After introducing a good friend to long range shooting, I recommended this rifle to him. He initially wanted a 5R, but I convinced him that the Creedmoor would be a better first rifle due to less recoil. I was very impressed with the rifle right out of the box. Factory ammo was 1/2 to 3/4. With reloads using the 142MK, I was shooting in the 3's. I still think Savages are a little ugly, but I'm looking for a Model 12VLP .223, 7 twist for myself.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just Ordered My First Long Range Rifle--A Savage 12 LRP!

- Thread starter TwoNiner

- Start date

... I had never used a Savage target accu-trigger prior to receiving this Model 12 LRP chambered in 6.5 creedmoor and I have to say I was extremely impressed with it with dry fire only.

I loved the super light break on my savage 12LRP out of the box but have ended up cranking it up to almost as stif as it would go after throwing a few premature shots down range at the tactical match at my local range.

She weighs in at a lofty 14lb 11oz. How much are your guys short action rifles weighing in at? It seems really heavy to me. I'm already considering ways to reduce weight but can't think of anything short of chopping a couple inches off the barrel which will reduce my shot velocity. How much I don't know...

Seems like you may be a bit confused as to what you are really looking for. If you wanted a light rifle then why buy a gun with a target action and heavy bull barrel. If you wanted a long range gun then why lighten it up and chop the barrel. The only stock that may be an upgrade would be a Mcmillan or Manners. HS makes a pretty good stock and even though it comes from the factory with one, it is hardly a "factory stock". And adding a muzzle break is going to increase the amount of dust it kicks up, not lessen it.

I would say go out and shoot the gun and not worry so much about changing things. If it is shooting an inch and a quarter then you are nowhere near the potential of the gun yet. I have one that is bone stock other than some CDI metal and it shoots even better at distance than at 100 yards. No need to change anything else on it for me. Even though I have more expensive custom guns, I just don't see the chance for much improvement on my LRP. Most reports have these guns shooting well under 1 MOA, so once you are there then look if there are things that need changed.

im itching to get one of these in 260... I just don't have the funds right now, but is going to be my next purchase, and my very first bolt rilfe (mostly an AR rifle man myself).

Everytime I see one of these it makes me question weather or not I should be building a custom 6.5 Creedmoor. Everyone of these I have seen flat out shoots.

I just recently picked up a 12 LRP in 6.5 CM,and gotta say for less than 1k,your getting a lot of gun.

The first thing I was going to do is change the stock,however it came with the newer style HS Precision,and now I'm not changing a thing.

Big +1 to savage for changing that.

Can't wait to get it going,and better yet its nice not having to rework a whole gun before shooting.

Add glass and pull the trigger!

The first thing I was going to do is change the stock,however it came with the newer style HS Precision,and now I'm not changing a thing.

Big +1 to savage for changing that.

Can't wait to get it going,and better yet its nice not having to rework a whole gun before shooting.

Add glass and pull the trigger!

Damn that's a fat barrel Savage puts on those...

Can't let Rem guys with their M24 contour have all the fun...

I got one a month or so ago in 6.5 CM. It has the old style stock. I may replace it, but I only have 68 rounds through it and will reserve judgement on the stock for now. It shoots 140 gr AMAX's lights out. Going to the range tomorrow to give it another whirl.

Ken Farrell makes a nice base without a recoil lug for this action. His rings are really nice as well. Here is a shitty cell phone pic but it shows the base and rings with a 56mm objective.

Ken Farrell makes a nice base without a recoil lug for this action. His rings are really nice as well. Here is a shitty cell phone pic but it shows the base and rings with a 56mm objective.

Attachments

First and foremost, for the money the Savage LRP is hard to beat for an out of the box semi-custom LR rig. I swapped out the Accu-trigger for a Rifle Basix and procured two 10 round magazines from Dan at Dark eagle Customs along with and extended mag release. Those mags have run flawlessly in three tactical precision matches with ZERO feed issues. I must have gotten lucky because it came with an EGW 20MOA rail installed.

However, accuracy wise I have been struggling with my model 12 LRP in .260Rem. I purchased it new in October 2012. It has never been a great shooter, hovering around 1.25MOA with some odd flyers on longer strings once past rounds six or seven. I did some pretty extensive load development and although the 41.8gr H4350 in Lapua brass under a 140gr HPBT may seem a bit "light" to some, it's as high as I could get without worrying about sticky bolt (42.3gr) or stuck bolt (42.7gr).

Overall I REALLY like my Savage LRP, but something has always been nagging me that something isn’t quite correct with it. Fast forward 250 rounds ldownrange and while cleaning it a few weeks ago I noticed that at the muzzle end one of the grooves was extremely fouled by copper (looked like it had been copper plated) while the rest exhibited virtually no copper fouling. I contacted my gunsmith and he asked me to stop by so he could investigate with a borescope.

Aside from a lot of tool marks and chattering throughout the barrel the biggest issue was that the chamber had been reamed off axis relative to the bore. Although I didn’t exactly understand all the technical terms, looking through the bore scope and performing a 360 rotation at the end of the throat it was self evident that something wasn’t correct. In my barrel not all of the lands and grooves ended/started at the same point in the barrel. Some stopped short of the throat while others extended to it or slightly beyond (free bore area?). Anyway in anticipation of returning the barrel to Savage we removed the barrel from the action. Unfortunately according to the Savage customer service representative I spoke with, that action completely voided my warranty. Oops!

Alas all has not been lost as I was able to procure a Shilen select match grade replacement barrel from Jim at Northland Shooter Supply (super nice guy to deal with). During our conversation Jim inquired why I was changing barrels. After informing him of the situation, he stated that this sadly was not the first time he has heard of this issue.

Late last week I received my rifle back from my smith after he installed the shilen barrel and threaded it for my suppressor. I utilized my existing load of 41.8gr H4350 under a 140gr Hornady HPBT. After 2 shots at 50yds to see if the scope needed adjusted (it didn't) I moved out to 100yds:

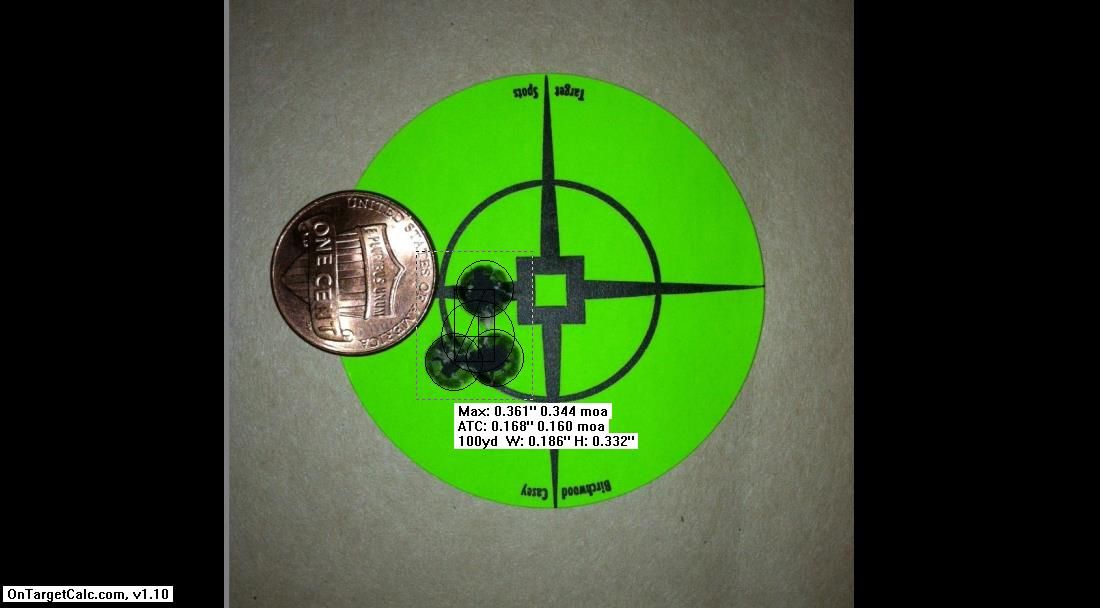

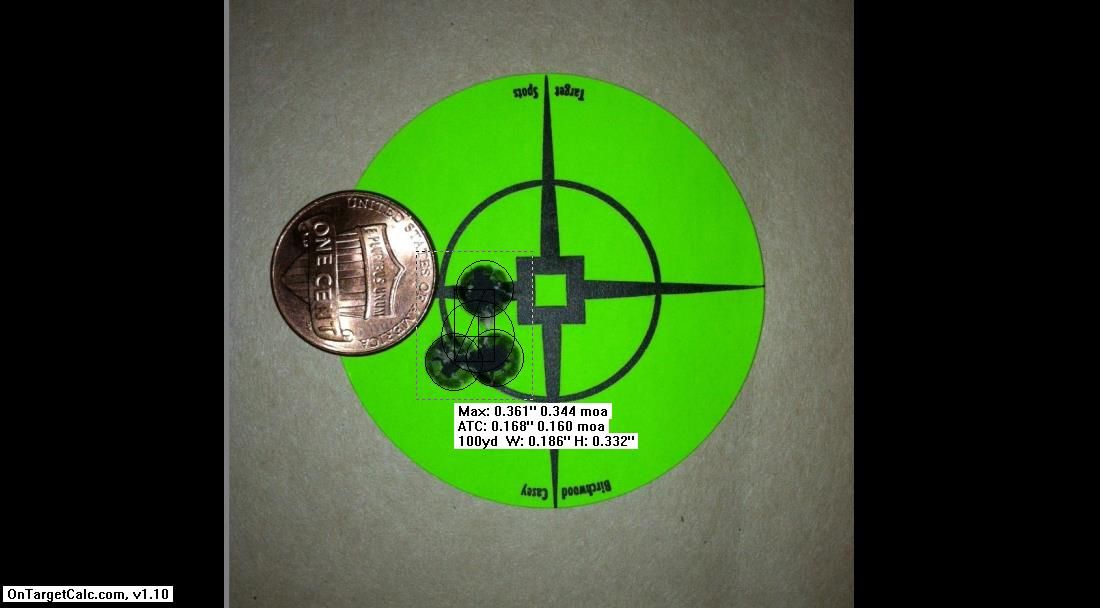

Shots 3-5 @100yds

Shots 6-8 @ 100yds

On Sunday I was able to get out to the farm and stretch things out to 300yds. I just went prone on the ground off the bipod and Accu-shot monopod. Wind was from 3 o'clock at ~12-15mph:

Shots 11-13 @ 300yds (12 & 13 are the two touching)

Also I did a quick 5 round string with the magnetospeed chrono and had an average of 2776fps which is identical to the previous barrel with this load. Overall, I'm very pleased with the Shilen barrel and the Savage LRP.

As for the factory tube my gunsmith is going to chop it ~2”, rechamber for a 6.5 Creedmore, and rethread for a small shank to use for F-class, or mid range applications. I've procured a Savage varmint action (small shank) that utilizes the LRP bottom metal so I can just swap barreled actions out of the LRP stock until my Manners arrives. A rebarreling and a “someday” future project about 18months ahead of schedule due to a bad factory barrel.

However, accuracy wise I have been struggling with my model 12 LRP in .260Rem. I purchased it new in October 2012. It has never been a great shooter, hovering around 1.25MOA with some odd flyers on longer strings once past rounds six or seven. I did some pretty extensive load development and although the 41.8gr H4350 in Lapua brass under a 140gr HPBT may seem a bit "light" to some, it's as high as I could get without worrying about sticky bolt (42.3gr) or stuck bolt (42.7gr).

Overall I REALLY like my Savage LRP, but something has always been nagging me that something isn’t quite correct with it. Fast forward 250 rounds ldownrange and while cleaning it a few weeks ago I noticed that at the muzzle end one of the grooves was extremely fouled by copper (looked like it had been copper plated) while the rest exhibited virtually no copper fouling. I contacted my gunsmith and he asked me to stop by so he could investigate with a borescope.

Aside from a lot of tool marks and chattering throughout the barrel the biggest issue was that the chamber had been reamed off axis relative to the bore. Although I didn’t exactly understand all the technical terms, looking through the bore scope and performing a 360 rotation at the end of the throat it was self evident that something wasn’t correct. In my barrel not all of the lands and grooves ended/started at the same point in the barrel. Some stopped short of the throat while others extended to it or slightly beyond (free bore area?). Anyway in anticipation of returning the barrel to Savage we removed the barrel from the action. Unfortunately according to the Savage customer service representative I spoke with, that action completely voided my warranty. Oops!

Alas all has not been lost as I was able to procure a Shilen select match grade replacement barrel from Jim at Northland Shooter Supply (super nice guy to deal with). During our conversation Jim inquired why I was changing barrels. After informing him of the situation, he stated that this sadly was not the first time he has heard of this issue.

Late last week I received my rifle back from my smith after he installed the shilen barrel and threaded it for my suppressor. I utilized my existing load of 41.8gr H4350 under a 140gr Hornady HPBT. After 2 shots at 50yds to see if the scope needed adjusted (it didn't) I moved out to 100yds:

Shots 3-5 @100yds

Shots 6-8 @ 100yds

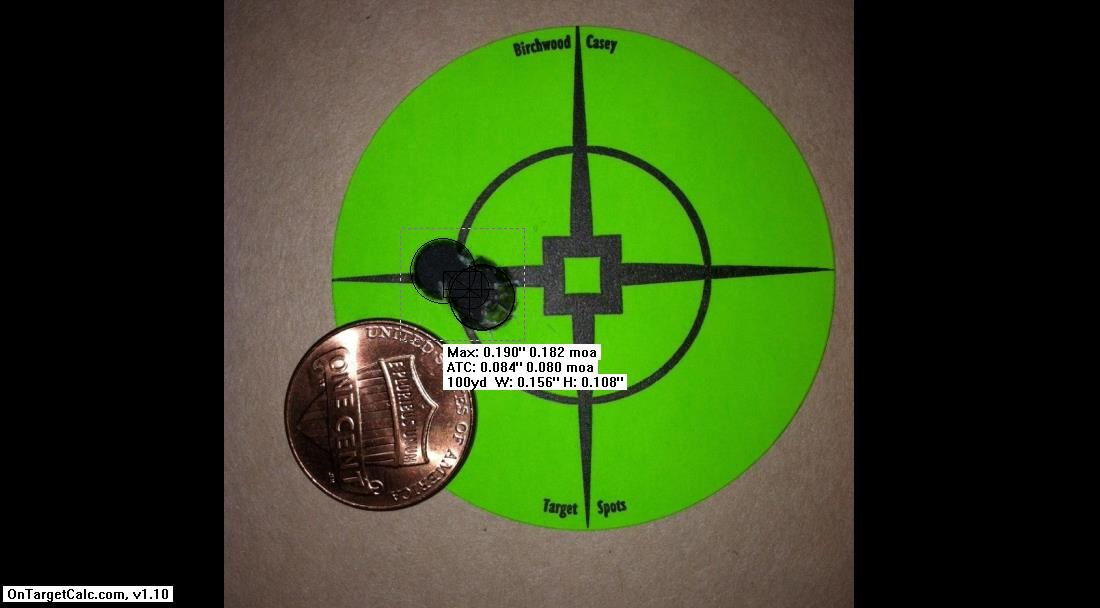

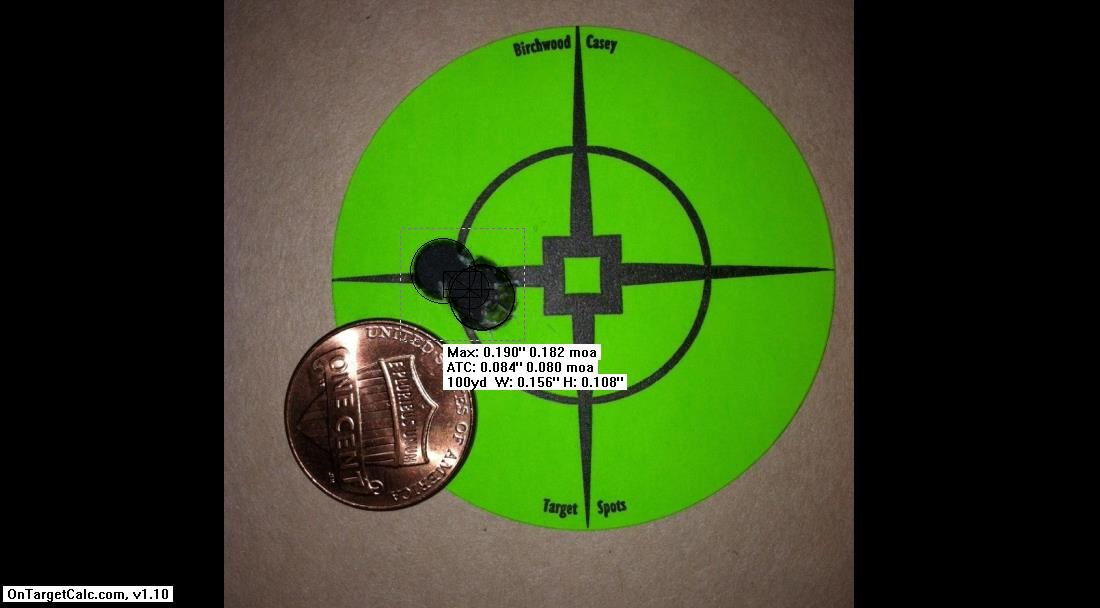

On Sunday I was able to get out to the farm and stretch things out to 300yds. I just went prone on the ground off the bipod and Accu-shot monopod. Wind was from 3 o'clock at ~12-15mph:

Shots 11-13 @ 300yds (12 & 13 are the two touching)

Also I did a quick 5 round string with the magnetospeed chrono and had an average of 2776fps which is identical to the previous barrel with this load. Overall, I'm very pleased with the Shilen barrel and the Savage LRP.

As for the factory tube my gunsmith is going to chop it ~2”, rechamber for a 6.5 Creedmore, and rethread for a small shank to use for F-class, or mid range applications. I've procured a Savage varmint action (small shank) that utilizes the LRP bottom metal so I can just swap barreled actions out of the LRP stock until my Manners arrives. A rebarreling and a “someday” future project about 18months ahead of schedule due to a bad factory barrel.

I had a chance to take the original Savage barrel cutback ~2in and rechambered in 6.5 Creedmoor for a spin this weekend with factory equivelent loads (41.5gr H4350 under a 140gr HPBT).

Unsuppressed

Suppressed with a TBAC-30P-1 (ignore the flyer at 3, I prematurely bumped the trigger getting set)

Not too shabby for a factory tube. Not quite on par with the Shilen replacement, but I think it will work okay. Too bad Savage botched the original chamber job. Alas now I've made two fine toys out of one rifle at the cost of a typical custom rifle build.

Unsuppressed

Suppressed with a TBAC-30P-1 (ignore the flyer at 3, I prematurely bumped the trigger getting set)

Not too shabby for a factory tube. Not quite on par with the Shilen replacement, but I think it will work okay. Too bad Savage botched the original chamber job. Alas now I've made two fine toys out of one rifle at the cost of a typical custom rifle build.

Lrp...incredible

Here is my LRP. This things shoots less than .5 moa all day every day at all distances. It is flat insanely incredible. Load development was an absolute breeze for the most part. It loves 130vld's and 140vld's equally. Almost zero recoil, easy to find components, hornady brass is lasting far beyond 5 loads and it just does everything I ever hopped at 100, 500, or 800 yards. It rings steel nice and loud and I can see splash with it just fine....

* I had major problems with magazine feeding initially and stuck case issues....that aside...the accuracy is out freaking standing. Here is mine:

Here is my LRP. This things shoots less than .5 moa all day every day at all distances. It is flat insanely incredible. Load development was an absolute breeze for the most part. It loves 130vld's and 140vld's equally. Almost zero recoil, easy to find components, hornady brass is lasting far beyond 5 loads and it just does everything I ever hopped at 100, 500, or 800 yards. It rings steel nice and loud and I can see splash with it just fine....

* I had major problems with magazine feeding initially and stuck case issues....that aside...the accuracy is out freaking standing. Here is mine:

Last edited:

I had those same ideas about about building a LRP in 260 but I had a really hard time finding the LRP in 260. I finally settled on a LRP in 243 and figured that I would shoot the barrel out of it and then rebarrel in 260. The really sad thing is that right after the 10 day jail time I found the LRP in 260 but that is how it goes sometime.

After shooting the old style stock for about 200 rounds I was unhappy with the how it felt as I have always been shooting AR's. I went with the Manners T5A and have really liked the way that the stock feels. The group is from last week but it still needs a little work or the shooter needs a little work as I am new to precision shooting.

After shooting the old style stock for about 200 rounds I was unhappy with the how it felt as I have always been shooting AR's. I went with the Manners T5A and have really liked the way that the stock feels. The group is from last week but it still needs a little work or the shooter needs a little work as I am new to precision shooting.

I got one a month or so ago in 6.5 CM. It has the old style stock. I may replace it, but I only have 68 rounds through it and will reserve judgement on the stock for now. It shoots 140 gr AMAX's lights out. Going to the range tomorrow to give it another whirl.

Ken Farrell makes a nice base without a recoil lug for this action. His rings are really nice as well. Here is a shitty cell phone pic but it shows the base and rings with a 56mm objective.

Which base is that exactly? The "round action" or the precision target?

Which base is that exactly? The "round action" or the precision target?

It is the Precision Target Action base.

It is the Precision Target Action base.

Thanks! Got one on order.

I had the chance to get my Savage 12 out on the range over the weekend. WOW, what a great rifle. I was able toproduce sub MOA groups after getting the scope sighted in. I would say the groups were close to .75. Not to bad for a beginner!

Here is a couple of picture

Savage 12 LRP 6.5 Creedmoor

Weaver Tactical 4-20x50 Scope

TPS 1 Piece Steel Scope Base

Weaver Xtreme Tactical Rings

Dark Eagle 10 Round Mag

Caldwell Bipod

Here is a couple of picture

Savage 12 LRP 6.5 Creedmoor

Weaver Tactical 4-20x50 Scope

TPS 1 Piece Steel Scope Base

Weaver Xtreme Tactical Rings

Dark Eagle 10 Round Mag

Caldwell Bipod

Attachments

Similar threads

- Replies

- 3

- Views

- 272

- Replies

- 13

- Views

- 539

- Replies

- 10

- Views

- 904