Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

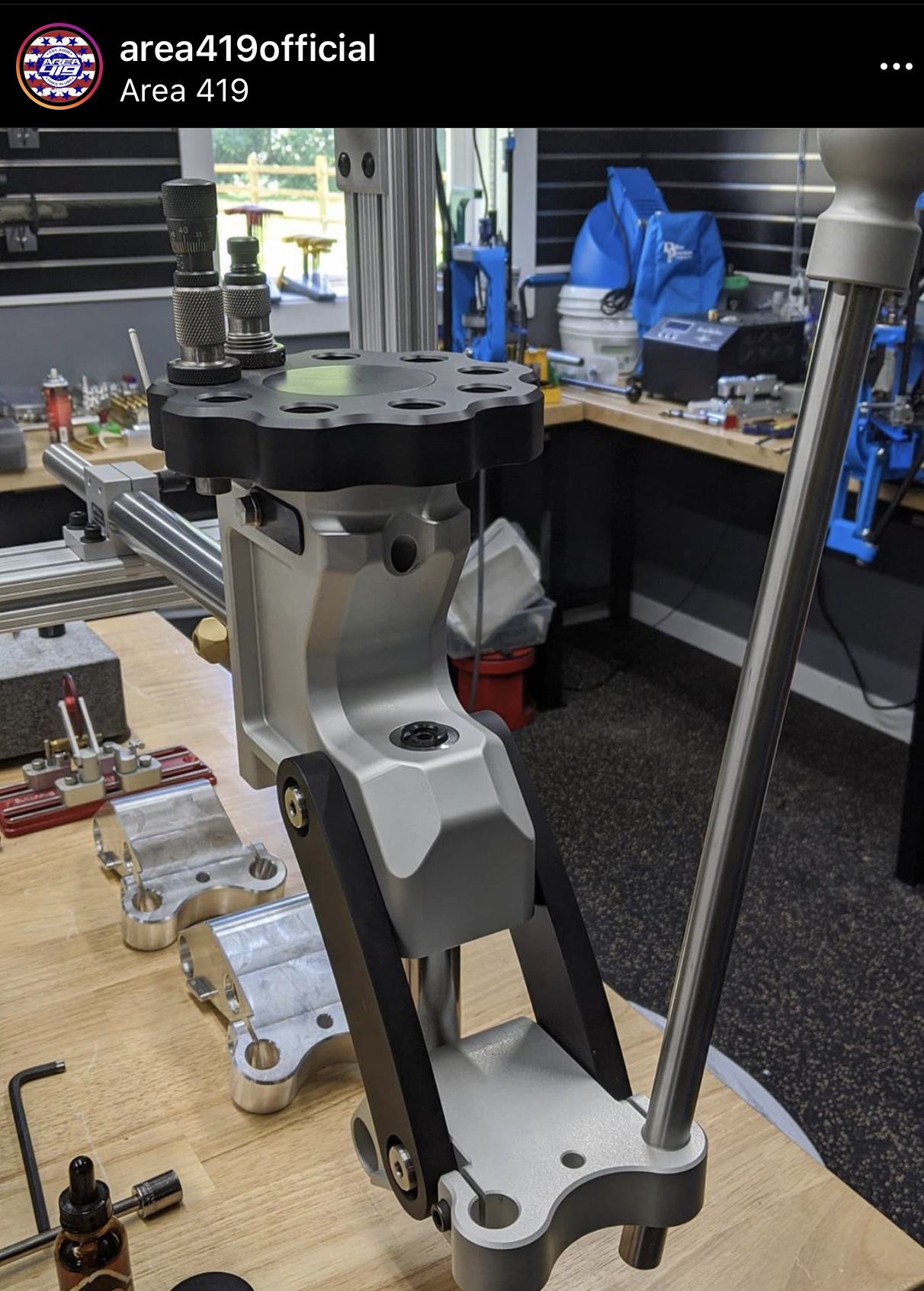

New press announcement from Area 419

- Thread starter Olen_4504

- Start date

I reload 308 sometimes but mostly 6.5 creedmoor. Is that the reason why? 6.5 creedmoor more node sensitive ?I do drop powder thru a funnel on about 3/4 of them usingan auto throw/ trickler. But it's no coincidence I chose 6GT and 6BR for full progressive with a bullet feeder and press mounted powder measure. 6BR is a small enough case to use 8208 which is probably the best temp stable stick powder to try to drop. I'm using a Redding BR30 mounted on a Dillon powder die. And the 6BR is the most likely to have a wide generous flat node that will mitigate less than super accurate, trickled to the kernel charges. And 6GT for the possibility of using staball.

Yes I agree with that. Different variable have exponential impacts on the projective the further out you go.Its a lot easier to lay down .3's at a hundred than it is to shoot 1" or less at 300. Even though mathematically it should be.

Yes I agree with that. Different variable have exponential impacts on the projective the further out you go.

Interesting. I'm loading starling small primer. Match king 150 gr with 40gr of vihtavauri N160 powder. I get 1 inch groups at 300 but I have to single stage load from what I've experienced. Interesting. Non the less I really think this Area419 Zero press with really put the cherry on top as far as my reloading equipment goes.

You can have big variances of powder charges and make bugholes provided your not shooting a 1000 yards.

Look at all the BR records made with thrown charges.

This. Group size is not affected by powder until you stretch out distance.

Very interesting. I've heard this from another well known die maker as well. So you're saying as long as your with in the favorable node you'll have minimal poi shift even if you powder charge varies and your bullet consentricity isn't optimal.

Ya i don't think Swiss watch ammo producing is for everyone. I know alot of ppl just enjoy producing perfect ammo even though its not necessary to be accurate. I know I enjoy being in my reloadong rooms and having my mind there 100 percent trying to make all my ammo the same the best I can and double checking everything for my long range stuff. When I load for pistol on my mark 7 I'm not all there and wish I baught the auto drive lol. Just me I guess.

Ya i don't think Swiss watch ammo producing is for everyone. I know alot of ppl just enjoy producing perfect ammo even though its not necessary to be accurate. I know I enjoy being in my reloadong rooms and having my mind there 100 percent trying to make all my ammo the same the best I can and double checking everything for my long range stuff. When I load for pistol on my mark 7 I'm not all there and wish I baught the auto drive lol. Just me I guess.

SimpleThen whats the point of load development at shorter distances?

I look for a velocity and/or a ES node.

Anymore all my load development is in two methods.

1-Good groups for my short range guns(AR) ES be damned.

2-stable Speed node with excellent vertical and tune with jump if needed for My 260 and 7 saum.

Anymore with good bullets and barrels I really don’t even bother looking at groups on paper.

My current 260 hasn’t punched a hole in paper yet and it’s probably getting pretty close to death.

If I had lots of $$$$ I’d almost certainly buy the 419 press....he said ironically on a thread for a $1200 press....

I like their stuff

Well I still happily run a lee Classic turret so it’s definitely an upgrade.I would buy it if I cared about single stage presses. But maybe in a year I will, and do.

The funnel is awesome, certainly all that bling isn’t needed but they work excellent and are super stable.I have a feeling you both would enjoy and wouldnt regret the press. I've always been impressed with there stuff.

I am not going to hold my breath. We don’t see a lot of high quality, statistically valid research in the gun world, partly because it’s expensive, difficult, and the skill set is rare. I have yet to see a bad product from Area 419 and I’m sure this will be worth it in the sense of being finely made and a joy to use. I may even sell my Prazipress and buy one.I'm looking forward to the empirical and quantifiable reviews.

But I’d be surprised if anyone could show a difference at the target. It’s conceivable it could happen when they introduce their dies and shell holders later on, but considering people are already getting to 0.1 MOA with normal presses, I’d be surprised.

It’s not everything but I’d be happy with atleast this kind of review / level of data measurement:

ultimatereloader.com

ultimatereloader.com

Fourteen Reloading Presses Compared: Single-Stage Shootout – Ultimate Reloader

ultimatereloader.com

ultimatereloader.com

At the risk of derailing this thread even further/again, I’ll say it’s obvious those that are balking at the price have never invested hundreds of thousands of dollars into a single machine, tens of thousands into software to program said machine plus yearly software maintenance fees, or $80,000 in tooling and fixturing to use in the machine for the sole purpose of producing something for a market, much less have the skills to use any of it. It’s simply ignorance of what’s involved in undertaking such a task. There’s an old quote that comes to mind. “Sometimes it’s better to keep your mouth shut and only appear stupid, than to open it and remove all doubt.” It’s perfectly fine to not want to buy this press. It’s completely something else to post about it being too expensive out of sheer ignorance.

Many on this site do know what it takes to conceptualize, create, and produce such items. They’re the ones not commenting, or commenting that they want one. I want one.

Many on this site do know what it takes to conceptualize, create, and produce such items. They’re the ones not commenting, or commenting that they want one. I want one.

I'm interested to know how you load .3 moa ammo on a progressive. Thats impressive. I think biggest variance would be in the powder drops. Whats your secret?

Some people still manually weigh and drop the powder while using progressive presses when the goal is precision. There are little adapters you can buy to use an Area419 funnel on a Dillon powder drop die.

I have a Mark 7 Evo and was debating whether or not to get the .308 shell plate + another tool head + case feeder parts to try to load 6 Dasher on it, but it comes out to about $600.

I went ahead and ordered the Area419 since it's not that much more and I can leave it setup 24/7 and not need to swap anything on the Mark 7 Evo. I figure that if I was going to manually weigh & drop on the progressive it wouldn't be much faster than on this single stage anyway... and I already bought the FX120i scale and auto trickler stuff. Might as well complete the package with a nice precision-focused single stage, I guess.

I may still get the parts to do it on the Mark 7 Evo eventually anyway. Could make for an interesting comparison.

At the risk of derailing this thread even further/again, I’ll say it’s obvious those that are balking at the price have never invested hundreds of thousands of dollars into a single machine, tens of thousands into software to program said machine plus yearly software maintenance fees, or $80,000 in tooling and fixturing to use in the machine for the sole purpose of producing something for a market, much less have the skills to use any of it. It’s simply ignorance of what’s involved in undertaking such a task. There’s an old quote that comes to mind. “Sometimes it’s better to keep your mouth shut and only appear stupid, than to open it and remove all doubt.” It’s perfectly fine to not want to buy this press. It’s completely something else to post about it being too expensive out of sheer ignorance.

Many on this site do know what it takes to conceptualize, create, and produce such items. They’re the ones not commenting, or commenting that they want one. I want one.

Area419 uses some pretty serious Haas Automation 5-axis CNC machines. They post a lot of machining work videos on Instagram. $$$$$$$$

Well, I mean.... you still have to stop each time, weigh/throw a charge, walk back over and drop it through the funnel, etc., right? I mean, I guess it's a bit faster, but you're not using the progressive to its full potential like you would be when cranking out 9mm or .223.

Mount a Prometheus to the top of a progressive. That'll solve your powder problem.

Quite a few people have done it. It's not nearly as bad as all that.That would be wonderful, but for some reason this is how I imagine it actually working out in my head....

I load really accurate and precise ammo with a Chargemaster 1500, and a Rockchucker. That doesn’t mean I don’t want a Prometheus and a Zero press.

I do appreciate the efficiency factory that loading on a progressive offers, and have nothing against doing that, but I do rather enjoy my time at the reloading bench. I normally throw on the latest Everyday Sniper podcast and crank out sub moa ammo.

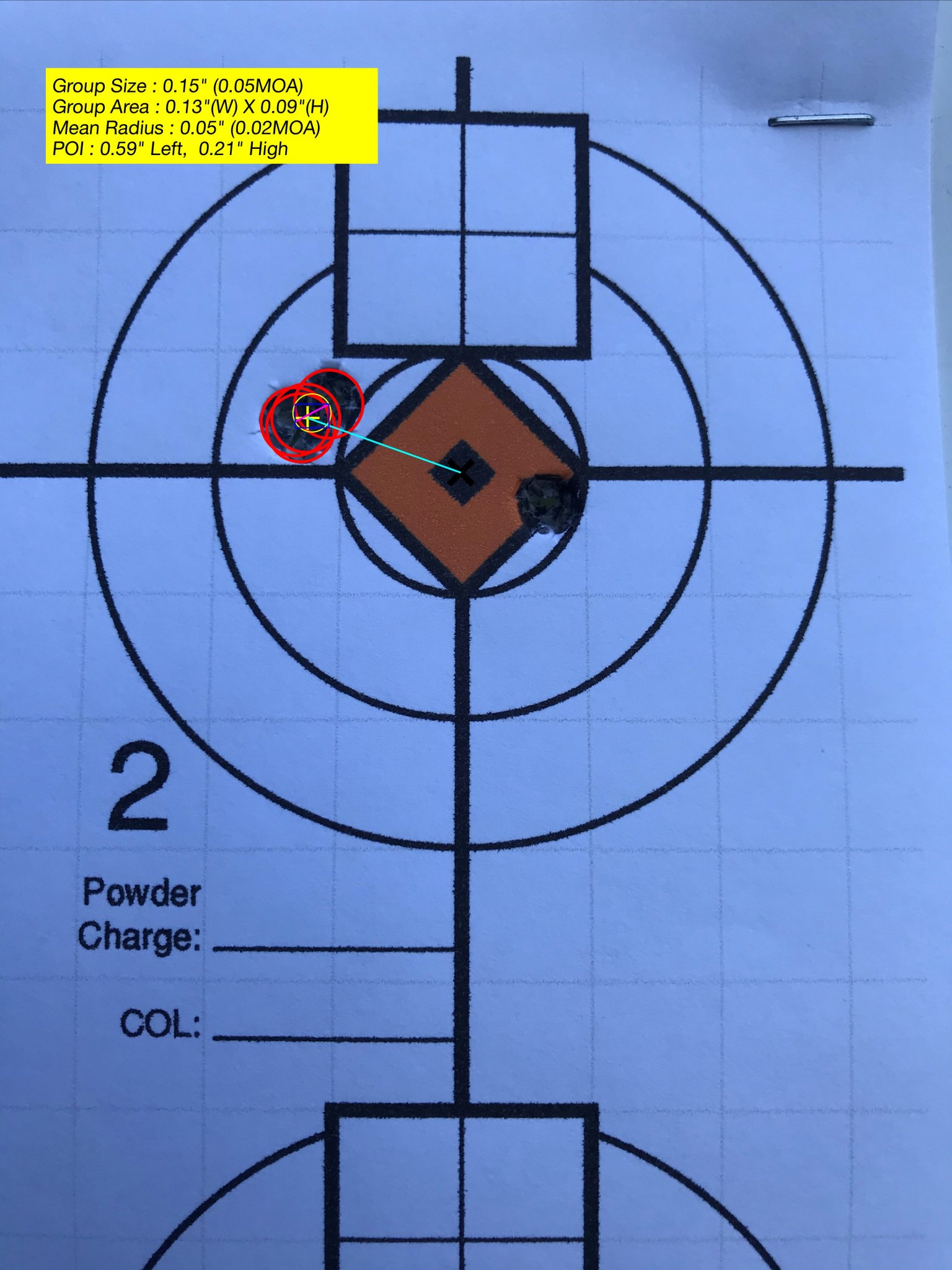

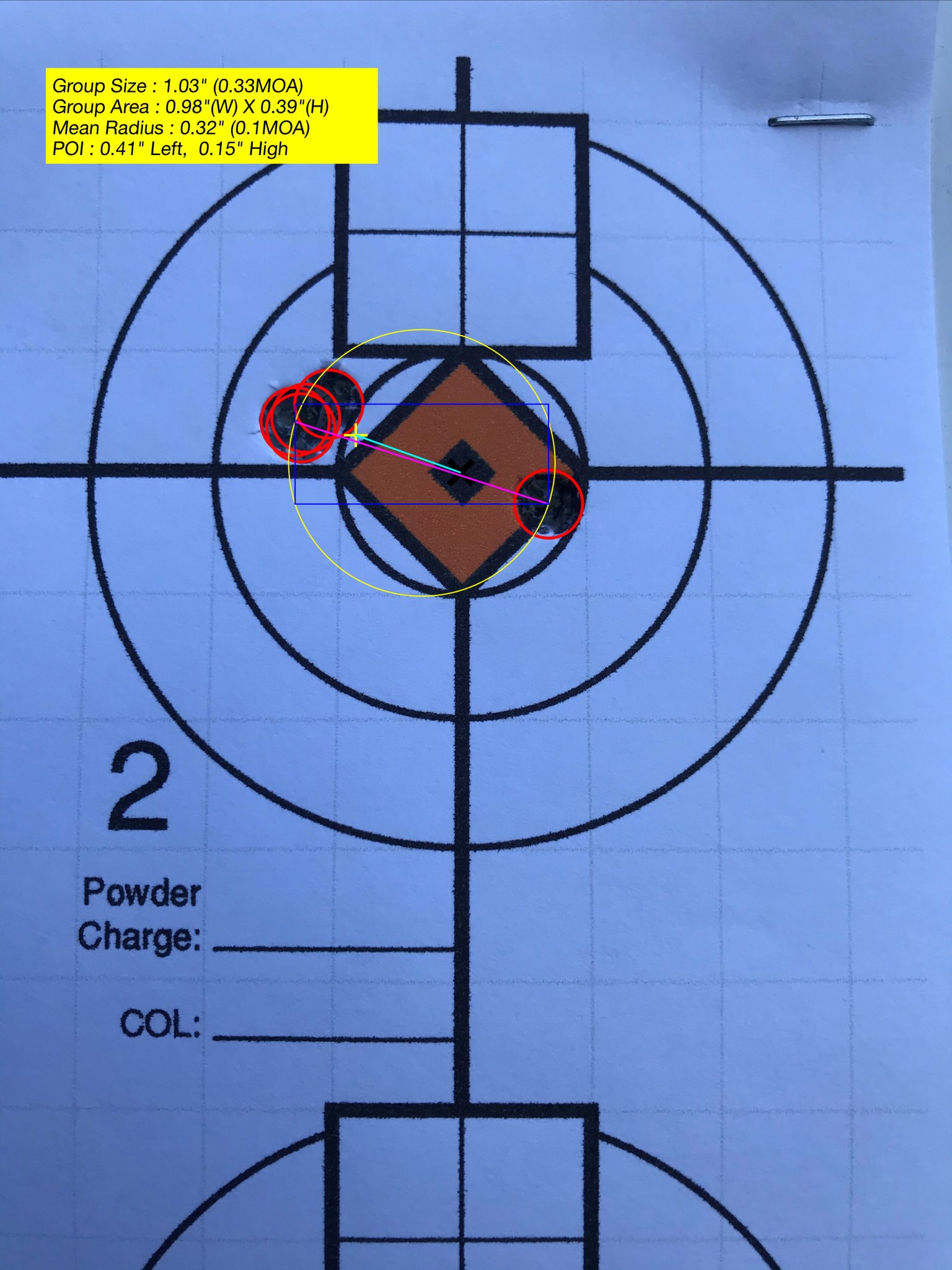

300 yards.

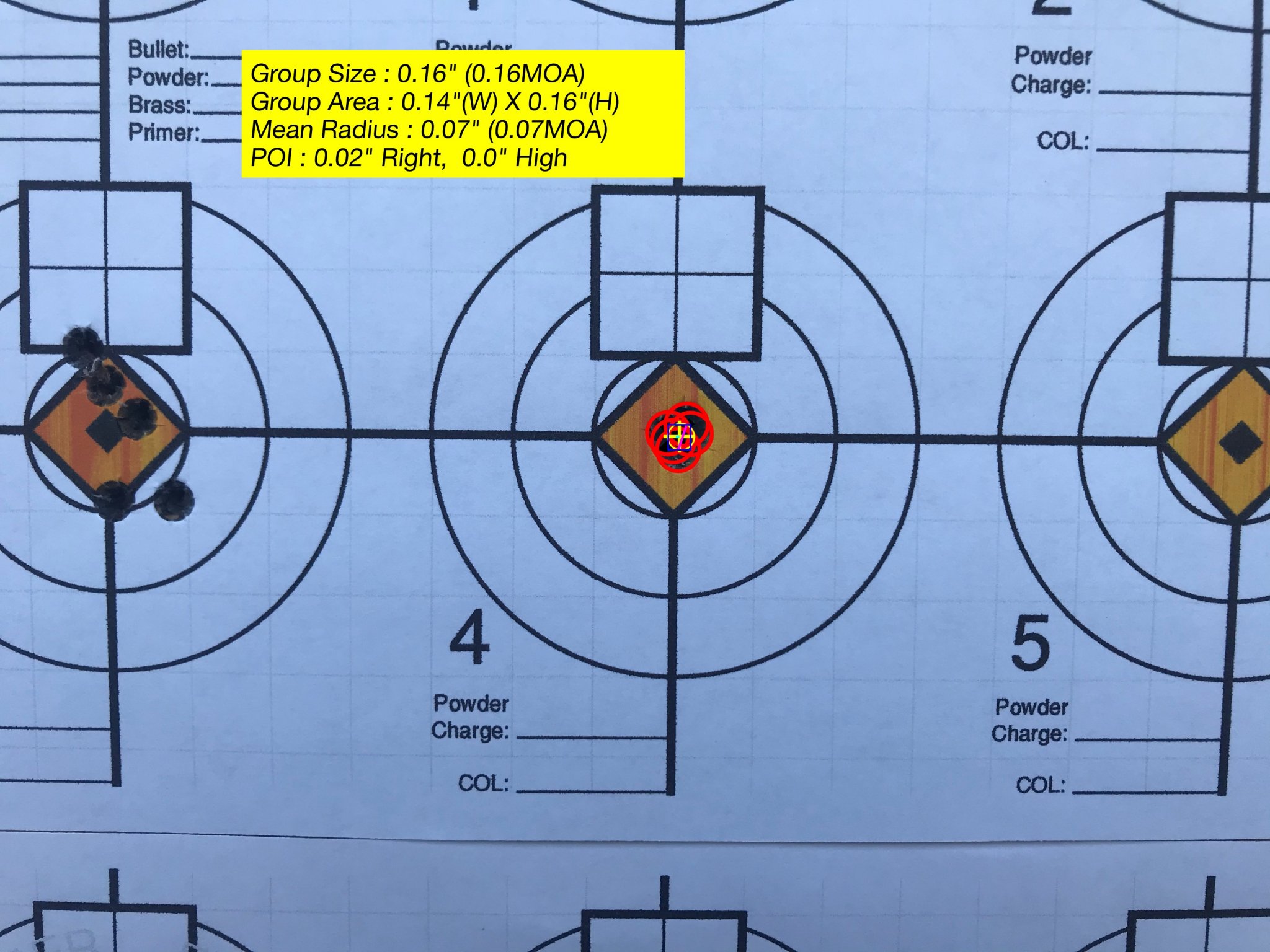

And then the 5th.

And then the 5th.

100 yards.

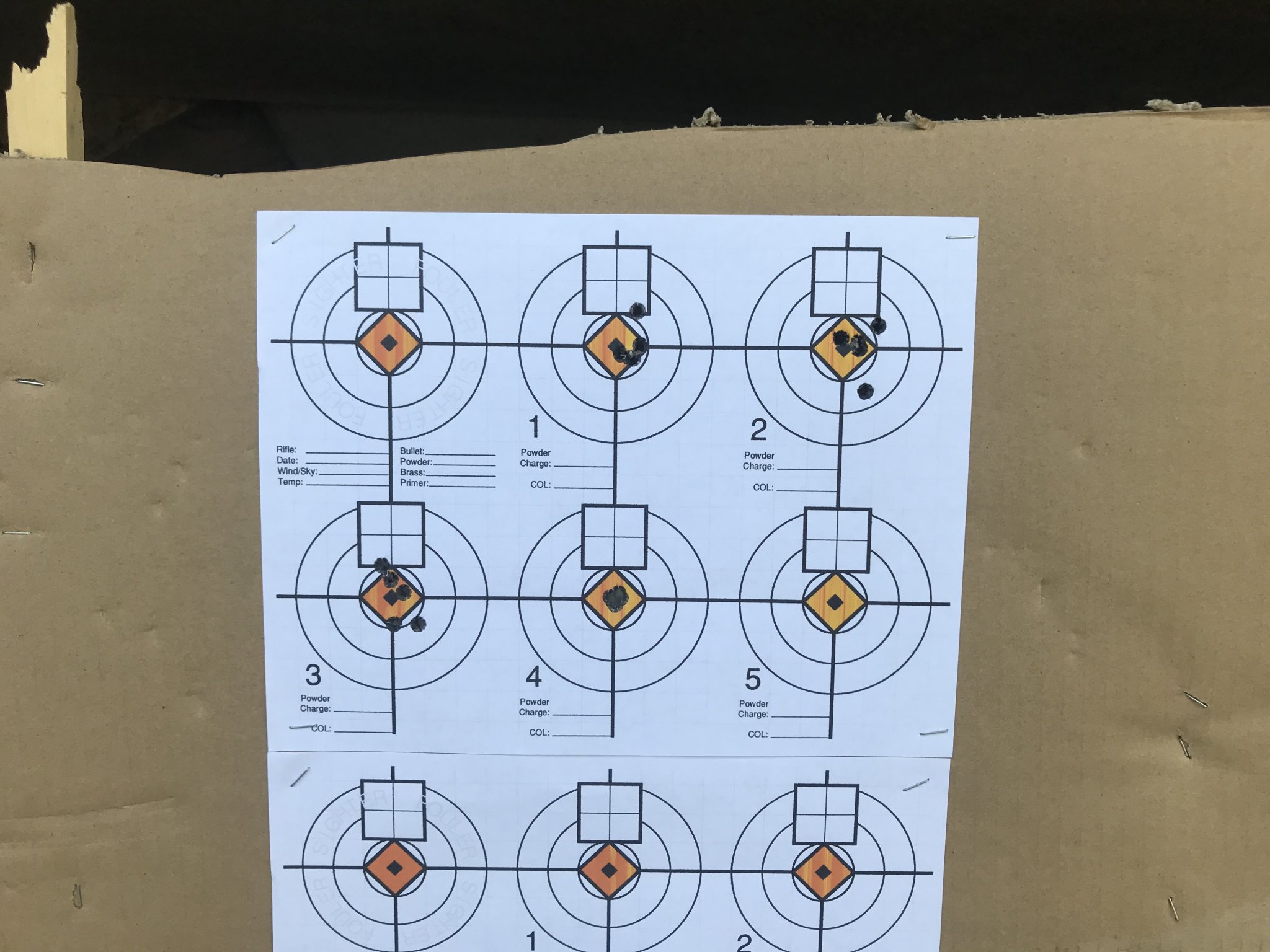

Rest of that load development target.

Rest of that load development target.

I do appreciate the efficiency factory that loading on a progressive offers, and have nothing against doing that, but I do rather enjoy my time at the reloading bench. I normally throw on the latest Everyday Sniper podcast and crank out sub moa ammo.

300 yards.

100 yards.

What you'll find when buying high end hardware, whether rifles, gear, or on the load bench... is not necessarily "significantly" better performance as it pertains to what "can" happen. Though it often is better, you "can" end up with cheap stuff performing quite well.

The expensive stuff significantly increases the consistency and reliability of the performance, and instead of it being semi-random with persistent "flyers," you end up with a significant reduction in flyers and a much more consistently high level of performance with a general absence of undesirable rounds. What "can" happen turns into what "will" happen. This is only valuable to those that are actually looking for and expecting that level of performance.

The expensive stuff significantly increases the consistency and reliability of the performance, and instead of it being semi-random with persistent "flyers," you end up with a significant reduction in flyers and a much more consistently high level of performance with a general absence of undesirable rounds. What "can" happen turns into what "will" happen. This is only valuable to those that are actually looking for and expecting that level of performance.

Up to and including shooting those above posted groups, and even still now, I believe that my system and ammo can shoot better than I can, but I do generally seem to know when I blatantly shank one. Other times, I’m not quite sure, and default to, “I fucked that one up somehow.”, but I do supposed it could always be something other than myself. That’s partly why I upgraded from Hornady to Redding dies. I wanted to eliminate a variable, so I started there. I’ll eventually have all the pieces to the puzzle that ensure myself and the weather are really the only variables.

Like I said, I'm more interested in how much unnecessary Swiss watch craftsman type crap i can cut out and still achieve a high level of accuracy for my chosen disciplines than how much I can deep dive stuff that I have yet to prove matters in my load.

This. My process has simplified over the years and makes the whole reloading experience much more enjoyable and less of tha chore with a great payoff for my efforts.

I see there making aluminum chips!!! I see my press coming to life.

Dang fellas, I got busy for a couple weeks and this thread blew up!

I think it has been said a bunch of times here - this press may not be the right choice for everyone. That said, for those of you that have made (thank you for believing in us) or will make the plunge, I guarantee you'll be pleased with your purchase.

Over the last few weeks, we have been dragging a press around the country to matches, wanting people to see and touch it. It's a beast in size, but has a sensitive feel that is impossible to appreciate in video.

Production is in full swing. The investment we have made into the production of this press has been tremendous, but we have also seen a response from customers that is really strong. We have sold literal tons of them, by weight, and know that when this first batch hits doorsteps things will move even faster.

If you're interested in the process, jump onto our FB or IG account, we are keeping a nice photo log of what is going into delivering (in our opinion) the finest precision reloading press ever manufactured.

I think it has been said a bunch of times here - this press may not be the right choice for everyone. That said, for those of you that have made (thank you for believing in us) or will make the plunge, I guarantee you'll be pleased with your purchase.

Over the last few weeks, we have been dragging a press around the country to matches, wanting people to see and touch it. It's a beast in size, but has a sensitive feel that is impossible to appreciate in video.

Production is in full swing. The investment we have made into the production of this press has been tremendous, but we have also seen a response from customers that is really strong. We have sold literal tons of them, by weight, and know that when this first batch hits doorsteps things will move even faster.

If you're interested in the process, jump onto our FB or IG account, we are keeping a nice photo log of what is going into delivering (in our opinion) the finest precision reloading press ever manufactured.

Every day! It's a literal mountain of parts and packaging going into this. Will be shipping out pallets of these before ya know itView attachment 7385733

More press parts turned out today

AL is great stuff, but its a compromise metal. In applications where weight and corrosion are a concern, its great. It is used so that APC doesn't weight 100 tons and can still be airlifted while not droping any bridge it tries to cost. Same with ships and we are now seeing just tell well AL susperstructures stand up to something like a collision with a tanker. (Hint, they dont).People tend to forget or not know there what can be done with aluminum:

ARTICLE: Advanced Aluminum Armor Alloys - Light Metal Age Magazine

Aluminum armor solutions have existed for 60 years. Aluminum producers have responded to new battle conditions by developing more advanced armor solutions.www.lightmetalage.com

No AL alloy has the toughness that modern Steel Alloys do. It cannot handle the same impact and while some propperties like yield strength can be similar, there is much more to it. You also arent getting hardness anywhere near a good heat treated steel allow without anodizing, which is just a surface treatment anyway. Think soft shell egg.

All things being equal, steel is a superior material for anything that is going to take abuse. We don't use aluminium reciecers in our bolt guns for a reason, and we don't use AL barrels for anything but rimfire with a steel liner.

AL is great stuff, but its a compromise metal. In applications where weight and corrosion are a concern, its great. It is used so that APC doesn't weight 100 tons and can still be airlifted while not droping any bridge it tries to cost. Same with ships and we are now seeing just tell well AL susperstructures stand up to something like a collision with a tanker. (Hint, they dont).

No AL alloy has the toughness that modern Steel Alloys do. It cannot handle the same impact and while some propperties like yield strength can be similar, there is much more to it. You also arent getting hardness anywhere near a good heat treated steel allow without anodizing, which is just a surface treatment anyway. Think soft shell egg.

All things being equal, steel is a superior material for anything that is going to take abuse. We don't use aluminium reciecers in our bolt guns for a reason, and we don't use AL barrels for anything but rimfire with a steel liner.

But we do use aluminum for uppers/lowers/handguards in carbines. I agree that aluminum is a compromise material, but so is steel. You're picking up strength but compromising workability and price. My point is that everything presents compromise. What we know is that the aluminum used in this press, in the places and manner it is being used, is more than sufficient for the role. There are also places where we are using steel, where the demands require it.

7075 Billet cut from plate (not extrusion) is a very, very tough material, and we think it will make some excellent components for this press.

Uppers lowers and rails in carbines could be made of plastic and still function. You have a steel bolt inside of a steel barrel extension attached to a steel barrel. That combustion is almost entirely contained in a steel vessel until the bolt unlocks.But we do use aluminum for uppers/lowers/handguards in carbines. I agree that aluminum is a compromise material, but so is steel. You're picking up strength but compromising workability and price. My point is that everything presents compromise. What we know is that the aluminum used in this press, in the places and manner it is being used, is more than sufficient for the role. There are also places where we are using steel, where the demands require it.

7075 Billet cut from plate (not extrusion) is a very, very tough material, and we think it will make some excellent components for this press.

Why aren't there aluminum bolt actions?

Not knocking the press at all, loots like a great piece of equipment. Just wanted to throw some two cents on the notion that aluminum is an acceptable replacement for steel. In many applications, it's not.

I'm not sure I understand your point. They aren't building APC's, it's a reloading press.AL is great stuff, but its a compromise metal. In applications where weight and corrosion are a concern, its great. It is used so that APC doesn't weight 100 tons and can still be airlifted while not droping any bridge it tries to cost. Same with ships and we are now seeing just tell well AL susperstructures stand up to something like a collision with a tanker. (Hint, they dont).

No AL alloy has the toughness that modern Steel Alloys do. It cannot handle the same impact and while some propperties like yield strength can be similar, there is much more to it. You also arent getting hardness anywhere near a good heat treated steel allow without anodizing, which is just a surface treatment anyway. Think soft shell egg.

All things being equal, steel is a superior material for anything that is going to take abuse. We don't use aluminium reciecers in our bolt guns for a reason, and we don't use AL barrels for anything but rimfire with a steel liner.

If it was made out of steel I'd have to get a crane company to set it on my bench. Just a guess, but a steel version would be in the

60-70 lb range.

Oh, and the press isn't going to operate at 1,000 Cycles per Minute either.......I'm not sure I understand your point. They aren't building APC's, it's a reloading press.

If it was made out of steel I'd have to get a crane company to set it on my bench. Just a guess, but a steel version would be in the

60-70 lb range.

The Corbin Mega Mite press I use for 50 BMG does weigh 70 lbsI'm not sure I understand your point. They aren't building APC's, it's a reloading press.

If it was made out of steel I'd have to get a crane company to set it on my bench. Just a guess, but a steel version would be in the

60-70 lb range.

YikesThe Corbin Mega Mite press I use for 50 BMG does weigh 70 lbs

An almost complete press. Maybe they are ahead of schedule!!!

That’s an nice looking piece of gear!An almost complete press. Maybe they are ahead of schedule!!!

View attachment 7394131

Similar threads

Reloading Equipment

Area 419 6 Dasher Zero-M Sizing Die

- Replies

- 0

- Views

- 107

- Replies

- 14

- Views

- 988