I don’t know where in the build process black oxide finish was. Skunk, I wonder if you have two take-offs and two that were never assembled (and hence never oxided?

Why the pictures show an unfinished lug I can only conjecture, but my guess is this.

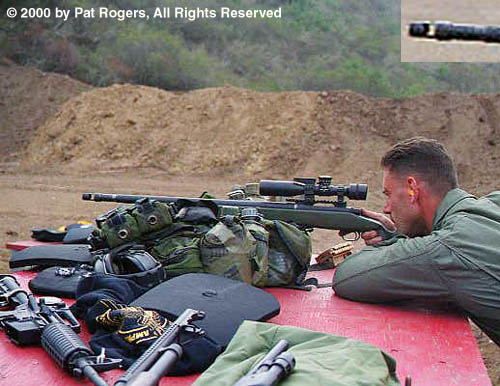

The pictures show that it’s being tested with a recon battalion (or at least the shooter is). Recon BN’s have 2112’s, though non-deployed work on a sniper rifle is very uncommon, it would normally just go back to PWS. Since this is a unit level modification, I’d say they spun the barrel off, reprofiled it, and used a replacement lug for whatever reason when they put it back on.

That doesn’t explain why the reprofiled section isn’t in the white either though, it would seem odd to refinish it and not a lug. Maybe it walked away mid modification? Unusual but not impossible.

The unfinished and polished part of a barrel profile usually involves an over the barrel silencer, such as the Mk11 silencer on the Mk13 sniper rifles. It's much easier to clean up the carbon and junk off a polished barrel vs finished barrel.

The Ops Inc silencers also go over the barrel, but their .22 cal. 12th Model that's used on all the rifles in the Mk12 series have always gone over a finished barrel (no polishing under the silencer). The USMC M14 DMR rifles with Ops Inc silencers (probably the same type that's seen on the prototype M40A3's) didn't have polished barrels either. Look at the photos below, it's just like the Mk12's that also use Ops Inc silencers, they all have fully finished barrels.

In the A3 photos, the rest of the barrel is black oxide finished, but only a small part under the silencer (right before the barrel taper that plugs the rear of the silencer) is shiny. But, it's only that small area that's shiny, not the entire area under the silencer. That black under the silencer might not be carbon build up on an unfinished part of the barrel, it could all be black oxided and the shiny area is just where the silencer is rubbing on the barrel finish and bits of carbon (carbon build-up can polish to the point that it's a little shiny). The silencer is constantly removed and attached during testing (back and forth, and spinning), so it's reasonable that the shiny part is wear from the silencer constantly rubbing on that spot. That's the Occam's Razor explanation.

The other explanation would be to black oxide the barrel, put it on the lathe, spin it up and remove the finish on the part of the barrel under the silencer, polish that area so that it's easier to clean carbon off it, mount the barrel to the receiver, shoot the A3 with the silencer on and let the carbon junk build up, remove the silencer, take a photo of the rifle without the silencer, fast forward 10 something years and post photo on the internet, have guys on Sniper's Hide examine a very low quality grainy photograph and come up with crazy explanations for why the barrel is shiny in only a certain spot while the rest of the barrel is black oxide, profit.

To me, the first explanation is more plausible, but I'm just speculating on this, so no one should just assume that my explanation is the correct one without further research! That's extremely important when it comes to speculations, it's just the best guess that I can give without further information. No more, no less. And this also applies to the recoil lug comments in the following paragraph below.

The recoil lug is probably in the white because it's a USMC just made the piece, and they might be testing different thicknesses or something like that. It's not a crucial part that needs to be finished, so just put it on the rifle as is instead of waiting to use the blueing tanks. I have a few original USMC recoil lugs, and one of them is a lot thicker than the normal A3/A5 recoil lugs! It could also be a prototype titanium or aluminum (the pre-Mk13's used a prototype aluminum "L" shaped recoil lug, but those lugs were anodized black) recoil lug, since the Marines also experimented with reduced weight parts in order to reduce the overall weight of the rifle. This is especially important if you're adding weight to the weapon (the silencer), but want to stay the same weight as a regular production A3. Badger Ordnance even submitted 5 or less prototype aluminum scope bases to PWS for testing. I actually have one of the prototype aluminum A3 scope bases that wasn't sent to PWS (Marty gave it to me long ago) in my collection.

So, I have absolutely no idea why the recoil lug in the photos is in the white, but I can speculate on it all day long! Maybe one of these thoughts is correct, or maybe they're all wrong. Again, we need further information for verification, so please don't take anything in my post as the actual explanation.

web.archive.org

web.archive.org