Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Official (DTA) SRS, HTI, Covert, Hunter Thread

- Thread starter patches

- Start date

Sorry, I just seen this. I sent mine back twice. The second time they sent a new chassis.As am I. How many times did you say you had to send it back before the problem was accurately diagnosed?

tighten the ones around teh magazine first and see if it helpsHow do adjust skins that are lined up with something like 10-12 bolts?

No problem. They are reassessing mine after I mentioned the issue you had. Guess I will have to see how it all plays out. Really sucks as I was so close to finalizing a good ATIP load.Sorry, I just seen this. I sent mine back twice. The second time they sent a new chassis.

Yeah that's my luck.No problem. They are reassessing mine after I mentioned the issue you had. Guess I will have to see how it all plays out. Really sucks as I was so close to finalizing a good ATIP load.

No problem. They are reassessing mine after I mentioned the issue you had. Guess I will have to see how it all plays out. Really sucks as I was so close to finalizing a good ATIP loL

What is your load with the 390gr A-tips?

How many rounds down your barrel?

Maybe 150-200 rounds I think. Don’t have the exact number with me here.What is your load with the 390gr A-tips?

How many rounds down your barrel?

134 grains H50BMG .100” off lands. Similar to yours I think right?

Sorry forgot to add I used Peterson brass and FED215Ms. It seems like that projectile likes 2960 & 2910ish with H50BMGWhat is your load with the 390gr A-tips?

How many rounds down your barrel?

I found that they like to be .010 & .100 off the lands. .025, .050, and .075 yielded shitty results.What is your load with the 390gr A-tips?

How many rounds down your barrel?

You get a replacement .375 barrel yet?

Yep, went with another factory DT one....I found that they like to be .010 & .100 off the lands. .025, .050, and .075 yielded shitty results.

You get a replacement .375 barrel yet?

Thats VERY interesting as i found the exact same thing...025, .050, and .075 yielded shitty results.

I actually found them "Jammed" and circa .100/.110" to be best. Anything in between the groups went to shit!!

Are you going to stick with ATIPS for the new barrel?Yep, went with another factory DT one....

Thinking of trying the Sierra 350 SMK "If" i can source some..Are you going to stick with ATIPS for the new barrel?

I actually just sold off some ( 500) of my Atips to a bloke here in Aus that hasn't been able to source any.. I still have 1700 odd here though.

What powder do you plan on using for the SMKs? Retumbo or N570?Thinking of trying the Sierra 350 SMK "If" i can source some..

I actually just sold off some ( 500) of my Atips to a bloke here in Aus that hasn't been able to source any.. I still have 1700 odd here though.

AR2225 ( Retumbo)What powder do you plan on using for the SMKs? Retumbo or N570?

Yes..That’s made in Australia right?

At present we basically only have ADI ( Re branded as Hodgdon in the US) available..

No more Vihtaivuori, no more Alliant or Winchester..

So I picked up my SRS covert today. It is an older gen chassis with old buttstock and no cheek rest, but has the monopod cut. How can I tell if the barrel lockup uses the old pin style or not? The installed barrel as well as included conversions are gen 2 with no notch on the extension, but that could just be gen 2 barrels in a gen 1 chassis.

So this looks like its the non pin gen 2? Looked down the chassis with the barrel out and didnt see any pins either.If it has a tiny notch at the bottom of the extension or a big gap where it would interface with the feed ramp.

Yep, you’ve got an SRS made between ~2010-2012. Only the Gen 1’s made prior had the RevA extension with the notch and not tapped for a monopod because they didn’t exist. Then they switched to the more robust RevB extension, made all receivers capable of using monopods, and added the Covert handguard. The A1s came next with the added cheek piece.

I have an extra 20" 6.5x47L barrel that I wanted cut down to 16.5" and Cerakoted. On a whim I sent it out to Rainier Arms as they now have a gunsmithing department and they did a great job!

What kind of bipod is that?I have an extra 20" 6.5x47L barrel that I wanted cut down to 16.5" and Cerakoted. On a whim I sent it out to Rainier Arms as they now have a gunsmithing department and they did a great job!

View attachment 8114888

View attachment 8114893

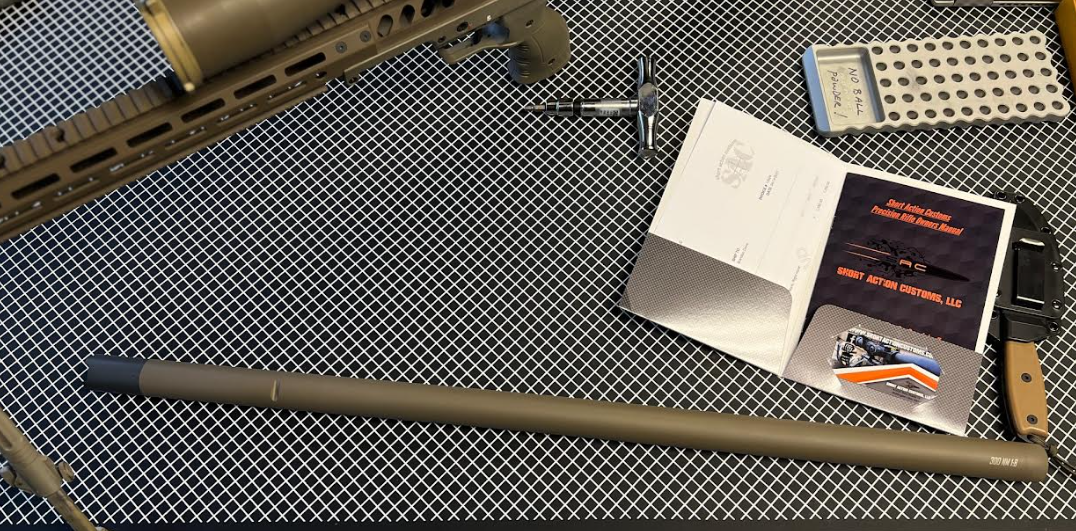

The new barrel rodeo continues...

Have you ever wondered if a straight 1.25" contour would work or even look like?

I don't recommend going that far - I can feel a little bit of contact from the MLOK bits on the M2 top rail.

EDIT: don't do this if you have an M2 chassis. The MLOK attachments from the top rail contact the barrel.Time to do some grinding this weekend. Actually, I just took off the top rail (MLOK is only on the front 3 screws) and ground down the exposed screw on the third-from-front MLOK until the screw was flush. Problem solved.

Have you ever wondered if a straight 1.25" contour would work or even look like?

I don't recommend going that far - I can feel a little bit of contact from the MLOK bits on the M2 top rail.

EDIT: don't do this if you have an M2 chassis. The MLOK attachments from the top rail contact the barrel.

Last edited:

That thing must be crazy heavy, I went with a 26" long in 1.045 straight from ES and that thing is like a truck axle.

I regularly shoot 36" .338LM Improved40 barrels with 1.045 contour. This 1.25" thing is bonkers, but hey I'm not in the Army anymore so I don't have to worry about humping or jumping it.

For my SAC 223, if I cycle my bolt at standard speed, it’s 50/50 on whether it wants to eject. If I go slow, it seems to flip it out a bit more consistently, maybe 80% of the time.Anybody have issues with spent casings ejecting from the SAC 223 conversion? Thing flings live rounds out of there just fine whether I slowly pull the bolt back or rip it back.

After firing though, if I slowly pull back I get 0% chance of the casing ejecting and if I rip it/run it back hard I get maybe a 50-60% chance of it ejecting. The left side of the case is angled out from the plunger but it gets held up in the extractor for some reason… again only with spent rounds

Thought maybe it needed to be broken in but coming up on 500rnds and it still does it.

I’m getting cratered primers with my magnum bolt and noticed this.

Can you see the chamfer around the firing pin hole. No bueno. I still have to contact DT about my defective magazine catch/release. I’m hoping they will just send me another mag release and bolt and I can send them this fucked up bolt and mag release back. I do not want to mail the chassis.

Can you see the chamfer around the firing pin hole. No bueno. I still have to contact DT about my defective magazine catch/release. I’m hoping they will just send me another mag release and bolt and I can send them this fucked up bolt and mag release back. I do not want to mail the chassis.

Mine does the same thing with the standard 308 bolt on rounds. Just how they do it on the A2’s I guess. My A1 didn’t have that chamfer.

My A2 .308 bolt doesn’t have a chamfer.Mine does the same thing with the standard 308 bolt on rounds. Just how they do it on the A2’s I guess. My A1 didn’t have that chamfer.

I have 2 x 308, 2x 6.5cm, 2x 300wm, 338lap..375ct and 50bmg conv...none have that chamfer..All my bolts (308, mag, lapua) have that chamfer

Interesting. My .308 doesn’t and my other magnum bolt does not. All three are A2.All my bolts (308, mag, lapua) have that chamfer

I’m figuring you get what looks to be cratered primers as well then.

I do, I thought I was getting some serious signs of over pressure on some hot 450bm loads… ended up shooting some watered down loads and factory. All had the chamfer imprint on the primers.Interesting. My .308 doesn’t and my other magnum bolt does not. All three are A2.

I’m figuring you get what looks to be cratered primers as well then.

I had 2 out of 6 DT bolts that had the chamfering on the bolt face. I sent them back to DT and they swapped out the bolt heads. They covered the shipping both ways. I refuse to shoot the chamfered bolt faces because they crater the primers and screw up my load development.

Yes, my chassis had to be replaced after I sent it in to be worked on. My issue started when a conversion kit didn't fit the chassis. Desert Tech has member 232593 rifle right now for this issue. My 50bmg went from 5/8"-3/4" groups to 12"-15" vertical stringing.Anyone with a HTI had a situation where out of the blue massive vertical stringing suddenly becomes an issue?

I don't know if their sure what it is. Are both calibers you have stringing? I think it's something to do with the barrel clamp/vise. The more the recoil, the worse the stringing. I'm not sure if who I referred to has theirs back yet but if you scroll pages 312-314 you'll find our conversation about it.What did DT deem the cause is?

My HTI up to this point has been flawless...But just recentley when i switched to my 50BMG conversion i have had issues. 100yd groups are still tiny 3 shot clover leafs...BUT... i first noticed it at 1000yds....one shot would be good, the next 10ft vertical...then another 10ft lower...horizontal dispersion is non existent , just vertical.

Today we shot at 2000yds... i had to give up...one shot on the the next high , next low... and so on...

Up till now this load has been flawless..

Today we shot at 2000yds... i had to give up...one shot on the the next high , next low... and so on...

Up till now this load has been flawless..

Mine was just vertical also. I was just shooting 100 yards. Almost has to be something to do with the barrel clamp or maybe the screws that torque it down.My HTI up to this point has been flawless...But just recentley when i switched to my 50BMG conversion i have had issues. 100yd groups are still tiny 3 shot clover leafs...BUT... i first noticed it at 1000yds....one shot would be good, the next 10ft vertical...then another 10ft lower...horizontal dispersion is non existent , just vertical.

Today we shot at 2000yds... i had to give up...one shot on the the next high , next low... and so on...

Up till now this load has been flawless..

The only possible thing that could happen is that the high recoil force of the 50bmg has somehow stretched or deformed the clamping area of the chassis...Mine was just vertical also. I was just shooting 100 yards. Almost has to be something to do with the barrel clamp or maybe the screws that torque it down.

If its gone "oval" shaped this could account for vertical movement but no horizontal due to the clamping screws being on the horizontal axis ??

DT needs to get serious about QC and process management

Last edited:

That's what me and dad were thinkingThe only possible thing that could happen is that the high recoil force of the 50bmg has somehow stretched or deformed the clamping area of the chassis...

If its gone "oval" shaped this could account for vertical movement but no horizontal due to the clamping screws being on the horizontal axis ??

...it had to be "stretched" oval for it to only to have vertical issues. There is or was room for DT to open my original chassis up to allow the conversion barrel to fit. That's where my problem started. I don't think they open the chassis up like that anymore for this reason but if it's opening up under heavy recoil, a lot more will start seeing this issue. DT did take care of it and sent me a new chassis.

Similar threads

- Replies

- 27

- Views

- 2K