don't know what the actual weight of your calibration weight is. Is it 50.002 or 49.028 for example? So your values will only be as accurate as your calibration weight.What check weights are everyone using? Also, if I'm working up all new loads, does it matter the quality of check weight I use?

But in the end, if you use the same scale, same calibration weight and use the same process consistently then you should be throwing the same weight of powder as you did during load development. I think that is the important factor. Until you know more info about your calibration weight, you will not know what the actual value is of your throw. Even then, it will be +/- based upon the scales ability as well as the accuracy of the weight/process you used to calibrate your calibration weight! In the end, I guess it's just about "consistency", "precision" and "predictability" of what you throw than it is about its ultimate "accuracy". But accuracy would be nice as well.

I ordered an inexpensive weight set off Amazon. The inexpensive set I bought does not have certification paperwork, so you are sort of at the mercy of the advertised level (+/- a specific amount) of accuracy of the weight. Otherwise the set (with tractability) would have been as expensive or more expensive than the scale itself. The set I picked had good reviews and a number or others had checked the weights against those with certifications and they mostly measured well. But even then, there is no guarantee that my experience will be the same as theirs.

I plan to take my cheap set to a local friend who has access to a metrology lab with more accurate scales that have been calibrated via certified weights. I am not looking for "offical" certified tractability, but rather just numbers as measured by good equipment/weights. Hopefully this will tell me how far off calibration weights (and thrown powder weights) are from reality. My goal is that that hopefully my 50g weight is very very close to 50g. I hesitate to even mention what I bought as I have yet to receive it and have it measured. It might be crap.

50g close to 50g is nice.

5 gram close to 5gram is nicer.

I'm guessing it's the red box set?

That is perfect . Taken care of it will be stable for a long time.

The likely calibration accuracy Probably M2 (even though some state M1) can be found here:

5 gram close to 5gram is nicer.

I'm guessing it's the red box set?

That is perfect . Taken care of it will be stable for a long time.

The likely calibration accuracy Probably M2 (even though some state M1) can be found here:

Doesn't the FX-120 require a 100g check weight? (I thought I read that somewhere when I ordered it.)

The default calibration check is 100g. I think you might be able to change what weight it gets calibrated at, but I know mine is looking for 100g.

We are probably talking about the same set. It is in a red box and is listed as M2. 15 weights ranging from 50g to 10mg. Tweezers look like crap and case appears to have a space for a 100g weight.50g close to 50g is nice.

5 gram close to 5gram is nicer.

I'm guessing it's the red box set?

That is perfect . Taken care of it will be stable for a long time.

Hmm, I had it in my mind for some reason that it used 50g but can't say how I came up with that value. The set I ordered goes up to 50g. Hopefully you can set it to a specific value otherwise I will be buying a 100g weight! Probably will do that anyhow.The default calibration check is 100g. I think you might be able to change what weight it gets calibrated at, but I know mine is looking for 100g.

Your set probably has 50g, 20g, 20g, 10g.

Using my common Core math skills that adds up to uhm uhh

Using my common Core math skills that adds up to uhm uhh

It does. I suspect I will like the convenience of a single weight for a quick recalibration. But that also depends upon what combo adds up the closest to 100g. I already ordered the 100g. It was like $8.50 or something like that. Hopefully the single will be closer to 100g than the combo you list! It will also fill up the empty case spot which the OCD part of me would be bothered by.Your set probably has 50g, 20g, 20g, 10g.

Using my common Core math skills that adds up to uhm uhh

With a really good scale you should be able to compare them.

And then check closer to something you actually weigh.

Take care of them.

With a whole set of weights you can have hours and hours of fun

Comparing the 20g to the 20g the 2 to the 2, finding the lighter and heavier, then combining to the next higher value.

Is the 50 heavier or lighter than the 20+20+10?

Then all of those compared to the 100.

Grasshopper, you have not seen OCD yet

You know how people calculate air density for trajectory?

Your weights are steel, your powder closer to the density of water

Buoyancy of your 8.0gr/cc weights might not matter for reloading.

But it's there and matters to your Metrologist friend.

And then check closer to something you actually weigh.

Take care of them.

With a whole set of weights you can have hours and hours of fun

Comparing the 20g to the 20g the 2 to the 2, finding the lighter and heavier, then combining to the next higher value.

Is the 50 heavier or lighter than the 20+20+10?

Then all of those compared to the 100.

Grasshopper, you have not seen OCD yet

You know how people calculate air density for trajectory?

Your weights are steel, your powder closer to the density of water

Buoyancy of your 8.0gr/cc weights might not matter for reloading.

But it's there and matters to your Metrologist friend.

Last edited:

Just had a really good chuckle over this comment...Your set probably has 50g, 20g, 20g, 10g.

Using my common Core math skills that adds up to uhm uhh

I just got a reasonably priced 100 gram weight on amazon. I dont care if its .008 grams off of true absolute nasa exact. I just know that when I calibrate my scale with it I am always setting it up the same way it was for the previous loading session every time.

Takes about 10 days to here but I have seen a few state the below

https://www.ebay.com/itm/F1-Class-1...496994&hash=item3d7dc60722:g:oY0AAOxy9eVRQE8n

https://www.ebay.com/itm/F1-Class-1...496994&hash=item3d7dc60722:g:oY0AAOxy9eVRQE8n

If you have a $50 scale, maybe spend $10 on calibration weights, a $500 dollar automated powder spiller, maybe a little better cal weight.

Don't get too side tracked with full scale calibration.

Even a worn out, unstable, nonlinear, zero hunting scale can look good at full scale.

Heck, if it does not pass the full scale calibration the first time you just try again right?

If you toss a charge of 100 grams (1543.2 grains) fine, but if you toss 60 grains how does your scale read there?

If you said "the same as last time" that's a good answer.

Was it really 60 grains?

"Yup, calibrated my scale at 1543.2 grains before I started, ought to be right on at 60".

Maybe not a great answer

A 5 gram check weight (77.16 grains) would be a great check weight.

The cheap 5g M2 class weight has a tolerance of +/- 0.077 grains. Good enough for just about anyone.

If your 100 gram scale has some linearity error down at the low end of it's range The check weight will find it.

BTW, the F1 5 gram weight has a tolerance of +/- 0.0025 grains, over 30 times more accurate.

That's good enough to check most reloading scales.

If you don't check it, you won't know.

If you keep multiple sets of weights, maybe even an E1 set, then you have a bad case of OCD

Don't get too side tracked with full scale calibration.

Even a worn out, unstable, nonlinear, zero hunting scale can look good at full scale.

Heck, if it does not pass the full scale calibration the first time you just try again right?

If you toss a charge of 100 grams (1543.2 grains) fine, but if you toss 60 grains how does your scale read there?

If you said "the same as last time" that's a good answer.

Was it really 60 grains?

"Yup, calibrated my scale at 1543.2 grains before I started, ought to be right on at 60".

Maybe not a great answer

A 5 gram check weight (77.16 grains) would be a great check weight.

The cheap 5g M2 class weight has a tolerance of +/- 0.077 grains. Good enough for just about anyone.

If your 100 gram scale has some linearity error down at the low end of it's range The check weight will find it.

BTW, the F1 5 gram weight has a tolerance of +/- 0.0025 grains, over 30 times more accurate.

That's good enough to check most reloading scales.

If you don't check it, you won't know.

If you keep multiple sets of weights, maybe even an E1 set, then you have a bad case of OCD

Last edited:

Lol, I dont even know what that means.Maybe the geared belt needs to be indexed 180 degrees out of phase?

Power everything off and manually push the arm to its bottom most position. Power up and retry.Well... set it all up. Tried to throw my first charge and for some reason, the motor tries to throw the arm down instead of up, like its backwards. Any ideas?

Did that twice. No dice. Same shitPower everything off and manually push the arm to its bottom most position. Power up and retry.

Try pushing the arm all the way up this time. I had the same problem, I just don’t remember if I pushed the arm to the top or bottom.Did that twice. No dice. Same shit

If you still have problems, e-mail Adam MacDonald. He’s usually really fast to respond.

Try pushing the arm all the way up this time. I had the same problem, I just don’t remember if I pushed the arm to the top or bottom.

If you still have problems, e-mail Adam MacDonald. He’s usually really fast to respond.

Did that too. Sends the arm down nice and smooth, then proceeds to vibrate and tries to continue pushing the arm down. I have a video, just cant post it in here. I sent it to Adam via facebook but he hasn't seen it yet. I'm sure hes probably asleep or something

Remove all powder from the measure, slightly loosen the nut on the “drum” of the measure and retry. I had to loosen the nut on mine before the stroke was smooth and would complete. It’s mentioned in either Adam’s or the powder measure instructions.Did that too. Sends the arm down nice and smooth, then proceeds to vibrate and tries to continue pushing the arm down. I have a video, just cant post it in here. I sent it to Adam via facebook but he hasn't seen it yet. I'm sure hes probably asleep or something

What powder? Ball powder is a no go. It gets into the skinny party of the autothrow and seizes it. Found that out with cfeblk, trickler only. You’ll have to take it apart and clean it out.Well... set it all up. Tried to throw my first charge and for some reason, the motor tries to throw the arm down instead of up, like its backwards. Any ideas?

If not a ballmpowder then try unscrewing the screw in the large top pully just a smidge. That should lessen the tension and allow it to spin easier.

Just watched again, are you sure you went through the set up procedure correctly? I can’t rememebr it even trying to continually run like that. When mines seized up before it’s just been for a second or two.

Curious too see the resolution here. My stuff came in the mail yesterday, and I intend to set it up this afternoon...

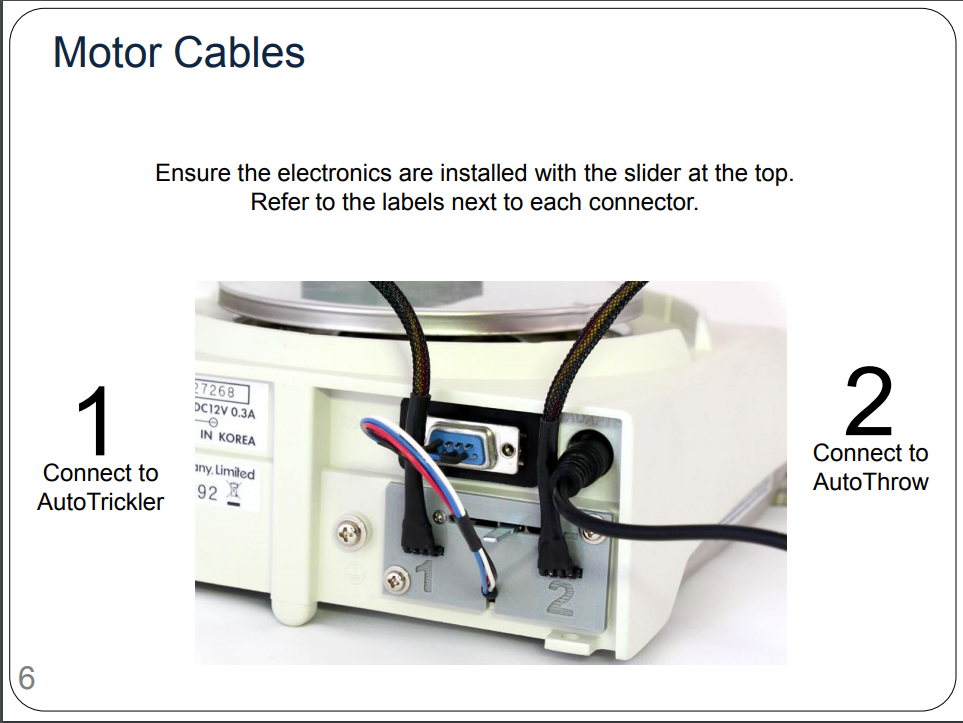

Try switching the two cords in back of scale.

i'll give it a try when i get home.

Thats a good problem solving step, mine are actually rotated 90 degrees from this page in the instructions so that the pins are all stacked in a line vertically instead of horizontally.

The trickler (1) cable goes out straight left and the throw (2) cable goes out to the right

The trickler (1) cable goes out straight left and the throw (2) cable goes out to the right

My dumb ass knew the way they were suppose to go, but sometimes i do shit backwards. I thought i had it right. been dying all day to get home and see. im sure thats what it is. Adam emailed me back today saying that i probably had them switched.

Yea, my retarded ass got the cords switched. got it running like a top now.

Last edited:

I'm about to pull the trigger on a setup and trying to decide between the stock auto throw setup, or going full baller and buying the full area 419 setup. The 500 bucks is quite a bit of change... i only reload about 300 rounds a month and mostly 6.5 creed, 28 nosler, and 338 lapua on my co-ax. From reading above sounds like i should go area 419? Thanks guys

I'm running the stock auto-thrower setup, and it works well. That being said, I'll probably upgrade to the 419 set when it is available again (directly from 419). Even stock though, it works really well.

IMO, the trickler base is a mandatory upgrade. The DramWorx hopper is another big one, especially when loading bigger cases. I just installed the AutoThrow upgrades last night, and I'm pretty impressed with them. They're all worthwhile, and if you don't get them up front, you will probably end up getting them all over time anyway.

Autotrickler base - WAY better than paper shims to get the trickler running right. Makes a huge difference in performance, and the stability provided by the heavier base makes a bigger difference in performance (and noise) than you'd think.

Billet powder cup - Nice to have, better quality than the little medicine cup, but doesn't really kick ass until you add the replacement tray

Centering tray - This is badass combined with the machined straw and billet cup. The wings put the cup in the exact right spot, and there's a small divot the cup sits in to hold it in the perfect position.

Lexan lid - WAY stronger/stiffer than the normal top wind screen, no 3d printed bits for extra support, and you can easily see what's happening with the trickler without leaning down or putting the scale on a stand.

Machined 'straw' - I despised the bendy straw. Stuck kernels getting knocked onto the pan when you bumped it, screwing up the weight.... Ugh. Do it.

Billet thrower housing - Just do it. You know you wanna.

DramWorx hopper - The machined cutoff is much nicer than the plastic one, it's tension adjustable and lockable with the outer collar, a sealing lid, and no more static. If you're loading any kind of magnums, this is basically mandatory. Same for standard SA cases when loading in volume for a match, etc.

Autotrickler base - WAY better than paper shims to get the trickler running right. Makes a huge difference in performance, and the stability provided by the heavier base makes a bigger difference in performance (and noise) than you'd think.

Billet powder cup - Nice to have, better quality than the little medicine cup, but doesn't really kick ass until you add the replacement tray

Centering tray - This is badass combined with the machined straw and billet cup. The wings put the cup in the exact right spot, and there's a small divot the cup sits in to hold it in the perfect position.

Lexan lid - WAY stronger/stiffer than the normal top wind screen, no 3d printed bits for extra support, and you can easily see what's happening with the trickler without leaning down or putting the scale on a stand.

Machined 'straw' - I despised the bendy straw. Stuck kernels getting knocked onto the pan when you bumped it, screwing up the weight.... Ugh. Do it.

Billet thrower housing - Just do it. You know you wanna.

DramWorx hopper - The machined cutoff is much nicer than the plastic one, it's tension adjustable and lockable with the outer collar, a sealing lid, and no more static. If you're loading any kind of magnums, this is basically mandatory. Same for standard SA cases when loading in volume for a match, etc.

Last edited:

Is the Dremworx hopper the one that comes in the full 419 upgrade kit? Or should I google it tooIMO, the trickler base is a mandatory upgrade. The DramWorx hopper is another big one, especially when loading bigger cases. I just installed the AutoThrow upgrades last night, and I'm pretty impressed with them. They're all worthwhile, and if you don't get them up front, you will probably end up getting them all over time anyway.

Autotrickler base - WAY better than paper shims to get the trickler running right. Makes a huge difference in performance, and the stability provided by the heavier base makes a bigger difference in performance (and noise) than you'd think.

Billet powder cup - Nice to have, better quality than the little medicine cup, but doesn't really kick ass until you add the replacement tray

Centering tray - This is badass combined with the machined straw and billet cup. The wings put the cup in the exact right spot, and there's a small divot the cup sits in to hold it in the perfect position.

Lexan lid - WAY stronger/stiffer than the normal top wind screen, no 3d printed bits for extra support, and you can easily see what's happening with the trickler without leaning down or putting the scale on a stand.

Machined 'straw' - I despised the bendy straw. Stuck kernels getting knocked onto the pan when you bumped it, screwing up the weight.... Ugh. Do it.

Billet thrower housing - Just do it. You know you wanna.

DramWorx hopper - The machined cutoff is much nicer than the plastic one, it's tension adjustable and lockable with the outer collar, a sealing lid, and no more static. If you're loading any kind of magnums, this is basically mandatory. Same for standard SA cases when loading in volume for a match, etc.

Is the Dremworx hopper the one that comes in the full 419 upgrade kit? Or should I google it too

I assume so, since i know it comes with the AutoThrow upgrade kit. The glass walls on it were a LOT thicker than I expected, which made me happy when it comes to durability.

Similar threads

Reloading Equipment

Auto-throw/trickler v2 + Upgrades + Area 419 Parts/Upgrades

- Replies

- 3

- Views

- 956

- Replies

- 7

- Views

- 548

- Replies

- 0

- Views

- 80