Well at least till I can find a way to build a room in the garage and kick out the wife's car…

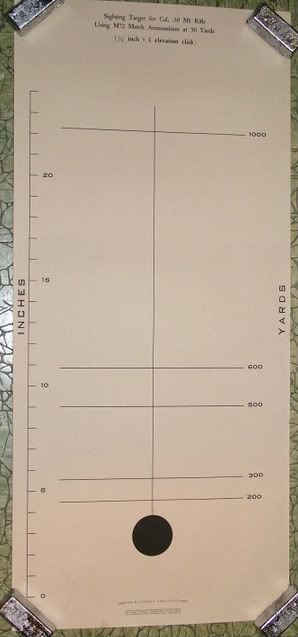

I was searching around last night and found this video on youtube. I like it not only for the concept, but much like the individual in the video I am about 55miles away from the closest 100yd range for testing rounds(next closest is 50yd range, but I am not sure that testing .308win & 6.5-.284win rounds there is a good idea)

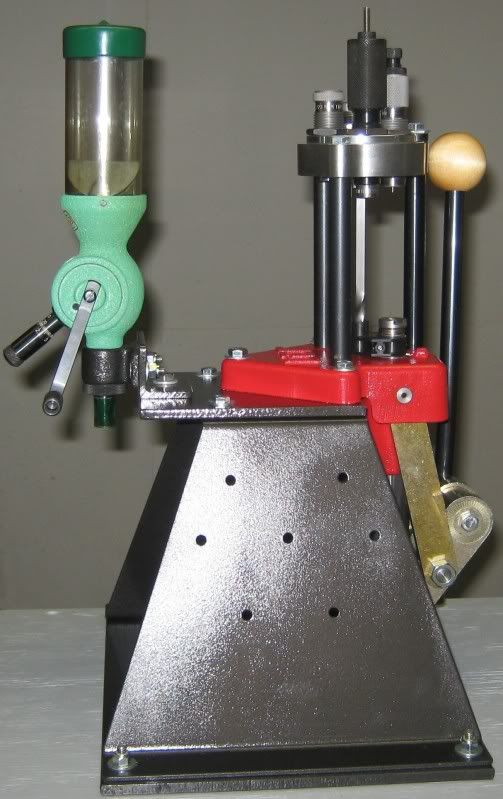

Have any of you built something along these lines? Here's my concept, I'm going to setup an RCBS rock chucker & powder measure on the platform, somewhat enclose the bottom for storage of other parts/dies/tools…..

I can clamp it down to the kitchen table inside, take it out in my truck to the range, etc. I can prep all my brass at home and for load development just take what I need out

Any advice or pointers fellas?

[video=youtube;W-_rdZc2pxQ]http://www.youtube.com/watch?v=W-_rdZc2pxQ[/video]

I was searching around last night and found this video on youtube. I like it not only for the concept, but much like the individual in the video I am about 55miles away from the closest 100yd range for testing rounds(next closest is 50yd range, but I am not sure that testing .308win & 6.5-.284win rounds there is a good idea)

Have any of you built something along these lines? Here's my concept, I'm going to setup an RCBS rock chucker & powder measure on the platform, somewhat enclose the bottom for storage of other parts/dies/tools…..

I can clamp it down to the kitchen table inside, take it out in my truck to the range, etc. I can prep all my brass at home and for load development just take what I need out

Any advice or pointers fellas?

[video=youtube;W-_rdZc2pxQ]http://www.youtube.com/watch?v=W-_rdZc2pxQ[/video]