Hey, not shooting related but you guys are collectively pretty smart, so maybe someone can help me.

I have 50yr old power feeder that feeds wood into a spindle shaper. It is a 1 HP, 220volt, 3 phase unit, made by a German co. Holz that is no longer in business, or if they are, they aren't making power feeders. The manual is in German, very technical German, which I can read (mostly).

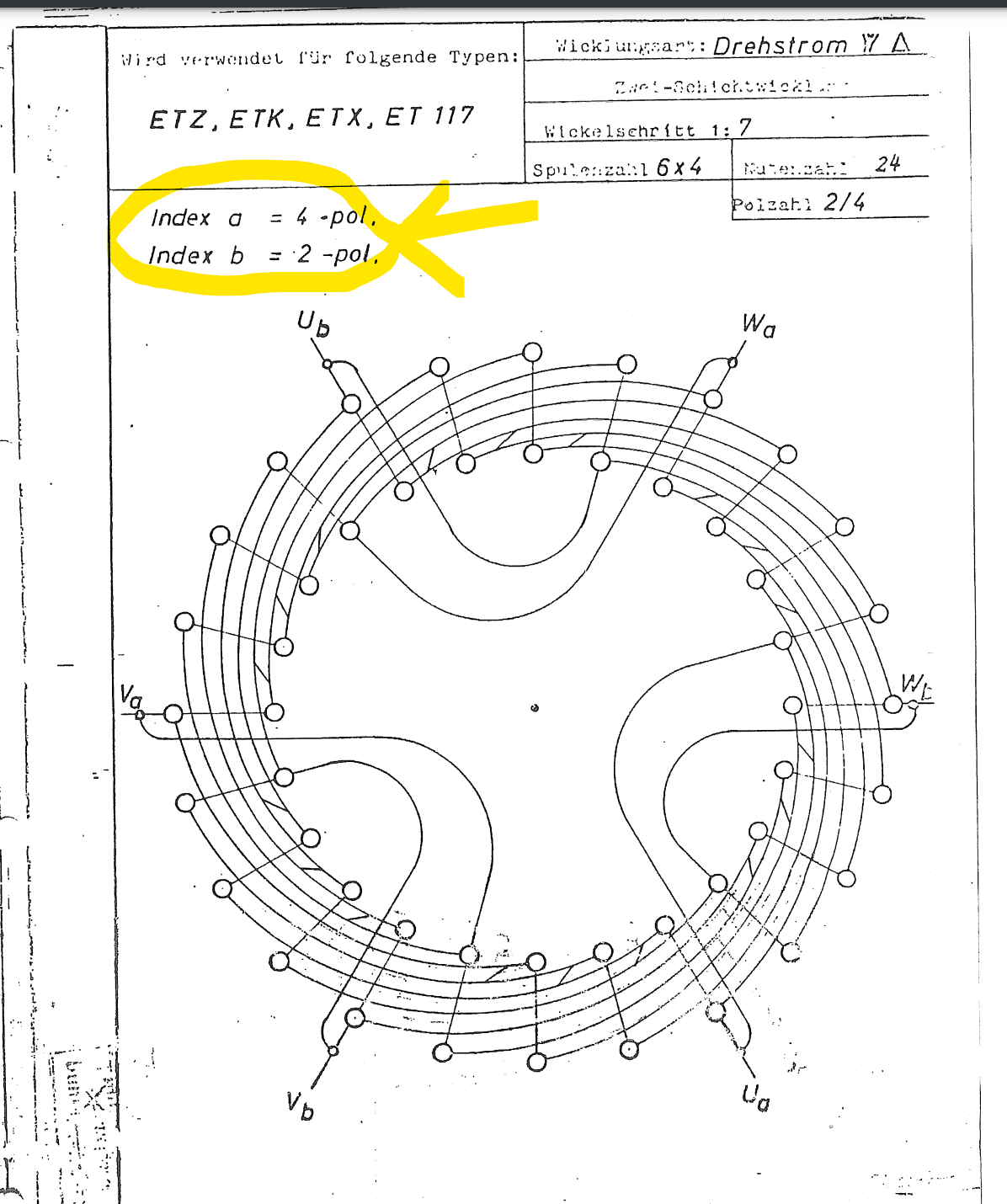

I want to change the poles from 4 to 2, in order to get a slower feed speed. I think the attached diagram explains how to make this switch. Does anyone know if this diagram illustrates this switch, and if so, how would I actually do it (the manual just says to look at this page).

Thanks much, appreciate any input.

I have 50yr old power feeder that feeds wood into a spindle shaper. It is a 1 HP, 220volt, 3 phase unit, made by a German co. Holz that is no longer in business, or if they are, they aren't making power feeders. The manual is in German, very technical German, which I can read (mostly).

I want to change the poles from 4 to 2, in order to get a slower feed speed. I think the attached diagram explains how to make this switch. Does anyone know if this diagram illustrates this switch, and if so, how would I actually do it (the manual just says to look at this page).

Thanks much, appreciate any input.