Started out as a basic blued, synthetic stock XT-22 and then the fun started. Everything looked pretty good from the factory, clean lines, barrel centered in the channel and a 3.5lb trigger pull. Accuracy at 50yards hung a little over or under 1" with a variety of high speed and subsonic ammo.

First thing on the menu was chopping the barrel to 16 1/4" to make it as short as possible for carrying on a mountain bike. I cannot find a lathe on the Big Island and I was not going to pay $150 to ship it out to the mainland for a cut and crown. It was done with a hack saw, file and brass lap so I will spare you the photos to prevent anyone from having a heart attack. Next up was opening and reinforcing the barrel channel. From the factory it was free floated but the stock touched with minimal pressure. I opened the free float to 1/10" and using a bow scale we measured only 12-14lbs of pressure to make the stock flex to the barrel.

The lateral reinforcing ribs were dremeled out and 6 carbon fiber arrow shafts were epoxied into place.

With the forend properly reinforced I bedded the barrel lug in Devcon 10110 and taped off the barrel to maintain the 1/10" free float. After bedding the force required to flex the stock to the action was 82 fricken pounds!! The forend was rock solid and you cannot twist it in your hands. I really think this might offer new life in some of the old tupperware stocks I have laying around. If you check a local archery shop they will have bags of scrap carbon fiber tubing from cutting down custom arrows. I have a trash can full of 6-8" scraps that were a perfect fit.

Added some devcon on the wrist and forend plus an Anderson bolt knob from PTG. At $12.50 it is the best deal on the market and its a perfect fit for a .22 handle. I turned down the bolt knob with nothing more than a file, threaded it and then epoxied the knob on. When I am ready to cerekote I will throw some epoxy on the joint and sand it down for a invisible fit.

DNZ rings to hold a tasco/stoney point combo I had sitting around from an old project. The more I use the DNZ rings the more I like them, perfect alignment with no lapping.

The Trigger was super simple to work on, quick polish on the sear/trigger interface and spring tuning dropped the pull down to a crisp 16oz with absolute reliability and I was ready for another trip to the range.

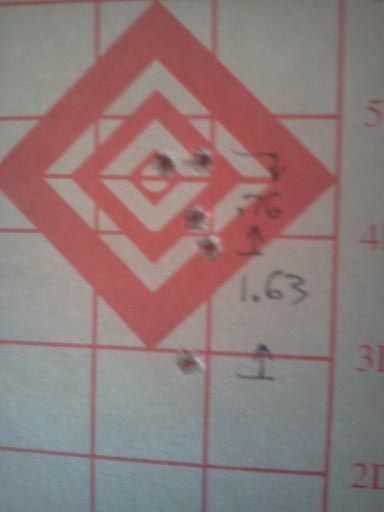

I forgot the camera to document the range work but it went very well. I looks like it is a toss up between the Winchester 38gr subsonic and the CCI subsonic HP, both very consistent at .4-.5" for five shot groups at 50 yards. I was also playing with torque on the front barrel lug screw and saw no changes in accuracy or point of impact, possibly based on the barrel being supported about 3" in front of the lug. I took it to 30lb and left it alone. Playing the the rear action screw (front trigger guard screw) was a different story and I was able to push vertical point of impact about 2" with every 5 lb of pressure. The area is completely unsupported on the factory stock and it was clearly flexing the entire action. The laminate stocks are solid in this area and Im sure bedding would reduce the sensitivity in screw torque. It was showing a definite preference at about 15lbs, going heavier or lower was really causing groups to open up, It was very similiar to working up a handload and finding the sweet spot.

I only have a couple hundred rounds through it but it has quickly become my favorite plinker. The balance is perfect I could not be more pleased with the outcome. Please ignore the crappy krylon on the action. Everything rust so damn quick in Hawaii it drives me insane. I am moving back to the mainland soon and it will get blasted in AO and given a nice base of cerakote something before the kids tear into it with a sponge paint job.

First thing on the menu was chopping the barrel to 16 1/4" to make it as short as possible for carrying on a mountain bike. I cannot find a lathe on the Big Island and I was not going to pay $150 to ship it out to the mainland for a cut and crown. It was done with a hack saw, file and brass lap so I will spare you the photos to prevent anyone from having a heart attack. Next up was opening and reinforcing the barrel channel. From the factory it was free floated but the stock touched with minimal pressure. I opened the free float to 1/10" and using a bow scale we measured only 12-14lbs of pressure to make the stock flex to the barrel.

The lateral reinforcing ribs were dremeled out and 6 carbon fiber arrow shafts were epoxied into place.

With the forend properly reinforced I bedded the barrel lug in Devcon 10110 and taped off the barrel to maintain the 1/10" free float. After bedding the force required to flex the stock to the action was 82 fricken pounds!! The forend was rock solid and you cannot twist it in your hands. I really think this might offer new life in some of the old tupperware stocks I have laying around. If you check a local archery shop they will have bags of scrap carbon fiber tubing from cutting down custom arrows. I have a trash can full of 6-8" scraps that were a perfect fit.

Added some devcon on the wrist and forend plus an Anderson bolt knob from PTG. At $12.50 it is the best deal on the market and its a perfect fit for a .22 handle. I turned down the bolt knob with nothing more than a file, threaded it and then epoxied the knob on. When I am ready to cerekote I will throw some epoxy on the joint and sand it down for a invisible fit.

DNZ rings to hold a tasco/stoney point combo I had sitting around from an old project. The more I use the DNZ rings the more I like them, perfect alignment with no lapping.

The Trigger was super simple to work on, quick polish on the sear/trigger interface and spring tuning dropped the pull down to a crisp 16oz with absolute reliability and I was ready for another trip to the range.

I forgot the camera to document the range work but it went very well. I looks like it is a toss up between the Winchester 38gr subsonic and the CCI subsonic HP, both very consistent at .4-.5" for five shot groups at 50 yards. I was also playing with torque on the front barrel lug screw and saw no changes in accuracy or point of impact, possibly based on the barrel being supported about 3" in front of the lug. I took it to 30lb and left it alone. Playing the the rear action screw (front trigger guard screw) was a different story and I was able to push vertical point of impact about 2" with every 5 lb of pressure. The area is completely unsupported on the factory stock and it was clearly flexing the entire action. The laminate stocks are solid in this area and Im sure bedding would reduce the sensitivity in screw torque. It was showing a definite preference at about 15lbs, going heavier or lower was really causing groups to open up, It was very similiar to working up a handload and finding the sweet spot.

I only have a couple hundred rounds through it but it has quickly become my favorite plinker. The balance is perfect I could not be more pleased with the outcome. Please ignore the crappy krylon on the action. Everything rust so damn quick in Hawaii it drives me insane. I am moving back to the mainland soon and it will get blasted in AO and given a nice base of cerakote something before the kids tear into it with a sponge paint job.