Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New press announcement from Area 419

- Thread starter Olen_4504

- Start date

What is on backorder that has been there a while? Other than the Chargemaster Lite tray and some CZ builds, we have recycled inventory on everything we make.I just wish their other products would get off backorder!

Fellas - been a bit since I jumped on.

Second batch: Initial goal had been to ship around Thanksgiving. Looks like it'll be the week of 12/7, plenty of time to get them under your Christmas trees. I expect the batch will be fully sold out in the next few days.

Third batch: Guessing mid-Feb with our coming shop move.

Black Friday: Everything we have/make will go on sale at some point, except for Zero/turrets/stands/etc. Until we can make enough of these to have them on the shelf, you won't see a sale. That may be summer.

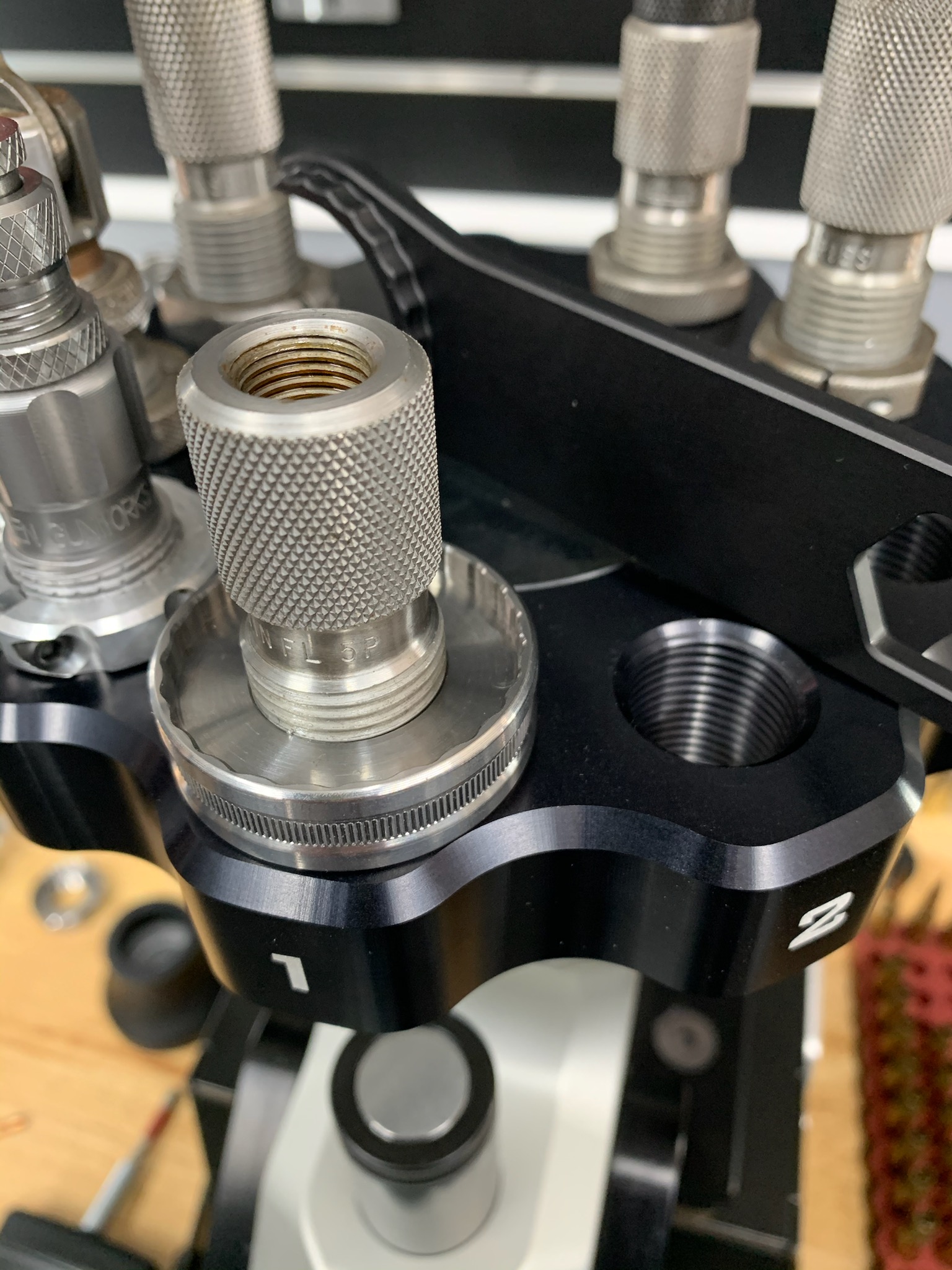

Love seeing all the pics and reviews! Let me know if you all have questions, and I look forward to rolling out some cool new stuff over the next few months. I'll leave you with a first look at the next accessory - lock rings. Tons of surface contact to square your dies, extra thread contact, better wrench interface, no grub screw or split to tilt or skew your die - you'll dig them. Will have them on the site in the next few days. We sent a bunch to nitride this week.

Second batch: Initial goal had been to ship around Thanksgiving. Looks like it'll be the week of 12/7, plenty of time to get them under your Christmas trees. I expect the batch will be fully sold out in the next few days.

Third batch: Guessing mid-Feb with our coming shop move.

Black Friday: Everything we have/make will go on sale at some point, except for Zero/turrets/stands/etc. Until we can make enough of these to have them on the shelf, you won't see a sale. That may be summer.

Love seeing all the pics and reviews! Let me know if you all have questions, and I look forward to rolling out some cool new stuff over the next few months. I'll leave you with a first look at the next accessory - lock rings. Tons of surface contact to square your dies, extra thread contact, better wrench interface, no grub screw or split to tilt or skew your die - you'll dig them. Will have them on the site in the next few days. We sent a bunch to nitride this week.

What is on backorder that has been there a while? Other than the Chargemaster Lite tray and some CZ builds, we have recycled inventory on everything we make.

Yes, been looking to get a powder cup for my Chargemaster Lite. Been out of stock for a few months, now. Just my luck to be one of the last items still unavailable... (And whichever checkout line I get into at the store will always be the slowest!)

Promise we are actively working on those - making some fitment changes and getting them back into full production.Yes, been looking to get a powder cup for my Chargemaster Lite. Been out of stock for a few months, now. Just my luck to be one of the last items still unavailable... (And whichever checkout line I get into at the store will always be the slowest!)

Promise we are actively working on those - making some fitment changes and getting them back into full production.

Appreciate the follow up!

Fellas - been a bit since I jumped on.

Second batch: Initial goal had been to ship around Thanksgiving. Looks like it'll be the week of 12/7, plenty of time to get them under your Christmas trees. I expect the batch will be fully sold out in the next few days.

Third batch: Guessing mid-Feb with our coming shop move.

Black Friday: Everything we have/make will go on sale at some point, except for Zero/turrets/stands/etc. Until we can make enough of these to have them on the shelf, you won't see a sale. That may be summer.

Love seeing all the pics and reviews! Let me know if you all have questions, and I look forward to rolling out some cool new stuff over the next few months. I'll leave you with a first look at the next accessory - lock rings. Tons of surface contact to square your dies, extra thread contact, better wrench interface, no grub screw or split to tilt or skew your die - you'll dig them. Will have them on the site in the next few days. We sent a bunch to nitride this week. View attachment 7478442

I sent you guys a message a few months back about die rings, this should be on everyone's list. I stoned a bunch of rings and it was very obvious pretty much none of them are flat.

How do those tighten? I'm in for 18 at least.

I sent you guys a message a few months back about die rings, this should be on everyone's list. I stoned a bunch of rings and it was very obvious pretty much none of them are flat.

How do those tighten? I'm in for 18 at least.

The scalloped shape on the inside of the top edge (if that makes ANY sense at all) - we have a wrench to fit. Think about it as being an open-ended torx wrench? That way you're not competing against other dies to grab the ring to tighten/loosen.

Never thought I'd spend $100 for a powder funnel either but that 419 powder funnel is awesome. Well worth it.

Quick review:

I finally got enough brass prepped to load some .223 and will be doing 6.5 CM tomorrow. I'll keep it short and just say it works as advertised which is great. The ram stroke is very smooth and precise. It gives very good feedback and I could tell the difference when full length sizing between brass that needed setback as opposed to brass that needed little to no setback. I really like the turret system which makes it super easy to switch between different operations and calibers. I just finished seating some .223 bullets for a ladder test and checked runout on all 18 of them. The worst runout was .00075 on 3 rounds. The rest were at or under .0005. Very happy with this press!

I finally got enough brass prepped to load some .223 and will be doing 6.5 CM tomorrow. I'll keep it short and just say it works as advertised which is great. The ram stroke is very smooth and precise. It gives very good feedback and I could tell the difference when full length sizing between brass that needed setback as opposed to brass that needed little to no setback. I really like the turret system which makes it super easy to switch between different operations and calibers. I just finished seating some .223 bullets for a ladder test and checked runout on all 18 of them. The worst runout was .00075 on 3 rounds. The rest were at or under .0005. Very happy with this press!

@flyer1a any idea when Brownells will carry the Zero in stock? I'm currently on a backorder. Would have bought directly from you guys but I had an opportunity to use a $500 gift certificate I won off a prize table this past summer.

I will certainly buy all the accessories off you guys! Looking forward to the lock rings, too!

I will certainly buy all the accessories off you guys! Looking forward to the lock rings, too!

I logged in to buy a zero press and they are sold out. Don’t really wanna wait till February. If anybody has one they would like to part with, cancel your order, please let me know.

Thanks,

Nick

Thanks,

Nick

I’d like to see a kit that has:

Thread insert that blanks off one of the turret spots

Adapter for ram that holds the Wilson seater base

Short handle that provides better feel

This would basically turn the press into an inverted arbor press. You raise the chamber seating die up into the blanked turret spots, instead of lowering the arbor head.

I was thinking the same thing about branking off one of the turret spots so that a Wilson type seater could be used on a standard press. While I'm waiting for my Zero to ship I decided to make my own. I stopped by my local bolt and screw shop and picked up a Grade 8 7/8-14 socket head cap screw and a couple of nuts. The face of the screw is quite rough so I used a square to make sure my belt sander table was true and used the two nut as a jig to face off the bolt to a nice flat surface. This worked out really nice. Now that it's done I'm wondering if there is enough space on the press to fit the Wilson seater. I don't own a Wilson seater yet, does any one know how tall they are?

I don't own a L.E Wilson Die to measure. I would think you would need the Hybrid Turret head to make this work.

From bullet seating plate to bottom of Turret is 4 3/4" (Again not sure of the length of Wilson die.) You would need to go up in the turret a bit.

Let me know w hat you guys think I am interested in this idea.

Thank you

Joseph

From bullet seating plate to bottom of Turret is 4 3/4" (Again not sure of the length of Wilson die.) You would need to go up in the turret a bit.

Let me know w hat you guys think I am interested in this idea.

Thank you

Joseph

Attachments

I’m running 6.5 creed with burger 140 hybridsI have a bunch of Wilson seating dies. I cut all of them from their blank. Lengths vary depending on case length. Which cartridge are you planning on using?

I have a bunch of Wilson seating dies. I cut all of them from their blank. Lengths vary depending on case length. Which cartridge are you planning on using?

Same 6.5 CM 140 Berger hybrids

Last edited:

I’m running 6.5 creed with burger 140 hybrids

What’s the height of your seating stem with an unseated bullet in the Wilson die?

The OAL of my Creed seating die is 4.357" using the Sinclair micrometer top. It will be longer or shorter depending on how high the top is seat.

Thank you

HA, wish I knew. I don’t have a Wilson die yet. Was hoping someone could give me that dimension so I could determine if this would work or not.What’s the height of your seating stem with an unseated bullet in the Wilson die?

To get any feel I would think it would need to go up in the Turret. I'm sure something could be made to fit the Hybrid turret.

And again it would also depend on the width of the Die as well.

There’s also an option of making an adapter that lets you mount a digital force gauge. No feeling needed.

The OAL of my 6 Creed seating die is 4.357" using the Sinclair micrometer top. It will be longer or shorter depending on how high the top is seat.

Can you tell me What the width of the 6.5CM L.E wilson Seating Die?

Thank you

Joseph

There’s also an option of making an adapter that lets you mount a digital force gauge. No feeling needed.

I might have figured a easy way to do this

Get a 1 1/4 Lee collet die take everything out except the cap and I think that might work

I have A set from an old rifle. it gives you an additional 3.25" to play with. internal diameter 1.0" so if the Wilson die will go up in there you go.

I don't have a hybrid turret or a Wilson die.

Attachments

A Wilson seater or a Zero press?Anyone looking for one in DFW, I saw one for sale at Scheels in The Colony sitting there on the shelf the other day

@flyer1a any idea when Brownells will carry the Zero in stock? I'm currently on a backorder. Would have bought directly from you guys but I had an opportunity to use a $500 gift certificate I won off a prize table this past summer.

I will certainly buy all the accessories off you guys! Looking forward to the lock rings, too!

Brownells has a pallet of them ordered in the batch we are about to ship, should be a good opportunity. Also, Scheels likely has a few in stock, but I don't know which stores has them left.

This whole arbor seater is something we very well may make, just a matter of getting time on machines. Once we move, this will be easier as we are buying a pile of new CNCs. If someone has to have one in the meantime, I think it would work with any of the heads, just make sure your surface on the underside doesn't exceed 1.25" OD or it wont be able to rotate with the turret head through the channel in the rear.

Also, if you're making something, remember that the threads are Class 2 - we don't like it but that's industry standard for dies.

Also, if you're making something, remember that the threads are Class 2 - we don't like it but that's industry standard for dies.

Happy dance ensues...Brownells has a pallet of them ordered in the batch we are about to ship, should be a good opportunity. Also, Scheels likely has a few in stock, but I don't know which stores has them left.

This whole arbor seater is something we very well may make, just a matter of getting time on machines. Once we move, this will be easier as we are buying a pile of new CNCs. If someone has to have one in the meantime, I think it would work with any of the heads, just make sure your surface on the underside doesn't exceed 1.25" OD or it wont be able to rotate with the turret head through the channel in the rear.

Also, if you're making something, remember that the threads are Class 2 - we don't like it but that's industry standard for dies.

If you can mad something (might need it’s own head) with a digital force gauge like this, would be cool.

Expensive......but I don’t think anyone with this press is intimidated by price for good shit.

Who makes this unit?If you can mad something (might need it’s own head) with a digital force gauge like this, would be cool.

Expensive......but I don’t think anyone with this press is intimidated by price for good shit.

View attachment 7485386

The major problem with simple putting a load cell in a press (or the arbors with needles) is the basic premise of Force = Mass X Speed. This is why the unit you show and the AMP seating unit have automated press function, as it makes the speed constant. On a manual press like the ZERO any variation in how fast you pull the handle will create variation in the force number. I think it would turn into selling an expensive part that doesn't give consistent function, and we don't like doing that.If you can mad something (might need it’s own head) with a digital force gauge like this, would be cool.

Expensive......but I don’t think anyone with this press is intimidated by price for good shit.

View attachment 7485386

The major problem with simple putting a load cell in a press (or the arbors with needles) is the basic premise of Force = Mass X Speed. This is why the unit you show and the AMP seating unit have automated press function, as it makes the speed constant. On a manual press like the ZERO any variation in how fast you pull the handle will create variation in the force number. I think it would turn into selling an expensive part that doesn't give consistent function, and we don't like doing that.

Ya, the user wouldn’t be able to go nuts.

Also the one I linked is manual. But it’s built in a way that you’d have to go nuts to affect it via speed.

New reloader, and all I've done so far is deprime, clean and size. 308 Win was fine, but I deprimed about over a thousand cases of 300BLK the other day and I would say about seventy-five to a hundred primers failed to make the transition from the ram, to the body, into the tray. They fell landing on the back side of the ram. Was like they didn't have enough ass to roll across the transition. Was using a Lee decapping die.

Anybody else with similar issues when doing small rifle primers?

Also, clean the primer tray often. Pain in the ass to get the primers out of the slot if they fall out when it's over full.

Anybody else with similar issues when doing small rifle primers?

Also, clean the primer tray often. Pain in the ass to get the primers out of the slot if they fall out when it's over full.

Your decapping die may have to be raised up a bit. I had the same thing w/ some BR brass. I think the pin holds the spent primer in the chute if it's set too long.New reloader, and all I've done so far is deprime, clean and size. 308 Win was fine, but I deprimed about over a thousand cases of 300BLK the other day and I would say about seventy-five to a hundred primers failed to make the transition from the ram, to the body, into the tray. They fell landing on the back side of the ram. Was like they didn't have enough ass to roll across the transition. Was using a Lee decapping die.

Anybody else with similar issues when doing small rifle primers?

Also, clean the primer tray often. Pain in the ass to get the primers out of the slot if they fall out when it's over full.

Set your decapper up just like a sizing die. Ram to the top, screw in the die until contact, lower the ram, thread in the die another 1/8-1/4 turn, tighten the lock ring. A few other guys have had the same issue, this has solved it for each of them.New reloader, and all I've done so far is deprime, clean and size. 308 Win was fine, but I deprimed about over a thousand cases of 300BLK the other day and I would say about seventy-five to a hundred primers failed to make the transition from the ram, to the body, into the tray. They fell landing on the back side of the ram. Was like they didn't have enough ass to roll across the transition. Was using a Lee decapping die.

Anybody else with similar issues when doing small rifle primers?

Also, clean the primer tray often. Pain in the ass to get the primers out of the slot if they fall out when it's over full.

Set your decapper up just like a sizing die. Ram to the top, screw in the die until contact, lower the ram, thread in the die another 1/8-1/4 turn, tighten the lock ring. A few other guys have had the same issue, this has solved it for each of them.

I have tried that, but it didn't exactly solve it. I have 223 to do yet, but not a whole lot compared to what I had in 300BLK.

I'm going to try what kindabitey suggested. It may work. I had some primers that felt like they didn't come out all the way so I couldn't pull the case out. Wondering if the primer held onto the pin and it seated it back in place somewhat. Maybe it's the pin? Going to keep playing with it. I must have messed with the decapping pin a dozen times. Was driving me crazy till I said screw it and decided I would deal with the mess after.

I have tried that, but it didn't exactly solve it. I have 223 to do yet, but not a whole lot compared to what I had in 300BLK.

I'm going to try what kindabitey suggested. It may work. I had some primers that felt like they didn't come out all the way so I couldn't pull the case out. Wondering if the primer held onto the pin and it seated it back in place somewhat. Maybe it's the pin? Going to keep playing with it. I must have messed with the decapping pin a dozen times. Was driving me crazy till I said screw it and decided I would deal with the mess after.

Your primers are probably sticking to the decapping pin and pulling back into the brass. That would also account for the timing of the falling primer being out of time with the moving ram and primer chute. On other presses such as Dillon progressives, a solution is to cut an angle on the tip of of the decapping pin.

Are you using a universal decapping die?

Yes, Lee Universal.

Your primers are probably sticking to the decapping pin and pulling back into the brass. That would also account for the timing of the falling primer being out of time with the moving ram and primer chute. On other presses such as Dillon progressives, a solution is to cut an angle on the tip of of the decapping pin.

I have a couple spare pins, I'll take one to work and put a 45 on it and smooth it out.

Fellas - been a bit since I jumped on.

Second batch: Initial goal had been to ship around Thanksgiving. Looks like it'll be the week of 12/7, plenty of time to get them under your Christmas trees. I expect the batch will be fully sold out in the next few days.

Third batch: Guessing mid-Feb with our coming shop move.

Black Friday: Everything we have/make will go on sale at some point, except for Zero/turrets/stands/etc. Until we can make enough of these to have them on the shelf, you won't see a sale. That may be summer.

Love seeing all the pics and reviews! Let me know if you all have questions, and I look forward to rolling out some cool new stuff over the next few months. I'll leave you with a first look at the next accessory - lock rings. Tons of surface contact to square your dies, extra thread contact, better wrench interface, no grub screw or split to tilt or skew your die - you'll dig them. Will have them on the site in the next few days. We sent a bunch to nitride this week. View attachment 7478442

When are these going to be available?

When are these going to be available?

We are going to wait to post these until they are back from Nitride. With things crazy as they are, we aren't making any moves to get ahead of ourselves. I'd expect them soon, and in time to have them under your christmas tree. Just make sure your wife doesn't open them with the Amazon packages

I'm not a fan of Gavintube but there is a good interview with Craig Arnzen about the Zero Press. Gavin doesn't do much talking which is probably why the interview was good. Craig briefly touches on some of the issues with other presses A419 sought to eliminate with the new press.

Similar threads

- Replies

- 3

- Views

- 158

- Replies

- 2

- Views

- 221

- Replies

- 0

- Views

- 86

- Replies

- 6

- Views

- 862