Re: Lathe and mill suggestions

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: caustic</div><div class="ubbcode-body">From your list the only major prob/expense will be your #4, all other I have covered.

Hay Clark, you have a Precision Matthews right? what do you think about the two models I'm looking at? I read in some older post of yours that your new lathe has gears that take 5min or so to change in order to change speeds, I would not like this in my new lathe , I couldn't find any references to that in these models, although I may have missed it. you had mentioned in that post that I came as a surprise to you do you think the two models I posted earlier would be the same as yours in that way?

</div></div>

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Clark</div><div class="ubbcode-body">October 07, 2009 My Precision Mathews PM1236 requires changing gears, a 5 minute process, to get from fine threads to coarse threads.

That was a rude surprise.

Unfortunately, the dividing line is between 20TPI Rem 700 and 12TPI Mauser.

The same change on my 1938 old Atlas takes 30 minutes.

The same change on my 1967 Clausing 5914 takes 10 seconds.

The same change on my brother's 1999 Jet 13x40 takes 10 seconds.

The Kent, Jet, Precision Mathews, GMC, Birmingham, Harbor Freight, the imported Clausing, etc. all come from the same designs in China. ~ 80% of the parts are interchangeable with the same size machines. </div></div>

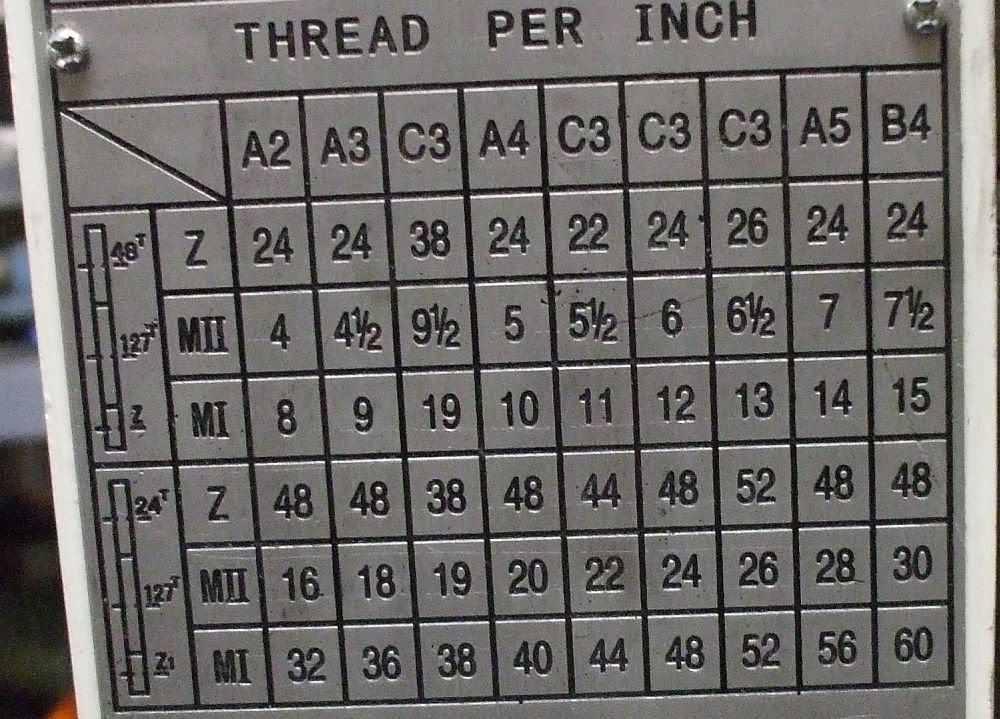

If you look at the thread chart, there are 27 squares with the 48 tooth gear on top. 24 TPI shows up 6 different times, but there are 27 squares.

On the bottom half of the chart there are 27 squares with the Z1 gear [24 tooth] is on top. 48 TPI shows up 6 different times, but there are 27 squares.

The 20 TPI [Rem700] only shows up on the bottom chart.

The 12 TPI [M98 Mauser] only shows up on the top chart.

To change from 20 TPI to 12 TPI, one would have to take the cover off the left side of the lathe by removing the two knurled knobs, loosen the 127 tooth gear hub with a 17mm wrench for front back movement, loosen the nut on the banjo behind the 127 tooth gear with a 17mm wrench for up down movement, remove the 24 tooth gear on top with a 5mm Allen wrench, remove the 48 tooth gear with a 5mm Allen wrench, and swap the gears. Then pull up and forward on the 127 tooth gear with the left hand [so all 3 gears engage nicely] while tightening the 17mm nut on the banjo and then the 17mm nut on the 127 tooth hub.

Then, while pushing the motor jog button, a knob is turned from MK2 position to MK1 position.

Then, while pushing the motor jog button,a knob is turned from A position to C position.

Then, while pushing the motor jog button, a knob is turned from 4 position to 3 position.

<span style="font-weight: bold">

<span style="color: #FF0000">OK, maybe that is not always 5 minutes.</span></span>

If you never did it before, it might take an hour.

Some ace could do it in 20 seconds.

He would still get his left hand dirty when pulling up and forward on the 127 tooth gear covered in grease.

kombayotch just bought a PM1236. I would guess he already knows more about them than I learned in a year of owning one.

But the guy who knows the most is the guy who sold me the PM1236

Matt Nadeja

Quality Machine Tools, LLC

701 Parkway View Dr.

BLDG #7

Pittsburgh, PA 15205

Ph# 412-787-2876

quality machine tools

Email

[email protected]

His company sells and services lathes. They installed the DRO on my lathe.